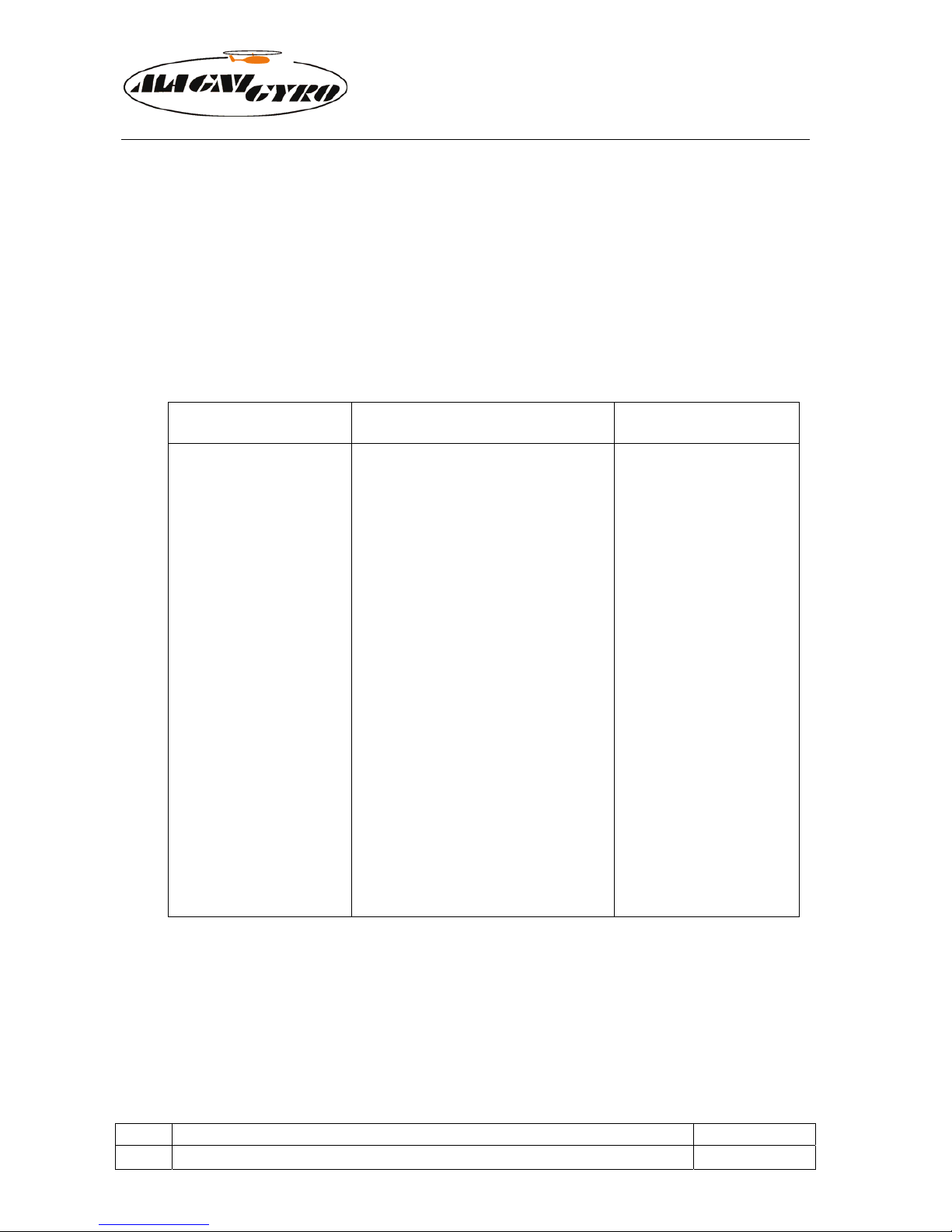

M16 (C) TANDEM TRAINER

MAINTENANCE MANUAL

PAGE

ISSUE

8

A_November 2012

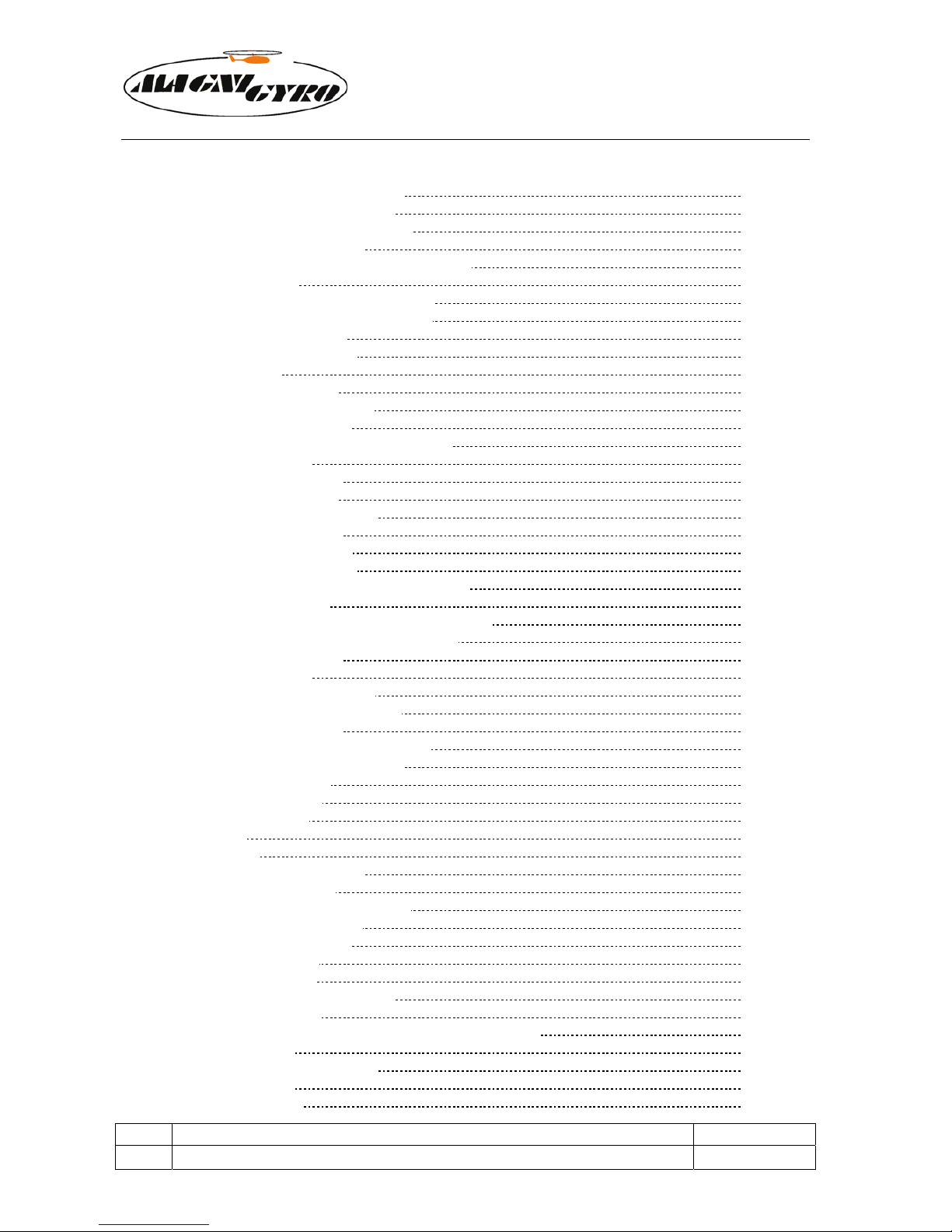

3.1.4 ‐ Installationofflexibleshaftpn118 36

3.1.5 ‐ Recommendedtypeoflubricant37

3.2 ‐ ADJUSTINGOFPREROTATIONUNIT37

3.2.1 ‐ Cablestretchingprocedure38

3.2.2‐Shimmingprocedureofprerotationassembly39

3.2.3 ‐ Operationaltest40

3.2.4‐Prerotationparameterssummarytable41

3.3 ‐ REPLACEMENTOFPULLEYSANDBELTS41

3.3.1 ‐ Replacementprocedure42

3.4 ‐ ROTORHEADINSPECTION43

3.4.1 ‐ Visualchecks43

3.4.2 ‐ Lubricationoperations45

3.4.3 ‐ Suggestedtypesoflubricant. 45

3.5 ‐ ROTORHEADOVERHAUL45

3.5.1 ‐ Instructionsfordisassemblyofrotorhead45

3.5.2 ‐ Rotordisassembly46

3.5.3 ‐ Rotorheaddisassembly48

3.5.4‐Rotorheadinstallation48

3.6‐INSPECTIONOFBENDIXGEAR49

3.6.1 ‐ Removalofbendixgear49

3.6.2 ‐ Inspectionofbendixgear49

3.6.3‐Installationofbendixgear50

3.7 ‐ FRICTIONINGOFROLLANDPITCHCONTROLS51

3.7.1 ‐ Frictioningprocedure51

3.8 ‐ MAINTENANCEANDCHECKSOFCONTROLRODS52

3.8.1 ‐ Replacementofcontrolrodsballjointends52

3.9 ‐ SECONDARYCONTROLS55

3.9.1 ‐ Chokecontrolline 55

3.9.1.1 ‐ Replacementofchokecables 55

3.9.2 ‐ Replacementofrotorbrakecable56

3.9.3 ‐ Brakesystemcableline58

3.9.3.1 ‐ Replacementofbrakingsystemcables58

3.9.4 ‐ Replacementofprerotationcable59

3.10‐RUDDERPEDALSLINE61

3.10.1 ‐ Generalinstructions61

3.10.1.1‐ Integrityofcables61

3.10.1.2‐ Chafing 61

3.10.1.3‐ Oxidation61

3.10.2 ‐ Cableinspectionprocedure61

3.10.3 ‐ Checkofcabletension62

3.10.4 ‐ Replacementofrudderpedalcable63

3.10.4.1‐ Removalofdamagedcable63

3.10.4.2‐ Preparationofnewcable63

3.10.4.3‐ Installationofcable63

3.10.4.4‐ Cabletensiontable65

3.10.5 ‐ Inspectionofrudderpedalsrods65

3.10.6 ‐ Inspectionofpedals65

3.11 ‐ INSPECTIONANDREPLACEMENTOFFRONTSUSPENSION66

3.11.1 ‐ Integrityoftyre66

3.11.2 ‐ Fixingofnosewheelandfork66

3.11.3 ‐ Integrityoffork66

3.11.4 ‐ Checkprocedure66