Makita DS4012 Manual

Other Makita Drill manuals

Makita

Makita DHP482 User manual

Makita

Makita DDF459 User manual

Makita

Makita DHP470 User manual

Makita

Makita DHP482 User manual

Makita

Makita 6227D User manual

Makita

Makita LXPH01 User manual

Makita

Makita DDF482ZJ User manual

Makita

Makita M6500 User manual

Makita

Makita DDF484RFJ User manual

Makita

Makita DP4011J User manual

Makita

Makita 6510LVR User manual

Makita

Makita GFD01 User manual

Makita

Makita DDF486 User manual

Makita

Makita DF001G User manual

Makita

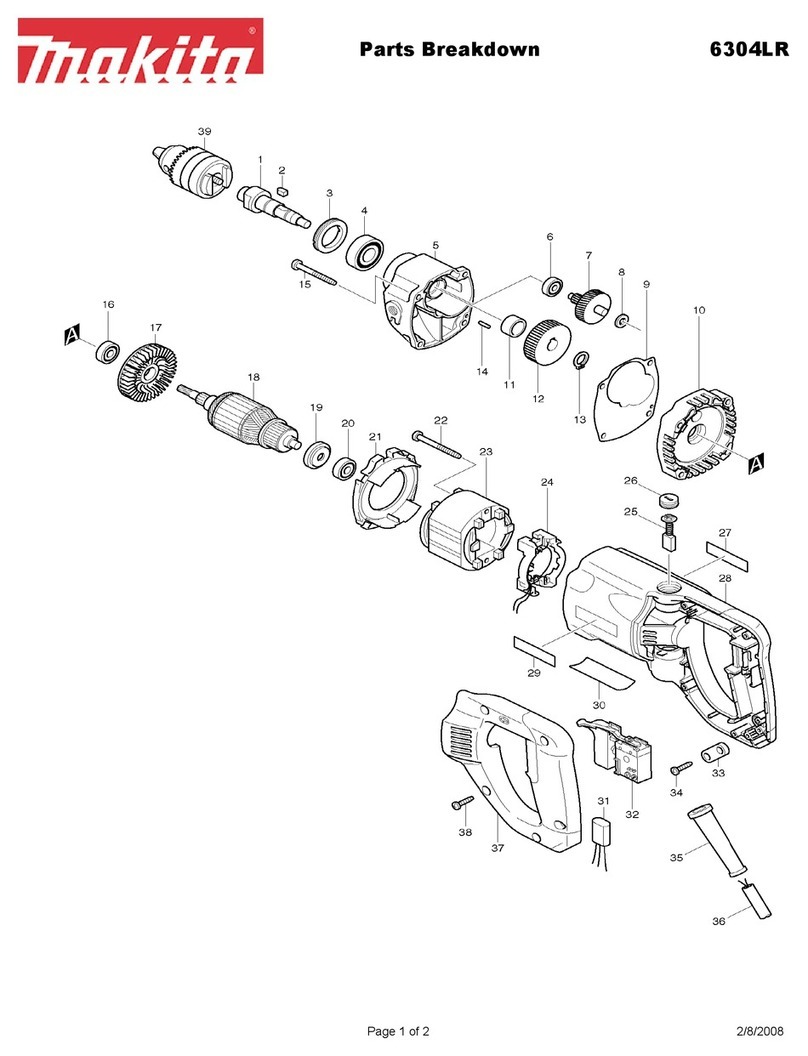

Makita 6304LR Quick start guide

Makita

Makita DP4010 User manual

Makita

Makita DHP441 User manual

Makita

Makita LXT BDF452Z User manual

Makita

Makita XFD13 User manual

Makita

Makita DHP448 User manual