www.madur.com

1.5. IRMA WORK MODES...................................................................................................................... 11

1.5.1. Work cycle................................................................................................................................ 11

1.5.2. Cyclic mea urement ............................................................................................................... 11

1.5.2.1. Cyclic mode (regular) – behaviour of the unit after turning on....................................................................................12

1.5.2.2. Cyclic mode (regular) – unit' behaviour at midnight..................................................................................................13

1.5.3. Mea urement according to cheduler....................................................................................13

1.5.3.1. Mea urement according to cheduler – behaviour of unit after turning on...............................................................14

1.5.3.2. Mea urement according to cheduler – behaviour of unit at midnight......................................................................14

1.5.4. Mea urement triggered by a digital input...............................................................................14

1.5.4.1. Mea urement triggered by a digital input – behaviour of unit after turning on..........................................................15

1.5.4.2. Mea urement triggered by a digital input – behaviour of unit at midnight.................................................................16

1.5.5. Monthly-cyclic mode................................................................................................................ 16

1.5.5.1. Monthly-cyclic mode – behaviour of unit after turning on............................................................................................16

1.5.5.2. Monthly-cyclic mode – behaviour of unit in the different-length month .....................................................................16

1.5.6. Monthly-cyclic mode with adju table length (1-30 day )..........................................................16

1.5.6.1. Monthly-cyclic mode with adju table length – behaviour of unit after turning on........................................................17

1.6. RESTRICTIONS WHEN USING LONG-TERM WORK MODES.....................................................17

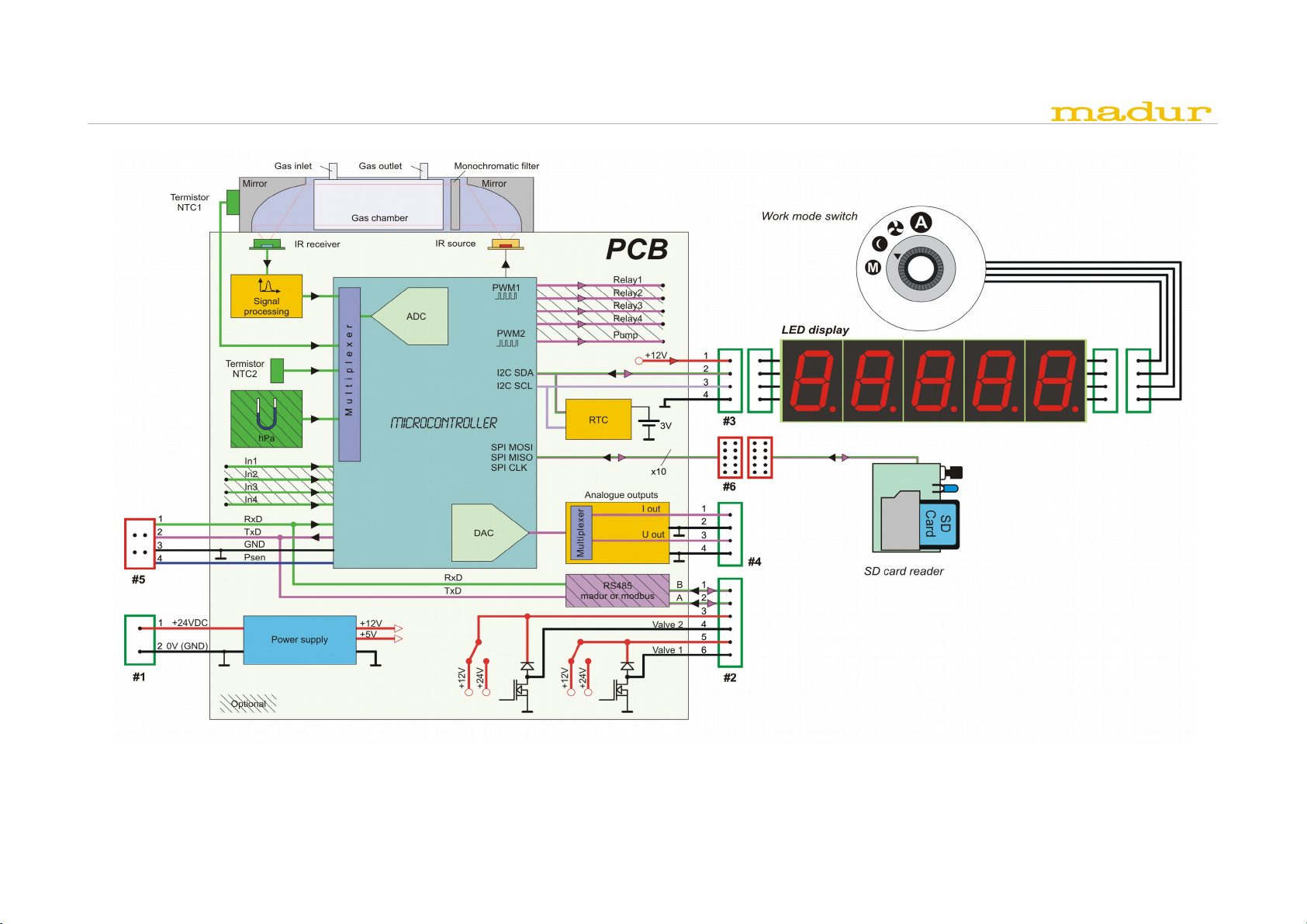

2. ADDITIONAL EQUIPMENT OF IRMA SENSOR.........................................................18

2.1. DATA-LOGGER............................................................................................................................... 18

2.1.1.1. Type of acceptable SD card .......................................................................................................................................20

2.1.1.2. Card' file y tem and maximum memory capacity....................................................................................................20

2.1.1.3. Starting/ topping torage to SD card..........................................................................................................................20

2.1.1.4. In erting SD card into data-logger...............................................................................................................................20

2.1.1.5. Ejecting the SD card from data-logger........................................................................................................................20

2.1.1.6. Powering down the en or when torage i in progre .............................................................................................21

2.1.1.7. Turning on the en or with the SD card in data-logger...............................................................................................21

2.1.1.8. Formatting a SD card in the IRma en or...................................................................................................................21

2.1.1.9. Storing mea urement data on SD card.......................................................................................................................21

2.1.1.10. Po ible fla h equence in data-logger module......................................................................................................22

2.1.1.11. SD card error ............................................................................................................................................................22

2.2. LED DISPLAY.................................................................................................................................. 23

2.3. LCD.................................................................................................................................................. 24

2.4. WORK KNOB................................................................................................................................... 25

2.4.1.1. Po ition “Ventilation”....................................................................................................................................................26

2.4.1.2. Po ition “Standby”.......................................................................................................................................................26

2.4.1.3. Po ition “Mea urement”..............................................................................................................................................27

2.4.1.4. Po ition “Auto”.............................................................................................................................................................27

2.4.1.5. Sen or' behaviour with work knob after power up.....................................................................................................27

2.4.1.6. Changing the knob' po ition......................................................................................................................................27

2.4.1.7. Work knob montage.....................................................................................................................................................28

2.5. ADAPTER USB↔SERIAL TTL TO PROGRAM SENSOR'S PROCESSOR....................................29

3. LOADING NEW FIRMWARE TO SENSOR'S MEMORY.............................................29

IRMA

MANUAL – VERSION 1.0 2/31