P 2 / 7

Repair

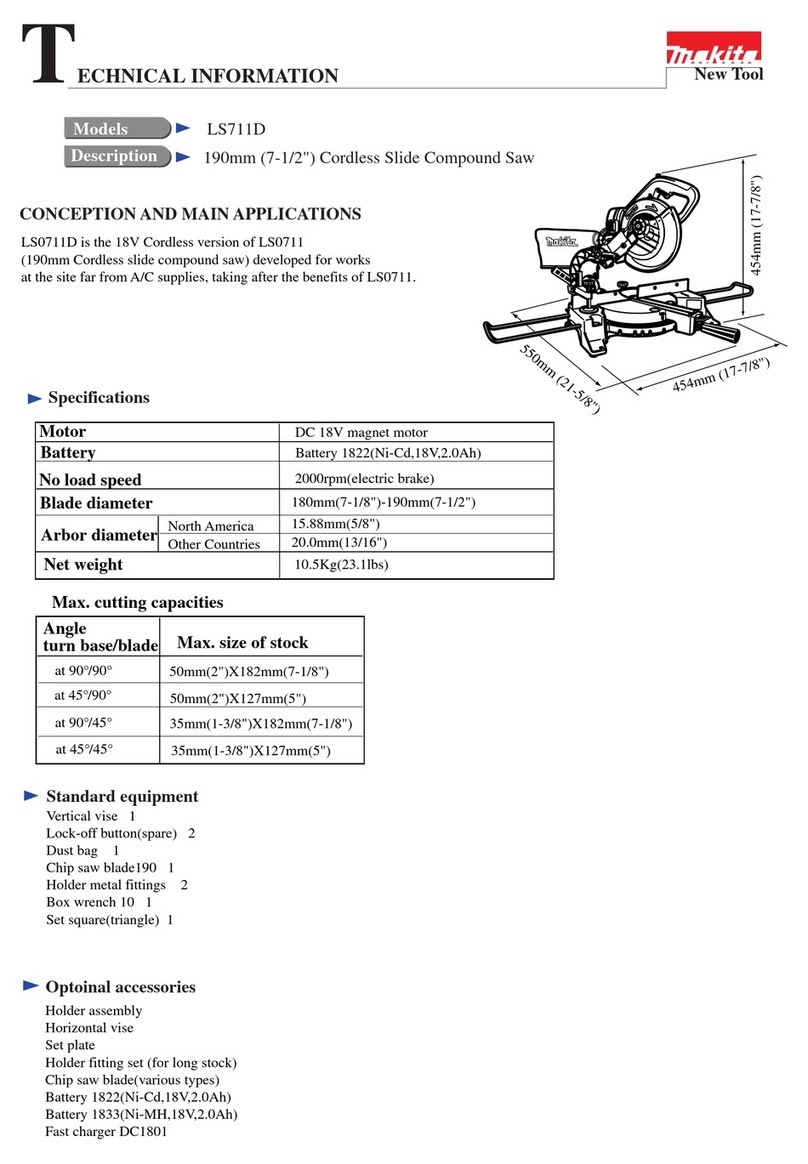

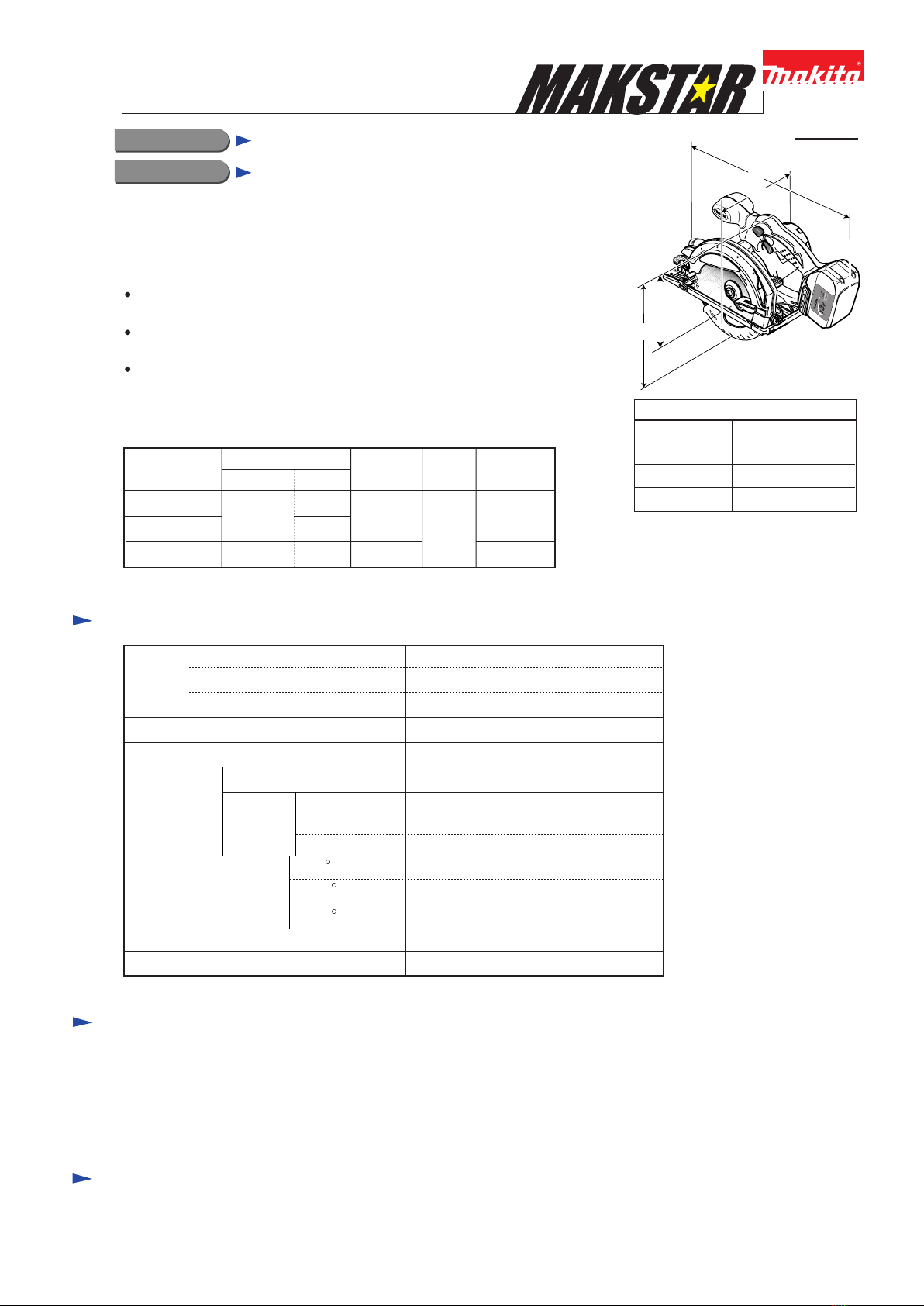

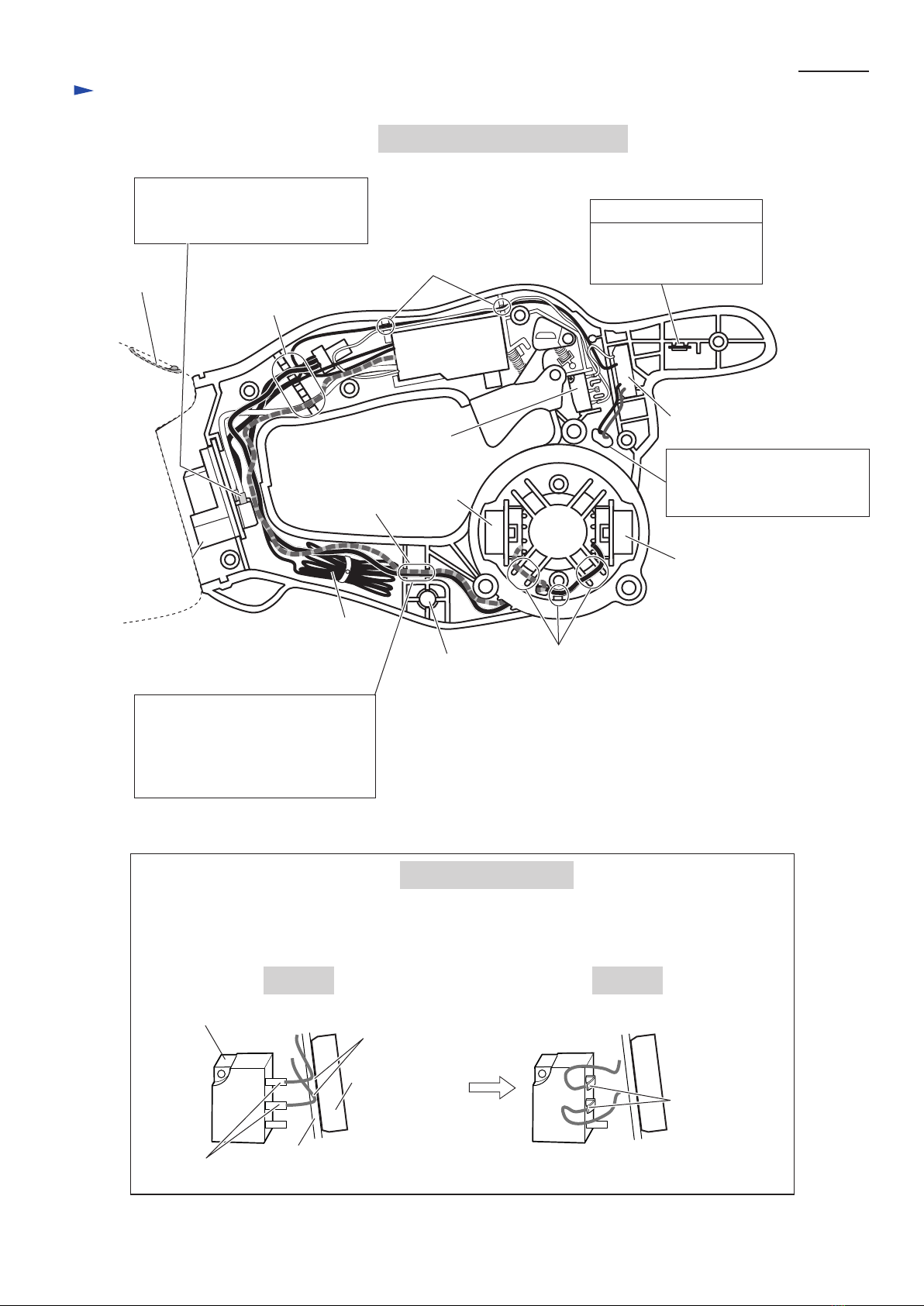

[2] LUBRICATION

Put Makita grease N. No.1 into the gear room indicated by the black triangle to protect parts and product from unusual

abrasion. See Fig.1.

Fig.1

[1] NECESSARY REPAIRING TOOLS

Makita Part No.

1R003 Retaining ring pliers ST-2N

1R026 Bearing setting pipe 16-8.2

1R208 90 Degree set square

1R232 Pipe 30

1R263 Bearing extractor

1R269 Bearing extractor

1R291 Retaining S & R pliers

Triangular rule

1R340 Bearing retainer wrench

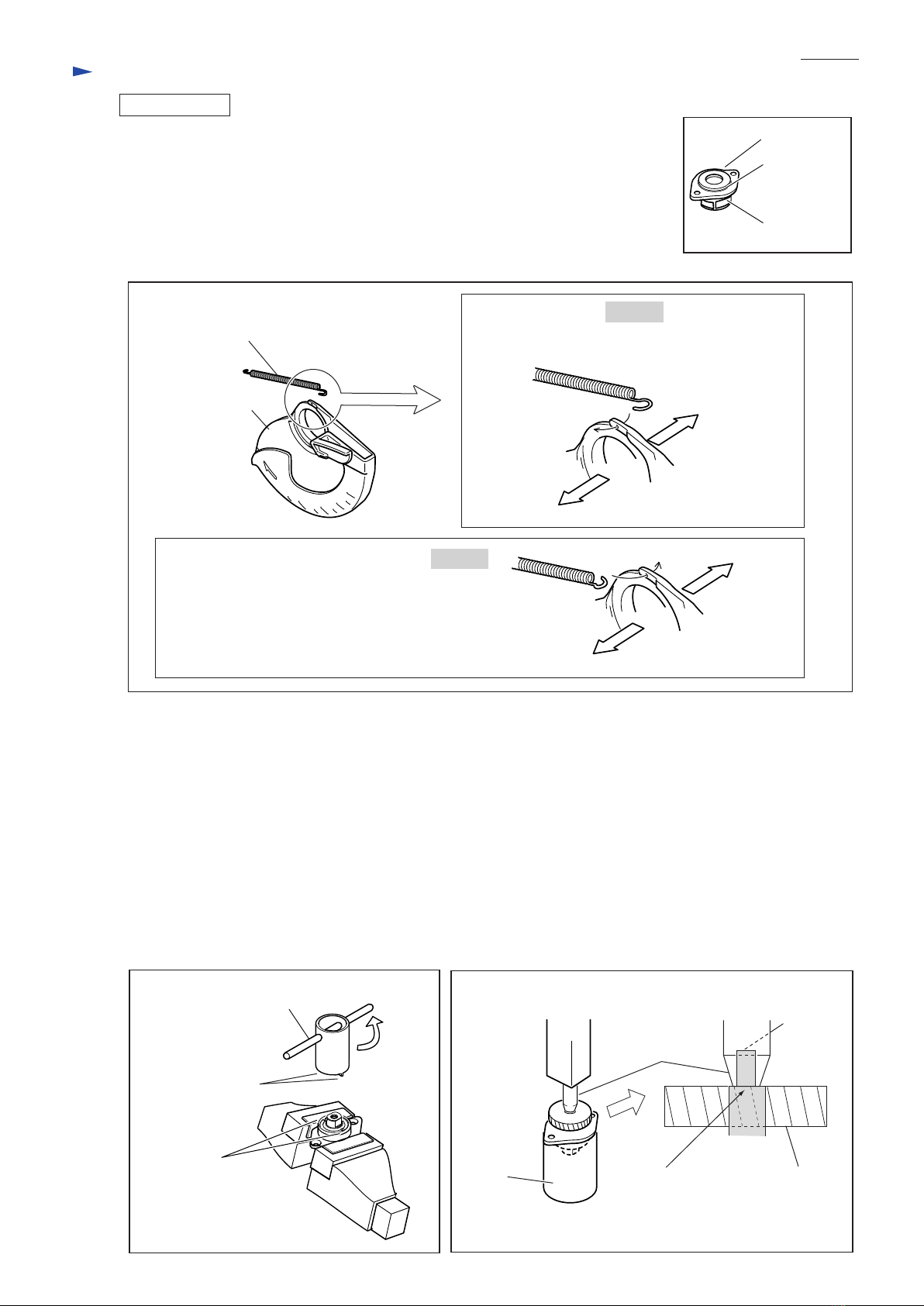

Removing / Mounting retaining ring

Removing helical gear 52

Adjusting the right angle of saw blade to base plate

Holding bearing box, when removing helical gear 52

Bearing extractor

Bearing extractor

Removing / Mounting retaining ring

Adjust the saw blade's angle of 45 degree to base plate

Removing / Mounting bearing retainer

Descriptions Purpose

Item No. Parts item Portion to be lubricated

Helical gear 52

Bearing box

31 Blade case

Amount

Gear room 6g

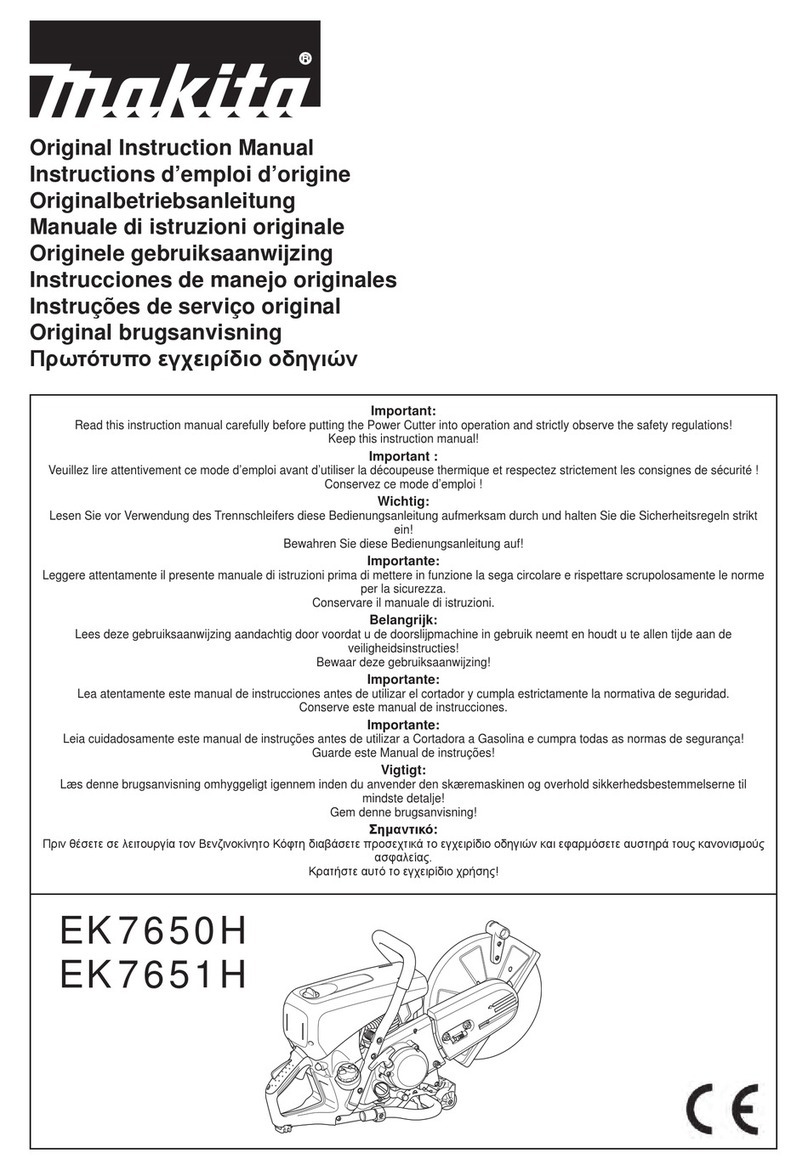

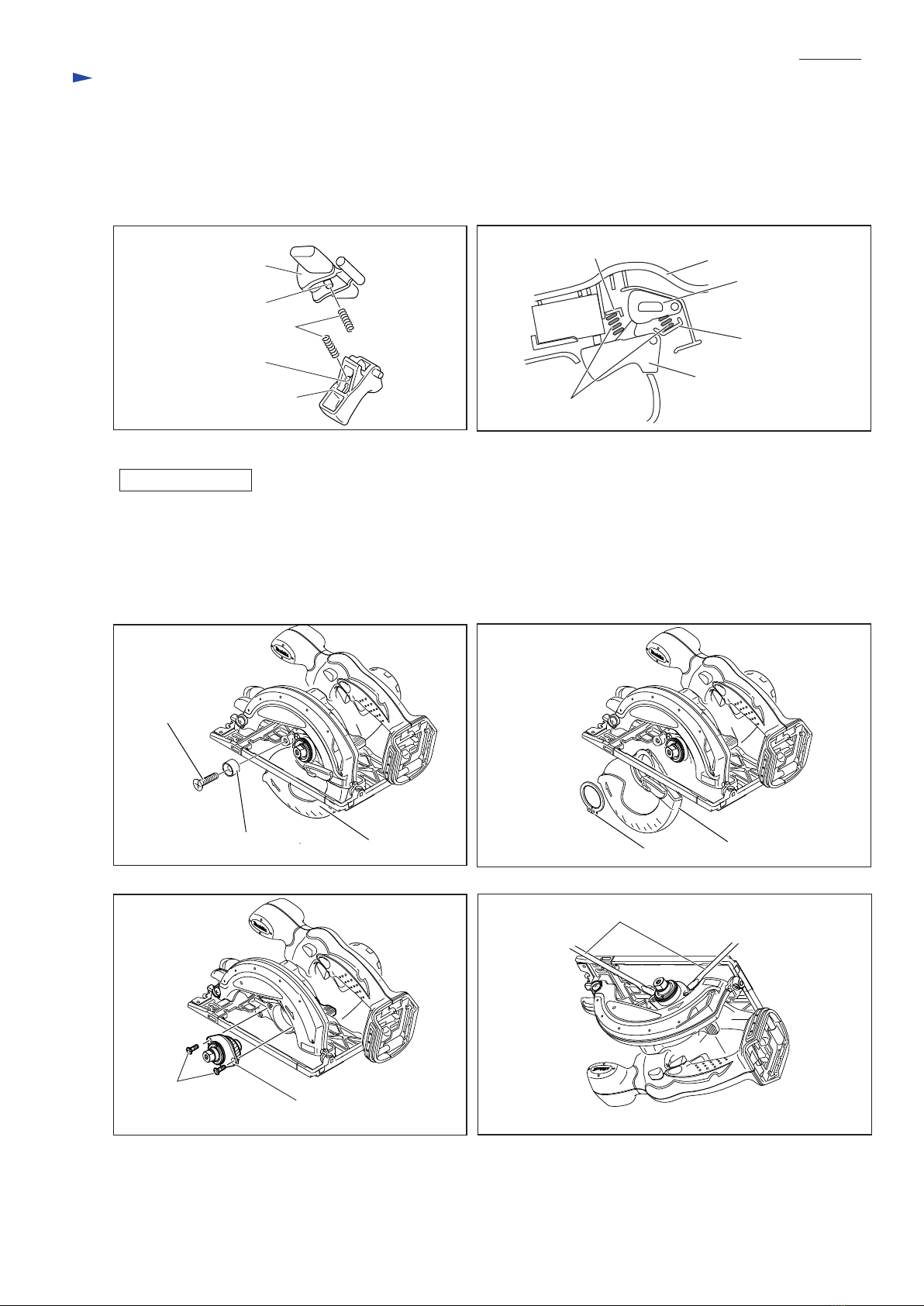

[3] Replacing Base complete

Fig. 2 Fig. 3

1. Loosen M5x6 Hex socket head set screw for fixing Depth guide to Base complete. See Fig.2.

Loosen Lever 40 and remove Shoulder pin 6-7 for connecting Depth guide and Base complete.

2. Remove the following parts as shown in Fig.3. Base complete can be separated from the machine.

A) Shoulder pin 6-7 for connecting Angular guide and Base complete

B) Stop ring E-8, M6 Hex nut, Flat washer 6 and M6x20 Cap square neck bolt for securing Lever 30

3. Reuse the above parts (for example, Mx6 Hex socket head screws) to replace the current base complete by the new one.

Note: M6 Hex nut in Lever 30 is not interchangeable with M6 Hex nut in Lever 40.

The former has left handed threads, the latter has right handed threads.

Stop ring E-8

Shoulder pin 6-7

Cap square

neck bolt M6x20

Hex socket head

set screw M5x6

Lever 30

Flat washer 6

Angular guide

Hex nut M6

Hex wrench

Base complete

Lever 40

Hex. wrench

M5x6 Hex socket set screw Shoulder pin 6-7

CAUTION: Remove Saw blade, Inner flange 40, Outer flange 40, Hex socket head bolt and

Battery cartridge from the machine for safety before repair/ maintenance !