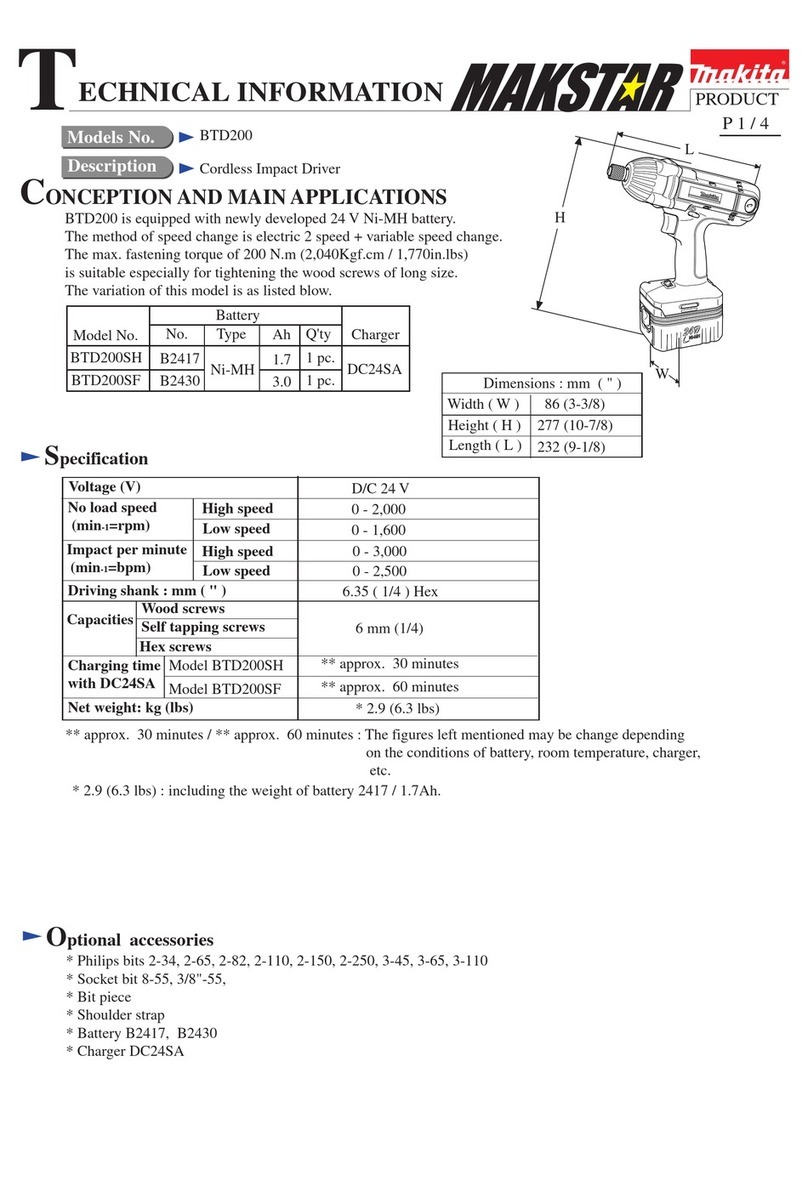

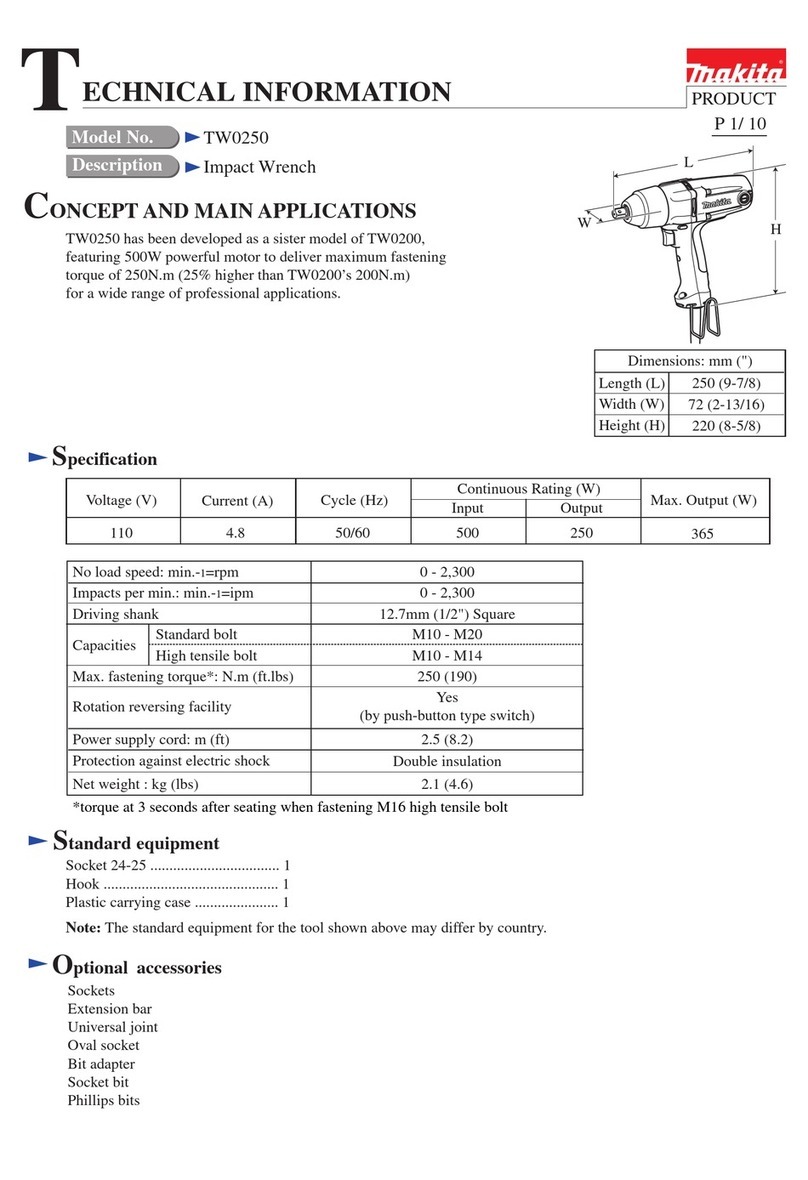

Models No.

Description

NEW TOOL

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

P 1 / 7

< Note > The standard equipment for the tool shown may differ from country to country.

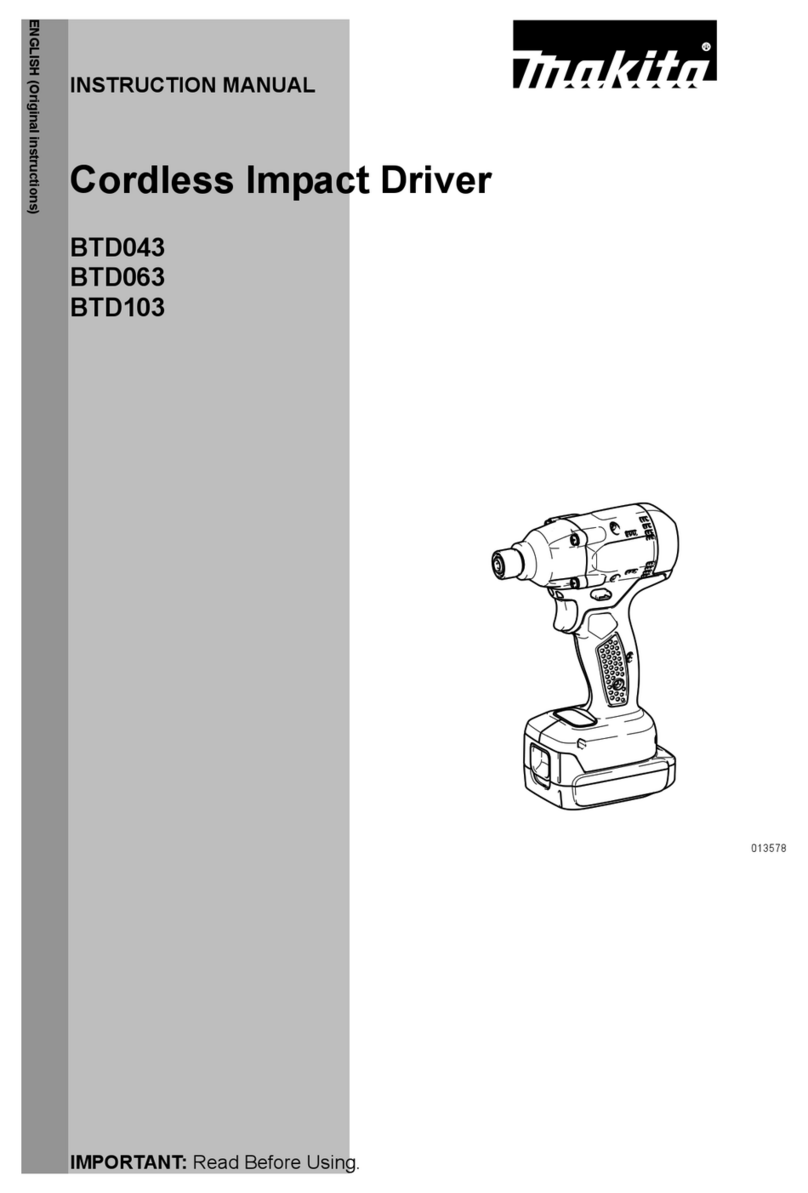

BTD123F

Cordless Impact Driver

Model BTD123F has been added to the MAKSTAR series models.

The brief features of the new 12V impact driver are;

*Compact design with an overall length of only 163mm (6-3/8")

*Extra-lightweight with the newly designed, compact and light

12V batteries, BH1220C or BH1233C

*Screw hole protrusions have been eliminated from hammer case

for increased maneuverability, allowing operator not to worry

about making scratches on workpiece with the tool.

This new product is available in the following variations.

Battery

No load speed: min.-1=rpm.

Impacts per min.: min.-1=bpm.

Max. fastening torque: N.m (kgf.cm/in.lbs)

Charging time: min.

Capacities

Electric Brake

Reversing switch

*Plastic carrying case .................................... 1 pc.

*Phillips bit 2-65............................................ 1 pc.

*Assorted Phillips bit, Socket bits and Drill chucks

*Bit piece

*Stopper assembly

*Batteries BH1220C, BH1233C, BH1220, BH1233

*Charger DC14SA, DC14SC, DC24SA

w/ 2.0 Ah battery

w/ 3.3 Ah battery

Net weight: kg (lbs)

Variable speed (electric)

Capacity: Ah

Cell

2.0Ah battery

3.3Ah battery

Voltage: V 12V

0 - 2,600

0 - 3,200

125 (1,270/1,110)

Standard bolt

High tensile bolt

Machine screw

M5 - M12 (3/16 - 15/32")

M5 - M10 (3/16 - 3/8")

Coarse thread screw 22 - 120mm (7/8 - 3-3/4")

M4 - M8 (5/32 - 5/16")

Yes

Yes

Yes

1.4 (3.1)

1.6 (3.5)

2.0 (battery BH1220C) / 3.3 (battery BH1233C)

Ni-MH

approx. 30 with DC14SC

approx. 50 with DC14SC

Dimensions: mm ( " )

Width ( W )

Height ( H )

w/ BH1220C

Length ( L ) 163 (6-3/8)

82 (3-1/4)

226 (8-7/8)

w/ BH1233C

234 (9-1/4)

L

H

W

BTD123FSJE

BTD123FSAE Ni-MH

BH1220C (2.0Ah)/ 2pcs

Ni-MH

BH1233C (3.3Ah)/ 2pcs

Model No. Battery Charger

DC14SC

DC14SC

Plastic

carrying case

Yes

BTD123FZ No No No

Yes