Page i

Contents

1. Gene al Info mation ........................................................................................................ 1

1.1. Important Note About ODS Pilot ............................................................................... 2

1.2. Fire Fret Dimensions ................................................................................................ 3

2. Use Inst uctions ............................................................................................................. 5

2.1. Lighting Procedure ................................................................................................... 5

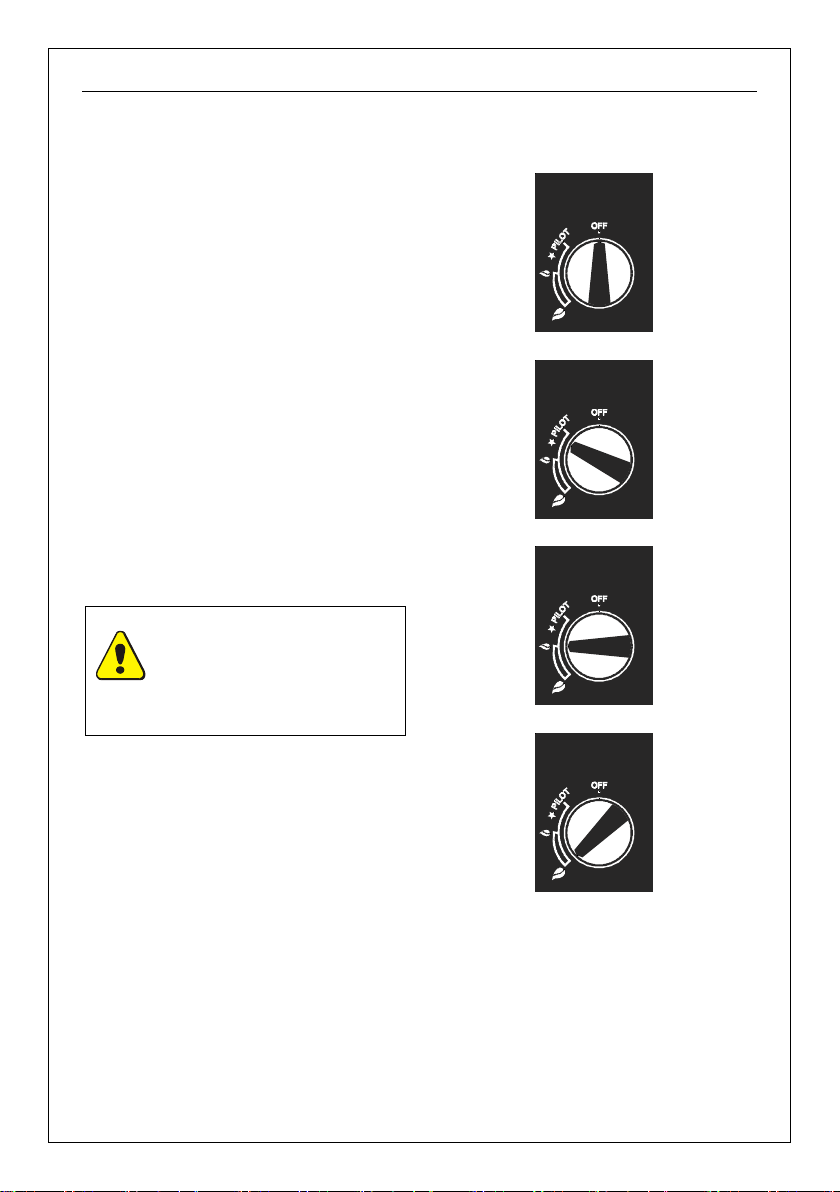

2.1.1. Lighting Procedure (Manual BM Control) ........................................................... 6

2.1.2. Lighting Procedure (Manual Mertik Control) ....................................................... 7

2.1.3. Lighting Procedure (Remote Control) ................................................................. 8

2.1.4. Lighting Procedure (Optimum Control) ............................................................... 9

2.1.5. Lighting Procedure ( otal Control) ................................................................... 10

2.1.6. Manual Operation ( otal Control) ..................................................................... 11

2.2. Battery Replacement (Remote Control and otal Control) ...................................... 12

2.2.1. Handset ........................................................................................................... 12

2.2.2. Receiver Unit ................................................................................................... 12

2.3. Battery Replacement (Optimum Control) ................................................................ 13

2.4. Fuel Effect Layout .................................................................................................. 14

2.4.1. Coal Layout ..................................................................................................... 15

2.4.2. Custom 18 Plus Example Coal Layouts ........................................................... 16

2.4.3. Custom 18 Plus/B and Custom 18 Plus/S Example Coal Layouts (up to 9.5”

deep) 16

2.4.4. Custom 18 Plus/S Example Coal Layouts (up to 11.5” deep) ........................... 17

2.4.5. Pebble Effect Layout ........................................................................................ 18

2.5. Home Improvements .............................................................................................. 23

2.6. Cleaning Instructions.............................................................................................. 24

2.6.1. Cleaning the Fire-Bed and the Imitation Coals/Pebbles ................................... 24

2.6.2. Cleaning the Pilot............................................................................................. 25

2.6.3. Black Painted Metal Surfaces .......................................................................... 25

3. Installation Inst uctions ................................................................................................ 27

3.1. General Safety Requirements ................................................................................ 27

3.2. Flue Requirements ................................................................................................. 27

3.3. echnical Data ....................................................................................................... 28

3.4. Appliance Location ................................................................................................. 29

3.4.1. Floor Level and Raised Fireplace Openings ..................................................... 30

3.4.2. Independent Canopy ....................................................................................... 31

3.4.3. Physical Barrier ............................................................................................... 32

3.5. Ventilation .............................................................................................................. 34

3.6. Contents Checklist ................................................................................................. 34

3.7. Installation Procedure ............................................................................................ 35

2.1.1. Installing the Fire ............................................................................................. 35

3.7.1. Continuation of Installation - Remote Control Model ........................................ 35

3.7.2. Continuation of Installation - Optimum Control Model....................................... 36

3.7.3. Continuation of Installation - otal Control Model ............................................. 37

3.7.4. Continuation of Installation - Detached Control Model ...................................... 38

3.7.5. Commissioning ................................................................................................ 39

3.7.6. Checking for Spillage ....................................................................................... 40

3.7.7. Instructing the User .......................................................................................... 40

4. Se vicing Inst uctions ................................................................................................... 41

4.1. General Requirements ........................................................................................... 41

4.2. Servicing Instructions ............................................................................................. 41