9ENGLISH

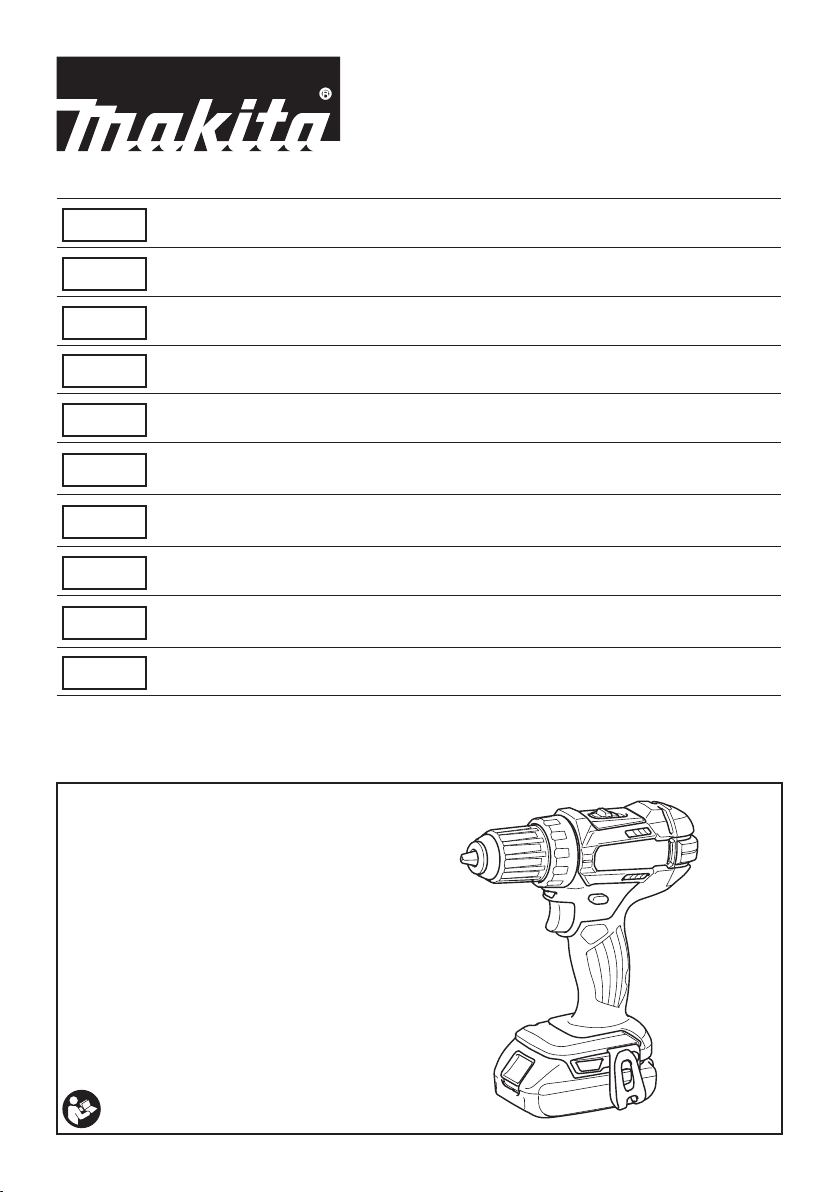

OPERATION

CAUTION: Always insert the battery cartridge

all the way until it locks in place. If you can see

theredpartontheuppersideofthebutton,itisnot

locked completely. Insert it fully until the red part can-

notbeseen.Ifnot,itmayaccidentallyfalloutofthe

tool,causinginjurytoyouorsomeonearoundyou.

CAUTION: When the speed comes down

extremely, reduce the load or stop the tool to

avoid the tool damage.

Holdthetoolrmlywithonehandonthegripandthe

otherhandonthebottomofthebatterycartridgeto

control the twisting action.

►Fig.12

Screwdriving operation

CAUTION: Adjust the adjusting ring to the

proper torque level for your work.

CAUTION: Make sure that the driver bit is

inserted straight in the screw head, or the screw

and/or driver bit may be damaged.

Placethepointofthedriverbitinthescrewheadand

apply pressure to the tool. Start the tool slowly and then

increase the speed gradually. Release the switch trigger

as soon as the clutch cuts in.

NOTE: When driving wood screw, pre-drill a pilot hole

2/3thediameterofthescrew.Itmakesdrivingeasier

and prevents splitting of the workpiece.

Drilling operation

First,turntheadjustingringsothatthepointerpointsto

the marking.Thenproceedasfollows.

Drilling in wood

Whendrillinginwood,thebestresultsareobtained

withwooddrillsequippedwithaguidescrew.Theguide

screwmakesdrillingeasierbypullingthedrillbitinto

the workpiece.

Drilling in metal

Topreventthedrillbitfromslippingwhenstartinga

hole, make an indentation with a center-punch and

hammeratthepointtobedrilled.Placethepointofthe

drillbitintheindentationandstartdrilling.

Useacuttinglubricantwhendrillingmetals.Theexcep-

tionsareironandbrasswhichshouldbedrilleddry.

CAUTION: Pressing excessively on the tool

will not speed up the drilling. In fact, this excessive

pressure will only serve to damage the tip of your drill

bit,decreasethetoolperformanceandshortenthe

service life of the tool.

CAUTION: Hold the tool rmly and exert care

when the drill bit begins to break through the

workpiece.Thereisatremendousforceexertedon

thetool/drillbitatthetimeofholebreakthrough.

CAUTION: A stuck drill bit can be removed

simply by setting the reversing switch to reverse

rotation in order to back out. However, the tool

may back out abruptly if you do not hold it rmly.

CAUTION: Always secure small workpieces in

a vise or similar hold-down device.

CAUTION: If the tool is operated continuously

until the battery cartridge has discharged, allow

the tool to rest for 15 minutes before proceeding

with a fresh battery.

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

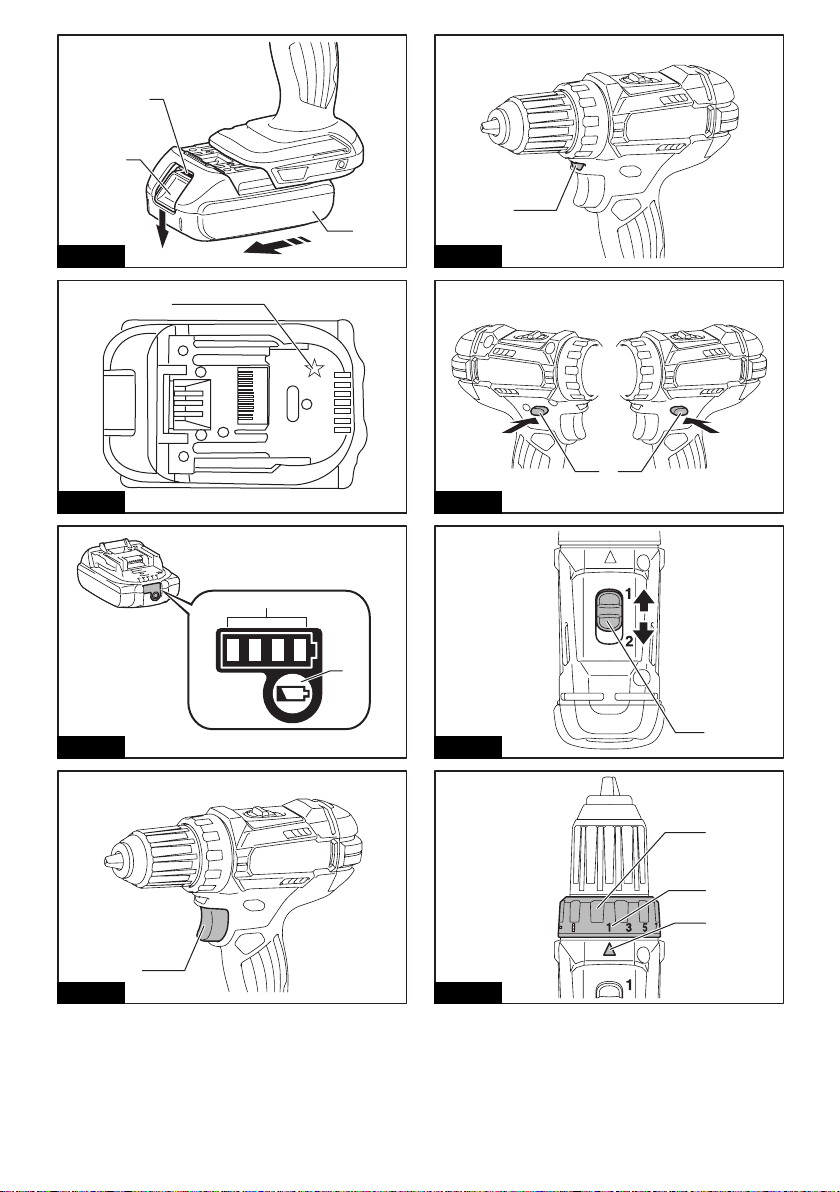

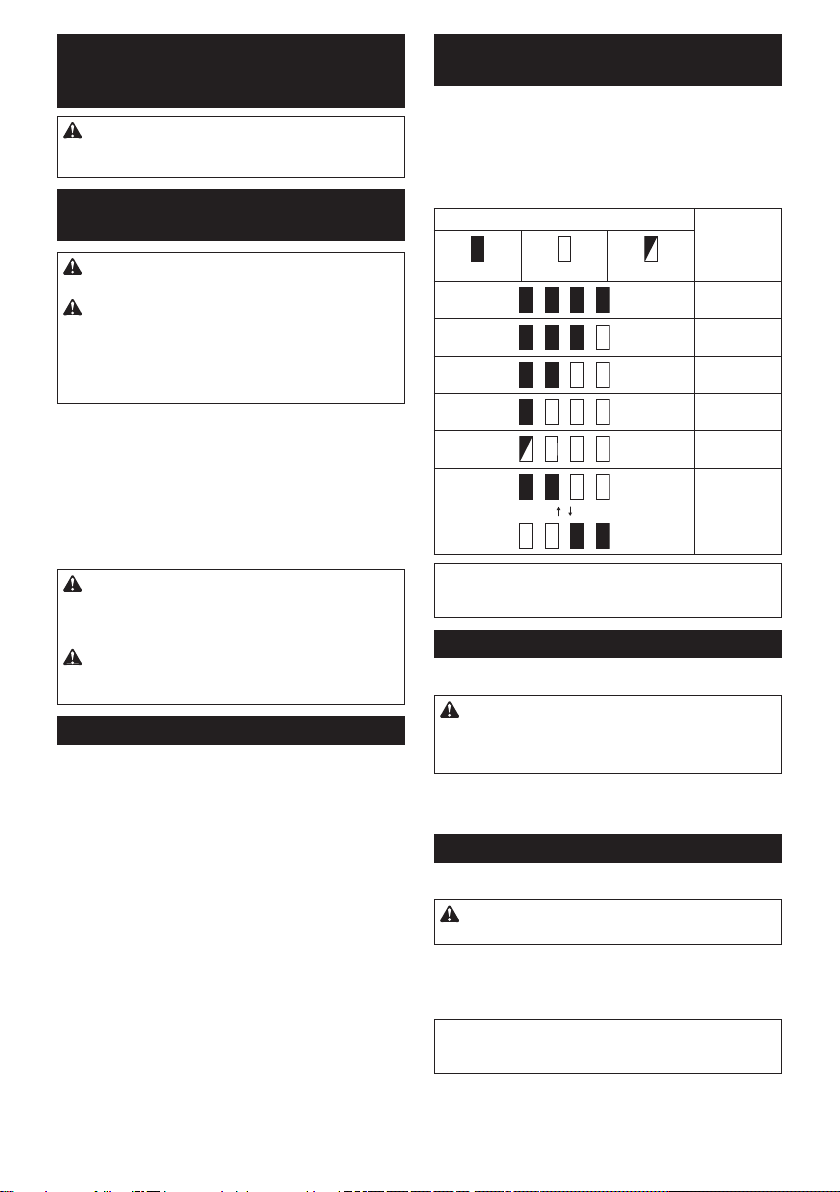

Replacing carbon brushes

►Fig.13: 1. Limit mark

Checkthecarbonbrushesregularly.

Replace them when they wear down to the limit mark.

Keepthecarbonbrushescleanandfreetoslipinthe

holders.Bothcarbonbrushesshouldbereplacedatthe

sametime.Useonlyidenticalcarbonbrushes.

1. Use a screwdriver to remove two screws then

remove the rear cover.

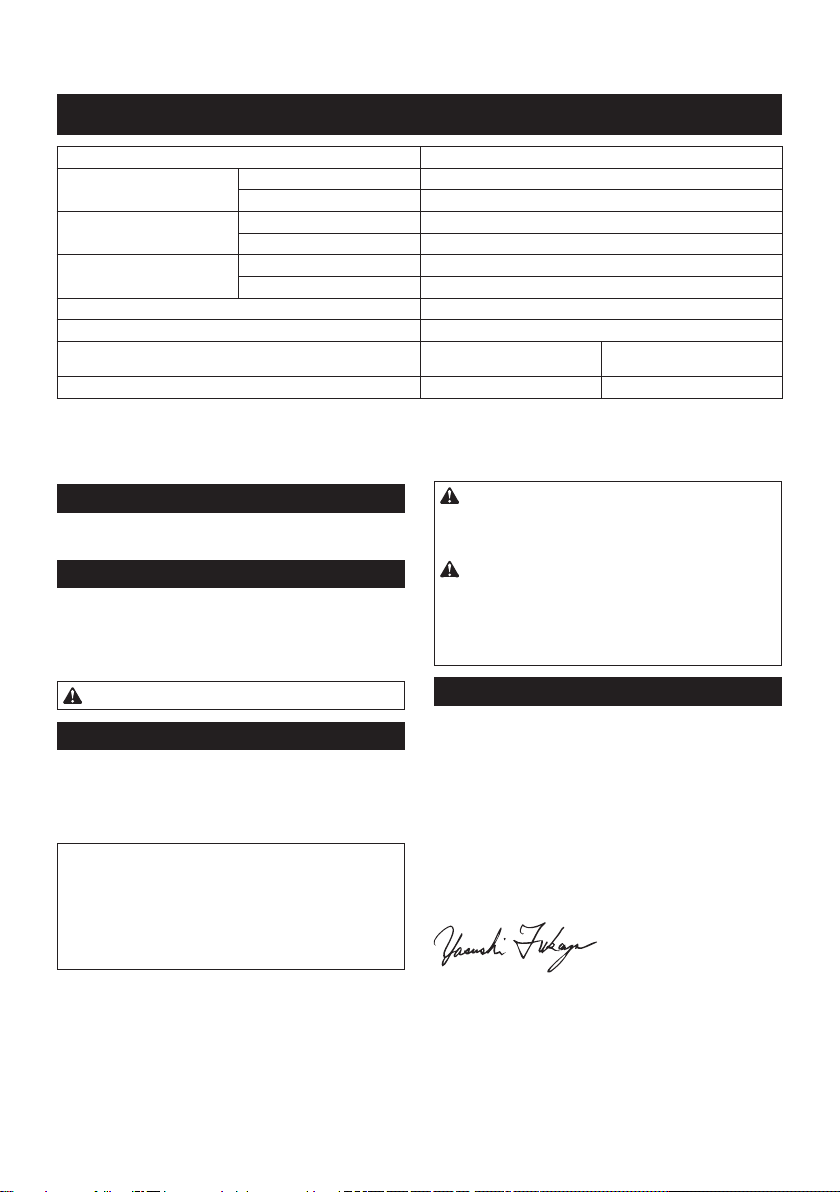

►Fig.14: 1. Rear cover 2. Screw

2. Raise the arm part of the spring and then place

itintherecessedpartofthehousingwithaslottedbit

screwdriver of slender shaft or the like.

►Fig.15: 1.Recessedpart 2.Spring 3.Arm

3. Useplierstoremovethecarbonbrushcapsof

thecarbonbrushes.Takeouttheworncarbonbrushes,

insertthenewonesandreplacethecarbonbrushcaps

in reverse.

►Fig.16: 1.Carbonbrushcap

4. Make sure to place the lead wire in opposite side

of the arm.

►Fig.17: 1.Leadwire 2.Carbonbrushcap

5. Makesurethatthecarbonbrushcapshavetinto

theholesinbrushholderssecurely.