PRODUCT

P 1/ 24

T

ECHNICAL INFORMATION

HR3200C HR3210C

Europe: 4.0 (13.1), Brazil: 2.0 (6.6), Other countries: 5.0 (16.4)

HR3210FCT

5.0 (11.0)

SDS-plus

32 (1-1/4)

4.4 (9.7) 4.8 (10.6)

13 (1/2)

32 (1-1/4)

315 - 630

1,650 - 3,300Impacts per minute: min-1= ipm

No load speed: min-1= rpm

Specification

Double insulation

Net weight: kg (lbs)

Power supply cord (m: ft)

Operation mode 3 modes

(Rotation only/ Rotation with Hammering/ Hammering only)

Concrete TCT bit

Steel

Wood

90 (3-1/2)Core bit

Capacities:

mm (”)

Model

Shank type

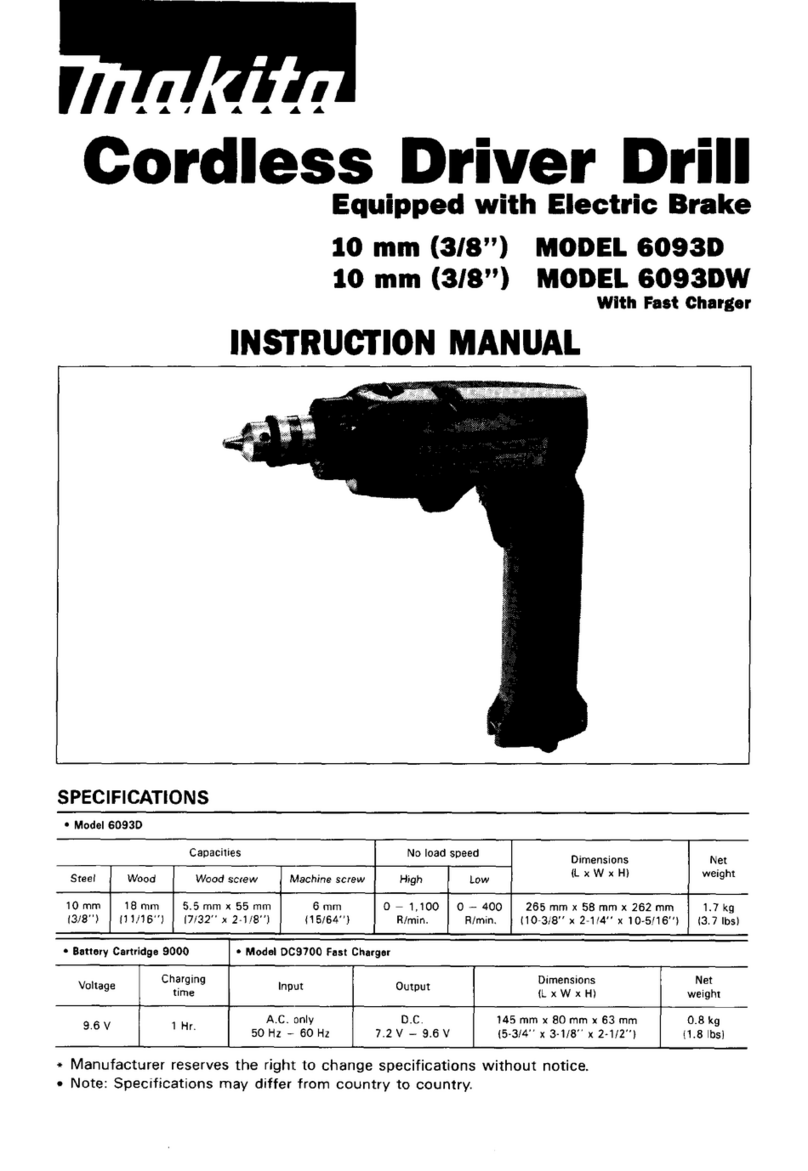

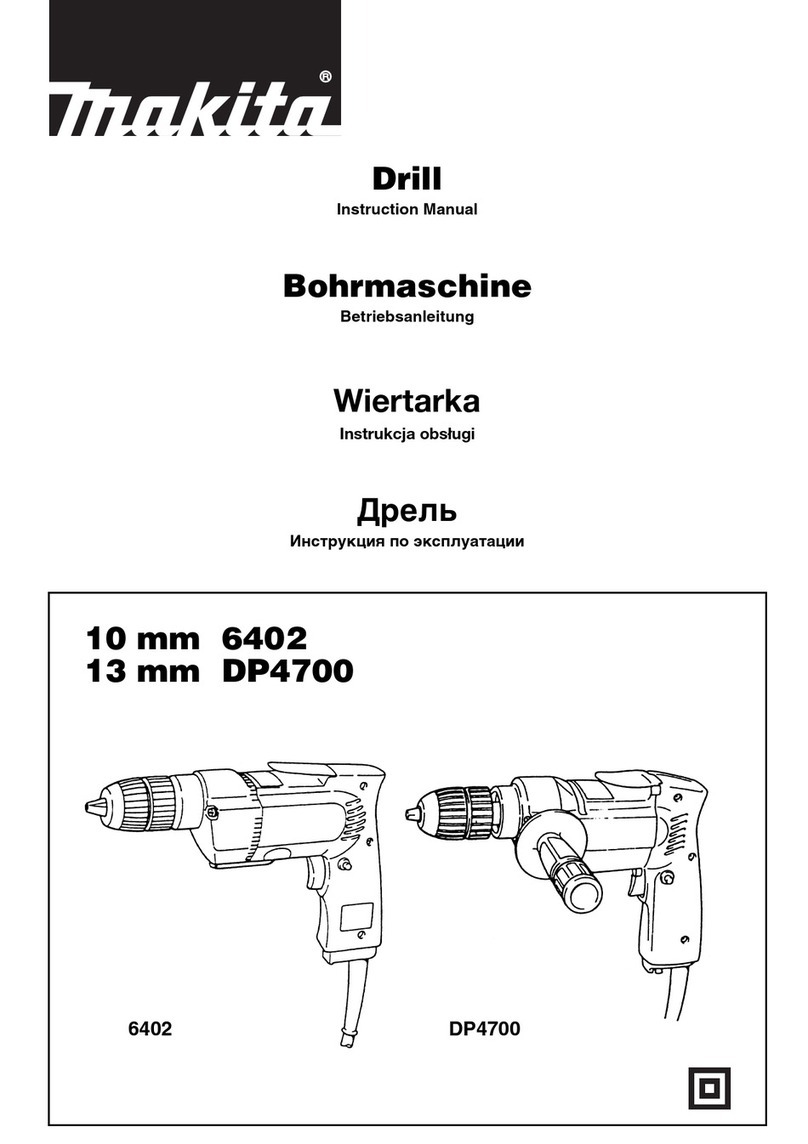

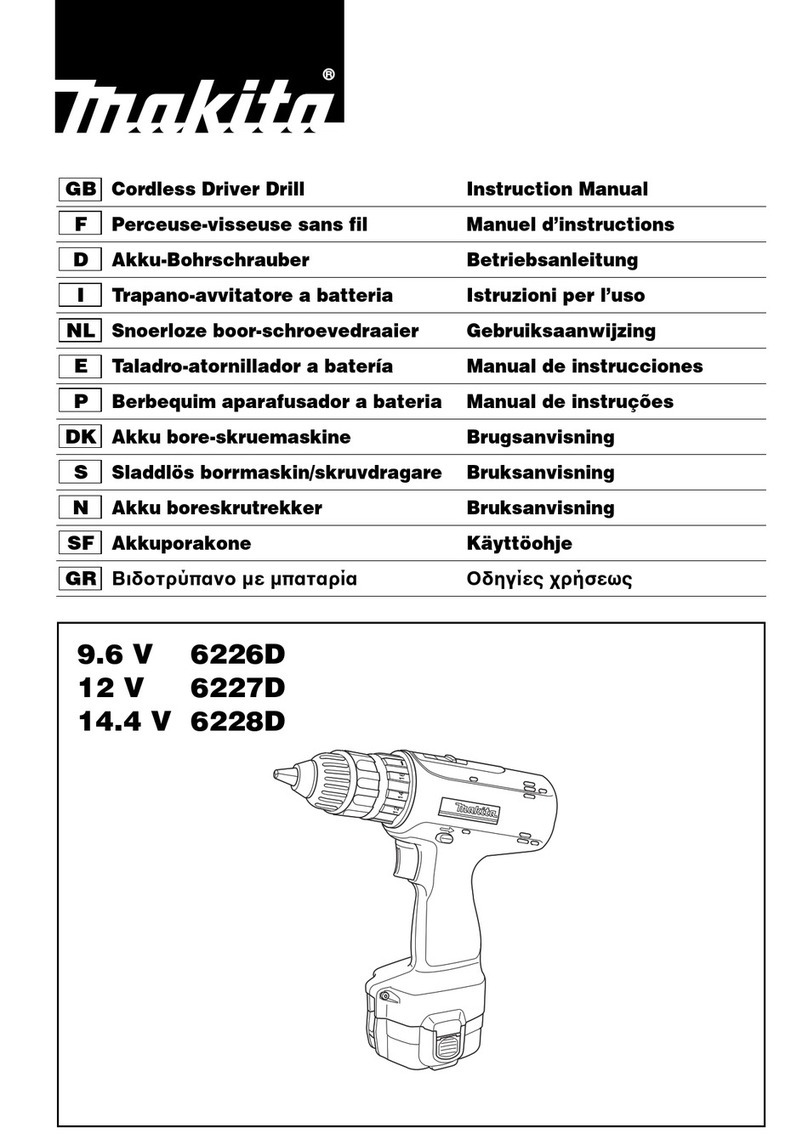

Model No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

Side handle (Bar-shaped) .... 1

Depth gauge ........................ 1

TCT bits (taper shank), Taper shank adapter, Cotter, Core bits, Center bit, Core bit adapter , Rod, Bull points, Cold chisels,

Scaling chisels, Grooving chisels, Scraper assembly, Dust cups 5 and 9, Drill chuck assembly,Drill chuck adapter,

Drill chuck S13, Chuck key S13, Depth gauge, Blow-out bulb, Grease vessel (containing 30g of Hammer grease), Grease

vessel 93G (Containing Bit grease), Safety goggle, Hammer service kit, Quick change drill chuck (for HR3210FCT only)

Grease vessel 93G (containing Bit grease) ................ 1

Quick change drill chuck (for HR3210FCT only) ..... 1

Plastic carrying ............ 1

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

Model No. HR3200C HR3210C HR3210FCT

398 (15-5/8) 424 (16-3/4)

114 (4-1/2)108 (4-1/4)

239 (9-3/8)

Note: The standard equipment for the tool shown above may differ by country.

HR3200C, HR3210C, HR3210FCT

Rotary Hammer 32mm (1-1/4")

HR3200C series models have been developed as successor models

of HR3000C, featuring low vibration level and lightweight design.

Listed below are specification differences among the three models.

HR3210FCT

HR3210C

HR3200C

L

H

W

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

110

120

220

230

240

8.6

8.2

4.4

4.4

4.4

50/60

50/60

50/60

50/60

50/60

850

---

850

850

850

300

300

300

300

300

1,100

1,100

1,100

1,100

1,100

Current (A)

Torque limiter

Electronic

features

Variable speed control by dial

Constant speed control

Soft start

Yes

Yes

Yes

Yes

Yes

Active dynamic vibration absorber

Model No.

AVT Vibration absorbing handle

Quick change drill chuck

Yes Yes

Yes

Yes

NoNo

No

LED Job light NoNo

HR3200C HR3210C HR3210FCT