Model OE-10

Installation, Operation and Maintenance

Page 10

Rev. 4/20/07

A2151_MAGNUM.doc

FINAL ADJUSTMENTS (CONTINUED)

SYNCHRONIZING CABLES

41) Raise lift and insure carriages lower into

same lock position.

42) Adjust synchronizing cables so the tension is

equal in both cables and carriages are firmly

sitting on locks.

43) Cycle lift to insure that latches operate

simultaneously.

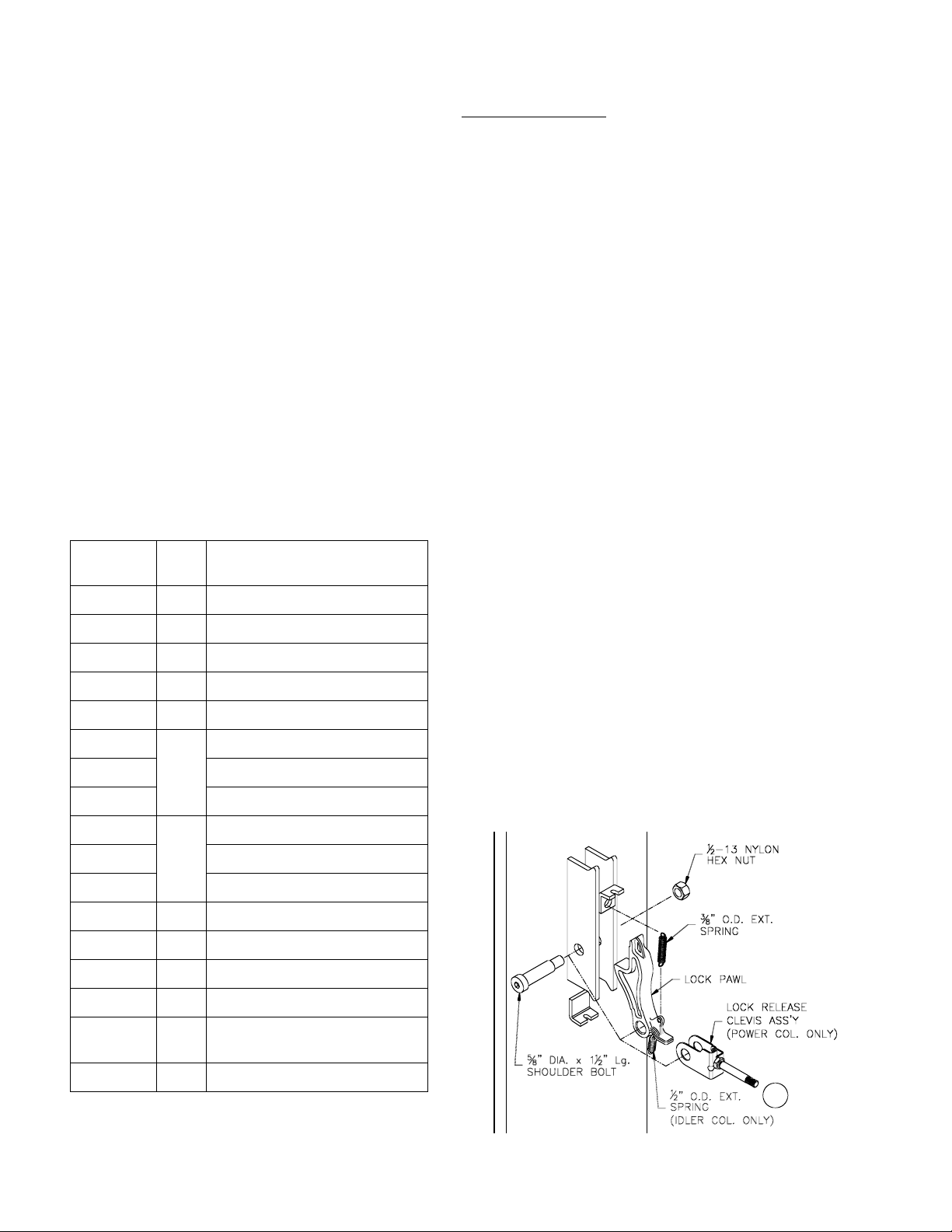

LOCK RELEASE CABLE

44) Lower lift to the floor and snap plastic cover

over Power Column lock assembly.

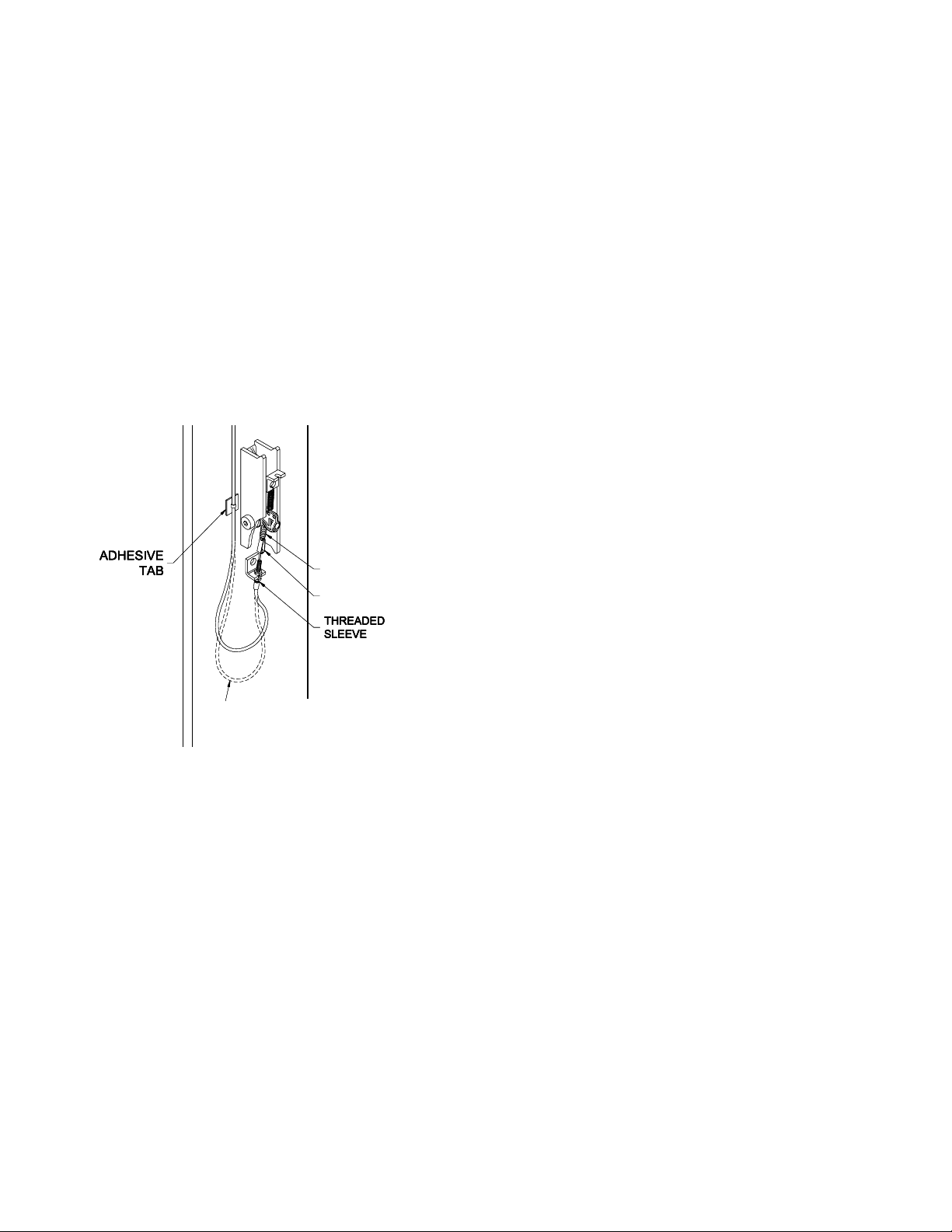

45) Pull and release Power Column lock release

handle while watching Idler Column lock.

Adjust lower threaded sleeve cable adjuster

jam nuts on Idler Column until Idler Column

lock disengages and engages fully. When

properly adjusted, the idler column lock

should just come to rest against the back of

the column when engaged and fully out

against the tab when disengaged. Tighten

Idler Column lower tab jam nuts.

IMPORTANT: IF IDLER SIDE LOCK PAWL DOES NOT

FULLY DISENGAGE, DAMAGE MAY RESULT TO IDLER

SIDE CARRIAGE AND OR CABLE SYNCHRONIZING

SYSTEM.

46) Tighten threaded sleeve cable adjuster jam

nuts and install lock release knob.

47) Tighten and trim wire ties.

48) Snap plastic cover over Idler lock assembly

(align release cable with notches in cover).

OWNER/OPERATOR CHECKLIST

49) Demonstrate the operation of the lift to the

owner/operator and review correct and safe

lifting procedures using the Lifting It Right

booklet as a guide.

50) Complete the Installation Checklist/Warranty

Validation questionnaire with the owner.

Review the terms of the warranty registration

card, and return the card and a copy of the

questionnaires to:

Challenger Lifts, Inc.

200 Cabel Street

Louisville, KY. 40206

OPERATION PROCEDURE

SAFETY NOTICES AND DECALS

This product is furnished with graphic safety

warning labels, which are reproduced on

page 3 of these instructions. Do not remove

or deface these warning labels, or allow them

to be removed or defaced. For your safety,

and the safety of others, read and understand

all of the safety notices and decals included.

OWNER/EMPLOYER RESPONSIBILITIES

This lift has been designed and constructed according

to ANSI/ALI ALCTV-1998 standard. The standard

applies to lift manufactures, as well as to owners and

employers. The owner/employer’s responsibilities as

prescribed by ANSI/ALI ALOIM-2000, are summarized

below. For exact wording refer to the actual standard

provided with this manual in the literature pack.

The Owner/Employer shall insure that lift

operators are qualified and that they are trained

in the safe use and operation of the lift using the

manufacturer’s operating instructions; ALI/SM

93 -1, ALI Lifting it Right safety manual; ALI/ST-

90 ALI Safety Tips card; ANSI/ALI ALOIM-2000,

American National Standard for Automotive Lifts-

Safety Requirements for Operation, Inspection

and Maintenance; ALI/WL Series, ALI Uniform

Warning Label Decals/Placards; and in case of

frame engaging lifts, ALI/LP-GUIDE, Vehicle

Lifting Points/Quick Reference Guide for Frame

Engaging Lifts.

The Owner/Employer shall establish

procedures to periodically inspect the lift in

accordance with the lift manufacturer’s

instructions or ANSI/ALI ALOIM-2000, American

National Standard for Automotive Lifts-Safety

Requirements for Operation, Inspection and

Maintenance; and the employer shall insure that

the lift inspectors are qualified and that they are

adequately trained in the inspection of the lift.

The Owner/Employer shall establish

procedures to periodically maintain the lift in

accordance with the lift manufacturer’s

instructions or ANSI/ALIOIM-2000, American

National Standard for Automotive Lifts-Safety

Requirements for Operation, Inspection and

Maintenance; and the employer shall insure that

the lift maintenance personnel are qualified and

that they are adequately trained in the

maintenance of the lift.

The Owner/Employer shall maintain the

periodic inspection and maintenance records

recommended by the manufacturer or ANSI/ALI

ALOIM-2000, American National Standard for

Automotive Lifts-Safety Requirements for

Operation, Inspection and Maintenance.

The Owner/Employer shall display the lift

manufacturer’s operating instructions; ALI/SM

93 -1, ALI Lifting it Right safety manual; ALI/ST-

90 ALI Safety Tips card; ANSI/ALI ALOIM-2000,

American National Standard for Automotive Lifts-

Safety Requirements for Operation, Inspection

and Maintenance; and in the case of frame

engaging lift, ALI/LP-GUIDE, Vehicle Lifting

Points/Quick Reference Guide for Frame

Engaging Lifts; in a conspicuous location in the

lift area convenient to the operator.