English

Table of contents

1Signs and symbols ........................................................................................................... 3

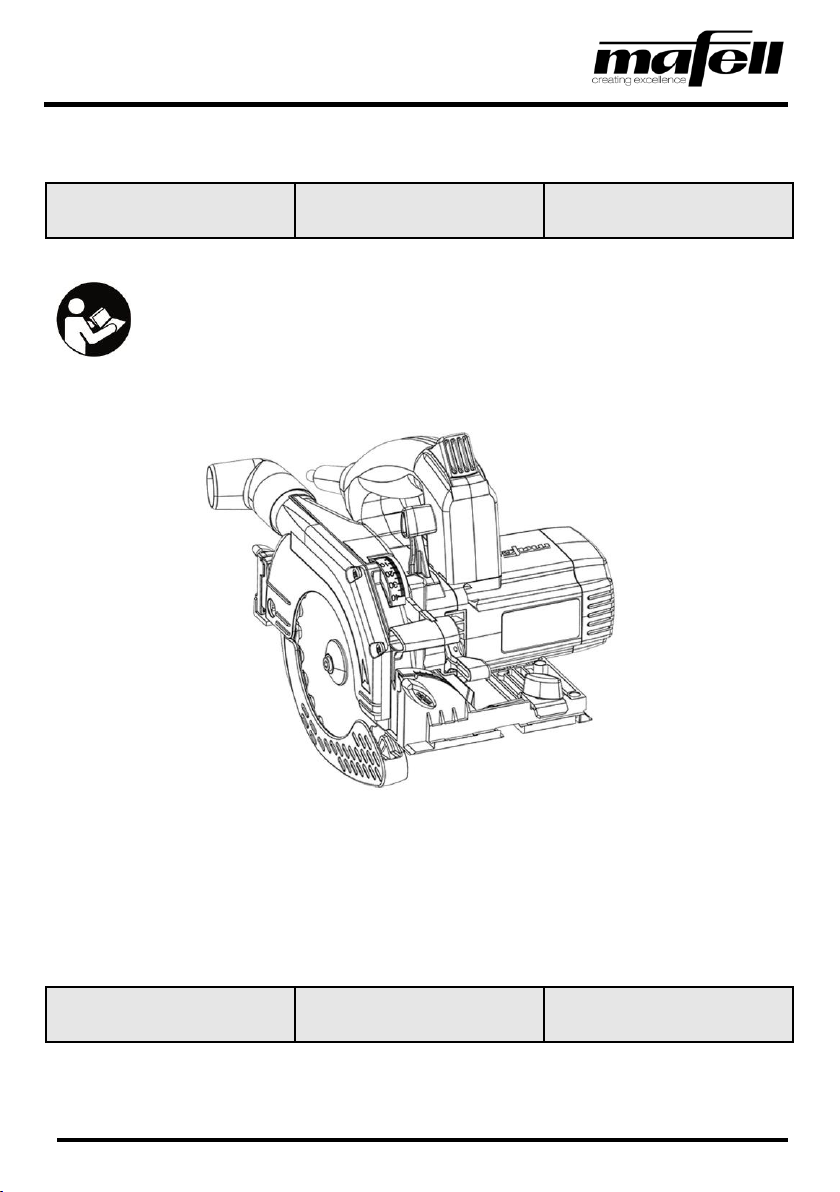

1.1 Identification of the device................................................................................................5

2Product specifications ......................................................................................................5

2.1 Technical data .................................................................................................................. 5

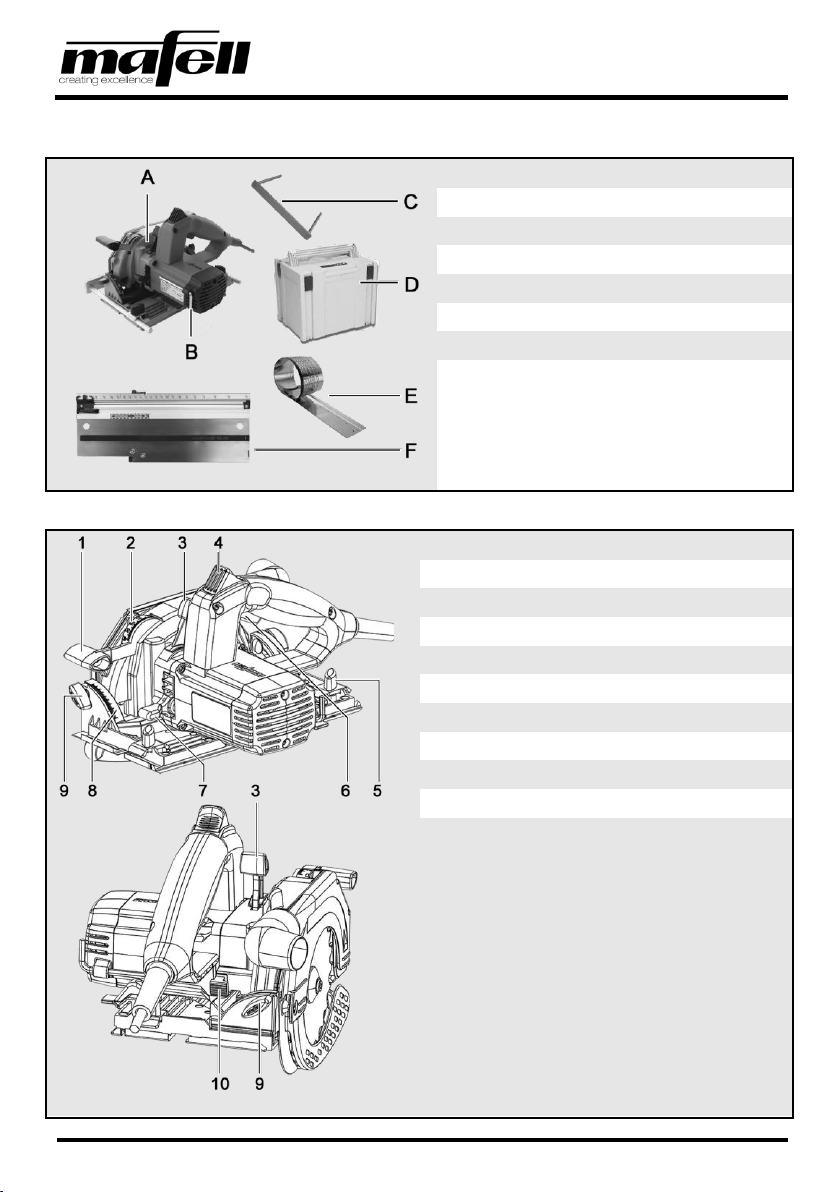

2.2 Scope of delivery.............................................................................................................. 6

2.3 Adjustment elements........................................................................................................6

3General safety .................................................................................................................. 7

3.1 Intended use..................................................................................................................... 7

3.2 Foreseeable misuse .........................................................................................................7

3.3 Safety instructions ............................................................................................................ 8

3.4 Specific safety rules .........................................................................................................9

3.5 Safety devices ................................................................................................................13

3.6 Residual risks ................................................................................................................. 14

4Setup / adjustment .........................................................................................................14

4.1 Mains connection ...........................................................................................................14

4.2 Routing of the connecting cable ..................................................................................... 14

4.3 Chip extraction ............................................................................................................... 15

4.4 Saw blade selection .......................................................................................................15

4.5 Changing the saw blade.................................................................................................15

4.6 Riving knife..................................................................................................................... 18

5Operation........................................................................................................................19

5.1 Startup............................................................................................................................19

5.2 Switching on ...................................................................................................................19

5.3 Switching off ...................................................................................................................19

5.4 Cutting depth setting ...................................................................................................... 20

5.5 Setting for bevel cuts......................................................................................................20

5.6 Plunge cuts..................................................................................................................... 21

5.7 Shadow gap cuts............................................................................................................ 22

5.8 Sawing with the Flexi bar ............................................................................................... 23

5.9 Sawing along markings ..................................................................................................24

5.10 Sawing with the parallel guide fence .............................................................................. 25

5.11 Working with the guiding device..................................................................................... 26

6Service and maintenance...............................................................................................26

6.1 Storage........................................................................................................................... 26

7Troubleshooting.............................................................................................................. 26

8Optional accessories ...................................................................................................... 28

9Exploded view and spare parts list................................................................................. 28