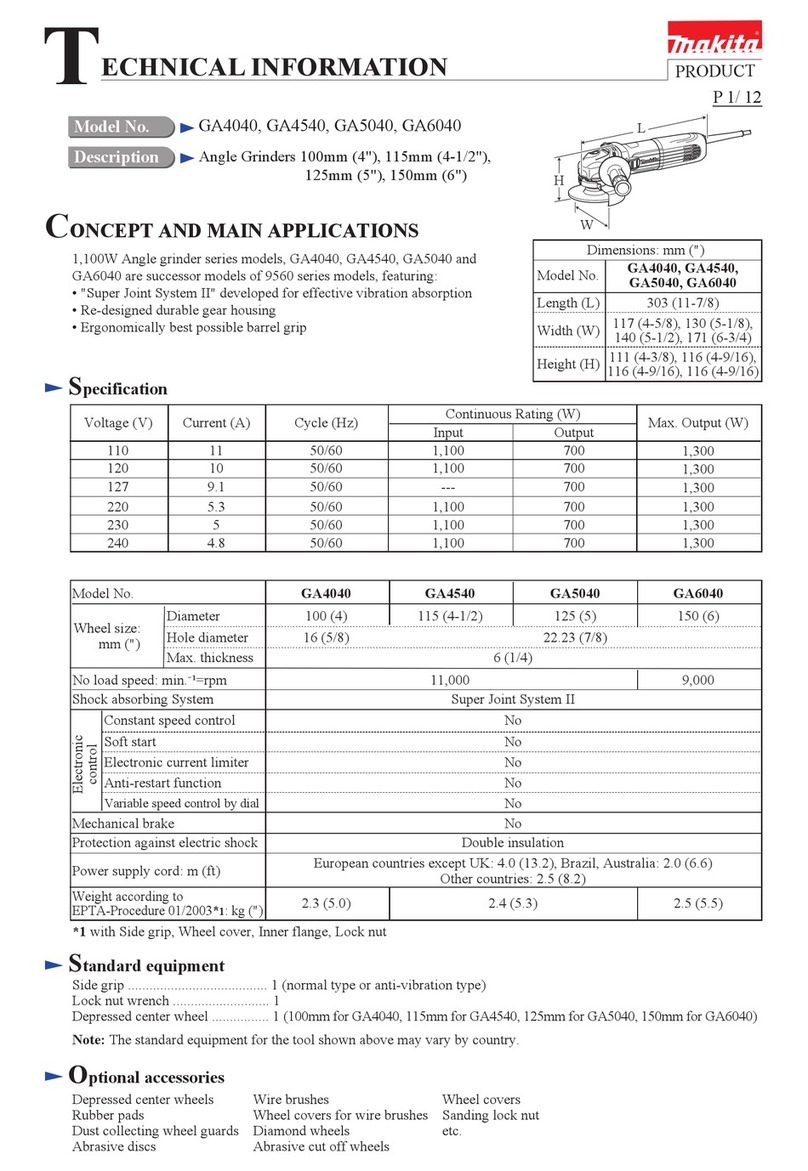

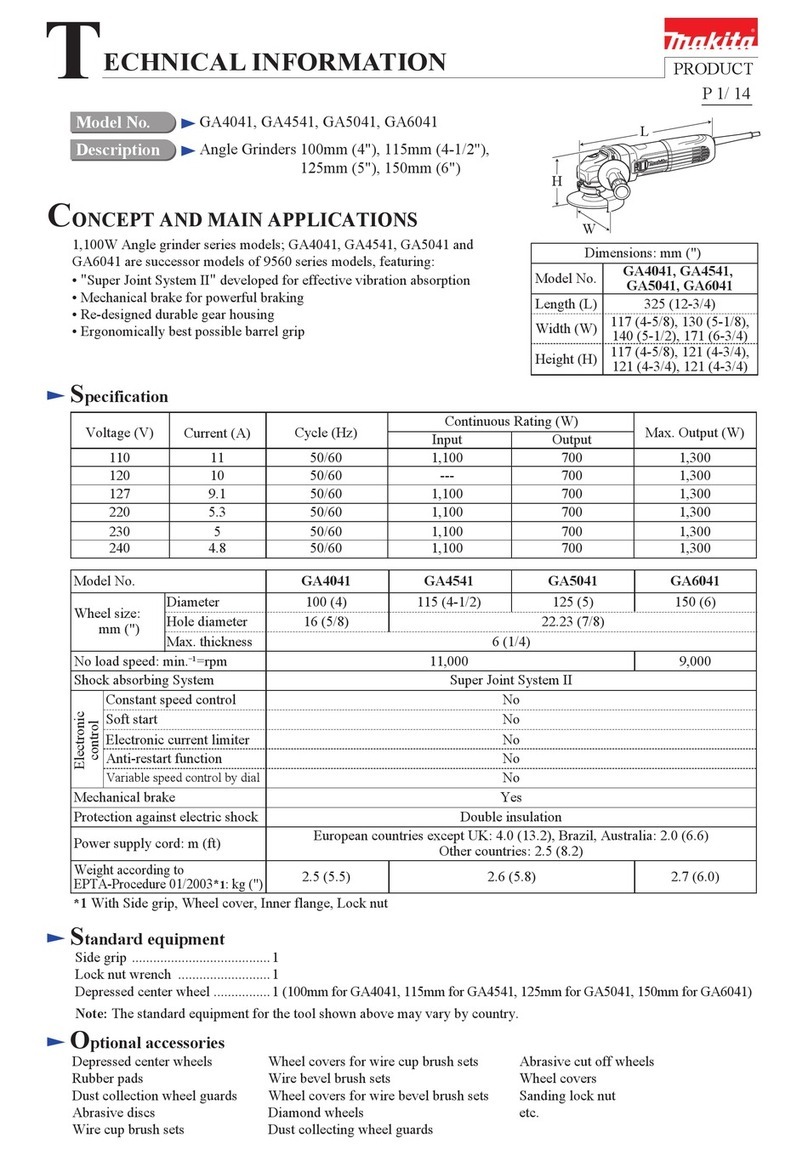

Model No.

Description

PRODUCT

CONCEPT AND MAIN APPLICATIONS

P 1/ 10

Specification

Standard equipment

Note: The standard equipment for the tool shown above may differ from country to country.

9564PC/ 9565PC/ 9566PC

9564PCV/ 9565PCV/ 9566PCV

Angle Grinders

115mm (4-1/2")/ 125mm (5")/ 150mm (6")

Models 9564PC/ 9565PC/ 9566PC have been developed

as sister tools of 9564C/ 9565C/ 9566C, featuring

paddle type on/off switch.

Models 9564PCV/ 9565PCV/ 9566PCV additionally feature

variable speed control by dial.

Lock nut wrench ................... 1

Depressed center wheel ......... 1 (115 for 9564PC/ 9564PCV, 125 for 9565PC/ 9565PCV, 150 for 9566PC/ 9566PCV)

Cut-off wheel ........................ 1 ( 9566PC for USA)

Side grip ................................ 1

Dimensions: mm (")

Width (W)

Height (H)

Length (L)

Model No. 9564PC

9564PCV

307 (12-1/8)

129 (5-1/8)

103 (4)

9565PC

9565PCV

139 (5-1/2)

9566PC

9566PCV

169 (6-5/8)

L

H

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output (W)

120

110 13 1,400

---

840 1,80050/60

6.7 1,400 840 2,10050/60

6.4 1,400 840 2,10050/60

6.1 1,400 840 2,10050/60

13 840 2,00050/60

220

230

240

Current (A)

Optional accessories

Anti-vibration grip, Dust cover attachment, Loop handle, Toolless wheel cover

9564PC/ 9564PCV: Accessories for 115mm (4-1/2") angle grinder

9565PC/ 9565PCV: Accessories for 125mm (5") angle grinder

9566PC/ 9566PCV: Accessories for 150mm (6") angle grinder

W

Model No.

No load speed:

min.-1 = rpm

Diameter

Hole diameter

Wheel size:

mm (")

Protection against electric shock

Power supply cord: m (ft)

Net weight: kg (lbs)

9564PC/ 9564PCV 9565PC/ 9565PCV 9566PC/ 9566PCV

115 (4-1/2)

Australia, Brazil, Chile: 2.0 (6.6), Other countries: 2.5 (8.2)

1.9 (4.2)

11,500/ 2,800 - 11,500

125 (5) 150 (6)

9,200/ 4,000 - 9,200

10,000/ 4,000 - 10,000

Double insulation

22.23 (7/8)

Super Joint System (SJS) Yes

Constant speed control Yes

Soft start Yes

Electronic current limiter Yes

Variable speed control by dial No/ Yes No/ Yes No/ Yes

China

Other countries

11,000/ 2,800 - 11,000

Electronic

control

TECHNICAL INFORMATION