GUARANTEE and Certificate Of Conformity

Before using the incubator, you should read this instruction manual in full. All instructions, without exception, given in this

manual are given in good faith, and we or our dealer / distributor, cannot be held responsible for any damage arising from

these instructions, however caused. This includes, without restriction, damages, and hypothetical damage refered to in the

use of this given instructions, such as: loss of goods, profits and income; loss of biological value; restoration and replacement

cost or other similar costs; or any other special, casual or consequential damage. This information has been written very care-

fully. We have used best available knowledge in drawing it up, incorporating best technologies and best techniques. However

its accuracy and its reliability are in no wise and in no case due to the dealer/ distributor. The authorization to make use of this

information is strictly reserved for personal use. Every part of the appliance has been tested by the producer before the deliv-

ery and consignment date. Therefore the maker's guarantee does not include damages resulting from an incorrect transporta-

tion of the appliance. The guarantee does not include damages to the electric supply and electronic parts resulting from an

incorrect connection to the electricity circuits or power surges. The guarantee includes any necessary spare parts and man-

power to bring back into use in a functional way the appliance due to any breakdowns that might occur during the following 24

months after the initial testing. The guarantee work is done at the Producers company, or their agent, and will not include re-

funds of the appliance, or refunds of the damages suffered during the manufacture. The repairs will only have to be done by

authorized staff. Not complying with this clause will cause the annulment of the guarantee.

REFERENCE SET OF RULES: This product complies with the main requisitions of Electromagnetic and Safety Con-

sistency provided by the Regulations: 89/33/CEE of May 3 1989 with subsequent changes (Regulation 92/31/CEE of April

28 1992 and Regulation 93/68/CEE of July 22 1993); 73/23/CEE of February 19 1973 with subsequent changes (Regulation

93/68/CEE of July 22 1993); Since it has been projected in compliance with the directions of the following Harmonized

Rules: CEI EN61000-3-2 (1998) + A14 (2000) ref. Harmonic Current Emissions; EN61000-3-3 ref. Voltage Fluctuations;

EN55014-1 ref. Conducted Radiodisturbance Emissions; EN55014-1 ref. Click; EN55014-1 ref. Power Disturbace (30/300

Mhz) & Immunity Tests EN55014-2 ref. ESD , CM , FSB , S, VDSI + EN60335 + EN60335-2-71.

The compliance with the above-said main requisitions is attested by means of the affixing of the marking CE¹ on the

product. The marking CE¹ was introduced in 1995.

We attract your attention on the following actions that may compromise the compliance as well as, obviously, the features of

the product: 1. Incorrect electric power; 2. Incorrect installation or incorrect or improper or in any case different use as to the

directions written on the user's manual given with the product; 2. Change of parts or of original accessories with others not

approved by the maker, or changed by non-authorized staff;

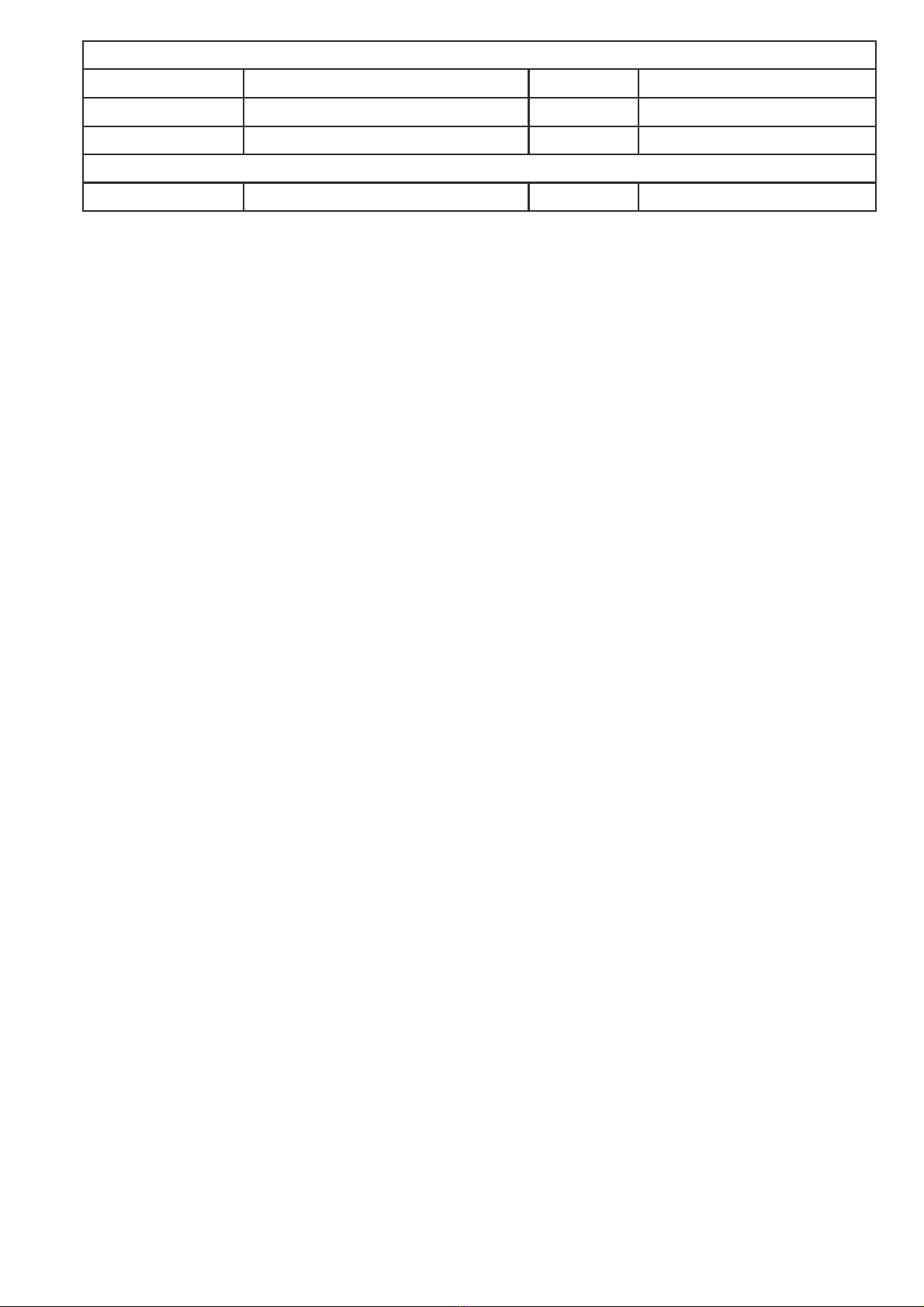

DECLARATION OF CONFORMITY according to the attachment II, A of DPR 45 / 6

THE PRODUCER : IT01555980133

DISTRIBUTED IN

THE UK BY :

Maino UK , "Dovers Orchard Farm", Hoo Lane, Chipping

Campden, Glos. GL55 6AZ VAT GB 275 2945 31

Sales:+44 (0)1386 841109

Web: www.maino.co.uk

The Appliance INCUBATOR or HATCHING

machine

Model: MPS12 (UK18)

Matriculation Num-

ber:

From 4512 - 07 - 2003 and so on , until new issue

IS PROJECTED AND REALIZED IN COMPLIANCE WITH THE MAIN REQUISITES OF SAFETY AND HEALTH OF THE

D.P.R. 459/ of July 21 1996 - ATTACHMENT I - The adhesive plate with the mark CE¹ sticked on the appliance is integrant

part of it; on the plate there is the specific information of the Appliance Directives.

The following Harmonized Rules has been used to implement in a correct way the main requisites of Safety and

Health of the ATTACHMENT I: CEI EN61000-3-2 (1998) + A14 (2000) ref. Harmonic Current Emissions; EN61000-3-3 ref.

Voltage Fluctuations; EN55014-1 ref. Conducted Radiodisturbance Emissions; EN55014-1 ref. Click; EN55014-1 ref. Power

Disturbace (30/300 Mhz) & Immunity Tests EN55014-2 ref. ESD , CM , FSB , S, VDSI + EN60335 + EN60335-2-71

Oltrona di San Mamette 01/07/2003, The declarant:

Disposal of old special Equipment (Applicable throughout the European Union and other

European countries with separate collection programs). The symbol, found on your product

or on its packaging, indicates that this product should not be treated as household waste when you

wish to dispose of it. Instead, it should be handed over to an applicable collection point for the recy-

cling. By ensuring this product is disposed of correctly, you will help prevent potential negative con-

sequences to the environment and human health, which could otherwise be caused by inappropriate

disposal of this product. The recycling of materials will help to conserve natural resources. For more

detailed information about the recycling of this product, please contact your local city office, house-

hold waste disposal service or the retail store where you purchased this product

RAEE ITALY: IT08040000004688 – VALID ONLY IN ITALY

DECLARES THAT: