Beveltools Bevel Mate EBA-12 S User manual

www.beveltools.com

01-2014

EBA-12

EBA-12 S

Instruction Manual

1

Content

1.1 General Notes of safety

1.2 Use of the machine for purposes for which it is intended

1.3 Incorrect use

1.4 CE declaration of conformity

1.5 Symbol legend

2.1 Prior to taking the machine into service

2.2 Taking the machine into service

2.3 Rating data

2.4 Operating conditions

3.1 Protection devices

3.2 Beveling tool

3.3 Working instructions

4.1 Preventive maintenance

4.2 Repair

4.3 Warranty

4.4 Storage

4.5 Disposal / Environmental compatibility

4.6 Maintenance and wearing parts

2

1.1 General notes on safety

This operation manual is applicable for the machines

EBA-12

EBA-12S

The machines may only be handled by personnel who are qualified. Hold power tools by insulated

gripping surfaces when performing an operation where the cutting tool may contact hidden wiring or its

own cord. Contact with a «live» wire will make exposed metal parts of the tool «live» and shock the

operator.

WARNING Read all safety warnings and all instructions.

Failure to follow the warnings and instructions may result in electric shock, fire and/or serious injury.

Save all warnings and instructions for future reference.

1.2 Use of the machine for purposes for which it is intended

The machines are intended for the purpose of beveling of metal and plastic materials without the use of

water.

1.3 Incorrect use

All uses other than those described under section 1.2 are regarded as incorrect use and are therefore

not admissible.

1.4 CE declaration of conformity

Beveltools BV of P.O.box 190, 6880 AD Velp Gld, hereby declares under sole responsibility that the

product with the serial or batch no. (see reverse side) complies with the requirements under the

Directive 2004/108/EC, 2006/42/EC, 2011/65/EU. Applied standards: EN ISO 12100, EN 60745,

EN 55014-1, EN 55014-2, EN 61000-3-2, EN 61000-3-3. Document

Agent: J.E. Hofman, July 2014 J.E. Hofman Managing Director

1.5 Symbol legend

Attention!

Make sure to read!

This information is very important for ensuring correct operation of the product. Failure to observe this

information can result in a defect.

Note on safety / Warning

This information serves to achieve safe operation. Failure to observe this information may compromise

the operator‘s safety.

Information

This information serves for a good understanding of the operation of the product, thereby permitting

full exploitation of the operational potential of the product.

Technical Document

Read the technical document prior to commissioning.

Safety glasses and ear protection.

Wear safety glasses and ear protection.

3

Disposal

Friendly-to-the-environment disposal.

Power connector

Before any work is carried out on the machine, disconnect the power connector.

2.1 Prior to taking the machine into service

Before connecting tool to a power source, be sure the voltage supplied is the same as specified on the

name plate of the tool. The power supply should not vary more than 10% above or below the voltage

indicated on the nameplate.

Working with worn or damaged router heads will cause the machine to fail.

• Check beveling tool prior to use.

• Sharp beveling tools will increase cutting speed and machine life.

• Beveling tools must be changed regularly.

• The beveling tool must be mounted centrally and positioned against the limit stop.

• The maximum allowable speed of the tool and of the chuck may not be exceeded under any

circumstances.

• Observe national regulations.

2.2 Taking the machine into service

Preselect speed with adjusting wheel according to speed table.

Adjusting wheel increment

Min-1 / rpm

1

4.200

2

5.200

3

6.400

4

7.600

5

8.800

6

10.000

During operation never increase the speed of the machine to above that of the maximum admissible

speed of the grinding tool!

4

2.2.1 Turn on

• Make sure you always have a firm footing when working with the machine.

• Whatever the position of the machine, always use two hands to control the machine.

• Never touch the milling head when the machine is running.

• Never use the machine above head height.

• The machine should only be used for conventional up‐cut milling.

• To turn the machine on, push the ON/OFF switch toward the front.

• Bring the machine slowly into contact with the work piece only after the selected tool speed has been

reached.

• When cutting a bevel always move the machine from left to right against the direction of rotation of

the milling head.

• When machining bore holes, always work in a clockwise direction.

2.2.2 Turn off

• Take Beveling machine from work peace and turn off.

• Motor stops.

2.3 Rating data

Power voltage (cf. replacement parts list)

120/230V; 50/60 Hz; 120/230V

Power Input

1530 W

Power Output

1000 W

No-load speed

10500 min-1/rpm

Max. wheel diameter

45 mm

Grinding spindle thread

M8

Sound pressure level according to EN 60745

89 dB (A) K = 3 dB

Noise emission level

100 dB (A) K = 3 dB

Vibration according to EN 60745

<2.5 m/s2 K = 1.5m/s2

Weight w/o cord set

4.3 kg

Protection class

/ II

The specified vibration value was measured with a standardized test procedure. It can be used to

compare products or to make an initial assessment of the exposure. The vibration emissions may differ

from the specified value, depending on how the power tool is used. Operating personnel must be

protected with defined safety measures based on the estimated exposure under the actual conditions of

use (these must take into account all phases of the operating cycle, e.g. the times when the power

tool is switched OFF and the times it is switched ON, but is not under load).

5

2.4 Operating conditions

Temperature range during operation: 0 to +50°C

Relative air humidity: 95% at +10°C not condensed

3.1 Protective devices

The machine may only be operated with the Flange head and the additional handle fitted!

3.1.1 Flange head

Adapt Flange head

• Turn the Flange head until it has reached the right depth.

• Rotate the guide plate until the required bevel height has been set as shown by the fixed main scale.

Cleaning depth mechanism

• Remove guide bearing and bevel head.

• Turn the Flange head until it comes off.

• Clean all parts and replace defective parts.

• Lubricate the thread with Teflon spray and gears with a little multi-purpose grease.

• Re‐assemble in reverse order.

3.1.2 Additional handle

The additional handle must be screwed in at the left and right with the supplied screws.

6

3.1.3 ON/OFF switch

Two-pole ON/OFF switch with turn-on inhibit and locking.

3.1.4 Protection of the machine

• Starting current limitation the electronically controlled soft starting provides for smooth starting of

the machine. Due to the low machine starting current a 16A fuse is adequate.

• Temperature-dependent overload protection for protection against overheating, when a critical

temperature is reached the electronic safety feature switches into the cool down mode. Then the

machine continues to run at approx.: 3,200 rpm and the electronic constant speed control is

deactivated. After a cool-down time of approx. 10 - 20 sec. the machine is again ready for operation.

Turn the machine off and back on again to activate the electronic constant speed control. When the

machine is at operating temperature the temperature-dependent overload protection reacts

correspondingly earlier time.

• Overvoltage/restarting protection

On short-time outage of the power voltage (pulled power connector, unstable power voltage etc.) the

machine will stop. On recovery of the power voltage the machine has to be turned off and back on

again. The machine is then ready for operation.

3.2 Beveling tool

Use only Beveling tools whose admissible maximum speed is equal to or higher than the no load speed

of the machine.

Use only clean tools!

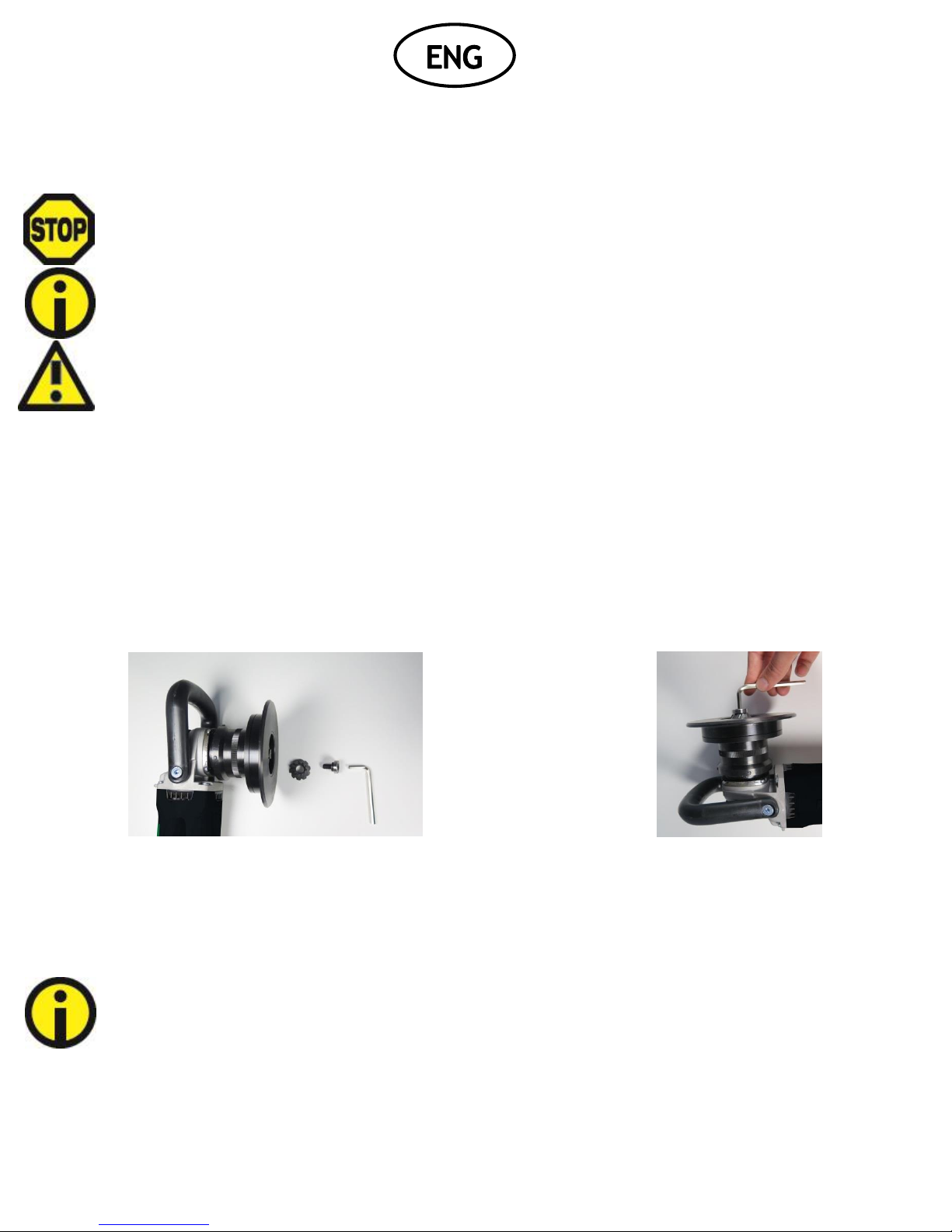

3.2.1 Changing a Bevel Head

• Disconnect from power supply.

• Turn the Flange head to its maximum depth.

• Lock spindle with the locking device on the back of the gearbox.

• Use the Hex wrench (5mm) to unscrew the guide bearing.

• Take the bevel head of.

3.2.2 Fitting a Bevel Head

• Before fitting the Bevel head clean the surface of the adapter and Bevel Head.

• Check the guide bearing, it should run smoothly, a guide bearing that doesn’t run smoothly will

damage the Bevel head and can lead to a broken Bevel Head.

• Place Bevel Head on the adapter, the pin on the adapter should easily fit into the pinhole in the Bevel

Head.

• Lock spindle with the locking device on the back of the gearbox.

• Use the Hex wrench (5mm) to tighten the guide bearing.

• Check if the Bevel head runs smoothly and true, not true running Bevel heads must be replaced

immediately.

Check Bevel tool before use. The Bevel head must be correctly mounted and must rotate freely.

Perform a trial run a minimum over a period of 30 seconds without load. Do not use Bevel Heads which

are damaged, which do not run true or which vibrate!

7

3.3 Working instructions

• To achieve an optimum Bevel result, move Bevel tool uniformly with light pressure.

• The electronic constant control maintains the speed nearly constant during idling and work under load

and assures a uniform result.

• Excessive pressure lessens the working capability of the machine, as well as the life of the Bevel tool.

• The machine is equipped with an electronic control and integrated overload protection.

• If the machine is overloaded, the speed will drop drastically. Immediately take the load off the

machine and allow to run for a short time without load.

Maximum depth per cut, on steel, no more than 4mm with a maximum Power-on time of 50%.

4.1 Preventive maintenance

• To work effectively and surely keep the machine and the ventilation slots clean at all times.

• After approx. 200 operating hours check carbon brushes and replace if necessary. Clean motor housing

and replenish grease filling in gearbox housing. When the brushes are spent, the machine will stop

automatically.

• To maintain the protective insulation the machine must be subjected to a technical safety inspection.

This work must be done exclusively by a specialized electrical workshop.

• When working on metal under extreme working conditions conductive dust deposits can occur inside

the machine, thereby impairing the protective insulation of the machine. In such cases the use of a

stationary vacuuming system, frequent blowing out of the ventilation slots and protection by a fault

current protection switch are advised.

4.1.1 Changing the carbon brushes

The Automatic-Stop feature protects the machine from defects due to excessively consumed carbon

brushes. The machine is equipped with two carbon brushes, i.e. one is installed in each handle half.

The carbon brushes must be changed as follows:

• Unscrew four screws and remove the handle halves.

• Lift spring with screwdriver and remove brush. Install new brushes. Clean carbon brush holders,

making absolutely sure not to change the arrangement of the elements of the carbon brush assembly.

• Fit handle halves and fasten with four screws.

• Repeat this change on the opposite side, making absolutely sure to avoid both handle halves from

being opened at the same time.

8

4.2 Repair

If despite strict observance of the manufacturing and testing method the tool should happen to fail, it

must be repaired by an authorized agency. Any replacement needed for the connecting line must be

installed by the manufacturer or its agent if safety risks are to be eliminated.

4.3 Warranty

In the event of the tool being improperly handled, used for purposes for which it is not intended and/or

of the service and maintenance instructions not being observed by non-authorized persons, no warranty

shall be in effect for damages/consequential damages. Complaints can only be honoured if the machine

is returned in the undissembled condition.

4.4 Storage

Temperature range during operation

-15°C upto +50°C

Max. relative air humidity

90 % at + 30°C

65 % at + 50°C

4.5 Disposal / environmental compatibility

This machine consists of materials which can be disposed of in a recycling process. Before disposal,

render the machine unusable. Do not throw the machine into the garbage collection. According to

national regulations this machine must be disposed of in an environmentally compatible recycling

process.

9

4.6 Maintenance and wearing parts

10

1

Armature with fan 230 Volt

30002482

100

Retaining ring

30001757

1

Armature with fan 230 Volt

30002483

102

Return line

30001754

17

Stator complete 230 Volt

30000900

103

Pinion gear

30001753

17

Stator complete 120 Volt

30000913

104

Nut

30001752

34

Stator Housing

30000761

105

Angle head

30002125

35

Carbon brush holder

30000702

106

Blocking bolt

30001748

37

Ball bearing

2768413

107

O-Ring

30001749

38

Ball bearing

30001755

108

Spring

30001750

39

Auto cut-out carbon brush

30000700

109

Button

30001751

39

Carbon brush USA

30000808

110

Needle bush

30001745

40

Stator screw fastening

30001138

111

Screw

30002489

41

Anti-kink guard

2802901

112

Screw

30001733

42

Special self-tapping screw

2801901

113

Spring lockwasher

30001734

43

Damping ring

5793701

114

Ball

30001735

44

Support ring

30000894

115

Ring

30001736

45

Annular magnet

5728701

116

Washer

30001737

46

Washer

5728901

117

Spindle

30001738

47

Countersunk head screw

2813401

118

Screw

30001739

49

Fan cover

30000791

119

Bearing cover

30001740

50

Eye protection

30000790

120

Washer

30001741

52

Half-shell handle left

30000814

121

O-Ring

30001742

53

Half-shell handle right

30000815

123

Bevel gear

30001744

54

PT screw

2799712

129

Two-hole nut drive

1244601

55

PT screw

2799516

130

Felt ring

30001841

56

Switch

30000816

131

Adapter

57

Cable clip

3518301

132

Flange Head

58

Power cable compl.

30001131

133

Ball bearing

58

Power cable compl. USA

30001884

134

Guide plate

61

Electronic control

30000699

61

Electronic control USA

30000904

69

Ratings plate

30001840

69

Ratings plate

30002387

11

12

P.O. Box 190

6880 AD Velp

The Netherlands

T: +31(0)26 369 92 22

F: +31(0)26 369 92 23

www.beveltools.com

2302 Centerline Ind. Dr.

St. Louis, MO 63146

United States of America

T: +1 855 882 3835

F: +1 314 567 0124

Other manuals for Bevel Mate EBA-12 S

1

Table of contents

Other Beveltools Power Tools manuals

Beveltools

Beveltools Mate EBA-12 User manual

Beveltools

Beveltools Bevel Mite EBI-06 Premium Instruction manual

Beveltools

Beveltools Bevel Mate EBA-12 S Instruction manual

Beveltools

Beveltools Bevel Mate EBA 3.0 User manual

Beveltools

Beveltools Mite EBI-C 3.0 User manual

Beveltools

Beveltools Bevel Mite ABIS-06 Premium User manual

Beveltools

Beveltools Bevel Mate ABA-12 User manual

Beveltools

Beveltools Bevel Mite ABIS-06 User manual

Beveltools

Beveltools Mite EBI-06 Premium Instruction manual