MIGE1203 Series Industrial Gigabit Media Converter/MIGE2205G Series

Industrial Ethernet Switch

Introduction

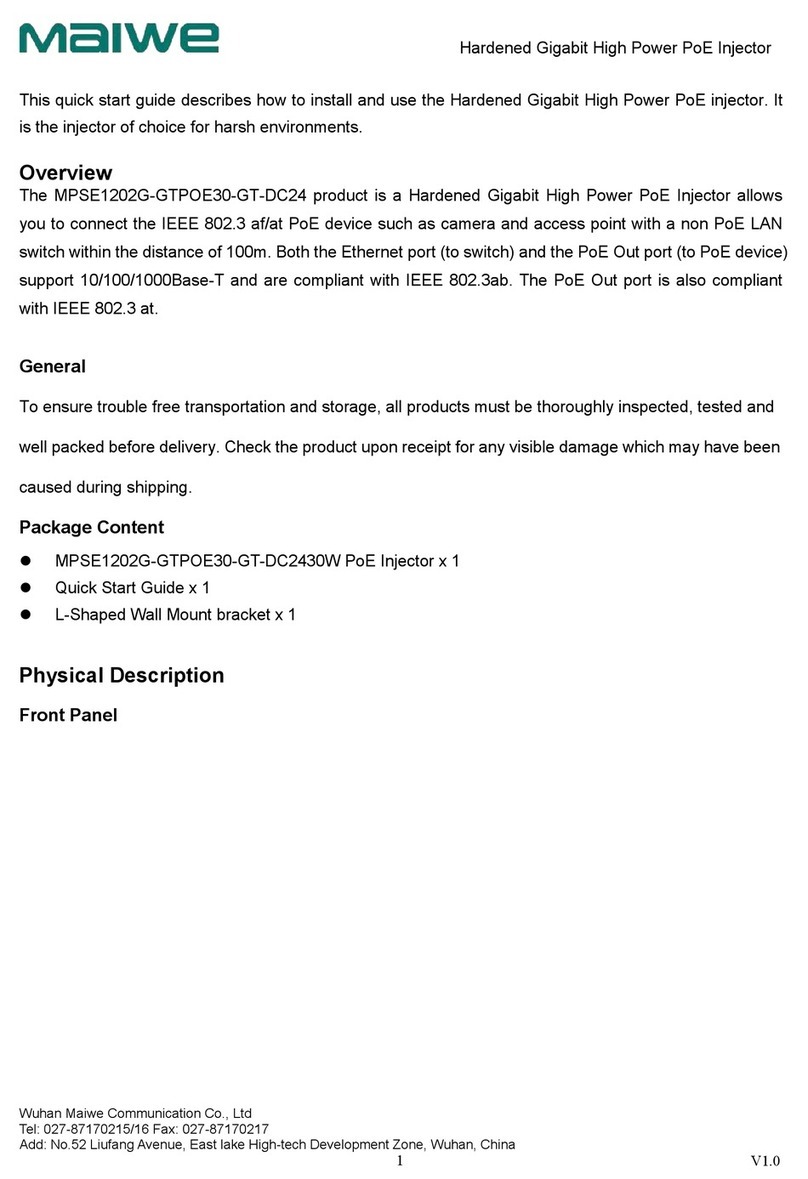

1. Product outline

1.1. Product Introduction

MIGE1203G-GS/M and MIGE1203G-GS/M-DB9 are 2 10/100/1

000Base-T port and 1 1000Base-X optical fiber interface adaptive

industrial-grade Ethernet Optical fiber transceiver which applied to the optical

fiber remote transmission of Ethernet signal.

MIGE2205G is 5 10/100/1000Base-T port adaptive high performance

industrial Ethernet switch. MIGE2205-GS/M is 4 10/100/1000Base-T port and

1 adaptive industrial Ethernet switch with 1000Base-X optical fiber

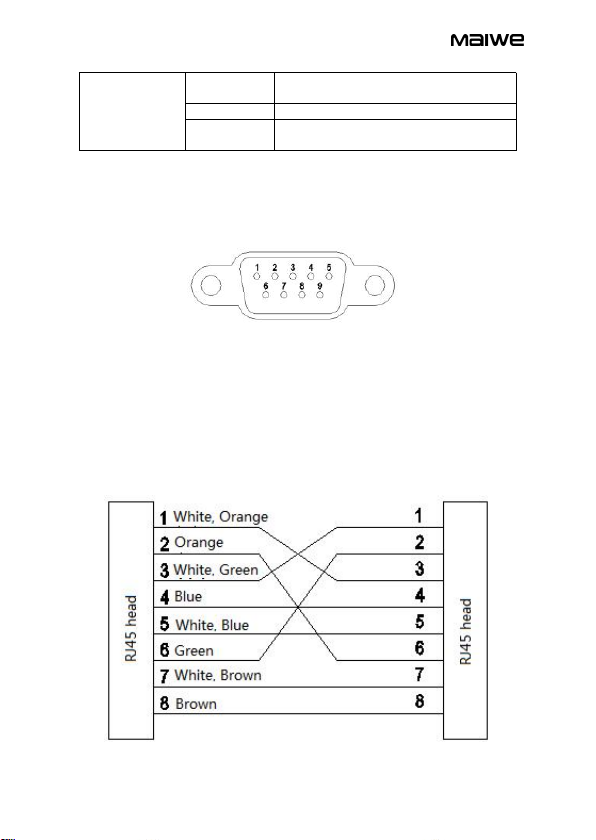

interface.One interface of MIGE1203G-GS/M-DB9 is a DB9 port.Other models

are all RJ45 ports, and each has an adaptive function, automatically configure

set to 10/100/1000Base-T state and full-duplex or half-duplex operation mode

and connect MDI/MDI-X. This product uses standard 35mm pitch DIN card and

the rail-mounted installation method is very suitable for installation applications

on industrial sites.

1.2. Features

1.2.1. High-performance Ethernet switch interface:

Data Store and Forward method

10/100/1000Base-T adaptive Ethernet electrical interface, of which

10/100Base-T support full-duplex or half-duplex mode, 1000Base-T supports

full-duplex mode

1000Base-X optical fiber interface, the interface is a shielded SFP base

Compliant IEEE802.3, IEEE802.3u, IEEE802.3ab, IEEE802.z,

IEEE802.3x

Lightning protection standard 10/700us: CM 6kV-150A and DM 2kV-50A

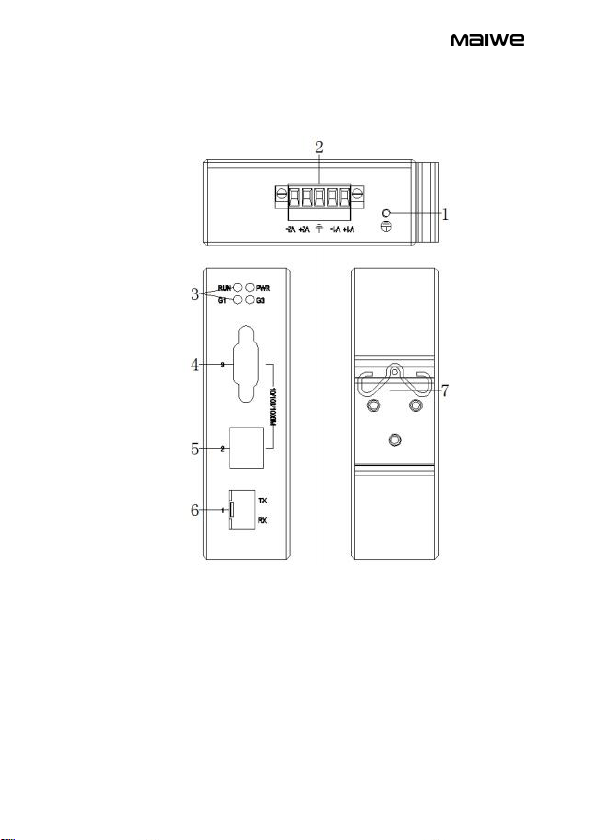

1.2.2. Industrial grade power supply design

Power range:

AC model AC85-264V or DC110-370V

DC standard model DC12-48V, optional DC48V (36-72V)

Electrical surge, overcurrent, anti-reverse protection and excellent EMC

performance

Environmental materials ,5.08mm pitch and easy to access power

terminals

1.2.3. Solid exterior design

Single-rib aluminum chassis design with heat dissipation surface, no fan