1

Installation instructions

KUS ultrasonic flow sensor

1General information

1.1 Use

The instrument described in this manual is a flow sensor designed

for use with a calculator for determining the consumption of

thermal energy in heating or cooling systems that use water.

The flow meter consists of a metal measuring part combined with

a calculator. These two components are connected by a cable.

1.2 General notes

The flow meter left the factory in a faultless condition where safety

is concerned. The manufacturer will provide additional technical

support on request. Calibration relevant security seal on the flow

meter must not be damaged or removed. Otherwise the guarantee

and calibration validity of the flow meter will lapse.

Keep the packaging so that you can transport the flow meter in

its original packaging following expiry of the calibration validity.

Lay all cables at a minimum distance of 500 mm to high voltage

and high frequency cables.

A relative humidity of < 93 % at 25 °C is permissible (without

condensation).

Avoid cavitation in the whole system due to overpressure i.e. at

least 1 bar at qp and approx. 3 bar at qs (applies for approx.

80 °C).

2Safety information

The flow meter may only be used in building service

engineering systems and only for the applications

described.

The local regulations (installation etc.) must be adhered

to.

Adhere to the operating conditions according to the dial

plate during use. Non-adherence can cause hazards and

the guarantee will lapse.

The flow meter is only suitable for circulating water in

heating systems.

The flow meter is not suitable for drinking water.

Adhere to the AGFW requirements regarding circulating

water (FW510).

Do not lift the flow meter by the calculator.

Be aware of sharp points on the thread, flange and

measuring tube.

Only personnel, trained in the installation and operation

of meters in heating and cooling systems, may install and

remove the flow meter.

Only install or remove the flow meter when the pipes are

pressure-less.

After installing the flow meter, check the leak-tightness

of the system.

Guarantee and calibration validity will lapse if the

calibration relevant security seals are broken.

Only clean the flow meter from outside with a soft,

lightly wetted cloth. Do not use any spirit or cleaning

solvent.

As far as disposal is concerned, the flow meter is a waste

electronic appliance in the sense of European Directive

2012/19/EU (WEEE) and it must not be disposed of as

domestic waste. The relevant national, legal regulations

must be observed as the appliance must be disposed of

via the channels provided for this purpose. The local and

currently valid legislation must be observed.

The meter contains lithium batteries. Do not dispose of

the meter and the batteries with domestic waste.

Observe the local stipulations and laws on disposal.

You can return the lithium batteries to the manufacturer

for appropriate disposal following use. When shipping

please observes legal regulations, in particular, those

governing the labelling and packaging of hazardous

goods.

Do not open the batteries. Do not bring batteries into

contact with water or expose to temperatures above

80 °C.

The flow meter does not have any lightning protection.

Ensure lightning protection via the in-house installation.

3Installation

Proceed as follows to install the flow meter:

Observe the dimensions of the flow meter and check whether

there is sufficient space available.

Rinse the system thoroughly before installing the flow meter.

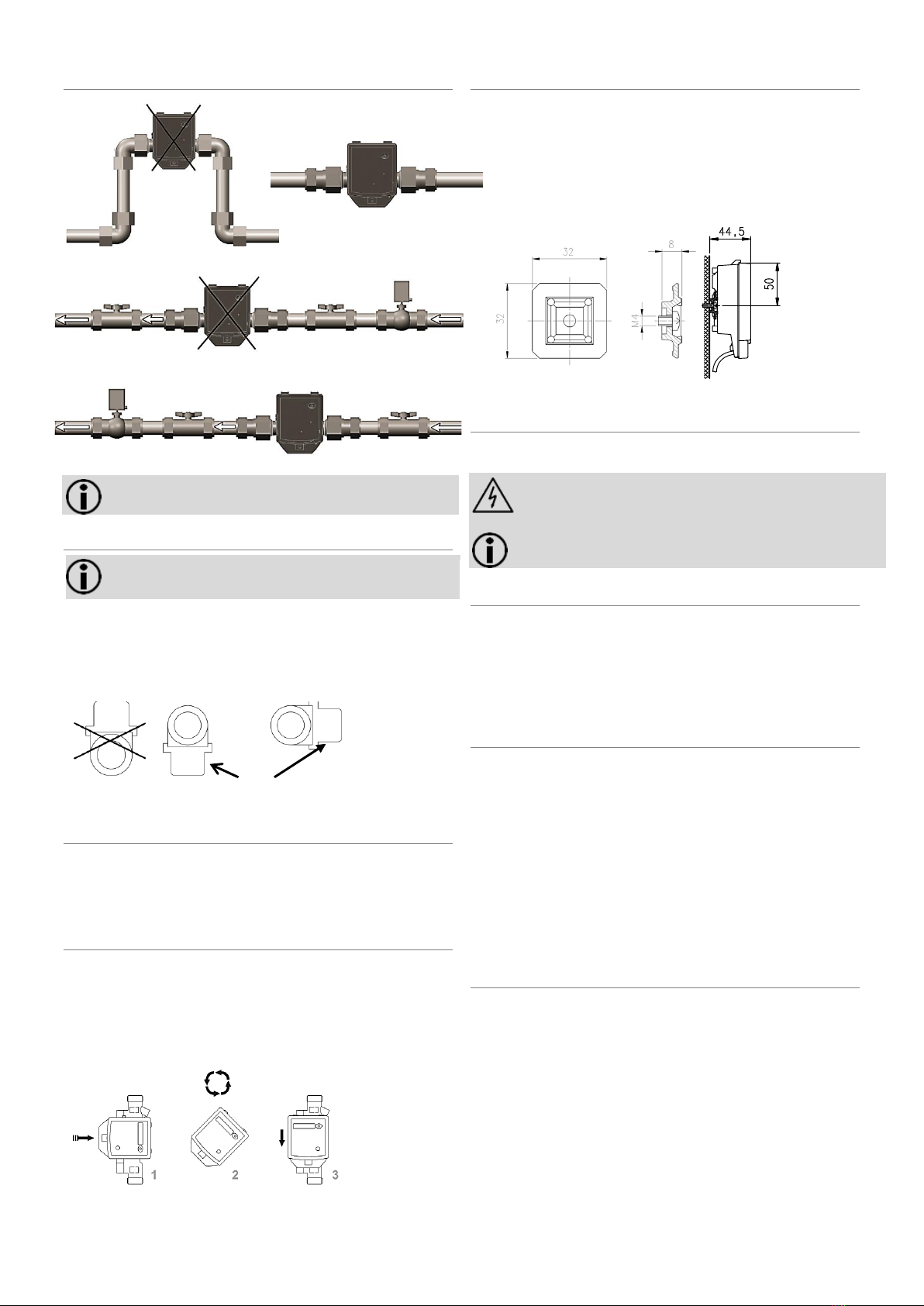

Fit the flow meter vertically or horizontally between two slide

valves so that the arrow on the housing and the flow direction

match. Also observe the installation situations and the

following examples of installation (see figure 2 and figure 3).

Loosen the elastic band or the cable tie, provided for the

transport, from the volume measurement unit. In operation,

the control cable should not depend directly on the volume

measurement unit.

If you install the flow meter for cold metering, follow the

appropriate instructions.

Recommendation: If you are installing more flow meters in one

unit, make sure that all the flow meters operate under the same

mounting conditions.

3.1 Installation notes

Note: When installing the flow meter the locally

applicable installation regulation for flow meters must be

observed.

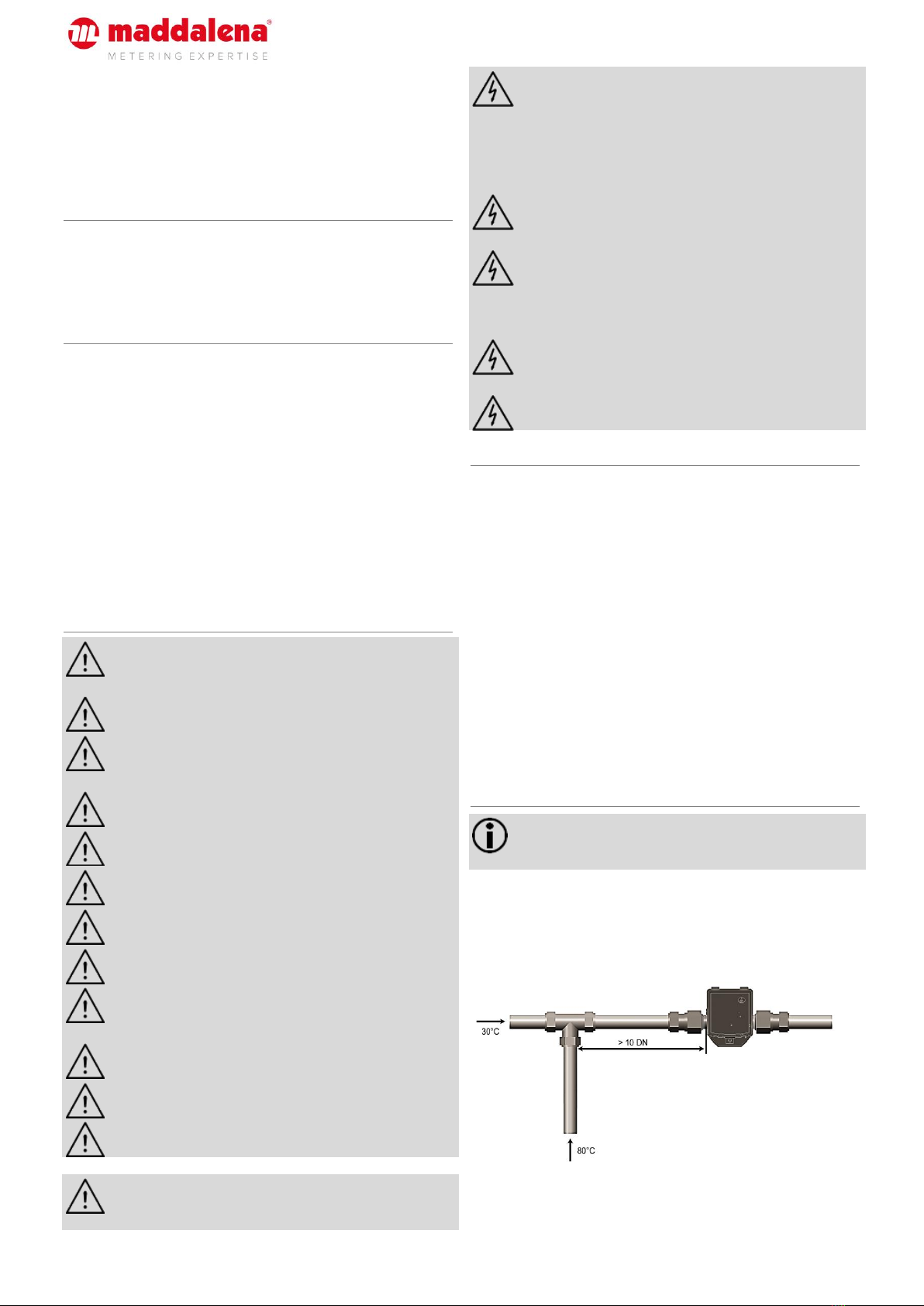

Upstream and downstream straight pipes are not necessary. If you

install the flow meter in the common return of two circuits,

determine a place of installation with a minimum distance of

10 × DN from the T-piece. This distance ensures a good thorough

mixing of the different water temperatures.

Fig. 1: Mixture of different return temperatures

|

Subject

to

technica