Dimensions: mm (")

Width (W)

Height (H1)*2

Height (H2)*3

*2: with BL1415

*3: with BL1430

Length (L) 171 (6-3/4)

79 (3-1/8)

250 (9-7/8)

233 (9-1/8)

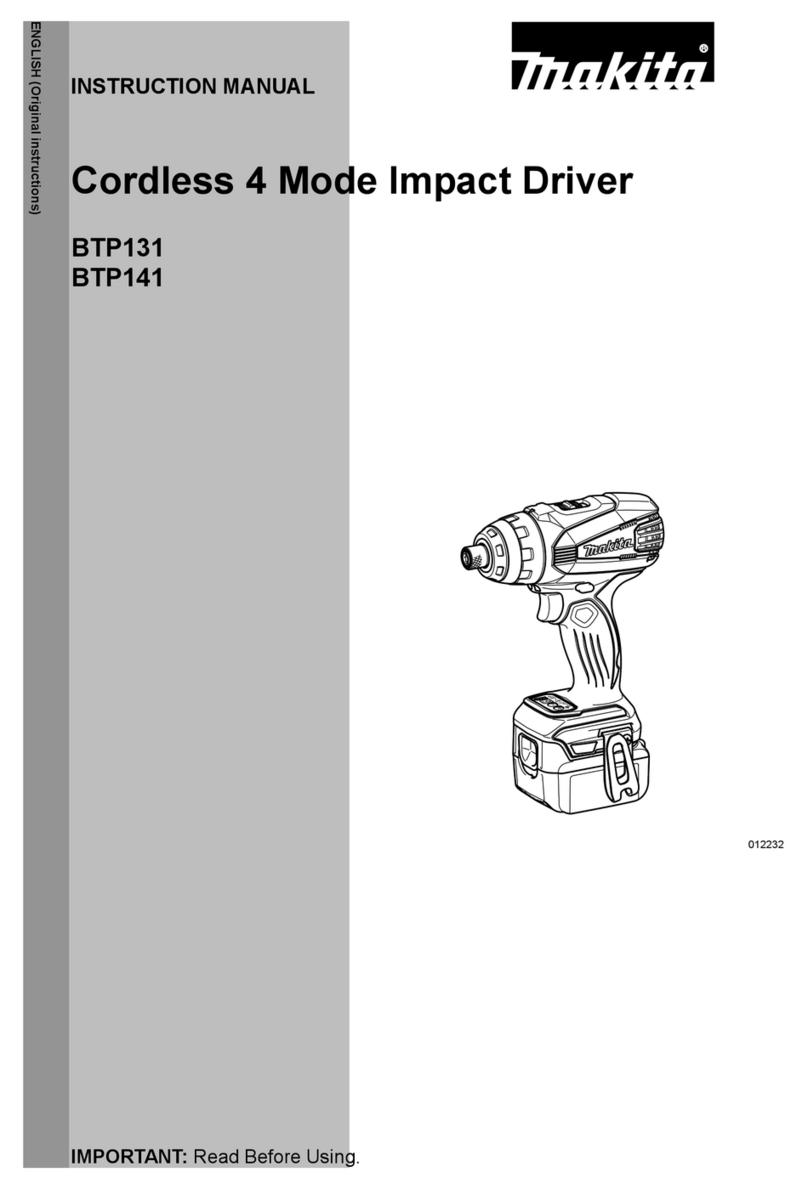

BTP131

Cordless 4 Mode Impact Driver

Model BTP131 Cordless 4 mode Impact Driver is an advanced version

of model BTP130. While maintaining the same high versatility as Model BTP130,

BTP131 additionally features more compact design achieved by using BLDC motor

(BrushLess DC motor) and Makita’s first electronic clutch mechanism.

This product is powered by 14.4V-1.3Ah Li-ion battery BL1415 and 14.4V-3.0Ah

Li-ion battery BL1430.

This product is available in the following variations.

H

W

Battery

Clutch torque setting on screwdriver mode

Charging time: min.

Max. fastening torque:

N.m (in.lbs)

Capacity: Ah

Cell

Voltage: V 14.4

Drill mode

Soft joint

Impact driver mode*5

12 (106)

1.3, 3.0

Li-ion

15, 22 with DC18RC

Hard joint 21 (186)

Lock torque 15 (133)

145 (1,280)

No load speed:

min.ˉ¹=rpm

Impact driver mode 0 - 2,800/ 0 - 2,200/ 0 - 1,400

0 - 3,200/ 0 - 2,400/ 0 - 1,200

Screwdriver mode

Drill mode

Hammer drill mode 0 - 2,800/ 0 - 700

0 - 1,100/ 0 - 300

(0 - 2,300/ 0 - 600)*4

Impacts per minute:

min.ˉ¹=ipm

Impact driver mode

Hammer drill mode 0 - 32,400/ 0 - 8,400

18 (9 each for high/low speeds)

+ Teks screw mode

Driving shank 6.35mm (1/4") Hex

Weight according to

EPTA-Procedure 01/2003: kg (lbs)

Torque range (approx.): N.m (in.lbs) 0.7 - 4.0 (6 - 35)/ 1.5 - 12.0 (13 - 106)

1.5*2 (3.3)*2, 1.7*3 (3.7)*3

Drilling:

mm (") Steel

Masonry

Wood 21 (13/16)

M4 - M8 (5/32" - 5/16")

10 (3/8)

8 (5/16)

Yes

Energy capacity: Wh 19, 44

Drill mode

Fastening

Machine screw

M5 - M14 (3/16" - 9/16")Standard bolt

M5 - M12 (3/16" - 15/32")High tensile bolt

22mm - 125mm (7/8" - 4-7/8")Coarse-thread

Impact driver mode

LED Job light

*4: Teks screw mode

*5: Torque at 3 seconds after seating, when fastening M14 high tensile bolt

Hammer drill mode

Capacity

PRODUCT

P 1/ 18

All models also include the accessories listed below in "Standard equipment".

Model No. Type Quantity

Charger

Plastic

carrying

case

Battery

cover

No

Battery

BTP131Z No No

BTP131RFE DC18RC Yes2

BL1430 1

Battery

fuel gauge

Yes

Yes

NoNo

TECHNICAL INFORMATION

Models No.

Description

CONCEPT AND MAIN APPLICATIONS

Specification

L

Hard/ Medium/ Soft

High/ Low

High/ Low

Hard/ Medium/ Soft

High/ Low

High/ Low