4

REGLES DE SECURITE

WARNING

Some illustrations may show the machine without protective

screen or shield. Never use the machine without these devices.

* Learn how to stop

the machine in emergency situation. Read this manual and the

tractor manual

* Never let anyone else use this machine if the person did not

read and understand this manual

* Never let children use this machine

* Always wear protective equipment for head, ears, hands and

feet using this machine

* Always wear close fitting clothing to avoid to be snatched by

the moving parts or to hang on

* Always work on daylight or with good artificial light.

* Make sure that the safety stickers are in place and in good

condition

* Clean the grass and debris accumulations

* Make sure that the machine is in good working condition

before using it

* Make sure that all the safety screens, grids and safety measures

are in place and in good condition

* Make sure that nobody or anything is behind you while

backing off

* Do not start or stop the engine abruptly on slopes

* Do not use the machine on too big slopes

DANGER

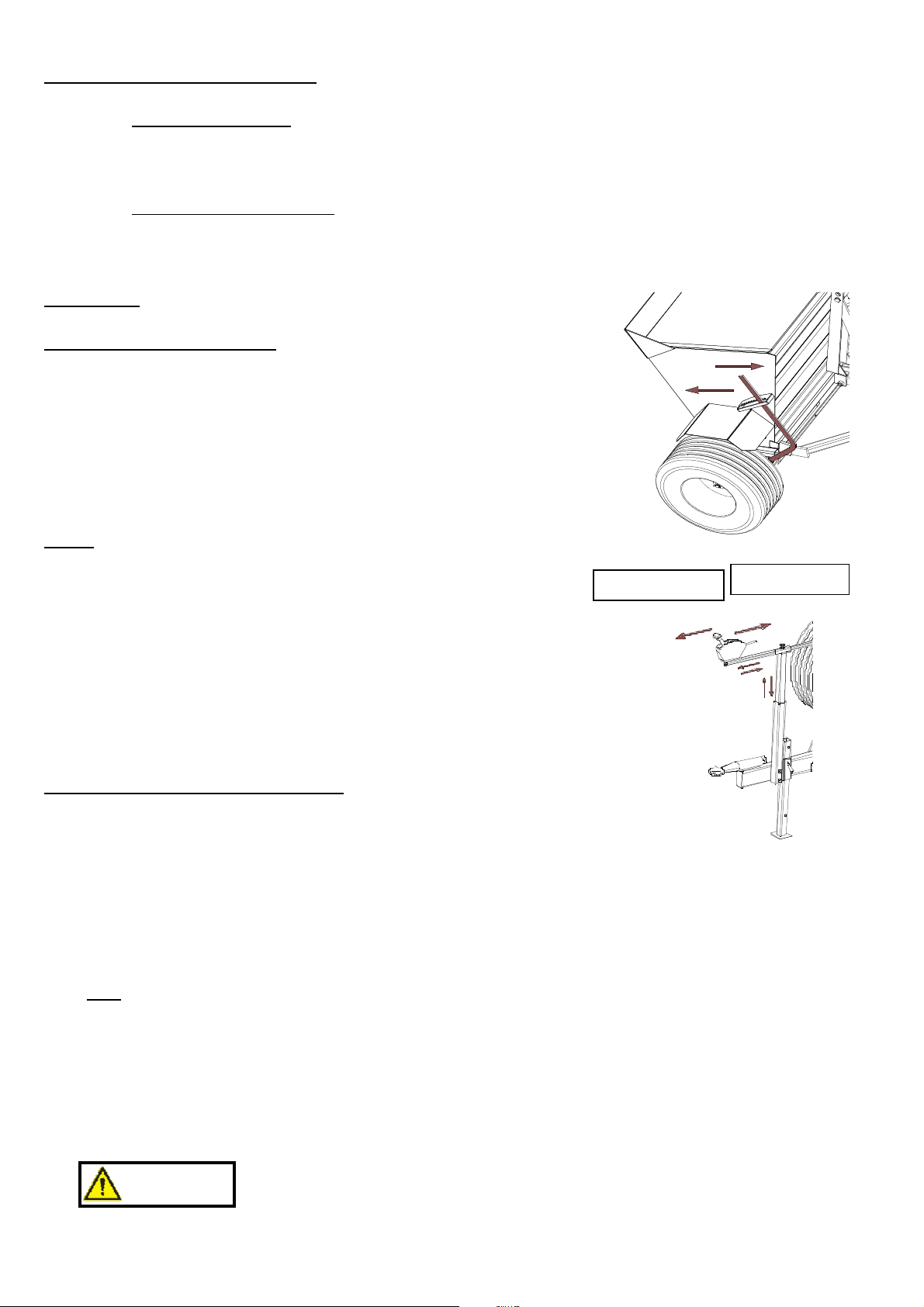

The montage of the Sand spreader on a tractor changes its centre

of gravity and reduces the capacity to use in slopes.

* Reduce speed in slopes and when turning narrow to avoid a

loss of control.

*Be careful while driving along embankments or ditches

* Stop the motor, apply the handbrake and remove the key

before all settings, adjustments, maintenance or disassembly

* Never let anyone else to the driver’s cabin during adjustment

interventions, maintenance or disassembly of the machine

*Check periodically tightening torques of all fasteners

* Never allow anybody to go under the Sand spreader when

lifted

.

*

* Never go or work under the Sand spreader or its accessories

unless it is blocked and in a locked position with enough security

*While maneuvering on slope always work up and down, never

across the slope

*Place the wheels according to the setting increase stability of the

tractor

* Avoid unstable embankments, rocks and holes; this can be

dangerous when moving

*Avoid aerial cables, high voltage lines and obstacles. Contact

with power lines causes electrocution and death

* Consider the length of the Sand spreader in turns

* Stop progressively the Sand spreader during lowering and

raising movements

* Make sure that the Sand spreader is parked with extended

parking supports

* Activate all the safety equipment

*Only operate the control panel when you are correctly seated in

front

*Check visually hydraulic leaks and missing or faulty parts.

Repair when necessary before every manoeuvre.

* A jet of hydraulic fluid caused by leaking may penetrate the

skin and cause fatal injury. If you are injured, consult a doctor.

* Do not change the adjustment of the pressure relief valve, it is

set in factory. An adjustment change may cause a system fail.

* Make sure that the user of the Sand spreader read thoroughly

and understood completely the manual to be informed of the

safety instructions to follow during maneuvres .

* During maintenance or replacement if the axles on the exterior

of the actuator, always use a bronze hammer to avoid injury by

splintered metal fragments

*Before coupling the Sand spreader, make sure that the tractor

and trailer together, when charged, does not exceed the permitted

total weight by the tractor manufacturer, that the hydraulic lifting

is able to bear the total weight of the ballasted Sand spreader

.