1INDEX

1INDEX .......................................................................................................................................................................................... 2

2CAUTION..................................................................................................................................................................................... 3

3HANDLING OF GASKET........................................................................................................................................................... 3

4NECESSARY REPAIRING TOOLS............................................................................................................................................ 4

5LUBRICANT AND ADHESIVE APPLICATION....................................................................................................................... 4

5-1 Recoil starter, Gear case assembly, Shaft ............................................................................................................................. 4

5-2 Cylinder block section.......................................................................................................................................................... 5

5-3 Cylinder block assembly...................................................................................................................................................... 6

5-4 M5x40 Hex socket head bolts for securing Muffler............................................................................................................. 6

6REPAIR ......................................................................................................................................................................................... 7

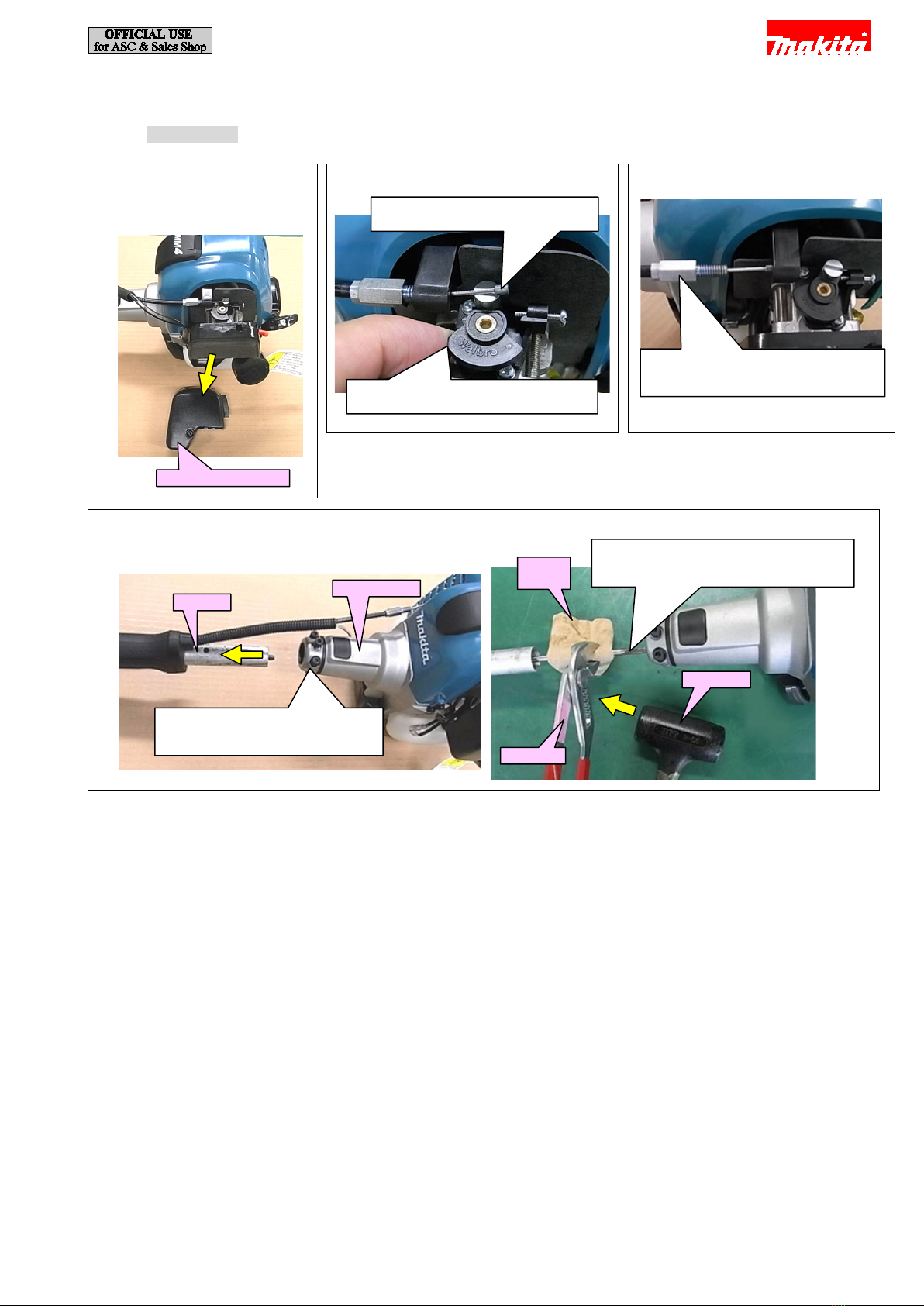

6-1 Engine and Shaft .................................................................................................................................................................. 7

6-1-1 Disassembling ............................................................................................................................................................. 7

6-1-2 Assembling.................................................................................................................................................................. 8

6-2 Shaft pipe complete.............................................................................................................................................................. 9

6-2-1 Disassembling ............................................................................................................................................................. 9

6-2-2 Assembling.................................................................................................................................................................. 9

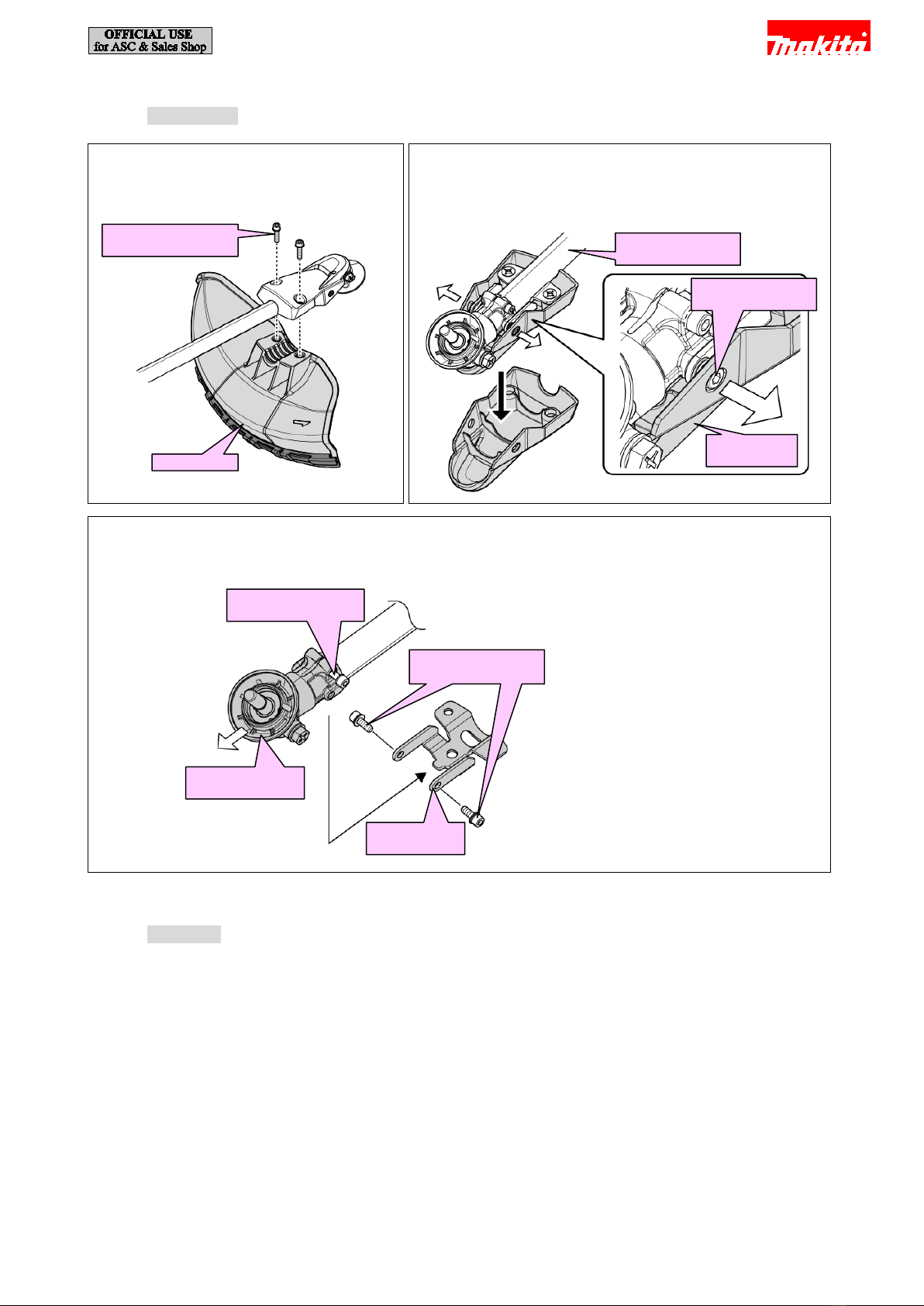

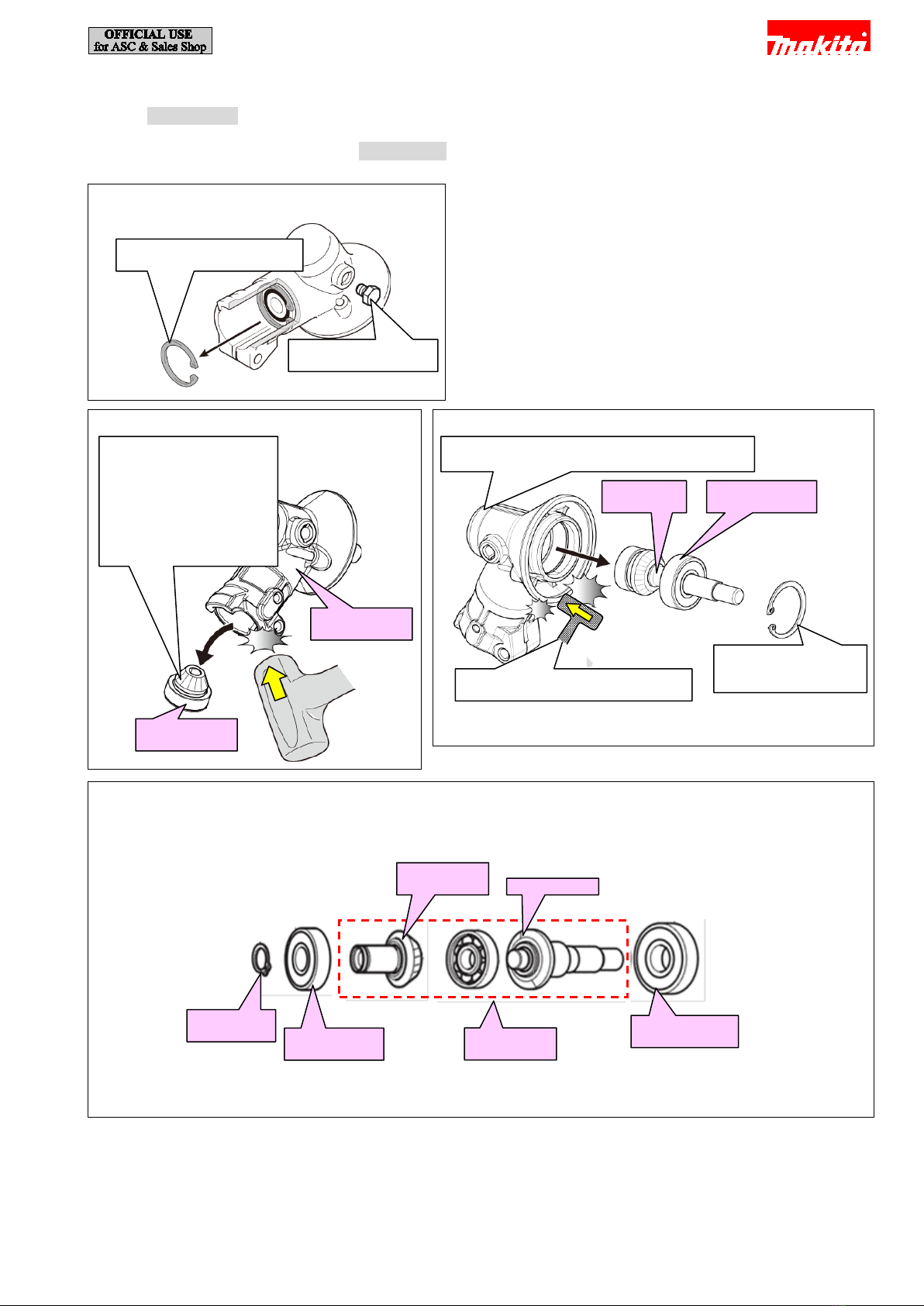

6-3 Gear case assembly ............................................................................................................................................................ 10

6-3-1 Disassembling ........................................................................................................................................................... 10

6-3-2 Assembling................................................................................................................................................................ 11

6-4 Control lever assembly....................................................................................................................................................... 11

6-4-1 For EBH252U and EBH253U................................................................................................................................... 11

6-4-2 For EBH252L and EBH253L.................................................................................................................................... 13

6-5 Clutch................................................................................................................................................................................. 16

6-5-1 Disassembling ........................................................................................................................................................... 16

6-5-2 Assembling................................................................................................................................................................ 17

6-6 Flywheel............................................................................................................................................................................. 18

6-6-1 Disassembling ........................................................................................................................................................... 18

6-6-2 Assembling................................................................................................................................................................ 18

6-7 Clutch case ......................................................................................................................................................................... 19

6-7-1 Disassembling ........................................................................................................................................................... 19

6-7-2 Assembling................................................................................................................................................................ 20

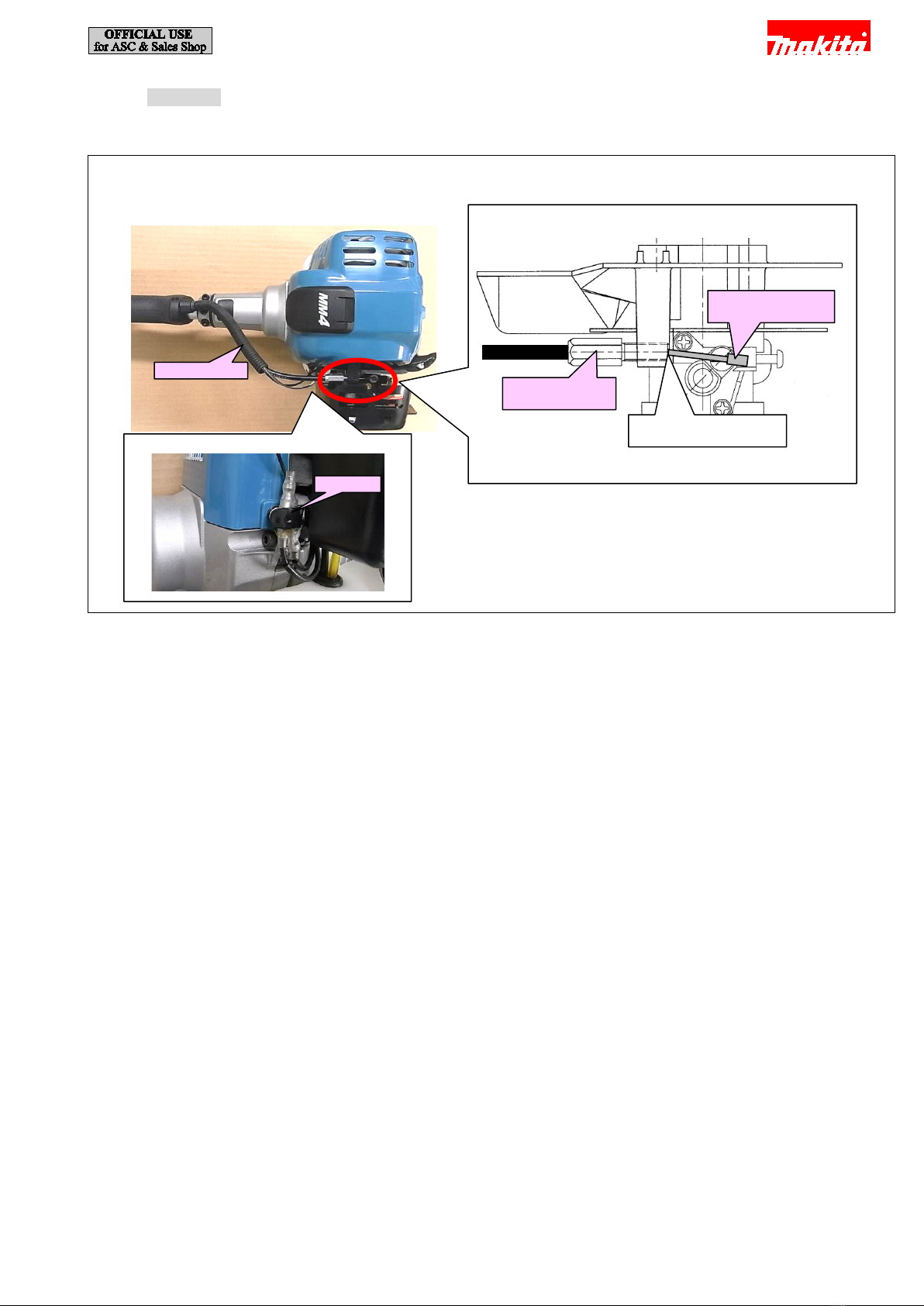

6-8 Carburetor .......................................................................................................................................................................... 21

6-8-1 Disassembling ........................................................................................................................................................... 21

6-8-2 Assembling................................................................................................................................................................ 22

6-9 Check of Spark plug........................................................................................................................................................... 22

6-10 Ignition coil ........................................................................................................................................................................ 22

6-10-1 Disassembling ........................................................................................................................................................... 22

6-10-2 Assembling................................................................................................................................................................ 23

6-11 Plug cap.............................................................................................................................................................................. 23

6-11-1 Disassembling ........................................................................................................................................................... 23

6-11-2 Assembling................................................................................................................................................................ 23

6-12 Checking of Ignition coil.................................................................................................................................................... 24

6-13 Checking of Ignition coil (cont.) ........................................................................................................................................ 25

6-14 Recoil starter Assembly...................................................................................................................................................... 26

6-14-1 Disassembling ........................................................................................................................................................... 26

6-14-2 Assembling................................................................................................................................................................ 28

6-14-3 Assembling................................................................................................................................................................ 29

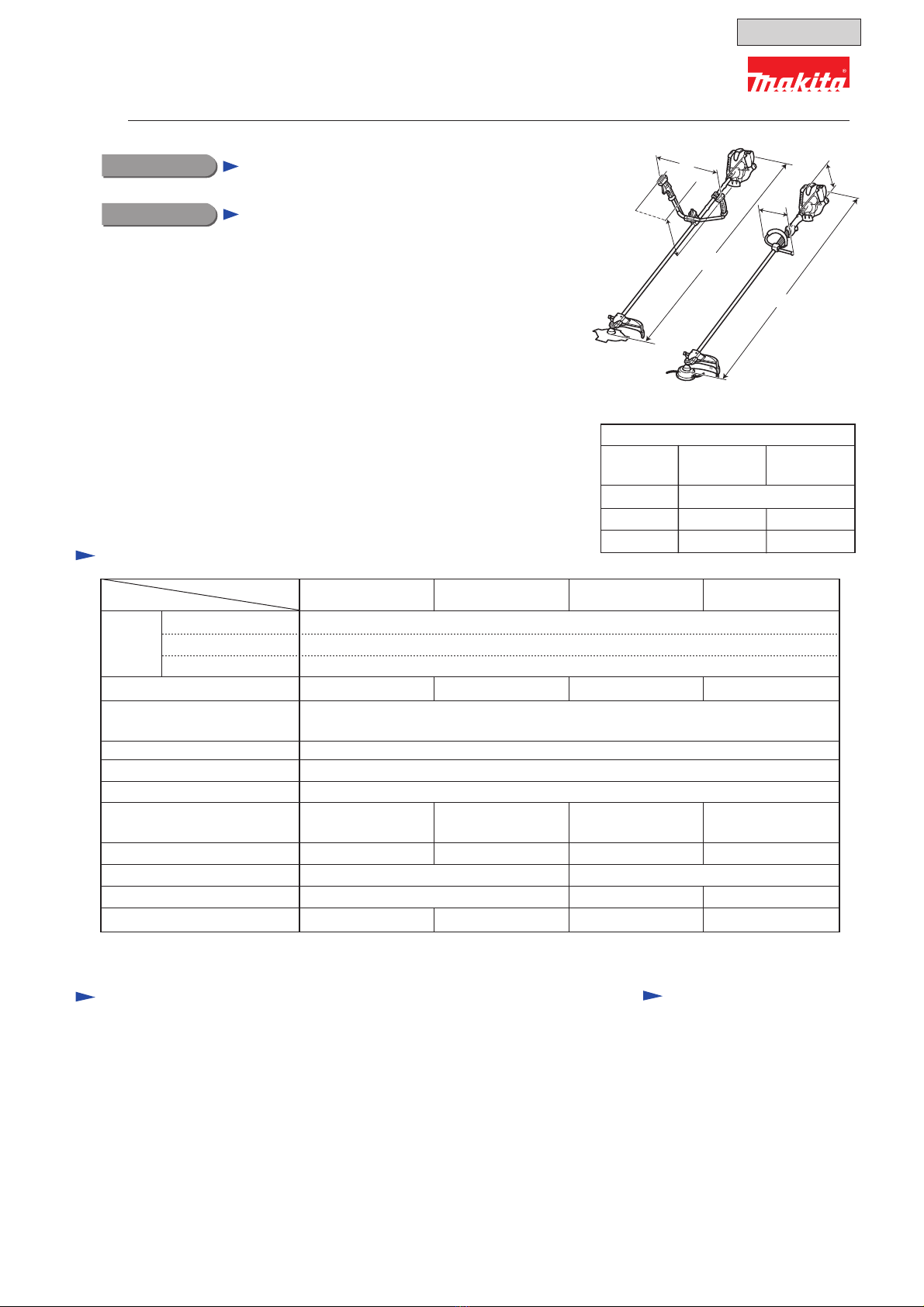

6-15 Pulley (plate) (EBH252 series) .......................................................................................................................................... 30

6-15-1 Disassembling ........................................................................................................................................................... 30

6-15-2 Assembling................................................................................................................................................................ 30

6-16 Pulley (aluminum diecast) (EBH253 series) ...................................................................................................................... 31

6-16-1 Disassembling ........................................................................................................................................................... 31

6-16-2 Assembling................................................................................................................................................................ 31

6-17 Engine block ...................................................................................................................................................................... 32

6-17-1 Disassembling ........................................................................................................................................................... 32

6-18 Engine block (cont. - Piston section).................................................................................................................................. 36

6-18-1 Replacing................................................................................................................................................................... 36

6-19 Engine block (cont. ) .......................................................................................................................................................... 37

6-19-1 Assembling................................................................................................................................................................ 37

6-20 Final check......................................................................................................................................................................... 39

7TIGHTENING TORQUE SPECIFICATIONS........................................................................................................................... 40

2 / 40