For advice on the safety and suitability of this equipment

contact your local HSS Lift & Shift Depot.

There is a serious risk of personal injury if you do not

follow all instructions laid down in this guide.

The hirer has a responsibility to ensure that all necessary

risk assessments have been completed prior to the use

of this equipment.

This equipment should only be used by an operator

who has been deemed competent to do so by

his/her employer.

This equipment is designed to be used by an able

bodied, competent adult who has read and understood

these instructions. Anyone with either a temporary or

permanent disability should seek expert advice before using it.

Keep children, animals and bystanders away from

the work area. Cordon off a NO GO area using cones

and either barriers or tape, available for hire from your local

HSS Lift & Shift Depot.

Never use this equipment if you are ill,

feeling tired, or under the influence of

alcohol or drugs.

Confined Spaces Can Be Dangerous

Do not enter until you have checked that it is safe to do so.

Gas detection equipment, fall arrest systems, escape

breathing packs and safety lighting are available for

hire from your local HSS Safe and Sure Depot.

Wear practical, protective clothing,

gloves and footwear. Avoid loose

garments and jewellery that could catch in moving parts,

tie back long hair.

Use this equipment for vertical lifts only and

use on a level area able to take the combined weight

of the load and the equipment.

Ensure the load is balanced, stable and that

personnel stand clear of the raised load.

Make sure you know how to operate this equipment

safely and are aware of its limitations before you use it.

Make sure that anyone in the immediate work area

is warned of what you are doing.

Check the condition of the equipment before use.

If it shows signs of damage or excessive wear, return it to

your local HSS Lift & Shift Depot.

GENERAL SAFETY

GETTING STARTED

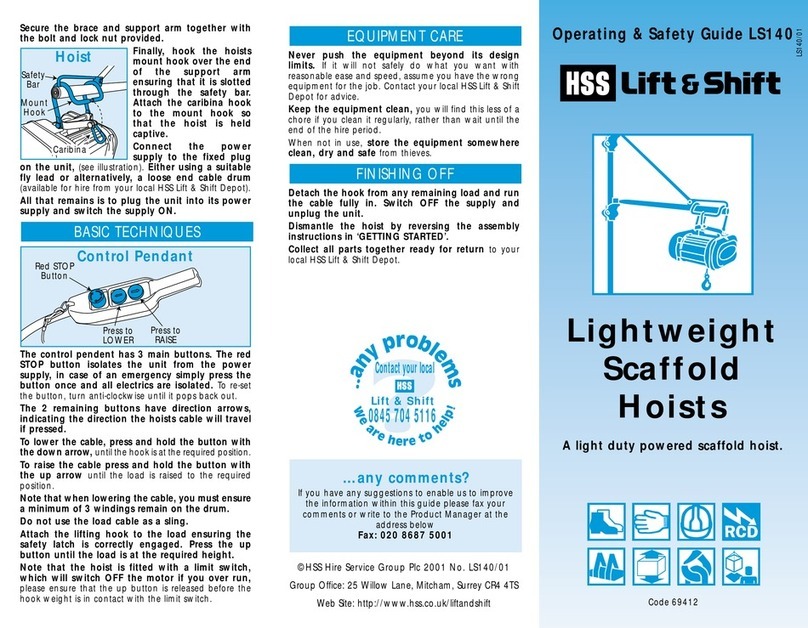

Hydraulic Manhole Lifter

Lifting Hook

Cross

Beam

Cross

Beam

Castor

Assembly

Thumbscrew

Main Body

Frame

Cross

Beam

Ram

Box

Section

Pressure

Release Valve

Take the main body frame and slide the crossbeam

through the end mounting box section.

Open the ram’s pressure release valve by turning

anticlockwise and once the ram is fully retracted,

close the valve.

Slide one lifting hook onto each end of the

crossbeam so that the hook is facing down with its

opening toward the ram.

Next, slide a castor assembly onto each end of the

crossbeam with the castors fork pointing horizontally

away from the ram. Secure the castor assembly to the

crossbeam by turning the thumbscrews clockwise, do

not overtighten.

Wheel the unit to the manhole cover and select

the correct key.

If using 2 keys…

Insert both keys into the keyways of the cover then

place their loop over each of the lifting hooks. Adjust

the distance between each hook as necessary but keep them

an equal distance from the centre of the cross bar.

If using 4 keys…

BASIC TECHNIQUES

Using 4 Keys

Loop

Clamp Frame Key

Wing Nut

Loop

Select the most suitable clamp frames and attach each to

one side of the cover using 2 keys on each. Insert each key

through the slots in the clamp frame and into the lifting holes,

turn the key 90 degrees then wind down the wing nuts until

under pressure.

Place the loop of each clamp frame over each of the lifting

hooks. Adjust the distance between each hook as necessary but

keep them an equal distance from the center of the cross bar.

Whichever you are using…

DO NO attempt to lift a cover using a single key.

Make sure that the lift pressure is balanced between each

lifting hole to ensure a vertical lift. Uneven pressure will

cause the cover to twist and could damage the equipment.