4

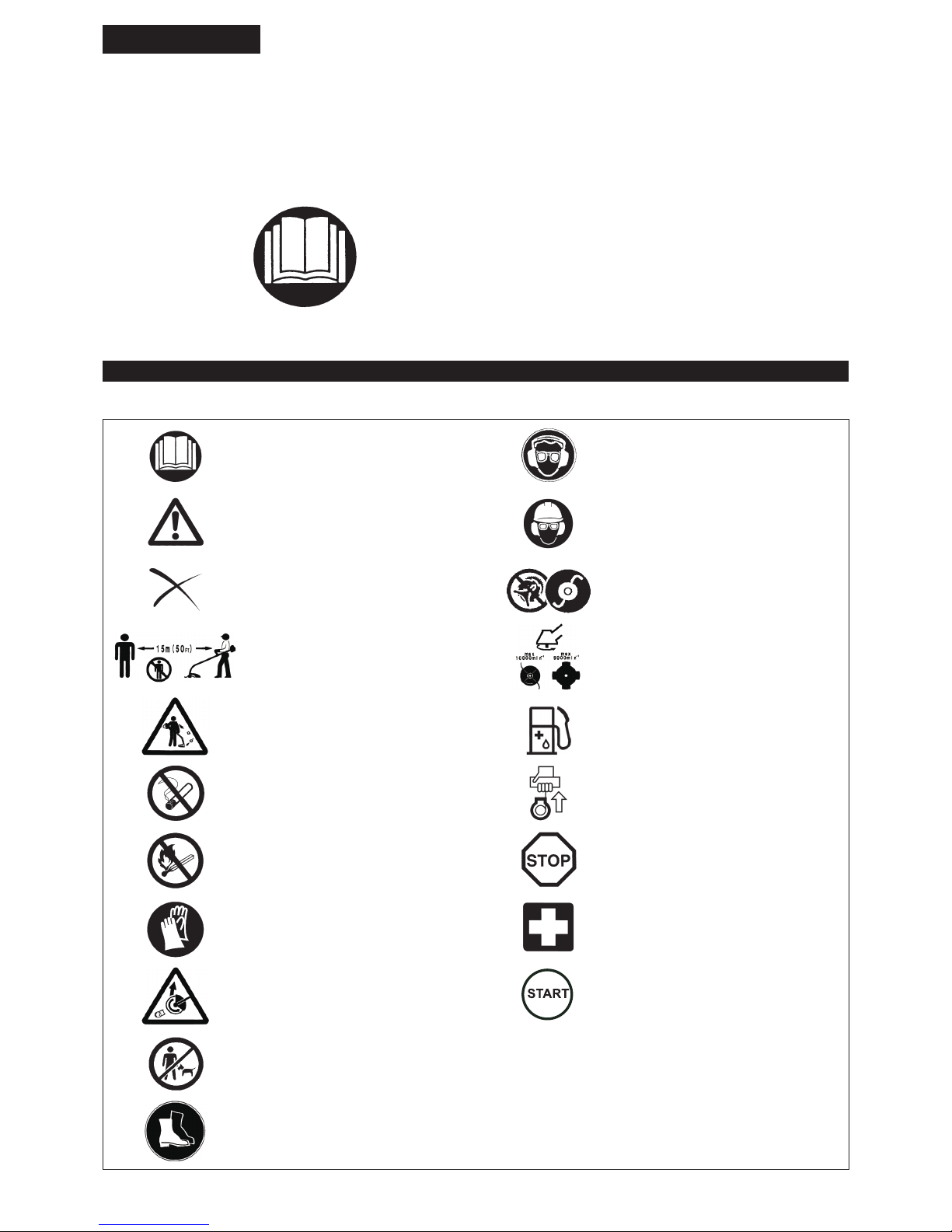

Resting•

Transport•

Refueling•

Maintenance•

Tool replacement•

3 meters

Start the brushcutter only in accordance with the instructions.

Do not use any other methods for starting the engine!–

Usethebrushcutterandthetoolsonlyforsuchapplicationsasspecified.–

Only start the engine, after the entire assembly is done. Operation of the–

device is only permitted after all the appropriate accessories are attached!

Before starting make sure that the cutting tool has no contact with hard–

objects such as branches, stones etc. as the cutting tool will revolve when

starting.

The engine is to be switched off immediately in case of any engine problems.–

Should the cutting tool hit stones or other hard objects, immediately switch off–

the engine and inspect the cutting tool.

Inspect the cutting tool at short regular intervals for damage (detection of–

hairline cracks by means of tapping-noise test).

Iftheequipmentgetsheavyimpactorfall,checktheconditionbefore–

continuing work. Check the fuel system for fuel leakage and the controls

and safety devices for malfunction. If there is any damage or doubt, ask our

authorized service center for the inspection and repair.

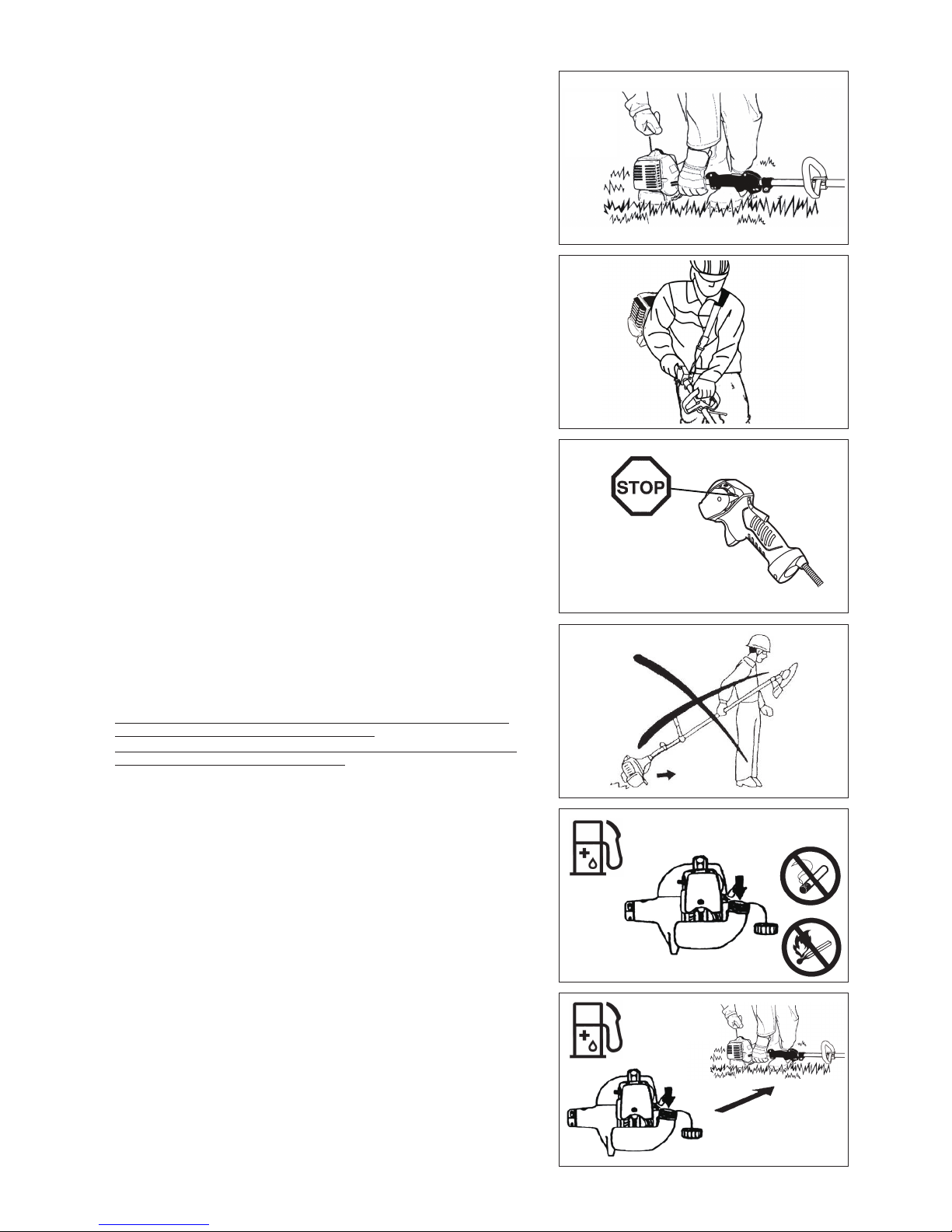

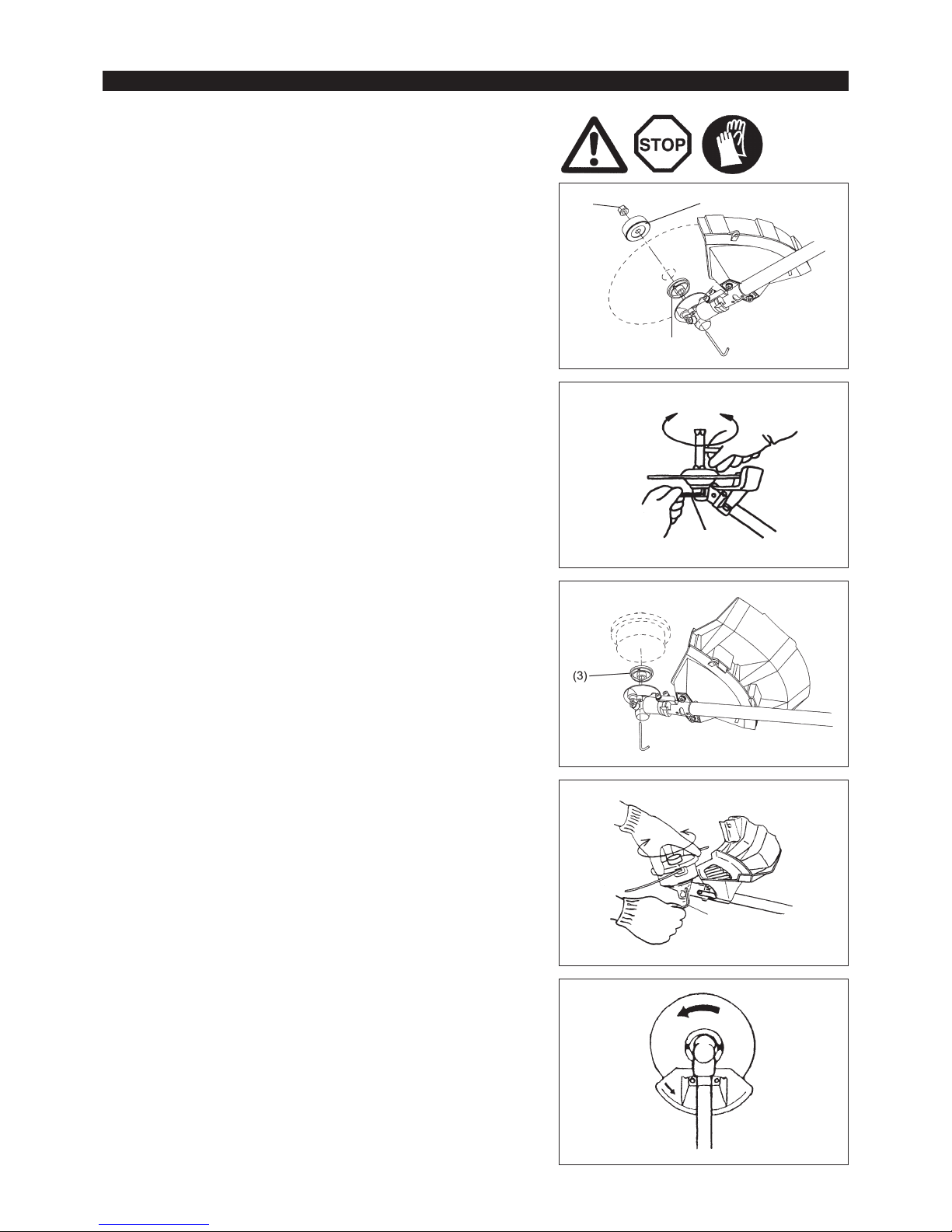

Operatetheequipmentonlywiththeshoulderharnessattachedwhichis–

to be suitably adjusted before putting the brushcutter into operation. It is

essential to adjust the shoulder harness according to the user size to prevent

fatigue occurring during use. Never hold the cutter with one hand during use.

During operation always hold the brushcutter with both hands.–

Always ensure a safe footing.

Operatetheequipmentinsuchamannerastoavoidinhalationoftheexhaust–

gases. Never run the engine in enclosed rooms (risk of gas poisoning).

Carbonmonoxideisanodorlessgas.

Switchofftheenginewhenrestingandwhenleavingtheequipment–

unattended, and place it in a safe location to prevent danger to others or

damage to the machine.

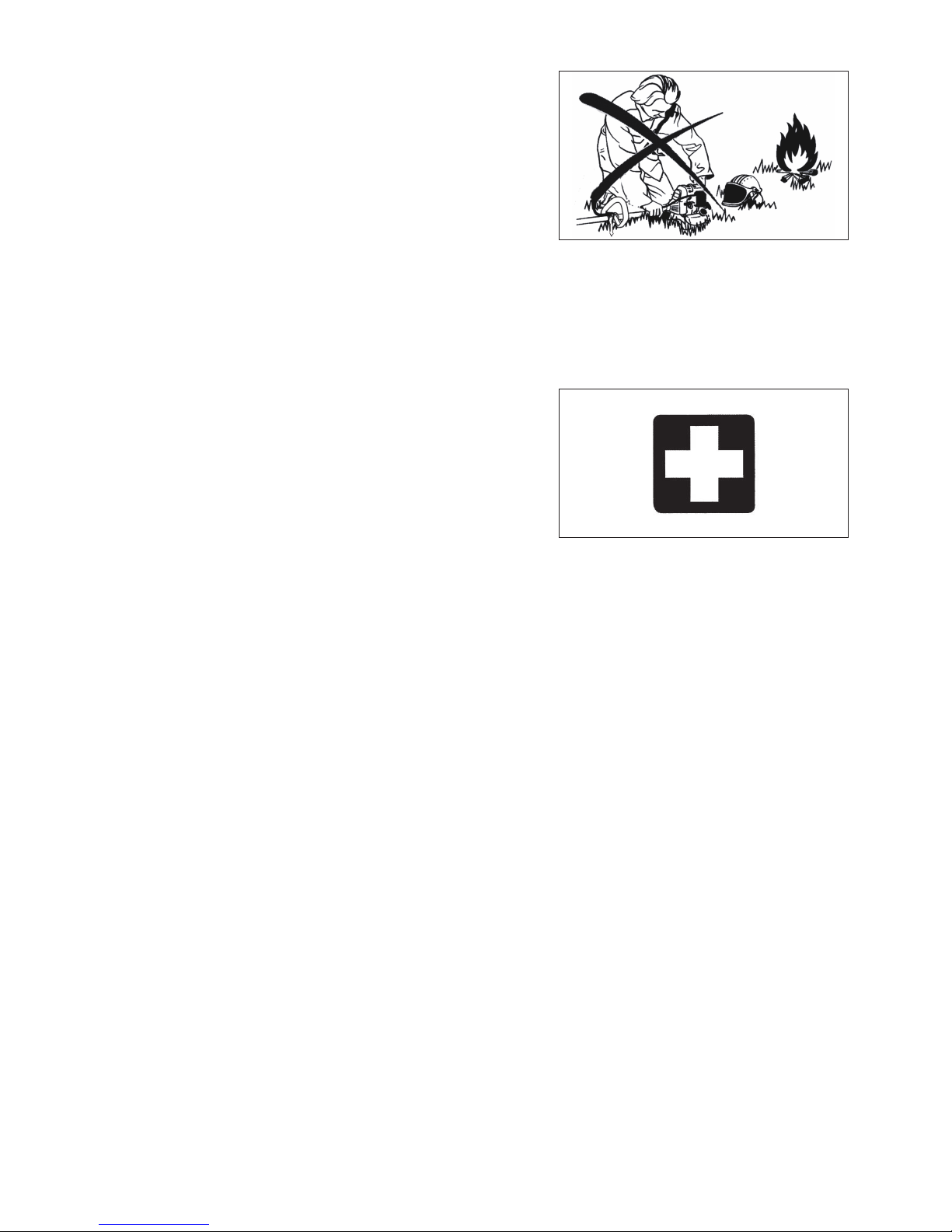

Never put the hot brushcutter onto dry grass or onto any combustible–

materials.

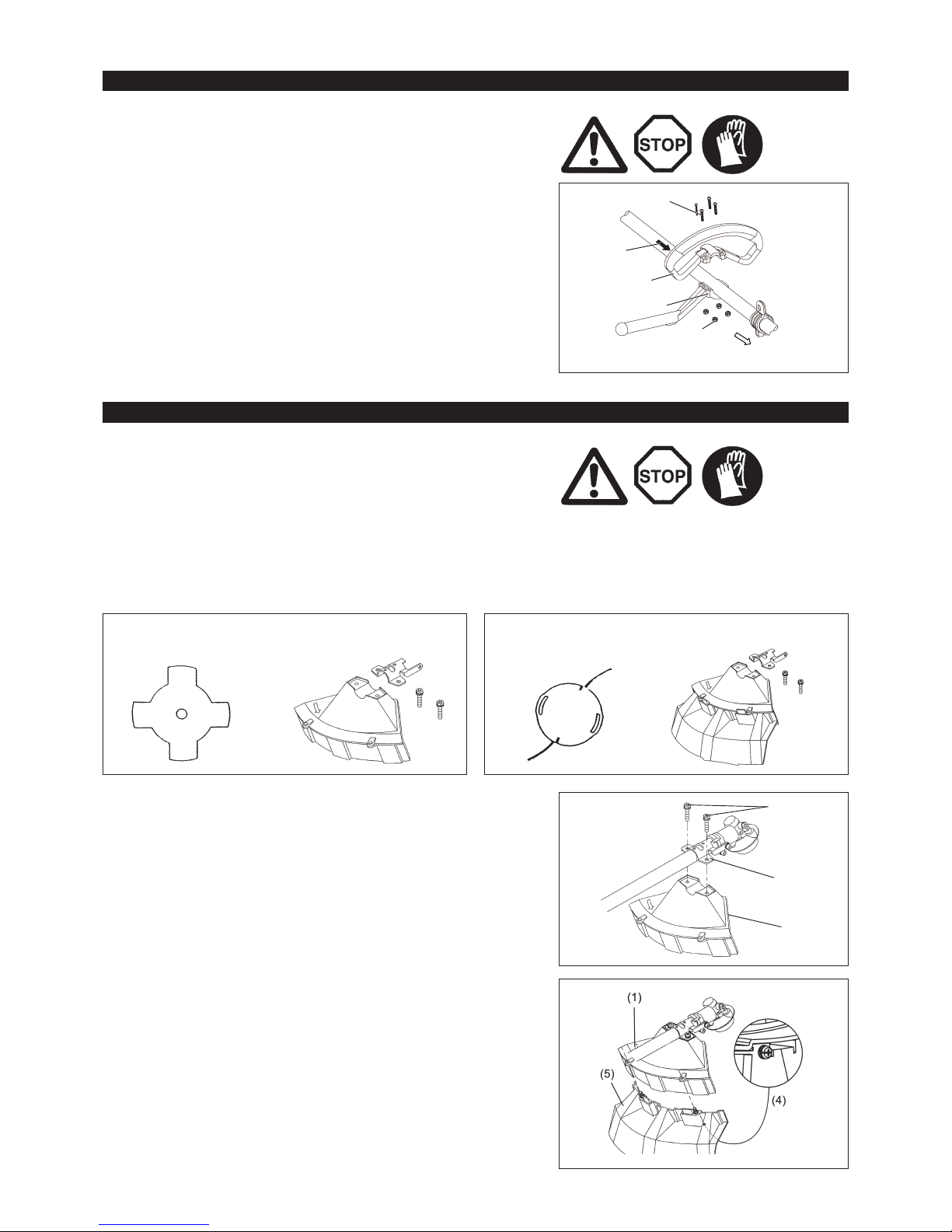

Alwaysinstalltheapprovedcuttingtoolguardontotheequipmentbefore–

starting the engine.

Otherwise contact with the cutting tool may cause serious injury.

All protective installations and guards supplied with the machine must be–

used during operation.

Neveroperatetheenginewithfaultyexhaustmuffler.–

Shut off the engine during transport.–

Whentransportingtheequipment,alwaysattachthecovertothemetalblade.–

Ensuresafepositionoftheequipmentduringcartransportationtoavoidfuel–

leakage.

When transporting, ensure that the fuel tank is completely empty.–

Whenunloadingtheequipmentfromthetruck,neverdroptheEnginetothe–

ground or this may severely damage the fuel tank.

Exceptincaseofemergency,neverdroporcasttheequipmenttotheground–

orthismayseverelydamagetheequipment.

Remembertolifttheentireequipmentfromthegroundwhenmovingthe–

equipment.Draggingthefueltankishighlydangerousandwillcausedamage

andleakageoffuel,possiblycausingfire.

Refueling

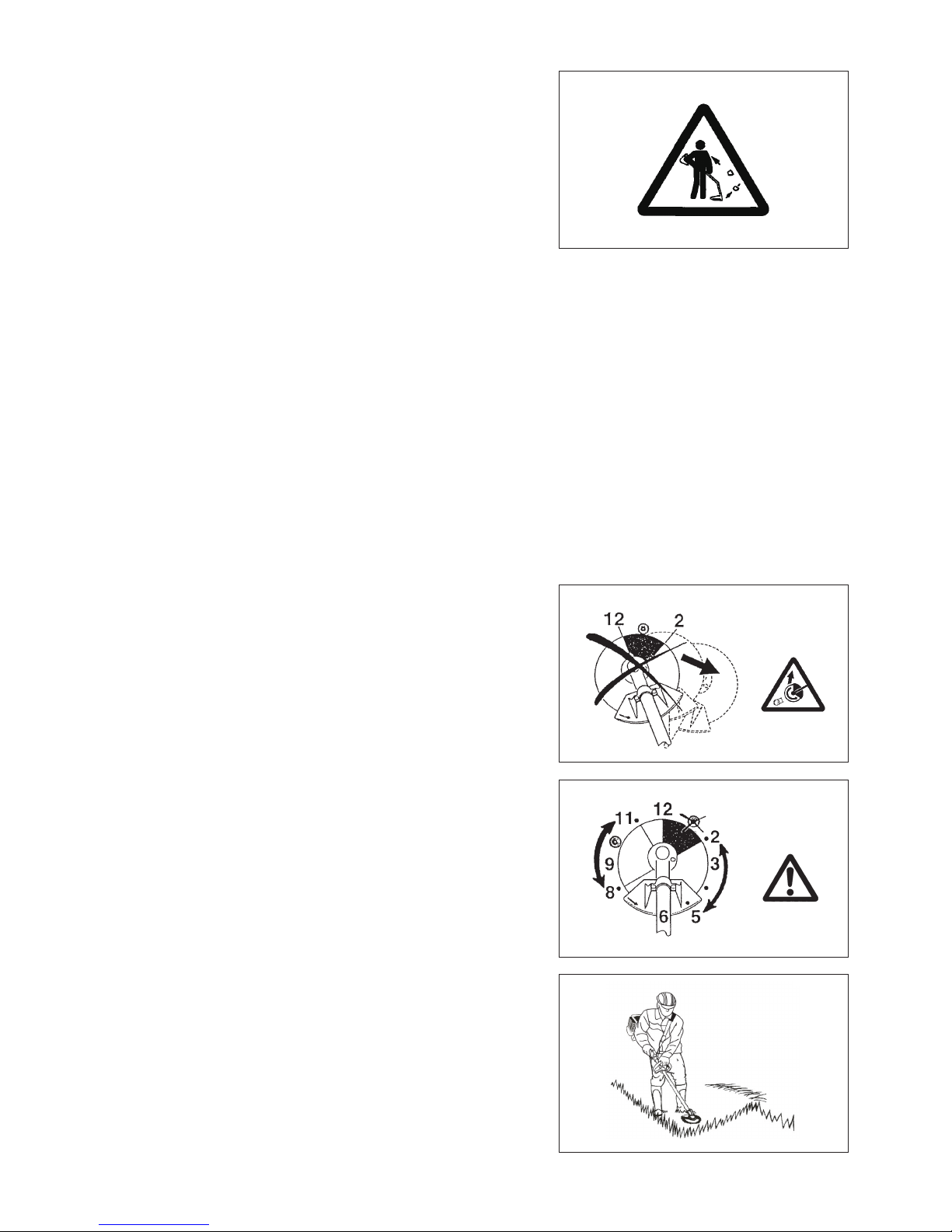

Shutofftheengineduringrefueling,keepawayfromopenflamesanddonot–

smoke.

Avoid skin contact with mineral oil products. Do not inhale fuel vapor. Always–

wear protective gloves during refueling. Change and clean protective clothing

at regular intervals.

Take care not to spill either fuel or oil in order to prevent soil contamination–

(environmental protection). Clean the brushcutter immediately after fuel has

been spilt.

Avoid any fuel contact with your clothing. Change your clothing instantly if–

fuelhasbeenspiltonit(topreventclothingcatchingfire).

Inspect the fuel cap at regular intervals making sure that it can be securely–

fastened and does not leak.

Carefully tighten the fuel tank cap. Change location to start the engine (at–

least 3 meters away from the place of refueling).

Never refuel in closed rooms. Fuel vapors accumulate at ground lever (risk of–

explosions).

Only transport and store fuel in approved containers. Make sure the fuel–

stored is not accessible to children.