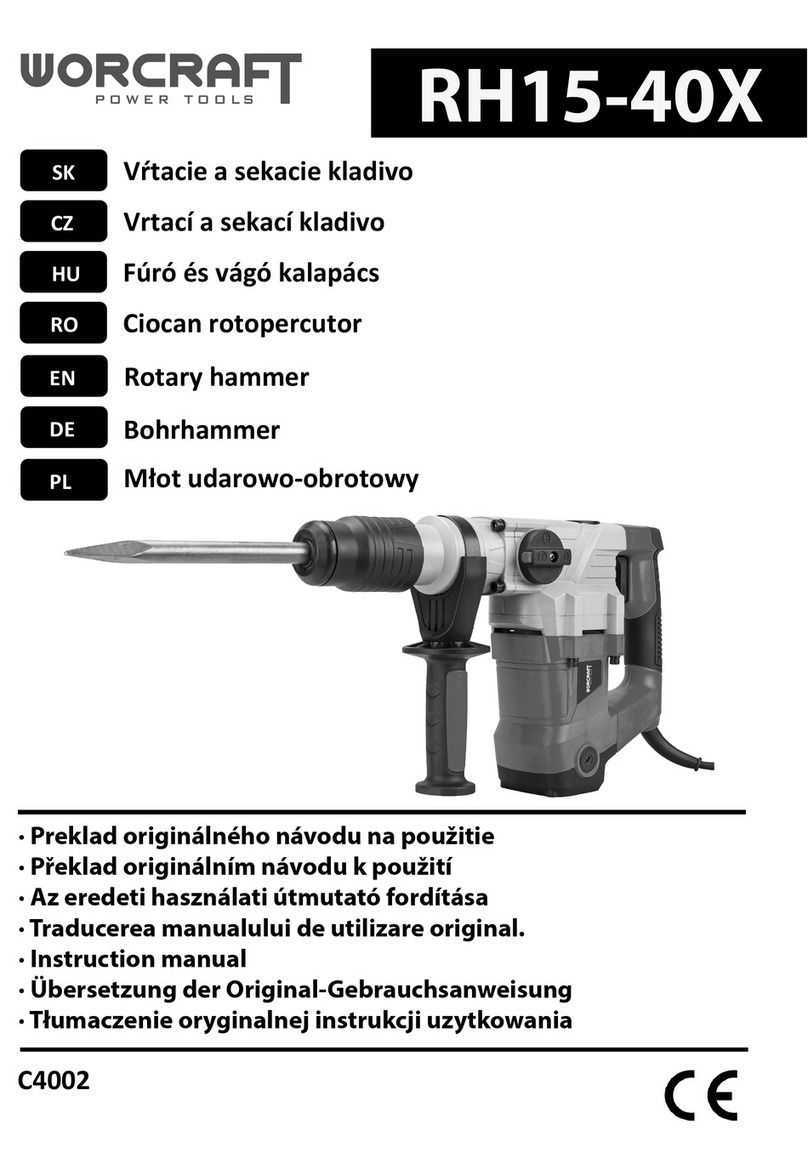

Maktec MT870 User manual

Rotary Hammer Instruction manual

Bor Getar Rotari Petunjuk penggunaan

Máy khoan ng lcTài liu hng dn

GB

VI

TH

ID

MT870

2

1012279 2012280

3012281 4012283

5003150 6010714

7012285 8012286

1

2

A

B

3

4

56

789

11

10 12

12

13

7

14

3

9012292 10 012293

15

16

4

ENGLISH

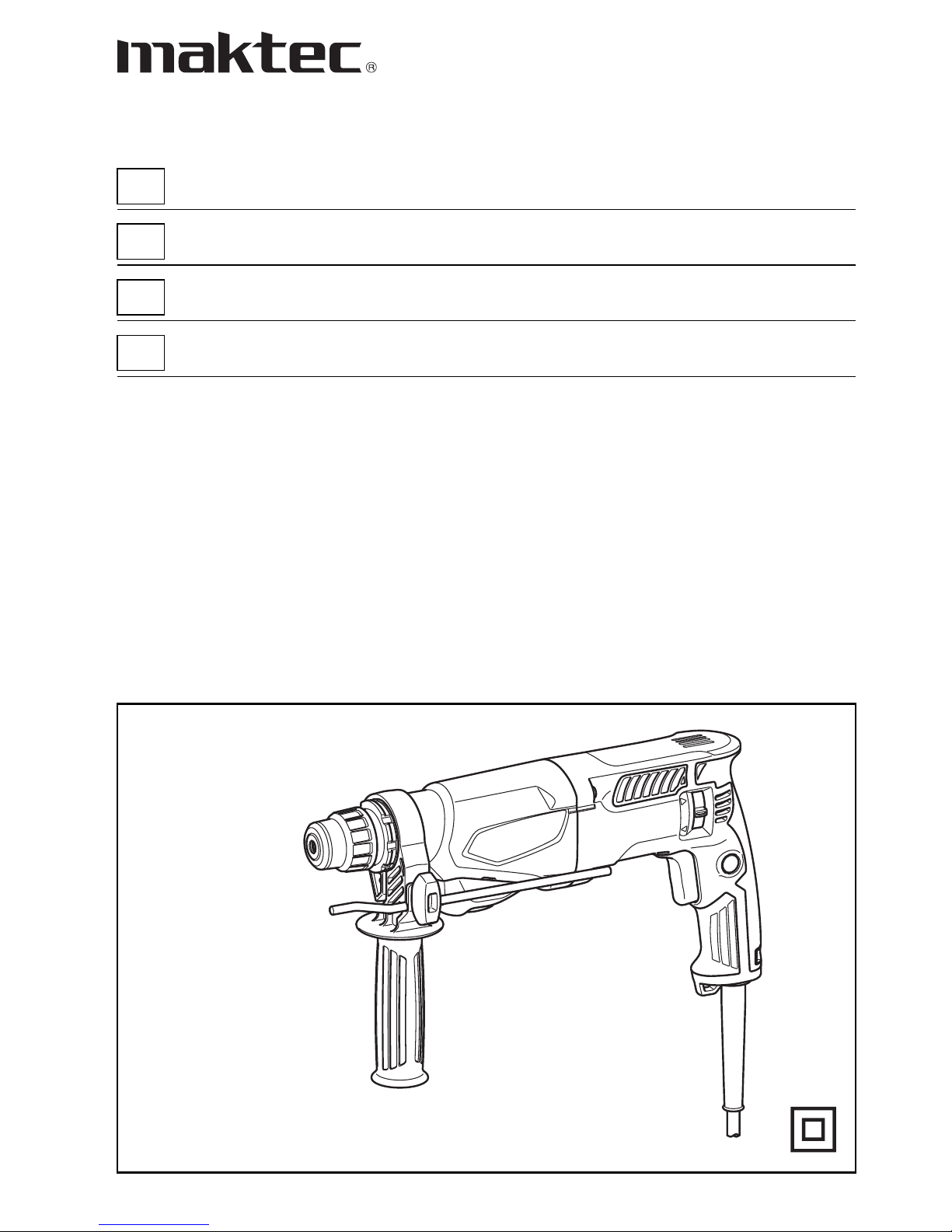

Explanation of general view

SPECIFICATIONS

•Due to our continuing programme of research and development, the specifications herein are subject to change without

notice.

• Specifications may differ from country to country.

• Weight according to EPTA-Procedure 01/2003

END201-5

Symbols

The following show the symbols used for the equipment.

Be sure that you understand their meaning before use.

.... Read instruction manual.

.............. DOUBLE INSULATION

ENE042-1

Intended use

The tool is intended for hammer drilling and drilling in

brick, concrete and stone.

It is also suitable for drilling without impact in wood, metal,

ceramic and plastic.

ENF002-1

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

GEA005-3

General Power Tool Safety

Warnings

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

Save all warnings and

instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

2. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

3. Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

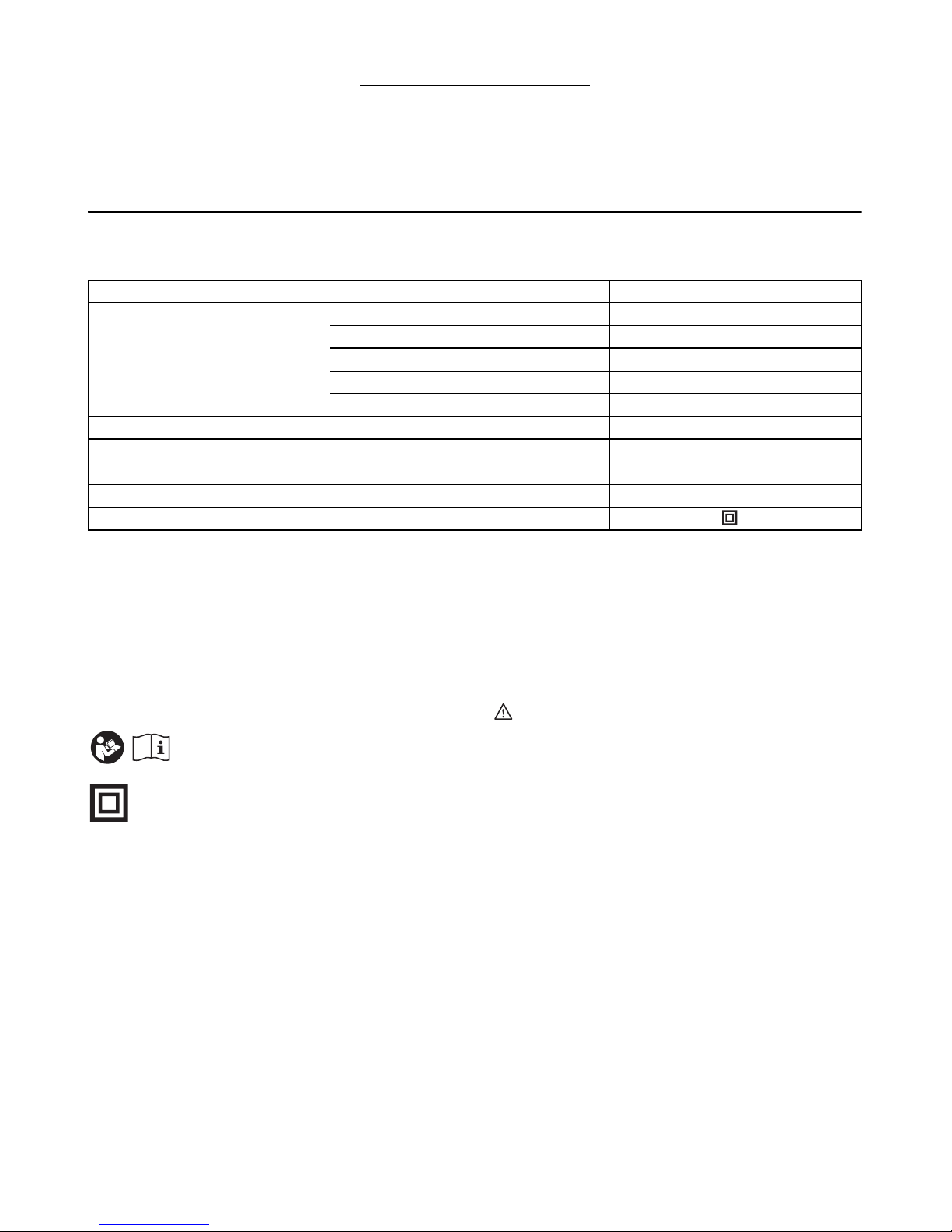

1. Switch trigger

2. Lock button

3. Reversing switch lever

4. Action mode changing knob

5. Rotation only

6. Rotation with hammering

7. Thumb screw

8. Protrusions

9. Grooves

10. Bit shank

11. Bit grease

12. Bit

13. Chuck cover

14. Depth gauge

15. Chuck adapter

16. Keyless drill chuck

Model MT870

Capacities

Concrete 22 mm

Core bit 54 mm

Diamond core bit (dry type) 65 mm

Steel 13 mm

Wood 32 mm

No load speed (min-1)0 - 1,100

Blows per minute 0 - 4,350

Overall length 362 mm

Net weight 2.5 kg

Safety class /II

5

Electrical safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

9. If operating a power tool in a damp location is

unavoidable, use a residual current device (RCD)

protected supply. Use of an RCD reduces the risk of

electric shock.

10. Use of power supply via a RCD with a rated

residual current of 30mA or less is always

recommended.

Personal safety

11. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

12. Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

13. Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

14. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

15. Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

16. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

17. If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

Power tool use and care

18. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

19. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

20. Disconnect the plug from the power source and/or

the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

21. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

22. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

23. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

24. Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

Service

25. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power tool

is maintained.

26. Follow instruction for lubricating and changing

accessories.

27. Keep handles dry, clean and free from oil and

grease.

GEB007-7

ROTARY HAMMER SAFETY

WARNINGS

1. Wear ear protectors. Exposure to noise can cause

hearing loss.

2. Use auxiliary handle(s), if supplied with the tool.

Loss of control can cause personal injury.

3. Hold power tool by insulated gripping surfaces,

when performing an operation where the cutting

accessory may contact hidden wiring or its own

cord. Cutting accessory contacting a “live” wire may

make exposed metal parts of the power tool “live” and

could give the operator an electric shock.

4. Wear a hard hat (safety helmet), safety glasses

and/or face shield. Ordinary eye or sun glasses

are NOT safety glasses. It is also highly

recommended that you wear a dust mask and

thickly padded gloves.

6

5. Be sure the bit is secured in place before

operation.

6. Under normal operation, the tool is designed to

produce vibration. The screws can come loose

easily, causing a breakdown or accident. Check

tightness of screws carefully before operation.

7. In cold weather or when the tool has not been

used for a long time, let the tool warm up for a

while by operating it under no load. This will

loosen up the lubrication. Without proper warm-

up, hammering operation is difficult.

8. Always be sure you have a firm footing.

Be sure no one is below when using the tool in

high locations.

9. Hold the tool firmly with both hands.

10. Keep hands away from moving parts.

11. Do not leave the tool running. Operate the tool

only when hand-held.

12. Do not point the tool at any one in the area when

operating. The bit could fly out and injure

someone seriously.

13. Do not touch the bit or parts close to the bit

immediately after operation; they may be

extremely hot and could burn your skin.

14. Some material contains chemicals which may be

toxic. Take caution to prevent dust inhalation and

skin contact. Follow material supplier safety data.

SAVE THESE INSTRUCTIONS.

WARNING:

DO NOT let comfort or familiarity with product (gained

from repeated use) replace strict adherence to safety

rules for the subject product. MISUSE or failure to

follow the safety rules stated in this instruction

manual may cause serious personal injury.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Switch action (Fig. 1)

CAUTION:

•Before plugging in the tool, always check to see that

the switch trigger actuates properly and returns to the

“OFF” position when released.

• Switch can be locked in “ON” position for ease of

operator comfort during extended use. Apply caution

when locking tool in “ON” position and maintain firm

grasp on tool.

To start the tool, simply pull the switch trigger. Tool speed

is increased by increasing pressure on the switch trigger.

Release the switch trigger to stop. For continuous

operation, pull the switch trigger, push in the lock button

and then release the switch trigger. To stop the tool from

the locked position, pull the switch trigger fully, then

release it.

Reversing switch action (Fig. 2)

CAUTION:

• Always check the direction of rotation before operation.

•Use the reversing switch only after the tool comes to a

complete stop. Changing the direction of rotation

before the tool stops may damage the tool.

•If the switch trigger can not be depressed, check to see

that the reversing switch is fully set to position (A

side) or (B side).

This tool has a reversing switch to change the direction of

rotation. Move the reversing switch lever to the

position (A side) for clockwise rotation or the position

(B side) for counterclockwise rotation.

Selecting the action mode (Fig. 3)

This tool employs an action mode changing knob. Select

one of the two modes suitable for your work needs by

using this knob.

For rotation only, turn the knob so that the arrow on the

knob points toward the symbol on the tool body.

For rotation with hammering, turn the knob so that the

arrow on the knob points toward the symbol on the

tool body.

CAUTION:

•Always set the knob fully to your desired mode symbol.

If you operate the tool with the knob positioned halfway

between the mode symbols, the tool may be damaged.

• Use the knob after the tool comes to a complete stop.

Torque limiter

The torque limiter will actuate when a certain torque level

is reached. The motor will disengage from the output

shaft. When this happens, the bit will stop turning.

CAUTION:

•As soon as the torque limiter actuates, switch off the

tool immediately. This will help prevent premature wear

of the tool.

•Bits such as hole saw, which tend to pinch or catch

easily in the hole, are not appropriate for this tool. This

is because they will cause the torque limiter to actuate

too frequently.

ASSEMBLY

CAUTION:

•Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Side grip (auxiliary handle) (Fig. 4)

CAUTION:

•Always use the side grip to ensure operating safety.

Install the side grip so that the protrusions on the grip fit in

between the grooves on the tool barrel. Then tighten the

thumb screw to fix the grip at the desired position. It may

be swung 360° so as to be secured at any position.

Bit grease

Coat the bit shank head beforehand with a small amount

of bit grease (about 0.5 - 1 g).

This chuck lubrication assures smooth action and longer

service life.

7

Installing or removing the bit

Clean the bit shank and apply bit grease before installing

the bit. (Fig. 5)

Insert the bit into the tool. Turn the bit and push it in until it

engages. (Fig. 6)

After installing, always make sure that the bit is securely

held in place by trying to pull it out.

To remove the bit, pull the chuck cover down all the way

and pull the bit out. (Fig. 7)

Depth gauge (Fig. 8)

The depth gauge is convenient for drilling holes of uniform

depth. Loosen the thumb screw and adjust the depth

gauge to the desired depth. After adjusting, tighten the

thumb screw firmly.

NOTE:

• The depth gauge cannot be used at the position where

the depth gauge strikes against the gear housing/motor

housing.

OPERATION

Always use the side grip (auxiliary handle) and firmly hold

the tool by both side grip and switch handle during

operations.

Hammer drilling operation (Fig. 9)

Set the action mode changing knob to the symbol.

Position the bit at the desired location for the hole, then

pull the switch trigger. Do not force the tool. Light pressure

gives best results. Keep the tool in position and prevent it

from slipping away from the hole.

Do not apply more pressure when the hole becomes

clogged with chips or particles. Instead, run the tool at an

idle, then remove the bit partially from the hole. By

repeating this several times, the hole will be cleaned out

and normal drilling may be resumed.

Set the action mode changing knob to the symbol.

CAUTION:

• There is a tremendous and sudden twisting force

exerted on the tool/bit at the time of hole break-

through, when the hole becomes clogged with chips

and particles, or when striking reinforcing rods

embedded in the concrete. Always use the side grip

(auxiliary handle) and firmly hold the tool by both side

grip and switch handle during operations. Failure to do

so may result in the loss of control of the tool and

potentially severe injury.

NOTE:

•Eccentricity in the bit rotation may occur while

operating the tool with no load. The tool automatically

centers itself during operation. This does not affect the

drilling precision.

Drilling in wood or metal (Fig. 10)

Use the optional drill chuck assembly. When installing it,

refer to the section “Installing or removing the bit”.

CAUTION:

•Never use “rotation with hammering” when the drill

chuck is installed on the tool. The drill chuck may be

damaged.

Also, the drill chuck will come off when reversing the

tool.

•Pressing excessively on the tool will not speed up the

drilling. In fact, this excessive pressure will only serve

to damage the tip of your bit, decrease the tool

performance and shorten the service life of the tool.

• There is a tremendous twisting force exerted on the

tool/bit at the time of hole breakthrough. Hold the tool

firmly and exert care when the bit begins to break

through the workpiece.

•A stuck bit can be removed simply by setting the

reversing switch to reverse rotation in order to back

out. However, the tool may back out abruptly if you do

not hold it firmly.

•Always secure small workpieces in a vise or similar

hold-down device.

Diamond core drilling

When performing diamond core drilling operations,

always set the change lever to the position to use

“rotation only” action.

CAUTION:

• If performing diamond core drilling operations using

“rotation with hammering” action, the diamond core bit

may be damaged.

MAINTENANCE

CAUTION:

•Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

•Never use gasoline, benzine, thinner, alcohol or the

like. Discoloration, deformation or cracks may result.

To maintain product SAFETY and RELIABILITY, repairs,

carbon brush inspection and replacement, any other

maintenance or adjustment should be performed by

Makita Authorized Service Centers, always using Makita

replacement parts.

8

BAHASA INDONESIA

Penjelasan tampilan keseluruhan

SPESIFIKASI

•Karena kesinambungan program penelitian dan pengembangan kami, spesifikasi yang disebutkan di sini dapat

berubah tanpa pemberitahuan.

• Spesifikasi dapat berbeda dari satu negara ke negara lainnya.

•Berat menurut Prosedur EPTA 01/2003

END201-5

Simbol

Berikut ini adalah simbol-simbol yang digunakan pada

peralatan ini.

Pastikan Anda mengerti makna masing-masing simbol

sebelum menggunakan alat.

.... Baca petunjuk penggunaan.

.............. ISOLASI GANDA

ENE042-1

Penggunaan

Mesin ini digunakan untuk pengeboran dengan getar dan

mengebor batu bata, beton dan batu.

Juga cocok untuk pengeboran tanpa hentakan pada kayu,

logam, keramik dan plastik.

ENF002-1

Pasokan daya

Mesin harus terhubung dengan pasokan daya listrik yang

bervoltase sama dengan yang tertera pada pelat nama,

dan hanya dapat dijalankan dengan listrik AC fase

tunggal. Mesin diisolasi ganda sesuai Standard Eropa dan

oleh sebab itu dapat dihubungkan dengan soket tanpa

arde.

GEA005-3

Peringatan Keselamatan Umum

Mesin Listrik

PERINGATAN! Bacalah semua peringatan

keselamatan dan semua petunjuk. Kelalaian mematuhi

peringatan dan petunjuk dapat menyebabkan sengatan

listrik, kebakaran dan/atau cedera serius.

Simpanlah semua peringatan dan

petunjuk untuk acuan di masa

depan.

Istilah “mesin listrik” dalam semua peringatan mengacu

pada mesin listrik yang dijalankan dengan sumber listrik

jala-jala (berkabel) atau baterai (tanpa kabel).

Keselamatan tempat kerja

1. Jaga tempat kerja selalu bersih dan

berpenerangan cukup. Tempat kerja yang

berantakan dan gelap mengundang kecelakaan.

2. Jangan gunakan mesin listrik dalam lingkungan

yang mudah meledak, misalnya jika ada cairan,

gas, atau debu yang mudah menyala. Mesin listrik

menimbulkan bunga api yang dapat menyalakan debu

atau uap tersebut.

3. Jauhkan anak-anak dan orang lain saat

menggunakan mesin listrik. Bila perhatian terpecah,

anda dapat kehilangan kendali.

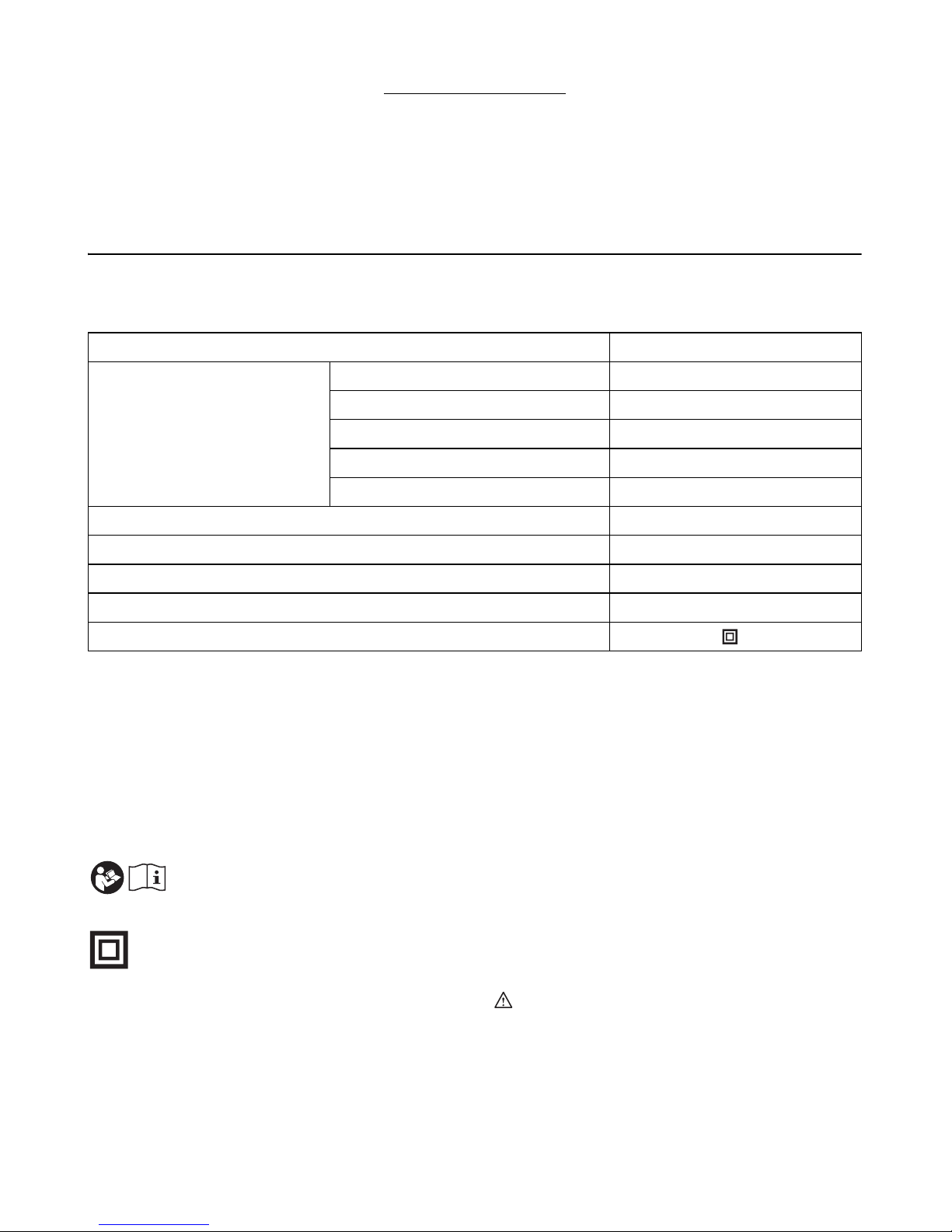

1. Saklar pemicu

2. Tombol kunci

3. Tuas saklar pembalik arah

4. Tombol pengubah mode kerja

5. Putaran saja

6. Putaran dengan getar

7. Sekrup putar

8. Tonjolan

9. Alur

10. Kepala tirus

11. Gemuk mata mesin

12. Mata mesin

13. Tutup cekam

14. Pengukur kedalaman

15. Adaptor cekam

16. Cekam bor tanpa kunci

Model MT870

Kapasitas

Beton 22 mm

Mata bor berteras 54 mm

Mata bor berteras intan (tipe kering) 65 mm

Baja 13 mm

Kayu 32 mm

Kecepatan tanpa beban (min-1)0 - 1.100

Hembusan per menit 0 - 4.350

Panjang keseluruhan 362 mm

Berat bersih 2,5 kg

Kelas keamanan /II

9

Keamanan kelistrikan

4. Steker mesin listrik harus cocok dengan

stopkontak. Jangan sekali-kali mengubah steker

dengan cara apa pun. Jangan menggunakan

steker adaptor dengan mesin listrik berarde

(dibumikan). Steker yang tidak diubah dan

stopkontak yang cocok akan mengurangi risiko

sengatan listrik.

5. Hindari sentuhan tubuh dengan permukaan

berarde atau yang dibumikan seperti pipa,

radiator, kompor, dan kulkas. Risiko sengatan listrik

bertambah jika tubuh Anda terbumikan atau terarde.

6. Jangan membiarkan mesin listrik kehujanan atau

kebasahan. Air yang masuk ke dalam mesin listrik

akan meningkatkan risiko sengatan listrik.

7. Jangan menyalahgunakan kabel. Jangan sekali-

kali menggunakan kabel untuk membawa,

menarik, atau mencabut mesin listrik dari

stopkontak. Jauhkan kabel dari panas, minyak,

tepian tajam, atau bagian yang bergerak. Kabel

yang rusak atau kusut memperbesar risiko sengatan

listrik.

8. Bila menggunakan mesin listrik di luar ruangan,

gunakan kabel ekstensi yang sesuai untuk

penggunaan di luar ruangan. Penggunaan kabel

yang sesuai untuk penggunaan luar ruangan

mengurangi risiko sengatan listrik.

9. Jika mengoperasikan mesin listrik di lokasi

lembap tidak terhindarkan, gunakan pasokan daya

yang dilindungi peranti imbasan arus (residual

current device - RCD). Penggunaan RCD

mengurangi risiko sengatan listrik.

10. Penggunaan pasokan daya melalui RCD dengan

kapasitas arus sisa 30 mA atau kurang selalu

dianjurkan.

Keselamatan diri

11. Jaga kewaspadaan, perhatikan pekerjaan Anda

dan gunakan akal sehat bila menggunakan mesin

listrik. Jangan menggunakan mesin listrik saat

Anda lelah atau di bawah pengaruh obat bius,

alkohol, atau obat. Sekejap saja lalai saat

menggunakan mesin listrik dapat menyebabkan

cedera diri yang serius.

12. Gunakan alat pelindung diri. Selalu gunakan

pelindung mata. Peralatan pelindung seperti masker

debu, sepatu pengaman anti-selip, helm pengaman,

atau pelindung telinga yang digunakan untuk kondisi

yang sesuai akan mengurangi risiko cedera diri.

13. Cegah penyalaan yang tidak disengaja. Pastikan

bahwa sakelar berada dalam posisi mati (off)

sebelum menghubungkan mesin ke sumber daya

dan/atau baterai, atau mengangkat atau

membawanya. Membawa mesin listrik dengan jari

Anda pada sakelarnya atau mengalirkan listrik pada

mesin listrik yang sakelarnya hidup (on) akan

mengundang kecelakaan.

14. Lepaskan kunci-kunci penyetel sebelum

menghidupkan mesin listrik. Kunci-kunci yang

masih terpasang pada bagian mesin listrik yang

berputar dapat menyebabkan cedera.

15. Jangan meraih terlalu jauh. Jagalah pijakan dan

keseimbangan sepanjang waktu. Hal ini

memungkinkan kendali yang lebih baik atas mesin

listrik dalam situasi yang tidak diharapkan.

16. Kenakan pakaian dengan baik. Jangan memakai

pakaian yang kedodoran atau perhiasan. Jaga

jarak antara rambut, pakaian, dan sarung tangan

Anda dengan bagian mesin yang bergerak.

Pakaian kedodoran, perhiasan, atau rambut panjang

dapat tersangkut pada bagian yang bergerak.

17. Jika tersedia fasilitas untuk menghisap dan

mengumpulkan debu, pastikan fasilitas tersebut

terhubung listrik dan digunakan dengan baik.

Penggunaan pembersih debu dapat mengurangi

bahaya yang terkait dengan debu.

Penggunaan dan pemeliharaan mesin listrik

18. Jangan memaksa mesin listrik. Gunakan mesin

listrik yang tepat untuk keperluan Anda. Mesin

listrik yang tepat akan menuntaskan pekerjaan

dengan lebih baik dan aman pada kecepatan sesuai

rancangannya.

19. Jangan gunakan mesin listrik jika sakelar tidak

dapat menyalakan dan mematikannya. Mesin listrik

yang tidak dapat dikendalikan dengan sakelarnya

adalah berbahaya dan harus diperbaiki.

20. Cabut steker dari sumber listrik dan/atau baterai

dari mesin listrik sebelum melakukan penyetelan,

penggantian aksesori, atau menyimpan mesin

listrik. Langkah keselamatan preventif tersebut

mengurangi risiko hidupnya mesin secara tak

sengaja.

21. Simpan mesin listrik jauh dari jangkauan anak-

anak dan jangan biarkan orang yang tidak paham

mengenai mesin listrik tersebut atau petunjuk ini

menggunakan mesin listrik. Mesin listrik sangat

berbahaya di tangan pengguna yang tak terlatih.

22. Rawatlah mesin listrik. Periksa apakah ada bagian

bergerak yang tidak lurus atau macet, bagian yang

pecah dan kondisi lain yang dapat mempengaruhi

penggunaan mesin listrik. Jika rusak, perbaiki

dahulu mesin listrik sebelum digunakan. Banyak

kecelakaan disebabkan oleh kurangnya pemeliharaan

mesin listrik.

23. Jaga agar mesin pemotong tetap tajam dan bersih.

Mesin pemotong yang terawat baik dengan mata

pemotong yang tajam tidak mudah macet dan lebih

mudah dikendalikan.

24. Gunakan mesin listrik, aksesori, dan mata mesin,

dll. sesuai dengan petunjuk ini, dengan

memperhitungkan kondisi kerja dan jenis

pekerjaan yang dilakukan. Penggunaan mesin listrik

untuk penggunaan yang lain dari peruntukan dapat

menimbulkan situasi berbahaya.

Servis

25. Berikan mesin listrik untuk diperbaiki hanya

kepada oleh teknisi yang berkualifikasi dengan

menggunakan hanya suku cadang pengganti yang

serupa. Hal ini akan menjamin terjaganya keamanan

mesin listrik.

26. Patuhi petunjuk pelumasan dan penggantian

aksesori.

27. Jagalah agar gagang kering, bersih, dan bebas

dari minyak dan gemuk.

10

GEB007-7

PERINGATAN KESELAMATAN

BOR GETAR ROTARI

1. Kenakan pelindung telinga. Terpaan kebisingan

dapat menyebabkan hilangnya pendengaran.

2. Gunakan gagang tambahan, jika disertakan

bersama mesin ini. Kehilangan kendali dapat

menyebabkan cedera.

3. Pegang mesin listrik pada permukaan genggam

yang terisolasi saat melakukan pekerjaan bila

aksesori pemotong mungkin bersentuhan dengan

kawat tersembunyi atau kabelnya sendiri. Aksesori

pemotong yang menyentuh kawat “hidup” dapat

menyebabkan bagian logam pada mesin teraliri arus

listrik dan menyengat pengguna.

4. Kenakan helm pengaman, kaca mata pengaman

dan/atau pelindung muka. Kaca mata biasa atau

kaca mata hitam BUKANLAH kaca mata

pengaman. Anda sangat dianjurkan untuk

mengenakan masker debu dan sarung tangan

tebal.

5. Pastikan mata mesin terpasang pada tempatnya

sebelum penggunaan.

6. Pada penggunaan normal, mesin dirancang untuk

menghasilkan getaran. Sekrup bisa menjadi

longgar dengan mudah, menyebabkan kerusakan

atau kecelakaan. Periksa kekencangan sekrup

sebelum penggunaan.

7. Pada cuaca dingin atau ketika mesin telah lama

tidak digunakan, lakukan pemanasan pada mesin

beberapa saat dengan mengoperasikannya tanpa

beban. Hal ini akan memperlancar pelumasan.

Tanpa pemanasan yang tepat, pengerjaan dengan

getaran menjadi sulit.

8. Selalu pastikan Anda berada di atas alas yang

kuat.

Pastikan tidak ada orang di bawahnya bila Anda

menggunakan mesin di tempat yang tinggi.

9. Pegang mesin kuat-kuat dengan kedua tangan.

10. Jauhkan tangan dari bagian yang bergerak.

11. Jangan tinggalkan mesin dalam keadaan hidup.

Jalankan mesin hanya ketika digenggam tangan.

12. Jangan mengarahkan mesin pada siapapun di

tempat kerja ketika mengoperasikan. Mata mesin

bisa terlempar dan melukai orang dengan serius.

13. Jangan menyentuh mata mesin atau benda kerja

segera setelah pengoperasian; suhunya mungkin

masih sangat panas dan dapat membakar kulit

Anda.

14. Bahan tertentu mengandung zat kimia yang

mungkin beracun. Hindari menghirup debu dan

persentuhan dengan kulit. Ikuti data keselamatan

bahan dari pemasok.

SIMPAN PETUNJUK INI.

PERINGATAN:

JANGAN biarkan kenyamanan atau terbiasanya Anda

dengan produk (karena penggunaan berulang)

menggantikan kepatuhan yang ketat terhadap aturan

keselamatan untuk produk yang terkait.

PENYALAHGUNAAN atau kelalaian mematuhi kaidah

keselamatan yang tertera dalam petunjuk ini dapat

menyebabkan cedera badan serius.

DESKRIPSI FUNGSI

PERHATIAN:

•Selalu pastikan bahwa mesin dalam keadaan mati dan

steker tercabut sebelum menyetel atau memeriksa

kerja mesin.

Kerja saklar (Gb. 1)

PERHATIAN:

• Sebelum memasukkan steker, selalu periksa apakah

picu saklar berfungsi dengan baik dan kembali ke

posisi “OFF” saat dilepas.

•Saklar bisa dikunci dalam posisi “ON” untuk memberi

kenyamanan pada operator selama penggunaan terus-

menerus. Selalu berhati-hati ketika mengunci mesin

dalam posisi “ON” dan pegang mesin kuat-kuat.

Untuk menjalankan mesin, cukup tarik picu saklarnya.

Kecepatan mesin akan meningkat dengan menambah

tekanan pada picu saklar. Lepaskan picu saklar untuk

berhenti. Untuk penggunaan terus-menerus, tarik picu

saklar, tekan tombol kunci dan kemudian lepas picu

saklar. Untuk membebaskan posisi terkunci, tarik picu

saklar sampai penuh, lalu lepaskan.

Kerja saklar pembalik arah (Gb. 2)

PERHATIAN:

•Selalu periksa arah putaran sebelum penggunaan.

• Gunakan saklar pembalik arah hanya setelah mesin

benar-benar berhenti. Mengubah arah putaran

sebelum mesin berhenti dapat merusak mesin.

•Jika picu saklar tidak bisa ditekan, pastikan bahwa

saklar pembalik arah diposisikan sepenuhnya ke posisi

(sisi A) atau (sisi B).

Mesin ini memiliki saklar pembalik arah untuk mengubah

arah putaran. Gerakkan tuas saklar pembalik arah ke

posisi (sisi A) untuk putaran searah jarum jam atau

posisi (sisi B) untuk putaran berlawanan arah jarum

jam.

Memilih mode kerja (Gb. 3)

Mesin ini menggunakan tombol pengubah mode kerja.

Pilih salahsatu dari dua mode yang sesuai untuk

kebutuhan kerja Anda dengan menggunakan tombol ini.

Untuk putaran saja, putar tombol sehingga tanda panah

pada tombol mengarah ke simbol pada badan mesin.

Untuk putaran dengan getar, putar tombol sehingga tanda

panah pada tombol mengarah ke simbol pada badan

mesin.

PERHATIAN:

• Selalu posisikan tombol sepenuhnya pada simbol

mode yang diinginkan. Jika anda memakai alat dengan

tombol berada di posisi tengah antara kedua simbol

mode alat bisa rusak.

•Gunakan tombol hanya setelah mesin berhenti penuh.

Pembatas torsi

Pembatas torsi akan berfungsi ketika mencapai tingkat

torsi tertentu. Motor akan terlepas dari poros keluaran.

Ketika hal ini terjadi, mata bor akan berhenti berputar.

11

PERHATIAN:

•Segera setelah pembatas torsi berfungsi, matikan

mesin dengan segera. Hal ini akan membantu

mencegah keausan dini pada mesin.

• Mata mesin seperti gergaji lubang, yang cenderung

terjepit atau terperangkap dalam lubang dengan

mudah, tidak sesuai untuk mesin ini. Karena hal ini

akan menyebabkan pembatas torsi terlalu sering

berfungsi.

PERAKITAN

PERHATIAN:

• Selalu pastikan bahwa mesin dalam keadaan mati dan

steker tercabut sebelum melakukan pekerjaan apapun

pada mesin.

Gagang sisi (pegangan tambahan) (Gb. 4)

PERHATIAN:

• Gunakan selalu gagang sisi untuk menjamin

keselamatan penggunaan.

Pasang gagang sisi sedemikian rupa hingga tonjolan-

tonjolan pada alas gagang berada tepat di antara alur-alur

pada silinder mesin. Lalu kencangkan sekrup putar untuk

menetapkan gagang pada posisi yang diinginkan.

Gagang dapat diputar 360° agar dapat ditahan di posisi

mana saja.

Gemuk mata mesin

Lapisi sebelumnya kepala tirus dengan sedikit gemuk

mata mesin (sekitar 0,5 - 1 g).

Pelumasan cekam ini menjamin kelancaran kerja dan

memperpanjang umur pemakaian mesin.

Memasang atau melepas mata mesin

Bersihkan kepala tirus dan beri gemuk sebelum

memasang mata mesin. (Gb. 5)

Masukkan mata mesin ke dalam mesin. Putar mata mesin

dan dorong sampai terpasang. (Gb. 6)

Setelah memasang, selalu pastikan bahwa mata mesin

benar-benar terpasang pada tempatnya dengan mencoba

menariknya keluar.

Untuk melepas mata mesin, tarik tutup cekam

sepenuhnya dan tarik mata mesin keluar. (Gb. 7)

Pengukur kedalaman (Gb. 8)

Pengukur kedalaman sangat tepat digunakan untuk

menghasilkan lubang-lubang pengeboran dengan

kedalaman yang seragam. Kendurkan sekrup putar dan

setel pengukur kedalaman pada kedalaman yang

diinginkan. Setelah penyetelan, kencangkan sekrup putar

kuat-kuat.

CATATAN:

•Pengukur kedalaman tidak bisa digunakan bila

posisinya berlawanan dengan rumahan gir/rumahan

motor.

PENGGUNAAN

Selalu gunakan gagang sisi (pegangan tambahan) dan

pegang mesin kuat-kuat pada kedua gagang sisi dan

pegangan saklar selama penggunaan.

Cara pengoperasian bor getar (Gb. 9)

Posisikan tombol pengubah mode kerja ke simbol .

Posisikan mata mesin pada lokasi yang diinginkan untuk

membuat lubang, kemudian tarik picu saklarnya. Jangan

memaksa mesin listrik. Tekanan yang ringan akan

memberi hasil yang terbaik. Jaga posisi mesin dan cegah

agar tidak selip dari lubang.

Jangan menambah tekanan bila lubang dipenuhi geram-

geram atau partikel. Tetapi, nyalakan mesin tanpa

putaran, lalu angkat mata mesin sedikit dari lubang.

Dengan melakukan hal ini beberapa kali, lubang akan

besih dan pengeboran normal bisa dilanjutkan kembali.

Posisikan tombol pengubah mode kerja ke simbol .

PERHATIAN:

• Akan timbul gaya yang sangat kuat dan tiba-tiba pada

mesin/mata mesin saat menembus lubang, bila lubang

dipenuhi geram-geram atau partikel, atau bila

menabrak besi-besi tulangan yang terpasang di dalam

beton. Selalu gunakan gagang sisi (pegangan

tambahan) dan pegang mesin kuat-kuat pada kedua

gagang sisi dan pegangan saklar selama penggunaan.

Kelalaian dalam melakukannya dapat menyebabkan

kehilangan kendali pada mesin dan berpotensi

mengakibatkan cedera berat.

CATATAN:

•Eksentrisitas pada putaran mata mesin bisa terjadi

ketika menggunakan mesin tanpa beban. Mesin akan

memusatkan diri secara otomatis selama penggunaan.

Hal ini tidak mempengaruhi kepresisian pengeboran.

Mengebor kayu atau logam (Gb. 10)

Gunakan pilihan rakitan cekam bor. Ketika

memasangnya, silakan mengacu pada “memasang atau

melepas mata mesin”.

PERHATIAN:

•Jangan sekali-kali menggunakan “putaran dengan

getar” ketika cekam bor terpasang pada mesin. Cekam

bor bisa rusak.

Cekam bor juga akan terlepas ketika membalik arah

mesin.

•Menekan mesin secara berlebihan tidak akan

mempercepat pengeboran. Bahkan, tekanan yang

berlebihan hanya akan merusak mata bor Anda,

mengurangi kinerja mesin dan memperpendek usia

mesin.

• Akan timbul gaya yang sangat kuat pada mesin/mata

bor saat menembus lubang. Pegang mesin dengan

kuat dan berhati-hatilah saat mata bor menembus

benda kerja.

• Mata bor yang macet dapat dicabut dengan menyetel

saklar pembalik arah agar mesin berputar berlawanan

arah untuk mundur. Tetapi, mesin bisa saja mundur

mendadak jika Anda tidak memegangnya dengan kuat.

•Tahan benda kerja berukuran kecil dengan penjepit

atau alat penahan lain.

Pengeboran dengan mata bor berteras

intan

Ketika melakukan pekerjaan pengeboran dengan mata

bor berteras intan, selalu posisikan tuas pengubah ke

posisi untuk menggunakan kerja “putaran saja”.

12

PERHATIAN:

•Jika melakukan pekerjaan pengeboran dengan mata

bor berteras intan menggunakan kerja “putaran dengan

getar”, mata bor berteras intan bisa rusak.

PERAWATAN

PERHATIAN:

• Selalu pastikan bahwa mesin dimatikan dan steker

dicabut sebelum melakukan pemeriksaan atau

perawatan.

•Jangan sekali-kali menggunakan bensin, tiner, alkohol,

atau bahan sejenisnya. Penggunaan bahan demikian

dapat menyebabkan perubahan warna, perubahan

bentuk atau timbulnya retakan.

Untuk menjaga KEAMANAN dan KEANDALAN mesin,

perbaikan, pemeriksaan dan penggantian sikat karbon,

serta perawatan atau penyetelan lain harus dilakukan

oleh Pusat Layanan Resmi Makita, selalu gunakan suku

cadang pengganti buatan Makita.

13

TING VIT

Gii thích v hình v tng th

THÔNG S K THUT

•Do chng trình nghiên cu và phát trin liên tc ca chúng tôi nên các thông s k thut trong ây có th thay i mà

không cn thông báo trc.

• Các thông s k thut có th thay i tùy theo tng quc gia.

•Trng lng tùy theo Quy trình EPTA tháng 01/2003

END201-5

Ký hiu

Phn di ây cho bit các ký hiu c dùng cho thit b.

m bo rng bn hiu rõ ý ngha ca các ký hiu này

trc khi s dng.

.... c tài liu hng dn.

.............. CÁCH IN KÉP

ENE042-1

Mc ích s dng

Dng c này c thit k khoan óng búa và khoan

vào gch, bê-tông và á.

Nó cng có th phù hp cho vic khoan không va p vào

g, kim loi, gm và nha.

ENF002-1

Ngun cp in

Dng c này ch c ni vi ngun cp in có in áp

ging nh ã ch ra trên bin tên và ch có th c vn

hành trên ngun in AC mt pha. Chúng c cách in

hai lp theo Tiêu chun Châu Âu và do ó cng có th

c s dng t các cm in không có dây tip t.

GEA005-3

Cnh báo An toàn Chung dành

cho Dng c Máy

CNH BÁO! c tt c các cnh báo an toàn và

hng dn. Vic không tuân theo các cnh báo và

hng dn có th dn n in git, ho hon và/hoc

thng tích nghiêm trng.

Lu gi tt c cnh báo và hng

dn tham kho sau này.

Thut ng “dng c máy” trong các cnh báo cp n

dng c máy (có dây) c vn hành bng ngun in

chính hoc dng c máy (không dây) c vn hành

bng pin ca bn.

An toàn ti ni làm vic

1. Gi ni làm vic sch s và có ánh sáng. Ni

làm vic ba bn hoc ti thng d gây ra tai nn.

2. Không vn hành dng c máy trong môi trng

cháy n, ví d nh môi trng có s hin din

ca các cht lng, khí hoc bi d cháy. Các dng

c máy to tia la in có th làm bi hoc khí bc

cháy.

3. Gi tr em và ngi ngoài tránh xa ni làm vic

khi ang vn hành dng c máy. S xao lãng có th

khin bn mt kh nng kim soát.

1. Cn khi ng công tc

2. Nút khóa

3. Cn công tc o chiu

4. Núm thay i ch hot ng

5. Ch khoan

6. Khoan óng búa

7. Vít có tai vn

8. G nhô ra

9. Các rãnh

10. u gn mi

11. Du tra u mi

12. Mi vít

13. Np ngàm

14. Thanh o sâu

15. Thanh dn ngàm

16. Ngàm khoan không cn khóa

KiuMT870

Công sut

Bê-tông 22 mm

u mi lõi 54 mm

u mi lõi kim cng (kiu khô) 65 mm

Thép 13 mm

G32 mm

Tc không ti (phút-1)0 - 1.100

S nhát mi phút 0 - 4.350

Chiu dài tng th362 mm

Trng lng tnh 2,5 kg

Cp an toàn /II

14

An toàn v in

4. Phích cm ca dng c máy phi khp vi cm.

Không bao gi c sa i phích cm theo bt

k cách nào. Không s dng bt k phích chuyn

i nào vi các dng c máy c ni t (tip

t). Các phích cm còn nguyên vn và cm phù

hp s gim nguy c in git.

5. Tránh c th tip xúc vi các b mt ni t

hoc tip t nh ng ng, b tn nhit, bp ga

và t lnh. Nguy c b in git s tng lên nu c

th bn c ni t hoc tip t.

6. Không dng c máy tip xúc vi ma hoc

trong iu kin m t. Nc lt vào dng c máy

s làm tng nguy c in git.

7. Không lm dng dây. Không bao gi s dng dây

mang, kéo hoc tháo phích cm dng c máy.

Gi dây tránh xa ngun nhit, du, các mép sc

hoc các b phn chuyn ng. Dây b hng hoc

b ri s làm tng nguy c in git.

8. Khi vn hành dng c máy ngoài tri, hãy s

dng dây kéo dài phù hp cho vic s dng ngoài

tri. Vic dùng dây phù hp cho vic s dng ngoài

tri s gim nguy c in git.

9. Nu bt buc phi vn hành dng c máy ni

m t, hãy s dng ngun cp in c bo v

bng thit b ngt dòng in rò (RCD). Vic s

dng RCD s gim nguy c in git.

10. Chúng tôi luôn khuyên bn s dng ngun cp

in qua thit b RCD có th ngt dòng in d

nh mc 30 mA hoc thp hn.

An toàn cá nhân

11. Luôn tnh táo, quan sát nhng vic bn ang làm

và s dng nhng phán oán theo kinh nghim

khi vn hành dng c máy. Không s dng dng

c máy khi bn ang mt mi hoc chu nh

hng ca ma tuý, ru hay thuc. Ch mt

khonh khc không tp trung khi ang vn hành dng

c máy cng có th dn n thng tích cá nhân

nghiêm trng.

12. S dng thit b bo h cá nhân. Luôn eo thit b

bo v mt. Các thit b bo h nh mt n chng

bi, giày an toàn chng trt, m bo h hay thit b

bo v thính giác c s dng trong các iu kin

thích hp s giúp gim thng tích cá nhân.

13. Tránh vô tình khi ng dng c máy. m bo

công tc v trí off (tt) trc khi ni ngun in

và/hoc b pin, cm hoc mang dng c máy. Vic

mang dng c máy khi ang t ngón tay v trí công

tc hoc cp in cho dng c máy ang bt thng

d gây ra tai nn.

14. Tháo mi khoá hoc chìa vn iu chnh trc khi

bt dng c máy. Vic chìa vn hoc khoá vn còn

gn vào b phn quay ca dng c máy có th dn

n thng tích cá nhân.

15. Không vi quá cao. Luôn gi thng bng tt và có

ch chân phù hp. iu này cho phép iu khin

dng c máy tt hn trong nhng tình hung bt ng.

16.

n mc phù hp. Không mc qun áo rng hay

eo trang sc. Gi tóc, qun áo và gng tay

tránh xa các b phn chuyn ng.

Qun áo rng,

trang sc hay tóc dài có th mc vào các b phn

chuyn ng.

17. Nu các thit b c cung cp kt ni các thit

b thu gom và hút bi, hãy m bo chúng c

kt ni và s dng hp lý. Vic s dng thit b thu

gom bi có th làm gim nhng mi nguy him liên

quan n bi.

S dng và bo qun dng c máy

18. Không dùng lc i vi dng c máy. S dng

úng dng c máy cho công vic ca bn. S

dng úng dng c máy s giúp thc hin công vic

tt hn và an toàn hn theo giá tr nh mc c

thit k ca dng c máy ó.

19. Không s dng dng c máy nu công tc không

bt và tt c dng c máy ó. Mi dng c máy

không th iu khin c bng công tc u rt

nguy him và cn c sa cha.

20. Rút phích cm ra khi ngun in và/hoc ngt

kt ni b pin khi dng c máy trc khi thc

hin bt k công vic iu chnh, thay i ph

tùng hay ct gi dng c máy nào. Nhng bin

pháp an toàn phòng nga này s gim nguy c vô

tình khi ng vô tình dng c máy.

21. Ct gi các dng c máy không s dng ngoài

tm vi ca tr em và không cho bt k ngi nào

không có hiu bit v dng c máy hoc các

hng dn này vn hành dng c máy. Dng c

máy s rt nguy him nu c s dng bi nhng

ngi dùng cha qua ào to.

22. Bo qun dng c máy. Kim tra tình trng lch

trc hoc bó kp ca các b phn chuyn ng,

hin tng nt v ca các b phn và mi tình

trng khác mà có th nh hng n hot ng

ca dng c máy. Nu có hng hóc, hãy sa cha

dng c máy trc khi s dng. Nhiu tai nn xy

ra là do không bo qun tt dng c máy.

23. Luôn gi cho dng c ct c sc bén và sch

s. Nhng dng c ct c bo qun tt có mép ct

sc s ít b kt hn và d iu khin hn.

24. S dng dng c máy, ph tùng và u dng c

ct, v.v... theo các hng dn này, có tính n iu

kin làm vic và công vic c thc hin. Vic s

dng dng c máy cho các công vic khác vi công

vic d nh có th gây nguy him.

Bo dng

25. nhân viên sa cha trình bo dng

dng c máy ca bn và ch s dng các b phn

thay th ng nht. Vic này s m bo duy trì

c an toàn ca dng c máy.

26. Tuân theo hng dn dành cho vic bôi trn và

thay ph tùng.

27. Gi tay cm khô, sch, không dính du và m.

GEB007-7

CNH BÁO AN TOÀN MÁY

KHOAN BÚA XOAY

1. eo thit b bo v tai. Vic tai tip xúc vi ting

n có th gây gim thính lc.

2. S dng các tay cm ph nu c cung cp kèm

theo dng c. Không iu khin c dng c s

gây ra thng tích cho con ngi.

15

3. Cm dng c máy bng b mt kp cách in khi

thc hin mt thao tác trong ó b phn ct có th

tip xúc vi dây dn kín hoc dây ca chính nó. B

phn ct tip xúc vi dây dn "có in" có th khin

các b phn kim loi b h ca dng c máy "có in"

và làm cho ngi vn hành b in git.

4. i m cng (m bo h), mang kính bo h và/

hoc mt n bo v mt. Mt thng hoc kính

râm KHÔNG phi là loi kính an toàn. Chúng tôi

ht sc khuyn cáo bn nên mang khu trang

chng bi và eo gng tay có m dày.

5. m bo rng u mi c gn cht úng v trí

trc khi vn hành.

6. Trong iu kin vn hành bình thng, dng c

c thit k to ra rung ng. Các c vít có th

d dàng b lng dn ra, gây ra hng hóc hoc tai

nn. Kim tra k cht ca các c vít trc khi

vn hành.

7. Khi thi tit lnh hoc không s dng dng c

trong thi gian dài, hãy làm nóng dng c mt lúc

bng cách vn hành không ti. iu này s giúp

du bôi trn giãn n ra. Nu không c làm

nóng úng cách, thao tác óng búa s gp khó

khn.

8. Luôn chc chn rng bn có ch ta chân vng

chc.

m bo rng không có ai di khi dùng dng

c nhng v trí trên cao.

9. Cm chc dng c bng c hai tay.

10. Gi tay tránh xa các b phn quay.

11. Không mc dng c hot ng. Ch vn hành

dng c khi cm trên tay.

12. Không c cha dng c vào bt c ai gn khi

vn hành dng c. u mi có th vng ra ngoài

và gây thng tích nghiêm trng cho ai ó.

13. Không chm vào u mi hoc các b phn gn

u mi ngay sau khi vn hành; chúng có th rt

nóng và gây bng da.

14. Mt s vt liu có cha các hóa cht có th rt

c hi. Phi cn trng tránh hít phi bi và

tip xúc vi da. Tuân theo các thông tin v an toàn

ca nhà cung cp i vi mi loi vt liu.

LU GI CÁC HNG DN NÀY.

CNH BÁO:

KHÔNG c s thoi mái hay quen thuc vi sn

phm (có c do s dng nhiu ln) thay th vic

tuân th nghiêm ngt các quy nh v an toàn dành

cho sn phm này. VIC DÙNG SAI hoc không tuân

theo các quy nh v an toàn c nêu trong tài liu

hng dn này có th dn n thng tích cá nhân

nghiêm trng.

MÔ T CHC NNG

CN TRNG:

•Phi luôn m bo rng dng c ã c tt in và

ngt kt ni trc khi chnh sa hoc kim tra chc

nng ca dng c.

Hot ng công tc (Hình 1)

CN TRNG:

•Trc khi cm in vào dng c, luôn luôn kim tra

xem cn khi ng công tc có hot ng bình thng

hay không và tr v v trí “OFF” (TT) khi nh ra.

•Công tc có th khóa v trí “ON” (BT) ngi vn

hành d dàng thun tin trong quá trình s dng kéo

dài. Cn ht sc cn trng khi khóa dng c v trí

“ON” (BT) và phi luôn gi cht dng c.

khi ng dng c, ch cn kéo cn khi ng công

tc. Tc dng c c gim xung bng cách tng lc

ép lên cn khi ng công tc. Nh cn khi ng công

tc ra dng. vn hành liên tc, hãy kéo cn khi

ng công tc, nhn nút khóa và sau ó nh cn khi

ng công tc ra. dng dng c t v trí ã khóa, hãy

kéo cn khi ng công tc ht mc, sau ó nh ra.

Hot ng công tc o chiu (Hình 2)

CN TRNG:

•Luôn luôn kim tra hng xoay trc khi vn hành.

•Ch s dng công tc o chiu sau khi dng c ã

dng hoàn toàn. Vic thay i hng xoay trc khi

dng c dng có th làm hng dng c.

•Nu không th nhn cn khi ng công tc, hãy kim

tra xem công tc o chiu có c cài y vào

úng v trí (mt A) hoc (mt B) cha.

Dng c này có mt công tc o chiu thay i chiu

xoay. Di chuyn cn gt o chiu sang v trí (mt A)

xoay theo chiu kim ng h hoc (mt B) xoay

ngc chiu kim ng h.

Chn ch hot ng (Hình 3)

Dng c này có th tn dng núm chuyn ch hot

ng. Chn mt trong hai ch phù hp vi nhu cu

công vic ca bn bng núm này.

vào ch ch khoan, hãy xoay núm sao cho mi tên

trên núm ch v phía biu tng trên thân dng c.

vào ch óng búa, hãy xoay núm sao cho mi tên

trên núm ch v phía biu tng trên thân dng c.

CN TRNG:

•Luôn luôn chnh núm này vào tht úng biu tng ch

mà bn mun. Nu bn vn hành dng c mà

núm này t gia các biu tng ch , dng c có

th b h hng.

•Ch s dng núm này sau khi dng c ã dng hoàn

toàn.

B phn gii hn lc vn xit

B phn gii hn lc vn xit s khi hot khi t ti mt

mc lc vn xit nht nh. ng c s c ngt khi

trc dn xut. Khi iu này xy ra, u mi s ngng

xoay.

CN TRNG:

•Khi b phn gii hn lc vn xit khi hot, hãy tt

dng c ngay càng sm khi có th. iu này s giúp

ngn nga dng c b mài mòn quá sm.

•Các u mi chng hn nh ca l có khuynh hng

d dàng b kp hoc kt vào trong l s không phù hp

vi dng c này. iu này là do chúng s làm cho b

phn gii hn lc vn xit khi hot quá thng

xuyên.

16

LP RÁP

CN TRNG:

•Luôn luôn m bo rng dng c ã c tt và tháo

phích cm trc khi dùng dng c thc hin bt c

công vic nào.

Tay cm hông (tay nm ph tr) (Hình 4)

CN TRNG:

•Luôn s dng tay cm hông m bo vn hành an

toàn.

Lp t tay cm hông sao cho phn nhô ra ca tay cm

khp vào gia các rãnh trên tang trng dng c. Sau ó

hãy vn vít có tai vn c nh tay cm ti v trí mong

mun. Tay cm có th xoay 360° c gi cht bt

c v tr nào.

Du tra u mi

Ph lên phía trc thân u mi mt lng nh du tra

u mi (khong 0,5 - 1 g).

Cht bôi trn ngàm này nhm m bo vn hành trôi

chy và kéo dài tui th dng c hn.

Vic lp t hoc tháo g u mi

V sinh thân u mi và bôi du tra u mi trc khi lp

u mi. (Hình 5)

Lp u mi và dng c. Xoay u mi và nhn vào cho

n khi nào vào khp. (Hình 6)

Sau khi lp, hãy luôn m bo rng u mi ã c gi

chc chn úng v trí bng cách th kéo ra.

tháo u mi, kéo np ngàm xung ht mc và kéo

u mi ra. (Hình 7)

Thanh o sâu (Hình 8)

Thanh o sâu rt thun tin khoan các l có chiu sâu

ng nht. Vn lng vít có tai vn và iu chnh thanh o

sâu n sâu mong mun. Sau khi iu chnh, vn cht

vít có tai vn li.

LU Ý:

• Thanh o sâu không th dùng v trí ni thanh o sâu

vng vào v ngoài hp s/v ngoài motor.

VN HÀNH

Luôn s dng tay cm bên hông (tay cm ph tr) và gi

cht dng c bng c hai tay cm bên hông và i tay

cm trong lúc vn hành.

Thao tác khoan búa (Hình 9)

Cài núm chuyn ch n biu tng .

nh v u mi vào v trí mong mun cho l khoan, sau

ó kéo cn khi ng công tc. Không dùng lc i vi

dng c máy. n nh s mang li kt qu tt nht. Gi

cho dng c úng v trí và ngn không b trt khi l

khoan.

Không c n mnh khi l khoan bt u b nghn bi

các mt vn và các ht. Thay vào ó, hãy chy dng c

ch ch, sau ó tháo riêng mi khoan khi l. Bng

cách lp li thao tác này vài ln, l khoan s c sch

s và có th tip tc khoan bình thng.

Cài núm chuyn ch n biu tng .

CN TRNG:

•S có lc xon rt ln và bt ng trên dng c/mi

khoan lúc l khoan c xuyên thng, khi l khoan bt

u b kt bi các mt vn và ht hoc khi ng vào

các thép gia cng có trong bê-tông. Luôn s dng tay

cm bên hông (tay cm ph tr) và gi cht dng c

bng c hai tay cm bên hông và i tay cm trong lúc

vn hành. Không làm nh vy có th mt iu khin

dng c và gây thng tích nghiêm trng.

LU Ý:

•Có th b lch tâm khi xoay u mi trong lúc vn hành

dng c không ti. Dng c s t ng chnh úng tâm

trong lúc vn hành. iu này không nh hng n

chính xác khi khoan.

Khoan trong g hoc kim loi (Hình 10)

S dng b phn ngàm khoan tùy chn. Khi lp nó, tham

kho phn “Lp hoc tháo u mi”.

CN TRNG:

•Không bao gi s dng ch “khoan óng búa” khi

ngàm khoan c lp trên dng c. Ngàm khoan có

th b h hng.

Ngoài ra, ngàm khoan s ri ra khi o chiu xoay

dng c.

•Nhn dng c quá mc s không tng tc khoan lên

c. Trên thc t, vic nhn mnh thêm này s ch

làm gây hng u mi ca bn, gim hiu nng và tui

th hot ng ca dng c.

•S có lc xoay rt ln trên dng c/mi khoan lúc l

khoan c xuyên thng. Gi cht dng c và chun

b ghìm lc quán tính li khi mi khoan xuyên thng vt

gia công.

•Mi khoan b kt có th c tháo ra n gin bng

cách t công tc o chiu sang ch xoay ngc

li rút mi khoan ra. Tuy nhiên, dng c có th quay

ngc ra bt ng nu bn không gi cht.

•Luôn luôn gi cht các vt gia công có kích thc nh

bng kìm hoc dng c kp tng t.

Khoan bng lõi kim cng

Khi thc hin các thao tác khoan bng lõi kim cng, luôn

luôn cài cn chuyn ch sang v trí s dng ch

“ch khoan”.

CN TRNG:

•Nu thc hin các thao tác khoan bng lõi kim cng

ch “khoan óng búa”, lõi kim cng có th b h

hng.

BO TRÌ

CN TRNG:

• Hãy luôn chc chn rng dng c ã c tt và ngt

kt ni trc khi c gng thc hin vic kim tra hay

bo dng.

•Không bao gi dùng xng, ét xng, dung môi, cn

hoc hóa cht tng t. Có th xy ra hin tng mt

màu, bin dng hoc nt v.

m bo AN TOÀN và TIN CY ca sn phm, vic

sa cha hoc bt c thao tác bo trì, iu chnh nào u

phi c thc hin bi các Trung tâm Dch v c y

quyn ca Makita (Makita Authorized Service Center),

luôn s dng các ph tùng thit b thay th ca Makita.

17

!"#"$%&

'(")*+,"&-)./0//).%123$4

!"#$%&'()*+),

!!"#$%&'())(*+,"+-,(-.'/01234/5"(%06(&

76%!"#$%& 8,%9:2';(!4(3<"!%)=(*>?/?"@A%('

!B2@$0"1B2&CD,ED0C967,%&1',&<F,G*(?26-&F",(

!8,%9:2';(!4(3%('17)76(&)/"CB<"17623B*3!GH

!"A;(F"/)7(98,%?/&+/?8%& EPTA 01/2003

END201-5

!"#$"%&'(

76%CB"@A+#%=/I2/)JKLG@$<M,=;(F*/?%NB)*KL

EB*DHO)J(+-(9F9(08%&=/I2/)JKL<F,!8,(<')6%")(*<M,&("

..... %6("+:69#%)(*<M,&("

................ >"-"=%&M/A"

ENE042-1

!"#$%&'()*+,(-)%./,(0.,

!+*#$%&9#%"@A<M,=;(F*/?!'(3)*31G)123!'(3%.P +%")*@7 F."

1230/&!F9(3=;(F*/?<M,!'(3ED0C969@)(*)*31G))/?C9,E2F3

!Q*(9.+ 12342(=7.)

ENF002-1

12%!32456

7,%&!M#$%976%!+*#$%&9#%)/?!+*#$%&'6(0CRG@$9@1*&!+2#$%"CRRS(7(9G@$

*3?NC-,<"BS(08,%9:2!+*#$%&9#% 123'37,%&<M,CRRS()*31==2/?1??

!R=!D@0-!G6("/A" %NB)*KL"@ACD,*/?)(*FN,9>"-"=%&M/A"7(99(7*P("

European Standard 123=(9(*T<M,)/?B2/U)CRG@$C969@=(0D."CD,

GEA005-3

-()*./#01")0-2)$3ְ!#7

*-8/9#7$/#:;;<)=592:3

!"#$%&'(! ')#(!"#$%&'(*+#(!,#-./'*0123/4!"#3(4(5

61789-*

!"#$%&'()*+,),"%-."/,012345-."3252."6+7!4&"81"9:&7;4

<=>/!)6$??@"AB1, $?$=%>345/=#01$6>#+**"6/9B*1C&"7#>"C3#7

1. =-.7ML=/$&&("

2. BNV92W%+

3. ),("=-.7ML!B2@$0"G.HG(&

4. BNV9F9N"!B2@$0"EF9D)(*G;(&("

5. )(*F9N"%06(&!D@0-

6. )(*F9N"4*,%9)*31G)

7. =)*:F(&1?"

8. =6-"G@$0#$"%%)9(

9. *6%&

10. ),("D%)=-6("

11. '(*3?@D%)=-6("

12. D%)=-6("

13. X(+*%?F/-'/?

14. !)'-/D+-(92O)

15. 7/-1B2&F/-'/?

16. F/-'/?D%)=-6("1??C969@)NI1'

*N6" MT870

+-(9=(9(*T<")(*!'(3

+%")*@7 22 99.

1)"D%)=-6(" 54 99.

D%)=-6("1)"!4M* (M".D1F,&)65

99.

E2F3 13 99.

C9,32 99.

+-(9!*W-8K3F9N"!B26( (*%?76%"(G@)0-1,100

%/7*(!'(3)*31G)76%"(G@ 0 - 4,350

+-(90(-ED0*-9 362 99.

"A;(F"/)=NGY. 2.5 99.

9(7*P("+-(9B2%DZ/0 /II

18

*>?@85>A)-()*./#0B&,-()B0,0()=5C7D$1

:2"*3E0!"#$%&#")7#F7G0#0)-.

+;(-6( "!+*#$%&9#%CRRS(#<"+;(!7#%""@A F9(0TO& !+*#$%&9#%CRRS( (9@

=(0) G@$G;(&("ED0<M,)*31=CRRS( F*#%!+*#$%&9#%CRRS( (C*,=(0) G@$

G;(&("ED0<M,1?7!7%*@$

)720$8,#9:4+,(;.<=>?/>@2(2=

1. #AB8;.<=>?/>@2(2=CDE0?)720'&,2#B8&0?B'(56'732( 4#A"G@$

*)*3!)3*3)3F*#%9#DGO?%('";(CB=:6)(*!).D%N?/7.!F7NCD,

2. ,432CFE(2=-)%./,(0.,566G2C='92;>?/,2!-1H#12%%&-IH#

-F3= C='J2=>?/>?/0?+,(-D87 1K2L D%.,M"N=O(>?/0?)"P'0I:QH

5756 !+*#$%&9#%CRRS('3=*,(&B*3)(0CR!4#$%'NDM"-"

XNV"[&

F*#%)\(QD/&)26(-

3.

*:3/;-)<9+-=$*>?@ 9A&'BC!!/'&D('2:)<(BAE$,F6=D?"#/18<G+

$!A&D'8-&';HHI#

!"#%D:)E7#*!82:%"F)1"9G."<=>-HI:JK/:DC

!"#-8*-H%

)720$8,#9:4#E2=566G2

4. $8:R1+,(-)%./,(0.,566G2QE,(;,#?1:I-QE2%:I ,432#:#B$8(

$8:R15037321%P?C#S ,432CFE$8:R1,&B#T$-Q,%*1:I

-)%./,(0.,

566G2>?/Q3,'24#H= B2/U)G@$C96T:)D/D1B2&123!7,(*/?CRG@$!8,()/"

4%D@'3M6-02D+-(9!=@$0&8%&)(*!).DCRRS(MW%7

5. %&7:(,432CDE%32(124':0O:'1:I;.<=OH7>?/Q3,'24#H= -F3= >3,

-)%./,(=@2)720%E,= -Q2D"(QE0 B8&QAE-4T= 9@+-(9!=@$0&G@$'3

!).DCRRS(MW%7=:&8OA" F()*6(&)(08%&+NK=/9[/=)/?4#A"

6. ,432CDE-)%./,(0.,566G2JA1=<@2D%.,,4A3C='92;-$U41F.<= "A;(

G@$CF2!8,(CB<"!+*#$%&9#%CRRS('3!4.$9+-(9!=@60&8%&)(*!).D

CRRS(MW%7

7. ,432CFE'2456,432(503-D02&'0 ,432CFE'2456-;./,41 #V(

D%., J,#$8:R1-)%./,(0.,566G2 -1TI'2456CDED32(!21

)720%E,= =<@20:= +,(0?)0 D%.,FH<='37=>?/-)8./,=>?/ =(0G@$

M;(*NDF*#%4/")/"'3!4.$9+-(9!=@$0&8%&)(*!).DCRRS(MW%7

8. +P&>?/CFE(2=-)%./,(0.,566G2=,1,2)2% )7%CFE'24Q3,

;37(>?/-D02&'01:I(2=924=,1,2)2% )(*<M,=(0G@$

!F9(3=9)/?&("Z(0"%)%(+(*'32D+-(9!=@$0&8%&)(*!).D

CRRS(MW%7

9. D21QE,(CFE(2=-)%./,(0.,566G2C='J2=>?/-$U41F.<= CDECFE

,"$1%P*$G,(1:=1%&B'56%:/7 (RCD) )(*<M,RCD '32D

+-(9!=@$0&8%&)(*!).DCRRS(MW%7

10. +,B=&=@2CDECFEBD83(!32456O32= RCD >?/0?1%&B'56%:/7

C=,:Q%2503-1H= 30 mA -'0,

)720$8,#9:4'37=I"))8

11. CDE%&0:#%&7:( B8&':(-1Q-'0,732)"P1@28:(>@2'H/(C#,4A3

B8&CFE'20:W'@2=V1C=+P&CFE(2=-)%./,(0.,566G2 ,432CFE

(2=-)%./,(0.,566G2C=+P&>?/)"P1@28:(-D=./,4 D%.,C=

'92;>?/0V=-02!2142-';QH# -)%./,(#./0B,81,X,8*D%.,

12%CFE42 M/$-8K3G@$8(D+-(9*39/D*3-/&!9#$%);(2/&<M,&("

!+*#$%&9#%CRRS(%('G;(<F,+NKCD,*/??(D!'W?%06(&*N"1*&

12. CFE,"$1%P*$G,(1:='37=I"))8 '70B73=Q2$G,(1:=-'0,

%NB)*KLBS%&)/" !M6" F",()())/"XNV" *%&!G,(".*Z/0)/"2#$" F9-)

".*Z/0 F*#%!+*#$%&BS%&)/")(*CD,0."G@$<M,<"=Z(4G@$!F9(3=9'3

M6-02D)(*?(D!'W?

13. $G,(1:=503CDE-$Y#CFE(2=,432(503Q:<(C! Q%7!',I732'7HQF*

,4A3C=Q@2BD=3($Y#13,=-F./,0Q3,1:IBD83(!32456 B8&/D%.,

F"#BIQ-Q,%?/ D%.,13,=12%41D%.,J.,-)%./,(0., )(*=%D

".A-9#%?*.!-K=-.7ML!4#$%T#%!+*#$%&9#%CRRS( F*#%)(*M(*L'CR

!+*#$%&9#%CRRS(<"8K3G@$!B]D=-.7ML%0:6%('";(CB=:6)(*!).D

%N?/7.!F7N

14. =@21"WB!$%:IBQ3(D%.,$%&B!,,113,=>?/!&-$Y#-)%./,(0.,

566G2 B*31'F*#%)NI1'G@$!=@0?+,(&%0:6<"M.A"=6-"G@$F9N"CD,8%&

!+*#$%&9#%CRRS(%('G;(<F,+NKCD,*/??(D!'W?

15. ,432>@2(2=C=%&4&>?/'"#-,.<,0 !:#>3212%4.=B8&12%

>%(Q:7CDE-D02&'0Q8,#-782 !4*(3'3G;(<F,+-?+N9

!+*#$%&9#%CRRS(CD,D@8OA"<"=T(")(*KLG@$C96+(D+.D

16. BQ3(124CDE-D02&'0 ,432'70-)%./,(BQ3(124>?/D870-1H=

5$ D%.,'70-)%./,($%&#:I #AB8503CDE-'E=O0 -'.<,OE2 B8&

J"(0.,,4A3C18EFH<='37=>?/-)8./,=>?/ !=#A%[,(*N69*6(9 !+*#$%&B*3D/?

F*#%[9G@$9@+-(90(-%('!8,(CB7.D<"M.A"=6-"G@$!+2#$%"G@$

17. D210?12%!:#,"$1%P*'@2D%:I#A#B8&!:#-1TIM"N=57EC=

'J2=>?/CDEQ%7!',I7325#E-F./,0Q3,B8&CFE(2=,"$1%P*=:<=

,432(-D02&'0 )(*<M,!+*#$%&D:D123'/D!)W?XNV"'3M6-02D

%/"7*(0G@$!).D'()XNV"[&CD,

12%CFEB8&#AB8-)%./,(0.,566G2

18. ,432MZ=CFE-)%./,(0.,566G2 CFE-)%./,(0.,566G2>?/-D02&'0

1:I12%CFE(2=+,()"P !+*#$%&9#%CRRS(G@$!F9(3=9'3G;(<F,CD,

&("G@$9@B*3=.GY.Z(4123B2%DZ/0)-6(7(98@D+-(9=(9(*T

8%&!+*#$%&G@$CD,*/?)(*%%)1??9(

19. ,432CFE-)%./,(0.,566G2 D21'7HQF*503'202%J-$Y#$Y#5#E

!+*#$%&9#%CRRS(G@$+-?+N9D,-0=-.7MLC96CD,!B^"=.$&%/"7*(0123

7,%&CD,*/?)(*Q6%91Q9

20. J,#$8:R1!21BD83(!32456 B8&/D%.,F"#BIQ-Q,%?/,,1

!21-)%./,(0.,566G213,=>@212%$%:IBQ3( -$8?/4=,"$1%P*

-'%H0 D%.,!:#-1TI-)%./,(0.,566G2 -.Y@)(*BS%&)/"D,("+-(9

B2%DZ/0D/&)26(-'3M6-02D+-(9!=@$0&8%&)(*!B]D<M,&("

!+*#$%&9#%CRRS(%06(&C967/A&<'

21. !:#-1TI-)%./,(0.,566G2>?/5035#ECFE(2=CDED32(!210.,-#T1

B8&,432,="W2QCDEI"))8>?/503)"E=-)41:I-)%./,(0.,566G2

D%.,)@2B=&=@2-D832=?<CFE(2=-)%./,(0.,566G2 !+*#$%&9#%

CRRS('3!B^"%/"7*(0!9#$%%0:6<"9#%8%&[:,G@$C96CD,*/?)(*X_)%?*9

22. 12%#AB8%:1[2-)%./,(0.,566G2 Q%7!',I12%$%&1,I>?/

503JA1QE,(D%.,12%-F./,0Q3,+,(FH<='37=

>?/-)8./,=>?/ 12%

19

BQ1D:1+,(FH<='37= D%.,'92;,./=S >?/,2!'3(O81%&>I

Q3,12%>@2(2=+,(-)%./,(0.,566G2 D210?)720-'?4D24 CDE

=@2-)%./,(0.,566G25$L3,0BL013,=12%CFE(2= %N?/7.!F7N

';("-"9()!).D'())(*D:12*/)J(!+*#$%&9#%CRRS(%06(&C96

T:)7,%&

23. 8:I)720)0B8&>@2)720'&,2#-)%./,(0.,12%Q:#,4A3-'0,

!+*#$%&9#%)(*7/DG@$9@)(*D:12%06(&T:)7,%&1239@8%?)(*7/D+9

9/)'39@B`IF(7.D8/D",%0123+-?+N9CD,&6(0)-6(

24. CFE-)%./,(0.,566G2 ,"$1%P*-'%H0 B8&7:'#"'H<=-$8.,( \8\

Q20)@2B=&=@2#:(18327 ;H!2%P2'92;12%>@2(2=B8&

(2=>?/!&8(0.,>@2 )(*<M,!+*#$%&9#%CRRS(!4#$%G;(&("%#$""%)

!F"#%'()G@$);(F"DC-,%('G;(<F,!).D%/"7*(0

12%I%H12%

25. =@2-)%./,(0.,566G2-+E2%:II%H12%!21F32(L3,0

>?/O32=12%

%:I%,(]#4CFE,&5D83BII-#?471:=->32=:<= !4*(3'3G;(<F,

)(*<M,!+*#$%&9#%CRRS(9@+-(9B2%DZ/0

26.

.JEB1%E%#-!"#3(4("#<(?#A9/)'/&D(3/4?#A$./=D2(

'C.?AFK$LAE-

27. #AB80.,!:ICDEBDE( '&,2# B8&5030?=<@20:=B8&!2%&I?

-$Z^,=

GEB007-7

-()*./#01")0-2)$3ְ!#7

H2I)0J8.)8K9

1. '70C'3,"$1%P*$G,(1:=-'?4( !=@0&G@$D/&!)."8"(D%('G;(<F,

=:I!=@0)(*CD,0."

2. CFE0.,!:I-'%H0 JE20?021:I-)%./,( )(*=:I!=@0+-(9+-?+N9

%('G;(<F,!).D)(*?(D!'W?

3. J.,-)%./,(0.,I%H-7P0.,!:I>?/-$_=`=7= +P&>@2(2=>?/

-)%./,(0.,Q:#,2!':0O:'1:I'2456>?/L3,=,4A3D%.,'2456

+,(-)%./,(-,( !+*#$%&9#%7/DG@$=/9[/=)/?=(0CRG@$ "9@)*31=

CRRS(CF2[6("#%('G;(<F,=6-"G@$!B^"E2F38%&!+*#6%&9#%CRRS(G@$

C969@>"-"FN,9 "9@)*31=CRRS(CF2[6("#123G;(<F,[:,Ba.?/7.&("

T:)CRRS(MW%7CD,

4. '70D071B+T( (D071=H%9:4) B73==H%9:4 B8&/D%.,

D=E2121$G,(1:= B73=Q2$1QHD%.,B73=1:=B##503CF3B73=

=H%9:4 B8&+,B=&=@2,432(4H/(CDE'70D=E21211:=M"3=B8&

J"(0.,D=2S

5. Q%7!',ICDEB=3C!732#,1'732=4V#B=3=-+E2>?/#?B8E713,=

12%CFE(2=

6. 924CQE12%>@2(2=$1QH -)%./,(0.,5#E%:I12%,,1BII02

-;./,'%E2(B%(':/='&->.,= #:(=:<= '1%AQ32(S !&D8705#E

(324 LV/(,2!>@2CDE-)%./,(-'?4D%.,-1H#,"I:QH-DQ"Q%7!',I

CDEB=3C!732+:='1%AB=3=#?B8E713,=12%CFE(2=

7. C='92;,212aD=27D%.,-0./,5030?12%CFE-)%./,(0.,-$_=

%&4&-782=2= QE,(,"3=-)%./,(0.,':1)%A3]#412%-$Y#-)%./,(

>H<(57E-`4S -;./,CDE0?12%D83,8./= D215030?12%,"3=-)%./,(

0.,,432(-D02&'0 12%-!2&'1:#!&>@25#E421

8. Q%7!',II%H-7P>?/4.=CDE0?)7200:/=)(-'0,D21CFE(2=

-)%./,(0.,C=;.<=>?/'A( %&7:(,432CDE0?)=,4A3#E2=832(

9. !:I-)%./,(0.,CDEB=3=#E740.,>:<(',(+E2(

10. %&7:(,432CDE0.,':0O:'1:IFH<='37=>?/-)8./,=>?/

11. ,432$83,4CDE-)%./,(0.,>@2(2=)E2(57ECFE(2=-)%./,(0.,C=

+P&>?/J.,,4A3->32=:<=

12. ,432CFE-)%./,(0.,F?<5$>?/I"))8C#C=;.<=>?/>@2(2=+P&CFE(2=

#,1'732=,2!D8"#,,1B8&>@2CDE5#E%:II2#-!TI%E24B%(

5#E

13. DE20':0O:'1:I#,1'732=D%.,FH<='37=>?/C18E1:I#,1'732=

>:=>?>?/>@2(2=-'%T! -=./,(!21#,1'732=D%.,FH<='37=,2!0?

)720%E,='A(B8&871OH7D=:(+,()"P5#E

14. 7:'#"I2(,432(,2!0?'2%-)0?>?/-$_=;H[ %&7:(,432'A##0M"N=

D%.,CDE'2%-D832=:<=':0O:'1:I%32(124 $bHI:QHQ20+E,0A8

#E2=)720$8,#9:4+,(OAEO8HQ7:'#"

@50=L>-()B0,0()*D&I)0KC

)@2-Q.,=:

,432CDE)720503%&0:#%&7:(D%.,)720)"E=-)41:IO8HQ9:Pc*

(!2112%CFE(2=L<@2D824)%:<() ,4A3-D=.,12%$bHI:QHQ20

1d-1Pc*#E2=)720$8,#9:4C=12%CFE(2=O8HQ9:Pc*,432(

-)%3()%:# 12%$bHI:QH,432(503-D02&'0D%.,12%503$bHI:QHQ20

1d-1Pc*#E2=)720$8,#9:4C=)A30.,CFE(2==?<,2!>eCDE-1H#

12%I2#-!TI,432(%"=B%(

-()#MF@)6>)8=()7)0

+E,)7%%&7:(:

!7*-'=%?<F,1"6<'-6(=-.7ML!+*#$%&9#%%0:6<"7;(1F"6&B]D!+*#$%&

123T%DB2/U)!+*#$%&9#%%%))6%"B*/?7/A&F*#%7*-'=%?)(*G;(

&("8%&!+*#$%&9#%

%)*+,)-)./0-!1234((5)6+78 1)

+E,)7%%&7:(:

!)6%"!=@0?B2/U)!+*#$%&9#% <F,7*-'=%?-6(=-.7ML=/$&&("=(9(*TG;(

&("CD,%06(&T:)7,%& 123)2/?CB0/&7;(1F"6& "OFF#!9#$%B26%0

!=-.7ML=(9(*T2W%+<"7;(1F"6& "ON#!4#$%M6-0<F,=3D-)<")(*

<M,&("%06(&76%!"#$%& <M,+-(9*39/D*3-/&!9#$%2W%+=-.7ML!+*#$%&9#%

<"7;(1F"6& "ON#123'/?!+*#$%&9#%<F,1"6"72%D!-2(

!B]D<M,!+*#$%&9#%ED0DO&=-.7ML=/$&&(" +-(9!*W-!+*#$%&9#%'3!4.$98OA"

!9#$%%%)1*&)DG@$=-.7ML=/$&&(" B26%0=-.7ML=/$&&("!4#$%F0NDG;(&("

T,(7,%&)(*<M,&("%06(&76%!"#$%& DO&=-.7ML=/$&&(" )DBNV92W%+12,-

B26%0=-.7ML=/$&&(" T,(7,%&)(*!2.)<M,&("!+*#$%&9#%<"7;(1F"6&2W%+

<F,DO&=-.7ML=/$&&("'"=ND '()"/A"B26%0=-.7ML

20

%)*+,)-)./0-!1234(9:$78;.+2<+)- (5)6+78 2)

+E,)7%%&7:(:

!7*-'=%?G.HG(&)(*F9N")6%")(*<M,&("!=9%

!<M,=-.7ML!B2@$0"G.HG(&F2/&!+*#$%&9#%F0ND=".G!G6("/A" )(*

!B2@$0"G.HG(&)(*F9N")6%"!+*#$%&9#%F0ND=".G%('G;(<F,!+*#$%&

9#%!=@0F(0CD,

!T,(C96=(9(*T)D=-.7ML=/$&&(" 7*-'=%?=-.7ML!B2@$0"G.HG(&<F,

%0:6<"7;(1F"6& (D,(" A) F*#% (D,(" B)

!+*#$%&9#%"@A9@=-.7ML!B2@$0"G.HG(& !4#$%<M,!B2@$0"G.HG(&)(*F9N"

B*/?),("=-.7ML!B2@$0"G.HG(&CBG@$7;(1F"6& (D,(" A) =;(F*/?)(*

F9N"7(9!8W9"(b.)( F*#%7;(1F"6& (D,(" B) =;(F*/?)(*

F9N"G-"!8W9"(b.)(

%)*9$=0%>?@A%)*+,)-). (5)6+78 3)

!+*#$%&9#%"@A9@BNV9F9N"=;(F*/?!B2@$0"EF9D)(*G;(&(" !2#%)EF9D<D

EF9DF"O$&G@$!F9(3)/?)(*G;(&("G@$+NK7,%&)(*ED0<M,BNV9F9N"

=;(F*/?)(*F9N"!G6("/A" <F,F9N"2:)?.D<F,2:)H*?"2:)?.D7*&)/?

!+*#$%&F9(0 ?"!+*#$%&9#%

=;(F*/?)(*F9N"123)(*)*31G)!G6("/A" <F,F9N"2:)?.D<F,2:)H*?"

2:)?.D7*&)/?!+*#$%&F9(0 ?"!+*#$%&9#%

+E,)7%%&7:(:

!F9N"BNV9F9N"CB0/&!+*#$%&F9(0G@$+NK7,%&)(*'"=ND F()+NK<M,

&("!+*#$%&9#%ED0G@$BNV9F9N"%0:6)O$&)2(&*3F-6(&=/I2/)JKLEF9D

!+*#$%&9#%%('!=@0F(0CD,

!<M,BNV9F9N"F2/&'()G@$!+*#$%&9#%F0ND=".G!G6("/A"

3"1B,)%"AC*-D2A

7/-';()/D1*&?.D'3G;(&("!9#$%1*&?.D8OA"CBTO&*3D/?F"O$& 9%!7%*L'3

[23%%)'()!42(=6&);(2/& !9#$%!B^"!M6""@A D%)=-6("'3F0NDF9N"

+E,)7%%&7:(:

!!9#$%7/-';()/D*%?G;(&(" <F,B]D=-.7ML!+*#$%&9#%<"G/"G@ "@$'3!B^"

)(*<M,BS%&)/")(*=O)F*%)6%");(F"D8%&!+*#$%&9#%

!D%)=-6("!M6"!2#$%0!'(3*:,9/)8?F*#%7.D)/?*:CD,&6(0 123C96!F9(3

=;(F*/?!+*#$%&9#%"@A !"#$%&'()=.$&"@A'3G;(<F,7/-';()/D*%?G;(&("

?6%0!)."CB

>)838,>#@

+E,)7%%&7:(:

!7*-'=%?<F,1"6<'-6(=-.7ML!+*#$%&9#%%0:6<"7;(1F"6&B]D!+*#$%&

123T%DB2/U)!+*#$%&9#%%%))6%"D;(!"."&("<Dc )/?!+*#$%&9#%

AE)@B"DAE)./E)- (@=0B"D9!*2@) (5)6+78 4)

+E,)7%%&7:(:

!<M,D,(9'/?D,("8,(&!=9% !4#$%+-(9B2%DZ/0<")(*<M,&("

<=6D,(9'/?D,("8,(& ED0<F,=6-"G@$0#$"%%)9(8%&D,(9'/?%0:6

*3F-6(&*6%&8%&!+*#$%&9#% 12,-F9N"73B:+-&<F,1"6"!4#$%0ODD,(9'/?G@$

7;(1F"6&G@$7,%&)(* QO$&%(''3F9N" 360° !4#$%<F,0OD1"6"G@$7;(1F"6&

<D7;(1F"6&F"O$&

B)*FD7A0%!1G).

G('(*3?@G@$D%)=-6("!2W)",%0)6%")(*<M,&("

(B*39(K 0.5 -1 )*/9)

)(*F26%2#$"'3M6-0<F,!+*#$%&9#%G;(&("CD,*(?*#6"0.$&8OA"123M6-00#D

%(0N)(*<M,&("8%&!+*#$%&9#%D,-0

%)*32A3"H-?*=0I0AA0%J/K1-

G;(+-(9=3%(D),("D%)=-6("123G('(*3?@G@$D%)=-6(")6%")(*

7.D7/A&D%)=-6(" (92;>?/ 5)

<=6D%)=-6("2&<"!+*#$%&9#% F9N"123D/"D%)=-6("'")*3G/$&!8,(G@$

(92;>?/ 6)

F2/&'())(*7.D7/A& 7*-'=%?<F,1"6<'-6(D%)C8+-&0OD1"6"!8,(G@$D@

12,-ED02%&40(0(9DO&%%)

!9#$%7,%&)(*T%DD%)=-6("%%) <F,DO&X(+*%?F/-'/?2&'"=ND123

DO&D%)=-6("%%) (92;>?/ 7)

9%B1"AK1)@$L% (5)6+78 8)

!)'-/D+-(92O)!F9(3=9G@$'3<M,=;(F*/?*:!'(3G@$9@+-(92O)!G6()/"

+2(073B:+-&!4#$%B*/?!)'-/D+-(92O)<F,CD,*3D/?7(97,%&)(* F2/&

'()B*/?!=*W'12,- <F,8/"73B:+-&<F,1"6"

D024-DQ":

!!)'-/D+-(92O)C96=(9(*T<M,G@$7;(1F"6&QO$&!)'M")/?!*#%"!)@0*L/

!*#%"9%!7%*LCD,

>)8GN"7)0

<M,D,(9'/?D,("8,(& (9#%'/?!=*.9) !=9% 123'/?!+*#$%&9#%<F,1"6"D,-0

D,(9'/?D,("8,(&1239#%'/?=-.7ML<"*3F-6(&)(*<M,&("

%)*M4E-).%)*9B)F%*FC+% (5)6+78 9)

7/A&BNV9F9N"!2#%)EF9D)(*G;(&("CBG@$!+*#$%&F9(0

-(&7;(1F"6&D%)=-6("G@$7;(1F"6&G@$7,%&)(*!'(3*:'()"/A")D

=-.7ML=/$&&(" %06(Xd"<M,!+*#$%&9#% )(*<M,1*&)D!?(c '3<F,[2D@G@$=ND

'/?!+*#$%&9#%<F,%0:6<"7;(1F"6&C-,123)/"C96<F,!+*#$%&9#%2#$"F2ND%%)

9('()*:G@$!'(3

F,(9<M,1*&)D9()8OA"!9#$%9@!HJE2F3 F*#%-/=DN%ND7/"G@$*: <F,<M,&("

!+*#$%&9#%G@$*%?!D."!?(1G" '()"/A"DO&D%)=-6("?(&=6-"%%)9(

'()*: )(*G;(1??"@AQA;(F2(0c +*/A&'3G;(<F,*:=3%(D 123=(9(*TG;(

)(*!'(3CD,7(9B)7.

7/A&BNV9F9N"!2#%)EF9D)(*G;(&("CBG@$!+*#$%&F9(0

Other manuals for MT870

3

Table of contents

Languages:

Other Maktec Rotary Hammer manuals