9

wood or the tape.

IMPORTANT:

All maintenance or cleaning on the machine must be

made with the same OFF and unplugged from the

outlet to prevent accidental discharges.

GENERAL

Periodic maintenance on your Edgebander CBC.E

MAKSIWA will ensure optimum performance. Make it

a habit to inspect your edgebander every time you

use it.

This section covers the service adjustments or

common procedures that may need to be made

during the life of your machine.

Verify if the following conditions for repair or

replacement are needed:

• Loosen screws.

• Switches or buttons damaged.

• Cables, plugs or sockets worn or damaged.

• Transmission chain damaged.

• Dirt Glue axis or glue pot. The dust coming from

saw machines can lock the axis. Keep your CBC.E as

distantly as possible of saw machines.

• Any other condition that could adversely aect the

safe operation of the equipment.

CLEANING

Clean your Edgebander CBC.E is relatively easy. Use

a vacuum cleaner to remove the tape remains, and

dusting with a dry cloth. If there is any glue residue

use a resin remover and a clean cloth to remove it.

Keep the table clean after each use.

Periodically (and always with the machine o) it

is important to do all the cleaning of the machine,

removing glue residue that could aect the proper

functioning of the equipment. Clean the guides, the

axes and the main cutter carefully.

To maintain quality of the cutter, it is very important

to keep the scissors free of glue residue or tape. To

clean it, use a cloth with thinner or kerosene, gently

wipe the cutter, removing all the glue residue.

LUBRIFICATION

Once all bearings are shielded and have permanent

lubrication, just leave them like this until it is need

to be replaced. Do not lubricate them. For the other

items on this machine, an occasional application of

micro-electric machine oil is needed in the hinge that

moves the glue pot and manual cutter scissors.

Before lubricating, try cleaning the areas to be

lubricated, eliminating the accumulation of dirt.

MAINTENANCE

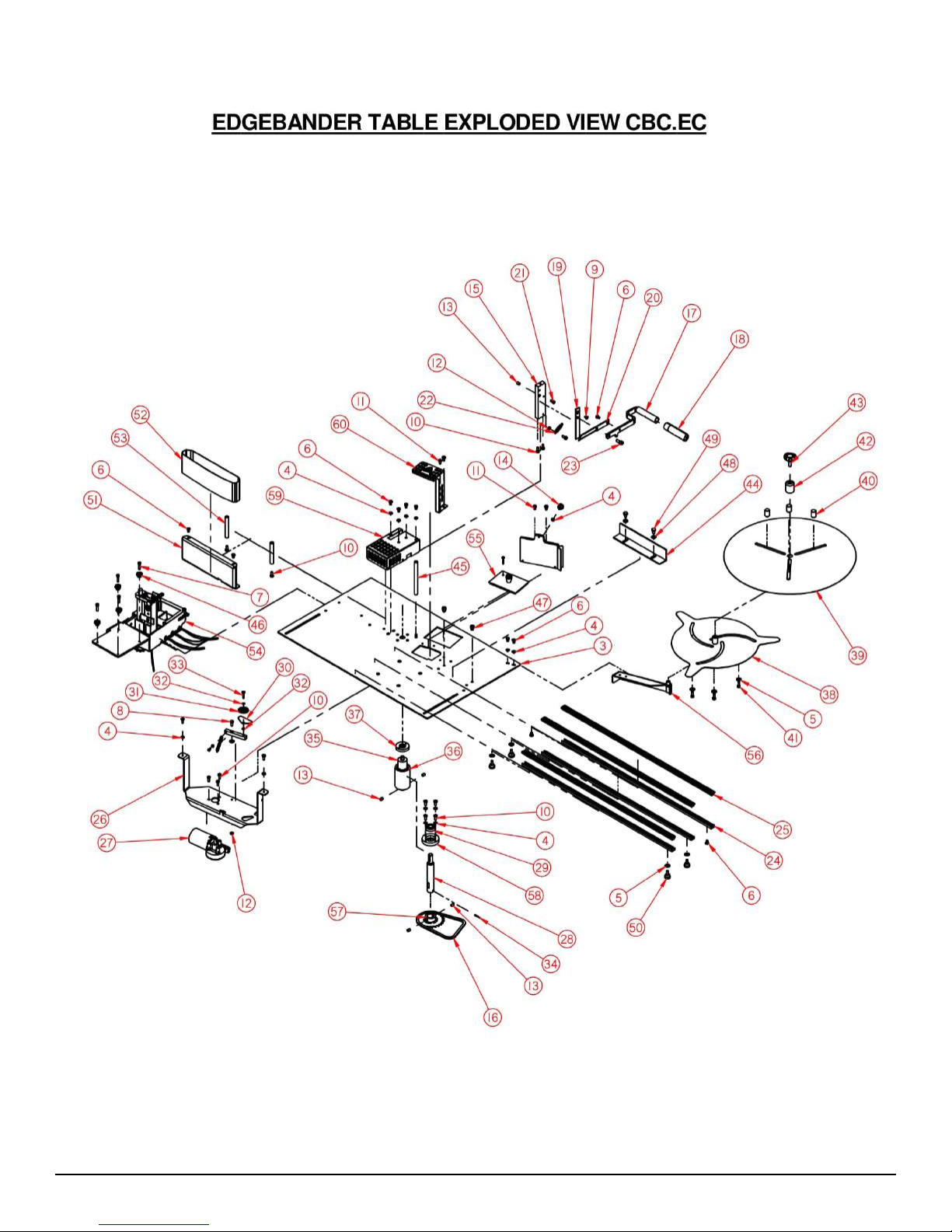

BRACKET

Due to transport and even during use, it may be that

the glue axis turn out of bracket.

The fact that the glue axis is out of bracket causes

incorrect application of glue in the wood paneling,

applying impartial glue or not even applying any glue

on the wood.

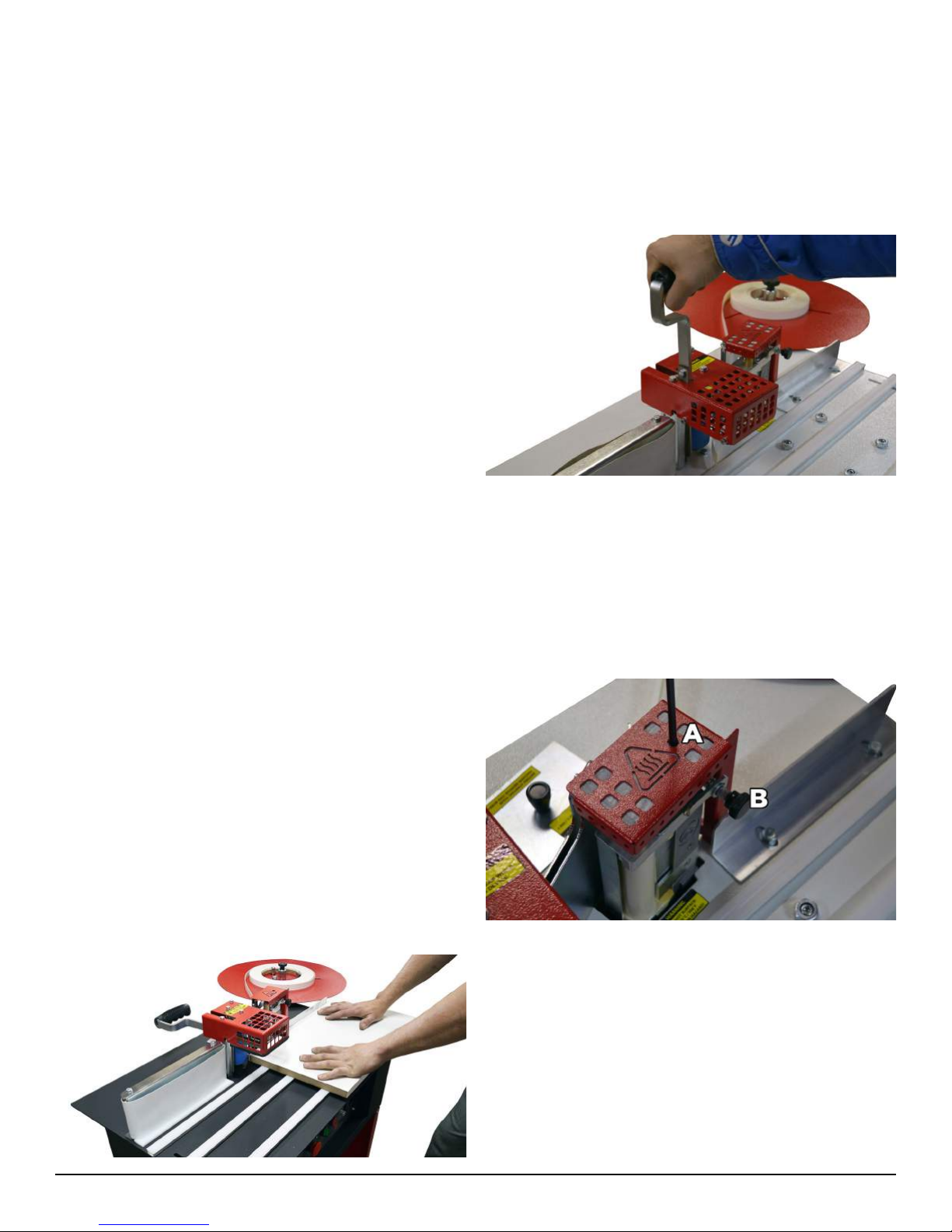

If the glue axis of your Edgebander is out of the

bracket, you can regulate it easily by following these

steps:

- Clean the glue axis, removing glue excess. For

this heat the machine until melt point of the glue,

facilitating the glue axis cleaning. Once the glue is

melted, turn o the machine, stopping the axis in

order to clean it and check the bracket.

- Support the side of a bracket on the table tabs,

leaning against the glue axis.

- If any point of the bracket face is not touching the

glue axis, you must do the following setting:

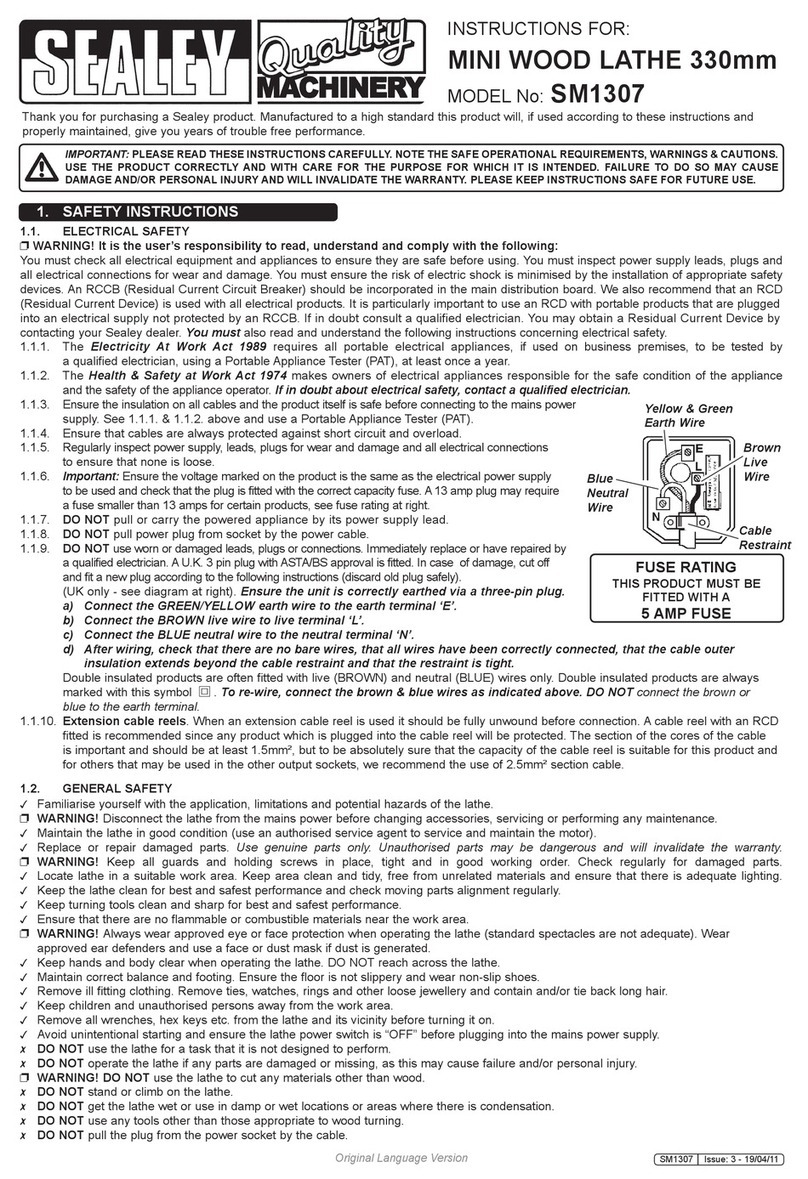

- If the top of the axis is tilted to the back of the

machine, loosen the Allen screws 5mm at point B (see

gure below) and press (about 1/4 turn) the hex bolts

also from the point B. Check the bracket again. If it is

corrected, tighten the Allen screws.

- If the top of the axis is tilted to the front of the

machine, loosen the Allen screws at point A and

tighten (about 1/4 turn) the hex screws. Check out

the bracket again. If it is corrected, tighten the Allen

screws; if not, repeat the procedure.

MAINTENANCE SCHEDULE

Daily:

• Aspirate all dust on top and around the machine.

• Clean the guides, rubberized axis and manual cutter,

freeing of all glue residue.

• Check the level of glue on the glue pot.

Weekly:

• Clean dust accumulation inside the back cover,

around the glue axis and glue pot of the machine.

• Check for wear or damage to the buttons and cord.