BA010101-en

Safety ....................................................................................................................5

1.1 Introduction..............................................................................................................5

1.2 Symbols and Signal Words ......................................................................................5

1.2.1 Personal Injury..........................................................................................................5

1.2.2 Property Damage.....................................................................................................5

1.2.3 Information...............................................................................................................5

1.3 Intended Use ...........................................................................................................6

1.4 Requirements on Operating and Service Personnel ..................................................6

1.5 Safety Instructions for Commissioning ......................................................................6

1.6 Safety Instructions for Operation...............................................................................6

1.7 Safety Instructions for Servicing................................................................................7

1.8 Safety Instructions for Handling Hydraulic Fluid.........................................................8

Specifications.........................................................................................................9

2.1 PMS Specifications ..................................................................................................9

2.2 LMS Specifications.................................................................................................10

Transport and Storage ......................................................................................... 11

Installation and Initial Operation............................................................................. 11

Operation............................................................................................................. 12

5.1 Main Switch ...........................................................................................................12

5.2 Preparing for Operation ..........................................................................................12

5.3 Operating the Axle Play Detector............................................................................13

5.4 Operating the Cable Hand Lamp............................................................................14

5.5 Operating the Radio Hand Lamp RHL (Option) .......................................................14

5.6 Service Mode.........................................................................................................15

5.7 Operating Diagrams ...............................................................................................15

Maintenance ........................................................................................................16

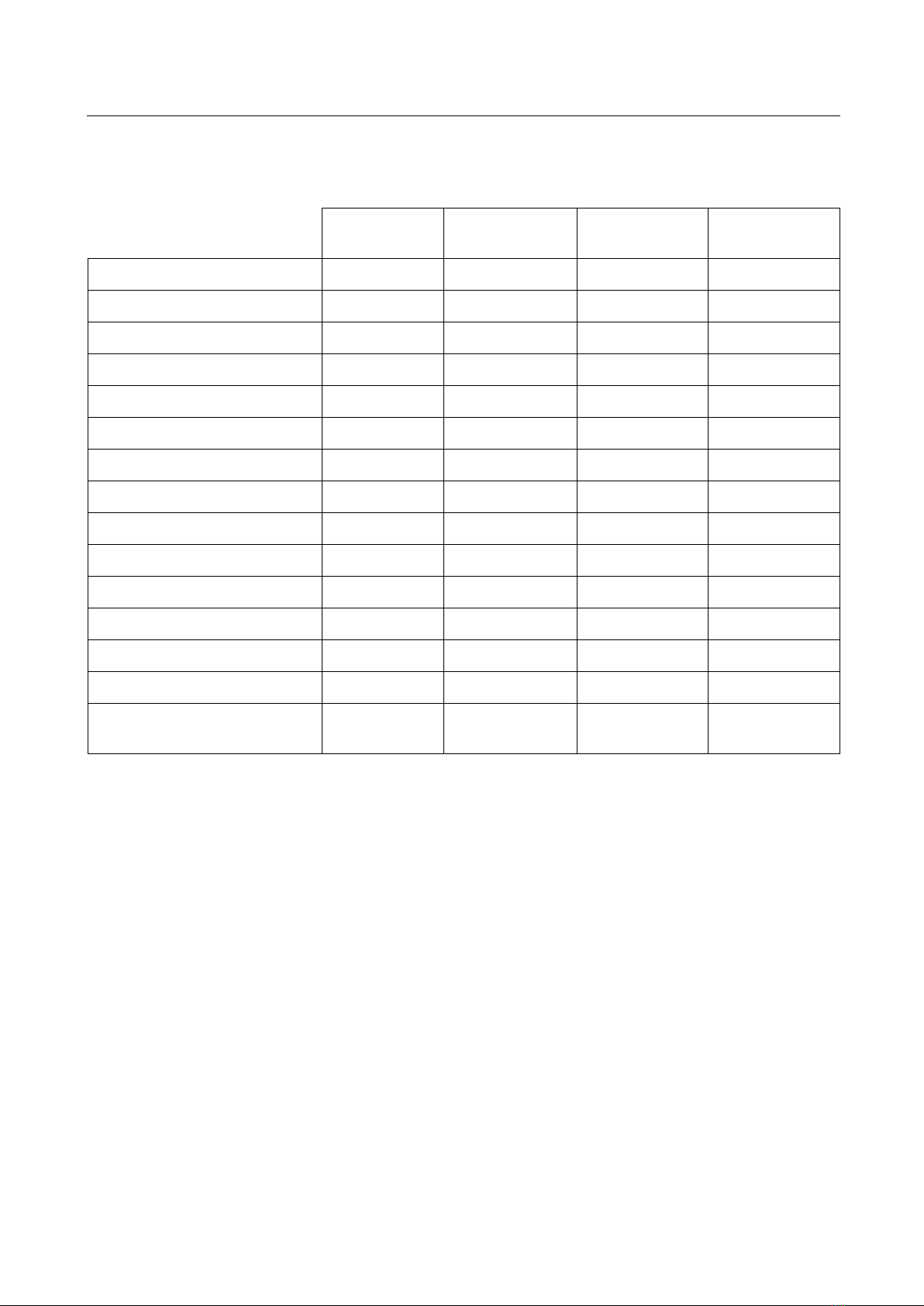

6.1 Maintenance Schedule...........................................................................................16

6.2 Annual Inspection...................................................................................................16

6.3 Maintenance by the Operator .................................................................................17

6.4 Greasing Points......................................................................................................17

6.5 Care Instructions ....................................................................................................19

6.6 Spare Parts............................................................................................................19

6.7 PMS Variants for Installation on Lift Runways .........................................................19

Dismantling..........................................................................................................23

Disposal............................................................................................................... 23

Contents of the Declaration of Conformity.............................................................23