3 Safety instructions

7

DANGER Danger if the relevant regula-

tions for electrical installations are not ob-

served.

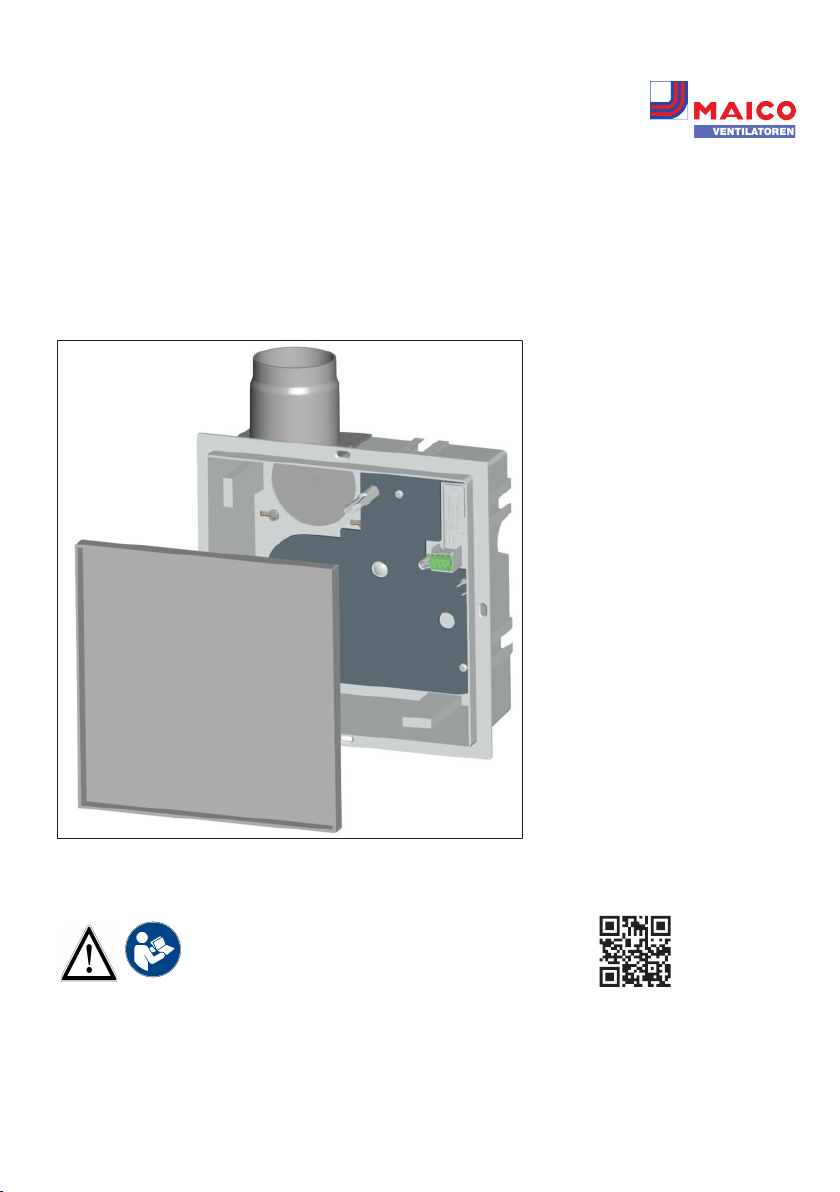

Before removing the housing cover or removing

the fan insert and before installing the electrics,

switch off all supply circuits, switch of mains fuse

and secure it against being accidentally switched

back on again. Attach a warning sign in a clearly

visible place.

Be sure to observe the relevant regulations for

electrical installation; e.g. DIN EN 50110-1. In

Germany, particularly observe VDE 0100, with

the corresponding sections.

A mains isolation device with contact openings of

at least 3mm at each pole is mandatory.

Only connect unit to permanently wired electrical

installation and with NYM-O or NYM-J cables,

depending on the unit variant, 3 x 1.5mm² or 5 x

1.5mm².

Units may only be operated using the voltage and

frequency shown on the rating plate.

Unit may be energized even when at a standstill

and may switch on automatically due to sensors

(time delay, humidity etc.). Maintenance and fault

finding only permissible when carried out by qual-

ified electricians.

The degree of protection stated on the rating

plate is only guaranteed if installation is under-

taken correctly and if the connecting cable is cor-

rectly guided through the stepped grommet (The

grommet must completely enclose the cable

sheathing). The fan insert must also be engaged

and the housing cover installed.

DANGER Danger due to fire transmission

if an incorrect connection duct is connected to the

housing. Always use the correct cable material

for the respective housing. Requirements in line

with approval [}12].

if an incorrect ceiling compound is used for ex-

haust air systems with an intermediate ceiling

(ceiling barrier system). Ensure that the gap re-

maining between the main duct and wall or ceil-

ing is fully sealed with non-flammable materials

resistant to deformation, such as concrete, ce-

ment mortar or plaster.

WARNING Risk to health if filters are not

replaced or if there are no air filters.

Heavily soiled or moist air filters can accumulate

harmful substances (mould, germs, etc.). This

may also happen if the unit is shut down for an

extended period. If the air filter is missing, the

unit and air ducts become soiled.

Never operate the unit without air filters.

Only use original filters.

Regularly change air filter when a filter change is

indicated (LED or TimeStrip).

If the unit has not been used for a long time, al-

ways replace the air filters.

WARNING Risk of injury when working at

heights.

Use appropriate climbing aids (ladders).

Stability should be ensured, if necessary have

the ladders steadied by a 2nd person.

Ensure that you are standing securely and can-

not lose your balance and that there is no one

under the unit.

WARNING Risk of injury and risk to

health from parts which may affect the ventil-

ation system which are added or modified at a

later date.

Parts (range hood, air-ventilated fireplace etc.)

which are added or modified at a later date may

result in health risks and operation which is not

permitted. Parts may only be added or modified

at a later date if system compatibility is estab-

lished/ensured by a planning office. If using an

exhaust air range hood or air-ventilated fireplace,

this must be accepted by a regional master chim-

ney sweep.

WARNING Risk of injury and health risk

in the event of changes or modifications or if

components which are not permitted are

used.

The unit may only be operated with original com-

ponents. Changes and modifications to the units

are not permitted and release the manufacturer

from any guarantee obligations and liability, e. g.

if the housing is drilled at a point which is not

permitted.

CAUTION Exercise caution when hand-

ling packaging materials.

Observe applicable safety and accident preven-

tion requirements.

Store packaging material out of the reach of chil-

dren (risk of suffocation).