MAKINEX MS-150 User manual

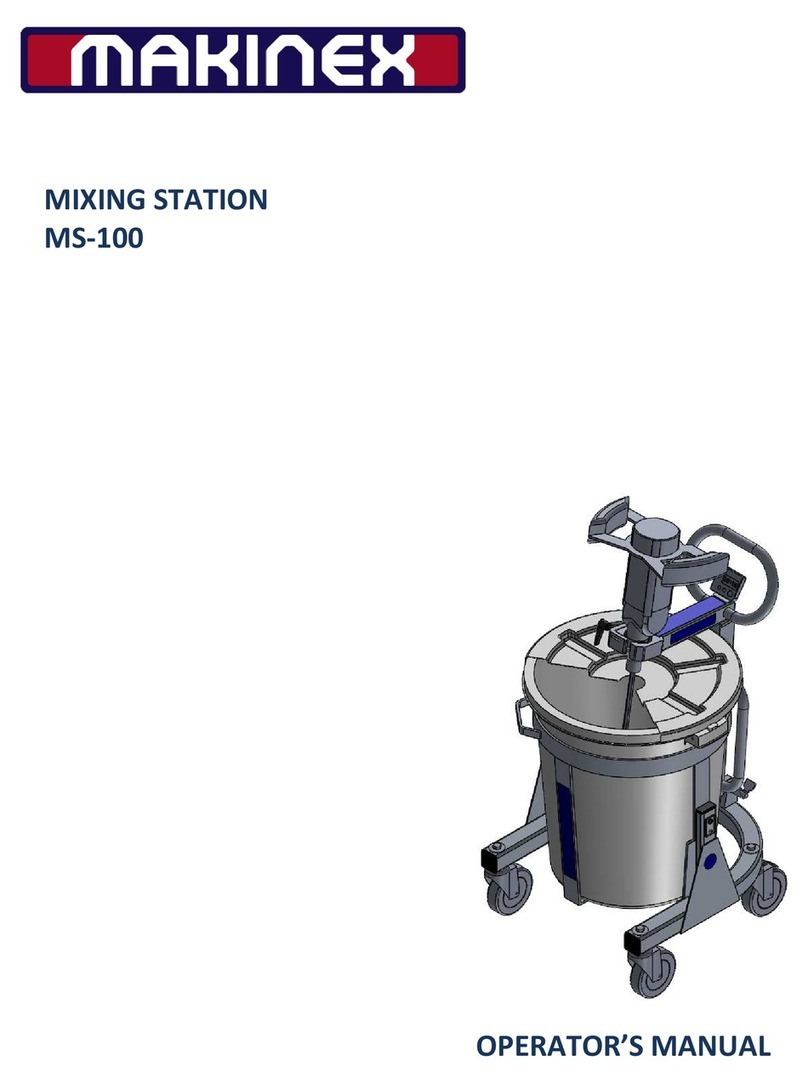

MIXING STATION

MS-150

OPERATOR’S MANUAL

Rev 1222

TABLE OF CONTENTS

INTRODUCTION ................................................................................................................................. 1

DISCLAIMER................................................................................................................................... 1

ABOUT THIS MANUAL.................................................................................................................... 2

SAFETY INFORMATION................................................................................................................. 2

SAFETY DECALS............................................................................................................................ 3

PRODUCT DESCRIPTION AND SPECIFICATION............................................................................. 4

INSTRUCTIONS FOR USE ................................................................................................................. 5

STEP 1 –ASSEMBLING THE HELIX PADDLE/ MIXER TO THE MS-150....................................... 5

STEP 2 –USING THE MS-150........................................................................................................ 7

STEP 3 –POURING AND PLACING LEVELLING COMPOUND..................................................... 9

STEP 4 –MAINTAINING THE MS-150.......................................................................................... 10

LIMITED WARRANTY....................................................................................................................... 11

WARRANTY EXCLUSIONS........................................................................................................... 12

OWNER’S RESPONSIBILITY UNDER THIS LIMITED WARRANTY ............................................. 12

CONTACT INFORMATION ............................................................................................................... 13

APPENDIX A –RISK ASSESSMENT ............................................................................................... 14

MAKINEX MS-150 Operator’s Manual Rev1222 Page 1 of 15

INTRODUCTION

Thank you for purchasing a MAKINEX product.

This manual provides information and procedures to safely operate and maintain the MS-150

Mixing Station. For your own safety and protection from injury, carefully read, understand,

and observe the safety instructions described in this manual.

Keep this manual or a copy of it with the machine. If you lose this manual or need an

additional copy, please contact MAKINEX. This machine is designed and built with user

safety in mind; however, it can present hazards if improperly operated and serviced. If there

are any questions regarding operating or servicing of this machine, please contact

MAKINEX.

All rights, especially copying and distribution rights are reserved.

Copyright 2023 by MAKINEX.

No part of this publication may be reproduced in any form or by any means, electronic or

mechanical, including photocopying, without express written permission from MAKINEX.

Any type of reproduction or distribution not authorised by MAKINEX represents an

infringement of valid copyrights and will be prosecuted. We expressly reserve the right to

make technical modifications, even without due notice, which aim at improving our machines

or their safety standards.

DISCLAIMER

MAKINEX and its affiliates take no responsibility for any damage, injury or death resulting

from the incorrect or unsafe use of this product. Use of this product should be undertaken by

competent persons only. It is the operator’s responsibility to ensure that the following safety

procedures are followed. If you are unsure, do not operate this product.

Record the model and serial numbers as well as date and place of purchase for future

reference. Have this information available when ordering parts and when making technical or

warranty enquiries.

MAKINEX SUPPORT

Refer to contact details on pg. 13

MODEL NO.

MS-150

SERIAL NO.

DATE OF PURCHASE

PURCHASE LOCATION

MAKINEX MS-150 Operator’s Manual Rev0322 Page 2 of 15

ABOUT THIS MANUAL

This manual uses the following symbols to help differentiate between different kinds of

information. The safety symbol is used with a key word to alert you to potential hazards in

operating and owning power equipment. Follow all safety messages to avoid or reduce the

risk of serious injury or death.

KEY TERMS

READ

CAREFULLY

READ CAREFULLY –refers to important information that should be paid

careful attention.

CAUTION

CAUTION - indicates a situation that may cause injury or damage to the

machine if the user does not follow the instructions.

WARNING

WARNING –indicates a situation that may cause injury or death if the user

does not follow the instructions correctly.

DANGER

DANGER –indicates a situation that will cause injury or death if the user

does not follow the instructions as written.

PROHIBITED

PROHIBITED –identifies actions that should never be carried out by

anyone interacting with the equipment.

These safety warnings do not eliminate all possible hazards that could occur therefore it is

essential to use common sense and to strictly follow any instructions to prevent accidents.

SAFETY INFORMATION

Throughout this document there are several safety warnings. The user should read through

this complete document before using the MS-150.

READ

CAREFULLY

Ensure you read all information contained in this manual before using the

MS-150.

READ

CAREFULLY

Ensure you read the User Manual and safety instructions for the MS-150

and other components that are part of this unit.

See Appendix for more information.

DANGER

Always wear the recommended personal protective equipment (PPE).

PROHIBITED

Do not expose power tools to rain or wet conditions. Water entering a

power tool will increase the risk of electric shock.

MAKINEX MS-150 Operator’s Manual Rev0322 Page 3 of 15

SAFETY DECALS

There is a safety and information panel provided on the Clamp Arm (see images below) of

the MS-150 to alert the user of potential safety risks/hazards. Please read and adhere to all

instructions on the Unit.

PROHIBITED

It is forbidden to remove any safety or instructional stickers or panels from

the MS-150.

READ

CAREFULLY

Read all safety and instructional stickers displayed on each component of

the MS-150.

MAKINEX MS-150 Operator’s Manual Rev0322 Page 4 of 15

PRODUCT DESCRIPTION AND SPECIFICATION

MS-150 is the ultimate mixing station for all self-levelling cement and compounds, producing

a perfect mix every time. Designed by contractors for contractors it provides efficient hands-

free mixing and fast precision pouring of materials saving time and effort on jobs.

An MS-150 mixing station can mix up to 160kg (353 lbs) (6 x 20kg bags plus water) in 7

minutes. The MS-150 is ultra-lightweight for easy transportation and the ergonomic design

with easy-tilt operation provides control and speed for precision pouring.

WHAT’S IN THE BOX

MS-150 DIMENSIONS:

HEIGHT HANDLE ATTACHED (Operating)

1084mm -1327mm (42.7 –52.2 inches)

HEIGHT HANDLE DETACHED (Transport)

1034mm (40.7 inches)

OVERALL WIDTH

612mm (24.1 inches)

OVERALL LENGTH

740mm (29.1 inches)

LENGTH OF HANDLE ADJUSTMENT

243mm (9.56 inches)

WEIGHT (WITHOUT MAKINEX ELECTRIC

MIXER AND HELIX PADDLE)

22kg (48.5 lbs)

WEIGHT (WITH MAKINEX ELECTRIC MIXER

AND HELIX PADDLE)

33kg (72.75lbs)

MAKINEX 2200W MIXER TECHNICAL DATA

NO-LOAD SPEED 1ST GEAR

150 –300 rpm

2ND GEAR

300 –650rpm

OUTPUT SHAFT THREAD

M14

WEIGHT

6.5kg (14.3 lbs)

CLASS OF PROTECTION

II

SOFT START

YES

OVER CURRENT PROTECTION

YES

OVER HEATING PROTECTION

YES

MS-150 X 1

Mixer X 1

Helix

Paddle X 2

22mm

Spanner X 2

Carbon

Brush X 2

MAKINEX MS-150 Operator’s Manual Rev0322 Page 5 of 15

INSTRUCTIONS FOR USE

WARNING

NEVER operate the MS-150 without wearing the appropriate

personal protective equipment (PPE) including appropriate footwear.

Assess the surrounding area for hazards. Ensure that any loose

clothing and long hair is firmly tied back.

WARNING

ALWAYS seek appropriate First Aid if Injury, Poisoning or Irritation

occurs due to contact with Materials and Substances.

CAUTION

ALWAYS ensure that the work place is well ventilated.

CAUTION

ALWAYS use dedicated mains power supply with extension lead not

exceeding 10 metres/11 yards

STEP 1 –ASSEMBLING THE HELIX PADDLE/ MIXER TO THE MS-150

WARNING

Ensure the Mixer is disconnected from mains power before Attaching

or Removing it to/from the MS-150 frame.

CAUTION

NEVER place hand under ‘Slider Clamp’or ‘Clamp Arm’ when

adjusting the height.

WARNING

CHECK the electrical lead and plug for damage before use of the

Mixer. Do not use the Mixer if there is evidence of damage.

1. Assemble the four Castor Wheels to the bottom of the Frame using the M12 Bolts,

Washers and Locknuts provided. Fit the two Braked Castor Wheels to opposite corners

of the Frame. Check that the Castor Brakes have been engaged after assembly.

2. Attach MS-150 Clamp Arm into the Slide Arm Collar of the MS-150 Frame; tighten

Collar Thumb Screw in place.

Braked Castor Wheels

MAKINEX MS-150 Operator’s Manual Rev0322 Page 6 of 15

3. When fitting the Mixer make sure the Slider Clamp is opened. Fit the Mixer through the

gap at the front and then position the collar part of the Mixer between the Slider Clamp

and tighten.

4. Connect Helix Paddle to Mixer output shaft and firmly tighten using 22mm spanner.

The MS-150 is supplied with a short Helix Paddle (up to 3 bag mix) and a large Helix

Paddle (4 - 6 bag mix). Adjust height of Clamp Arm if necessary if Helix Paddle is

touching base of Bucket.

NOTE: Always grab the mixer by the handles and make sure the mixer is securely

tightened, but do not over-tighten!

Adjustable Slider Clamp

Clamping

Lever

Helix Paddle

Slide Arm

Collar

Clamp Arm

Collar

Thumb

Screw

Tighten Helix

Paddle with

22mm

spanner

MAKINEX MS-150 Operator’s Manual Rev0322 Page 7 of 15

When fitting the Makinex Electric Mixer, ensure the Electrical Cord is facing to back of the

MS-150. Connect Makinex Mixer Electrical Cord to extension cord. Connect the extension cord

from mains power to the Cable Clip on Vac Lid Module.

STEP 2 –USING THE MS-150

WARNING

NEVER place hands or other articles into the Bucket whilst Mixer is

Mixing.

ALWAYS disconnect Mixer from mains power before placing hands into

the Bucket.

WARNING

ALWAYS ensure the Mixer is switched OFF before plugging it in.

ALWAYS wind-up the Extension Cord before moving the MS-150.

ALWAYS be aware of the Extension Cord position when working around

the MS-150™.

CAUTION

Maximum SAFE Load: 160kg (353lbs) of wet levelling compound.

DO NOT EXCEED 160kg (353lbs)

ALWAYS use correct lifting technique when loading materials.

1. Ensure Makinex Electric Mixer is firmly secured in the ‘Slider Clamp’.

2. Attach Vac Lid Module to Bucket by clipping Side Hooks onto frame

3. Make sure the ‘Locking Pin’is engaged (i.e., locked to prevent the bucket from

pivoting) at the base of the Bucket and that the Castor Wheel Brake has been applied.

4. Attach a vacuum hose to the ‘Vacuum Port’. Use the supplied adaptor if using a 50mm

vac hose. Connect water hose from mains supply to Water Nozzle quick connect fitting.

Locking Pin

Mixer cord faces back

Extension cord to switch

board positioned in cable

clip

Vac Lid Module

Bag Rests

Side Hooks

Water Nozzle

MAKINEX MS-150 Operator’s Manual Rev0322 Page 8 of 15

5. Add in correct amount of water for desired mix quality (refer to Levelling Compound

manufacturer’s recommendations).

READ

CAREFULLY

Read material manufacturer’s instructions before mixing

6. Make sure Makinex Electric Mixer is switched to low gear (1st Gear) and speed 1.

7. Plug in Makinex Electric Mixer to extension cord to Mains Power.

8. Press Trigger to turn ‘ON’ mixer and lock in Trigger.

9. Start adding Bags of Levelling Compound one at a time. The Bucket has bag rests that

can be used to support the weight of the Bags while pouring.

10. Leave Makinex Electric Mixer on low-speed gear (1st Gear). The mixing speed can also

be adjusted using the speed dial (there are six speeds)

11. After final bag of Levelling Compound has been added, STOP the Makinex Electric

Mixer and THEN switch to high-speed gear (2nd Gear). It may be necessary to rotate

the helix paddle forward and backwards slightly by hand to engage the gear. Restart

the mixer. It is not recommended to exceed speed 3 when in gear 2.

12. During mixing, wait for 30 seconds as the compound is being mixed; turn ‘OFF’ Mixer

temporarily and scrape off any excess powder that has gathered around top of bucket.

NOTE: After the final bag of Levelling Compound has been added, the whole mixing

operation should take approximately 2 minutes.

Vacuum Port

Optional 38mm to

50mm adaptor

Hose to mains

water (not

included)

Trigger Lock & Trigger

High / Low

Gear

Selector

Speed dial 1-6

MAKINEX MS-150 Operator’s Manual Rev1222 Page 9 of 15

13. Switch Mixer back ‘ON’ and return to Maximum Power until Levelling Compound is mixed

to a lump-free consistency.

14. Once equal consistency has been achieved, turn off the Makinex Electric Mixer.

15. Unplug Makinex Electric Mixer from extension cord; wind-up the Power Cord on the MS-

150 Handle.

STEP 3 –POURING AND PLACING LEVELLING COMPOUND

CAUTION

ALWAYS check that power cord is secured around the MS-150 handle

before pivoting the bucket.

CAUTION

NEVER place hand near the ‘Pivot Pin’ (Pivot Point) when rotating the

bucket.

CAUTION

NEVER move or operate the fully loaded MS-150 over an unstable surface.

CAUTION

ALWAYS protect open drains nearby from spillages of compound

1. Lift and remove the Vac Lid Module in a sideways direction with extension cord, vac hose

and water hose still connected and place nearby. The Vac Lid Module is released from the

Bucket by unclipping the Side Hooks.

2. Check the ‘Locking Pin’ is engaged (i.e., locked to prevent the bucket from pivoting) at the

base of the bucket.

3. Disengage castor wheel brake.

4. Wheel the MS-150 to the desired area (use caution when moving the loaded bucket).

5. Disengage (unlock) ‘Locking Pin’at the base of the bucket.

Vac Lid Module with vac

hose, extension cord

and water hose attached

Side Hooks

MAKINEX MS-150 Operator’s Manual Rev0322 Page 10 of 15

6. Using a controlled motion (use the MS-150 Side Handle and Rear Handle) pour mixed

Levelling Compound where required.

STEP 4 –MAINTAINING THE MS-150

CAUTION

ALWAYS use two people when loading and unloading the MS-150.

1. It is very important to clean the equipment after use. Use water or a high-pressure hose to

clean all Levelling Compound from the MS-150 Frame, Vac Lid Module, Wheels, Bucket

and Helix Paddle after use. The water nozzle in the vac lid module can be removed and

used for cleaning.

2. Extra attention should be focused on cleaning the Wheels.

3. Wheels should be oiled / greased regularly.

4. The ventilation slots on the Makinex Electric Mixer motor casing should be cleaned out

periodically

5. After 100 hours of operation check the carbon brushes in the Makinex Electric Mixer.

When the carbon brushes are worn see the diagram below to replace the carbon brush.

One pair of replacement carbon brushes are included. Remove the brush cap with a flat

blade screwdriver and remove the worn carbon brush. Place new carbon brush into the

brush holder inside. Replace and tighten brush caps with flat blade screwdriver.

6. After 200 hours of operation renew the grease filling the gearbox

NOTE: With two MS-150 Portable Mixing Stations, another mix could be completed

using the same Mixer while one is being poured.

MAKINEX MS-150 Operator’s Manual Rev0322 Page 11 of 15

LIMITED WARRANTY

To take advantage of the MAKINEX limited warranty, you must have maintenance performed by

an authorised MAKINEX dealer or MAKINEX service technician. You are free to have your

MAKINEX product serviced by any suitably qualified persons and this will not affect your

statutory warranties, however, failure by the owner to have the recommended servicing carried

out by an authorised MAKINEX dealer/service technician means that you cannot take advantage

of the MAKINEX limited warranty.

MAKINEX warrants each new mixer to be free from defects in material and workmanship under

normal domestic and industrial use and service for the period specified below, conditional to the

limitations and exclusions printed on this page. This warranty applies only to new MAKINEX

mixer distributed by us and by our authorised MAKINEX dealers.

Under the limited warranty and at MAKINEX’s discretion, upon evaluation, inspection and testing

by a MAKINEX dealer or a MAKINEX service technician, MAKINEX will repair and replace of

defective part(s).

AUSTRALIA: Our goods come with guarantees that cannot be excluded under the Australian

Consumer Law. You are entitled to a replacement or refund for a major failure and

compensation for any other reasonably foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to be of acceptable quality and the failure

does not amount to a major failure.

WARRANTY: (Ex-factory/ Reseller premise)

MAKINEX warrants to the original purchaser:

MAKINEX provides a Limited One Year Warranty that applies to MS-150 Mixing Station only

(this excludes the Helix Paddle/mixer and any other attachments and consumables).

All wheels must be thoroughly cleaned after each use, failure to do so will void warranty.

Warranty only applies to the original purchaser and is not transferable.

MAKINEX MS-150 Operator’s Manual Rev0322 Page 12 of 15

WARRANTY EXCLUSIONS

Warranty does not cover wear and tear, breakage, misuse or theft.

Warranty does not cover consumables (e.g., Bucket and Vac Lid Module, Wheels) and

attachments (Mixers/Helix Paddle)

Warranty will not apply to parts and/or labour if the Mixing Station is deemed to be misused,

neglected, installed improperly or set up incorrectly.

Cosmetic defects such as decals and coating.

Failures due to acts of God and other force majeure events beyond the manufacturer’s control.

Problems caused by parts that are not original MAKINEX parts.

Expedited freight costs.

OWNER’S RESPONSIBILITY UNDER THIS LIMITED WARRANTY

Strict adherence to the maintenance checks and schedule with proof of scheduled maintenance

service required by an authorised agent or qualified mechanic. It is the consumer’s responsibility

to deliver the machine in question to our service premises or to the premises of our appointed

agent at the consumer’s expense for replacement or repair as applicable. Maintenance services

are not covered under warranty.

Claim Procedure:

Contact MAKINEX by phone or email informing us of your machines problem or defect.

Once the extent of the claim has been assessed, we retain the right to compensate the

consumer for such defect, or repair (parts & labour), or replace the machine under warranty.

All warranties will be carried out by MAKINEX authorised staff or appointed agents at a premise

to be determined by the Manufacturer.

It is the responsibility (and cost) of MAKINEX or our appointed agent to return the machine to be

repaired or replaced under warranty to the consumer- this is valid for domestic territories only

(e.g., machine purchased in USA will repaired/replaced under warranty and returned to the USA

consumer. Machine purchased in Australia will be repaired/replaced under warranty and

returned to the Australian consumer, machine purchased in Europe will be repaired/replaced

under warranty and returned to the consumer of that specific European nation etc.)

Where the specific warranty component (e.g., Mixer/Helix Paddle) is under a Manufacturer’s

warranty other than MAKINEX (e.g., Collomix, Festool etc), the consumer can either contact

MAKINEX or the applicable Manufacturer for repairs where such warranty was registered with

that manufacturer at purchase.

Warranty calls will only be carried out by our representatives and not via client’s choice of

repairer. We will not accept back charges for any work not carried out by our representatives or

accept any charges due to equipment being un-operational for any reason even during its

warranty period.

MAKINEX MS-150 Operator’s Manual Rev0322 Page 13 of 15

CONTACT INFORMATION

For sales, service, warranty and parts for all MAKINEX products; please refer below.

SALES, SERVICE, SPARE PARTS & WARRANTY

AUSTRALIA

SALES

TEL 1300 795 953 or

+61 2 9460 8071

WEB www.makinex.com.au

SERVICE, SPARE PARTS & WARRANTY

EMAIL [email protected]

USA

SALES

TEL +1 855-625-4639

WEB www.makinex.com

SERVICE, SPARE PARTS & WARRANTY

EMAIL [email protected]

EUROPE

UK

Or your nearest MAKINEX distributor

We have very knowledgeable, experienced staff to assist you with help and advice.

MAKINEX MS-150 Operator’s Manual Rev0322 Page 14 of 15

APPENDIX A –RISK ASSESSMENT

MAKINEX MS-150 Operator’s Manual Rev0322 Page 15 of 15

MAKINEX MS-150 Operator’s Manual Rev0322 Page 16 of 15

Table of contents

Other MAKINEX Music Mixer manuals

Popular Music Mixer manuals by other brands

Air Comm Systems

Air Comm Systems ACS 775SL-100 Installation and operation manual

Omnitronic

Omnitronic CS-612 user manual

Guardian Audio

Guardian Audio B6 owner's manual

Veeder-Root

Veeder-Root TLS-450PLUS Module Replacement Instructions

Mackie

Mackie 1402-VLZ PRO Specifications

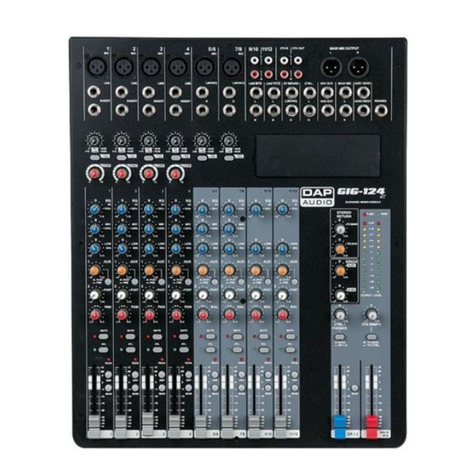

DAPAudio

DAPAudio GIG-124C manual