iii

Table of Contents

SAFETY PRECAUTIONS .......................................................................................................................I

REVISIONS TO THIS MANUAL .............................................................................................................II

REVISION DATE ...............................................................................................................................................................II

TABLE OF CONTENTS ........................................................................................................................III

TABLE OF FIGURES ...................................................................................................................................................... IV

PREFACE .............................................................................................................................................. V

PURPOSE OF THIS MANUAL ....................................................................................................................................... V

WHO SHOULD USE THIS MANUAL ............................................................................................................................ V

MANUAL ORGANIZATION ........................................................................................................................................... V

SYMBOLS USED IN THIS MANUAL ........................................................................................................................... VI

1. INTRODUCTION ...............................................................................................................................1

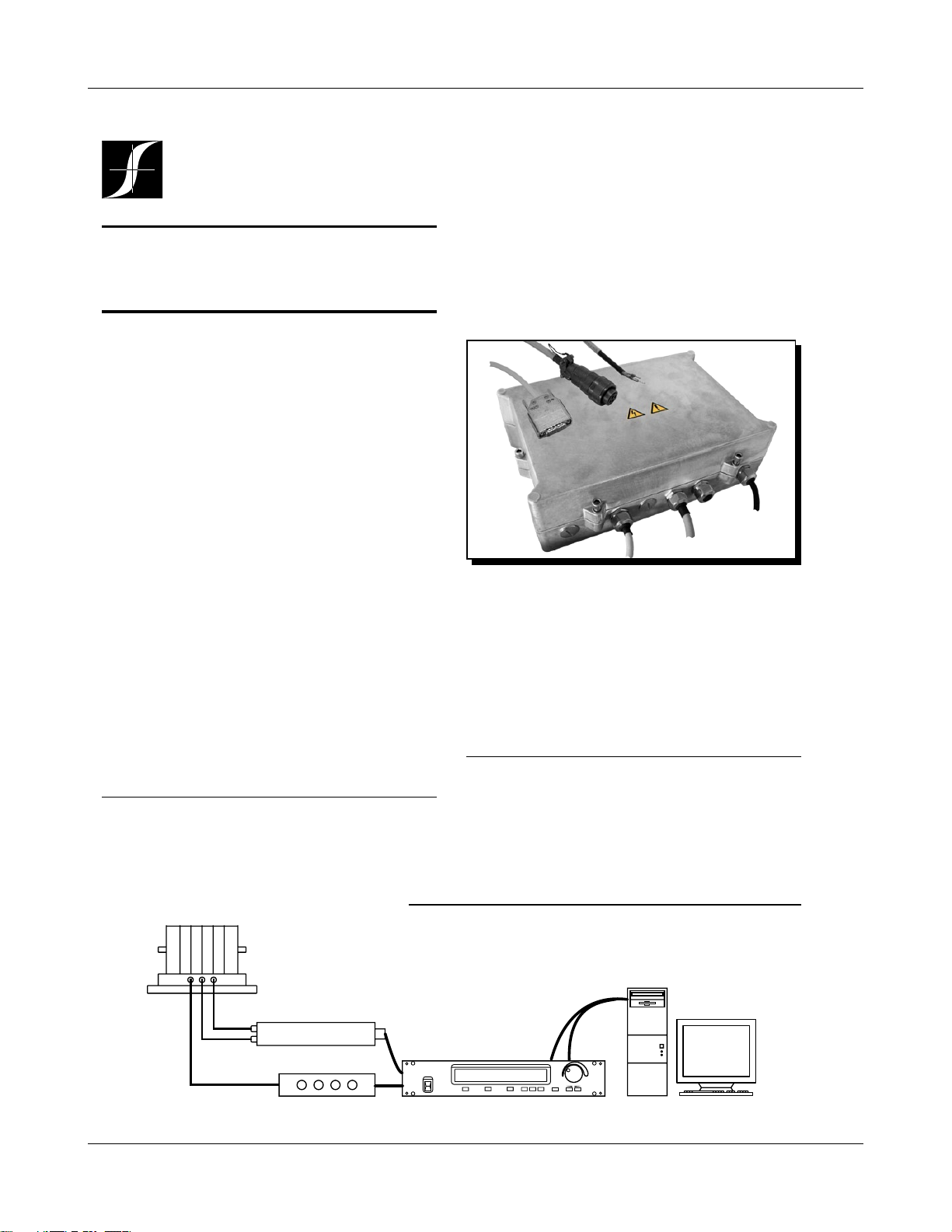

1.1 GENERAL INFORMATION ...................................................................................................................................... 1

1.2 DATA SHEET .............................................................................................................................................................. 2

2. INSTALLATION / CONFIGURATION ................................................................................................6

2.1 GENERAL DESCRIPTION ....................................................................................................................................... 6

2.2 DES 410 & DES 411 SAFETY WARNING ............................................................................................................... 7

2.3 MOUNTING WITHOUT COOLING ......................................................................................................................... 7

2.4 MOUNTING WITH COOLING PLATE (OPTIONAL) ............................................................................................ 8

2.5 CONNECTION BETWEEN THE VARIOUS UNITS.............................................................................................. 10

2.6 CONNECTING THE DES 410 AND DES 411 POWER SUPPLY.......................................................................... 11

2.6.1 Passing Unshielded Cables Into Stuffing Gland ......................................................................................... 11

2.6.2 Passing Shielded Cables Into Stuffing Gland (with EMC stuffing gland) .................................................. 12

2.7 CONFIGURATION OF THE DES 410 AND DES 411 POWER SUPPLY ............................................................. 13

2.7.1 DES 410 Main Board : F1,F2, F3, SL12, SW1 & SW2 Location .............................................................. 13

2.7.2 DES 411 Main Board: F1, F2, F3, SL12, SW1 & SW2 Location .............................................................. 14

2.7.3 DES 410 & DES 411 CPLD Board : R39, R102, SL1 Location ................................................................ 14

2.7.4 Main Board: F1, F2, F3, SL12, SL1, SL3, SW1 & SW3 Set-Up ............................................................... 15

2.7.5 CPLD Board: R39, R102, SL1 Set-Up ....................................................................................................... 15

2.7.6 Set-Up Values .............................................................................................................................................. 15

2.8 CONNECTING THE DES 410 TO THE DSP 7000 CONTROLLER ..................................................................... 16

2.9 CONNECTING THE DES 411 TO THE DSP 7000 CONTROLLER ..................................................................... 17

3. CALIBRATION ................................................................................................................................18

4. REPAIR ...........................................................................................................................................19

4.1 REPAIR ..................................................................................................................................................................... 19