Maktek MR20 Setup guide

RADIANT HEATER

INSTALLATION,USAGE AND

MAINTENANCE MANUAL

MR20 -MR30 -

MR 40 -MR55

INSTALLATION INSTRUCTIONS

Important data before installation.......................................................................................................3

Points to take into account hile installation......................................................................................4

Opening chain and brackets………………………………………………………………………………...5

Placing heater pipes...........................................................................................……………………...6

Installation of pipe set.....................................................................................................................….7

Reflector installation............................................................................................................................8

Burner installation................................................................................................................................9

Heater gas and electricity line connection schema....................................................................….…10

Burner electricity schema...................................................................................................................11

Safety Warnings .................................................................................................................................12-13

First use of radiant............................................................………………………………………………...14

Error detection and generating solutions.....................................................................……………......15

Cleaning and Maintenance of Radiant...........................................................…………………………...16

Guarantee Conditions............................................................................................................................17

Autorised Service Instructions

Demounting of Burner...................................................................................................……………….18

Changing Electrods........................................................………………………………………………….19

Ignition card and demounting gas valve..................................................................................………..20-21

Gas valve and bridge parts.............................................................………………………………………22

Burner parts..................................................................................………………………………………..23

TECHNICAL SPECIFICATIONS

MODEL MR20 MR30 MR40 MR55

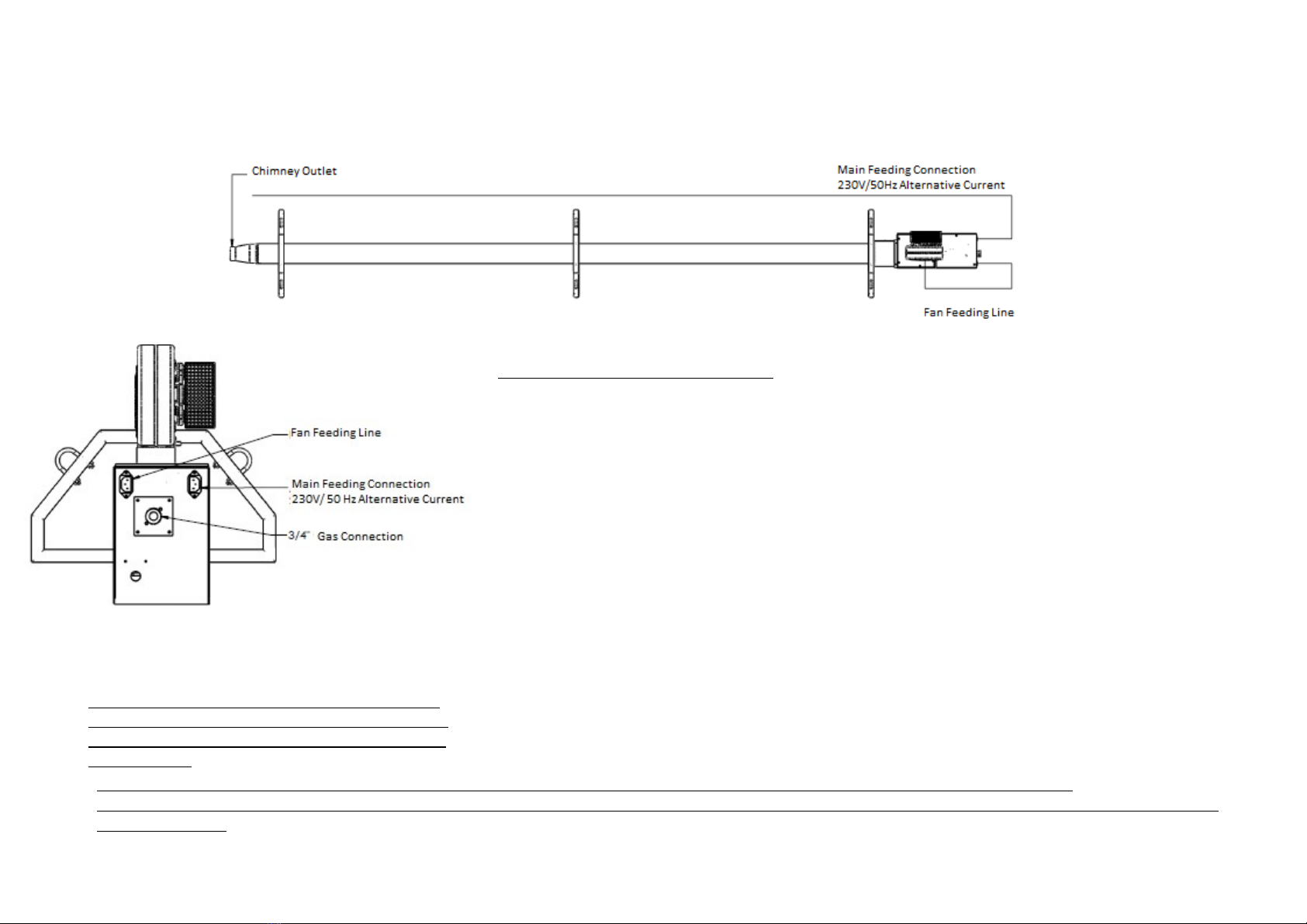

Gas Connection 1/2"

Electricity Connection 230V 50HZ

Fan 230V 50HZ MONOPHASE

Current 1A (Max)

External Fuse 10A

Exhaust diameter (mm) Till 3 meter Ø 60 , bet een 3 – 6meter Ø 80

Electric isolation IP X4D

Gas Category I2H Natural Gas (G20)

Ignition System Automatic ionisation controlled

Nominal po er (kW) 20 30 40 55

Nominal po er (kcal/h) 17200 25800 34400 47300

Gas input pressure (mbar) 20 20 20 20

Injector diameter (mm) 4 4,5 5,5 6

Injector pressure (mbar) 11 16 11,5 14

Gas consumption (m/h) 2,08 3,13 4,17 5,7

Reflective surface lenght (mm) 5950 7850 15650 15650

Weight (kg) 65 86,5 103 103

Producer com any has the right to make any changes about roducts and content without any information.

1

Dear Maktek customer,

We are proud to inform you that, by choosing MAKTEK RADIANT HEATER you obtained a high techno ogy product with its modern

and aesthetic design, to operate efficient y in your workp ace for many years.

This handbook is prepared to ensure that you get the highest effectivity and efficiency from your product. I nappropriate mounting,

insta ation, setting, service and maintenance may cause the product to ma function, resu ting in the ap iance to go out of warranty

or even may cause injuries to peop e. P ease read through this handbook before starting to operate your product.

Repairs shou d be done on y by AUTHORISED MAKTEK SERVICE PERSONNEL.

P ease read the safety instructions section of this handbook carefu y to avoid any possib e injuries.

P ease keep this handbook in a secure p ace, to refer to in the future when needed.

We are Stronger with You...

2

IMPORTANT DATA BEFORE INSTALLATION

Fresh air is necessary for running Radiant heater. Be sure that there is 6 cm2 open space for every K value of radiant capacity in installation

place.

If there are corrosive and abrasive effect smoke gases and materials in air, it is necessary to provide fresh air from the unpolluted place for

radiant.

Radiant heater's exhaust gas shouldn't be allo ed to depositing in orking place and eject ith exhaust gas flue connection. Radiant

heaters must be installed places here maintenance and repairing cabn be done comfortably.

Radyant stclarn montajnn yapld ve stclarn altrlaca alanlarda, yanc ve parlayc maddeler bulundurulmamaldr!.

Please check the voltage, frequency and electricity feeding before the firs operating. Check the fuel type hich ould be used and input

pressure.

Areas of Usage :

Radiant usage is not suiatble for closed small places like house, ofis and buro. Radiant is designed for heating places as follo ing:

Sports halls,

Tenis courts

Storehouses

Factory and plants

Restaurants and halls

Shops

Hangars

Maktek Radiant heaters are designed for efficinet heating in industrial facilities, ide and open areas and shouldn't be misused.

Maktek can not be held responsible for any inconvenience and negativities that may arise as a consequence of subsequent changes in the

environment in hich the device is first installed and hich may result in the environment becoming unsuitable for radiant heater use.

3

MAKTEK RADIANT HEATER is produced in compliance ith TS EN 416-1 standarts. It is necessary to pay attention for installation distance that

as stated in this guide for maksimu efficiency, thermal comfort and reducing fire risk.

!"#

E = 2 Meter

F = 2 Meter

H = 4 Meter

C = 0,75 Meter

X = 2,80 Meter

A = 0,5 Meter

4

Stage 1: Hanging Chain and

Brackets

Distance Bet een Hanger Profiles According to Models;

Model *L* Distance Total Heater Lenght Bracket Number

MR20 1906mm 6 Meter 4

MR30 1912mm 8 Meter 5

MR40 1921mm 16 Meter 9

MR55 1921mm 16 Meter 9

P ints will Taken Int Acc unt While Hanging Chains and Brackets

•Chains and brackets must be hanged on strong place hich can lift the eight of radiant heater.

•All chains must be in equal length, on a same line and brackets must be on scale.

•Distance bet een chains and brackets must be illustrated sizes.

ATTENTION: Regulation and rules determined by Maktek AS and subscribed gas company, must be implemented exactly hile choosing the

installation place. Producer company can not be held from the negative situations and conditions caused from failing to comply regulations and

rules.

5

Stage 2: Placing Heater Pipes

1. Extend the pipes onto the hanger profiles.

2.Mount the pipe retainers (U-Bolt) on hanger profiles as

sho n in picture.

3.Set the 100mm distance bet een burner's ends that chimney ill fix and hanger profile.

4.Tighten the krom pipe end point's U-bolt in the ay completely tighten the pipe hich burner

inserted , tighten other U-bolts in the ay pipe ill be released by help of lock nuts.

IMPORTANT NOTE: THERE IS NO LOCK NUT IN U-BOLT WHICH IS INFRONT OF BURNER

AND ONLY THIS U-BOLT TIGHTENS THE PIPE COMPLETELY. THERE IS LOCK NUT IN ALL

OTHER U-BOLTS, THEY WILL SLACK THE PIPE.

6

Stage 3: C mbining Heater Pipe Set

$%%#& &'$ #%()*

$$! !$%%%##(% %%&$ $$! $%%&%##$(%+#),##('-&'#$

##$ ' %(*

.($$#$/ +%0) %%1#2$#&*

7

Stage 4: Installati n f Heat Reflect r

Fistly pass the reflectors in hanger profiles and extend on pipes as sho n in picture. Leave 100mm distance bet een reflector end and pipe's burner

fix end.

There are 5 each scre holes on 3mm diameter one end and 4mm diameter other end of the reflectors.

For making radiant connections healthly, superimpose 4mm diameter perforated end on 3mm diameter perforated end of the reflector and align the

hole centers, make scre ing on all holes and lastly sre the reflector holder part as sho n in picture.

8

Stage 5: Installati n Of Burner

Mate the cast barrel at the end of burner into the crome pipe and push till the fulcrum lean on pipe.

Finally ,fix burner to the chrome pipe by using M8 Setscre . You can tighten setscre s ith allen key.

9

3-454

WARNINGS ABOUT WASTE GAS

1-IF THE RUNNING PLACE OF THE RADIANT, IS OPEN

Waste gas can be left in open areas.If there is flammable material or stuff near the aste

gas outlet, aste gas must be removed ith 90 degree elbo s.

2- IF THE RUNNING PLACE OF THE RADIANT, IS CLOSED

Waste gas must remove from the place by a chimney in closed places. Until 3 meter

distance 60 chimney pipe, more than 3 meter distance 80 chimney pipe must be used.

Maximum chimeny length is 6 meters.

3-MAKING CHIMNEY CONNECTION

When chimney connection is making, chimney must be connected ith a do n slope to

prevent first burning perspiration and rain ater to canalise to ards radiant.

Maximum ork pressure is 20mbar for natural

gas. Radiator gets harm above these pressure.

Do not get connected unless checking net ork

gas pressure.

NOTE: Radiant is designed for orking onlt ith natural gas and it is forbidden to transform other gas types for any reason.

In case of disobeying the ban, radiant ill be out of arranty and producer company can not be held responsible for financial and emotional damage

caused from this. 10

11

SAFETY WARNINGS

While using the radiant, it is al ays necessary to take follo ing security precautions for reducing the electric shock, burning, injuring risks and

preventing radiant to be out of arranty.

•Please read the informations in this manual before start using radiant.

•ATTENTION: ELECTRIC SHOCK RISK. Do not try to open or epair the radiant by yourself.

•Attention should be paid to minimum installation distances bet een radiant and flammable surfaces and materials stated in this guide.

• Radiant can break do n for any reason.Radiant can sho errors caused from anything. Mekanik yada elektriksel ayarlama, tamir ve bakm

durumlar iin sadece MAKTEK YETK6L6 SERV6S7 lerini araynz. You can understand if user can fix or intervention of autorised service can fix the

problem, by reading data and directives in this guide. Only call MAKTEK AUTORISED SERVICES for mechanic or electrical adjustment, main and

repair issues.

•Do not use the radiant in open places that rain come into contact.

•Do not use radiant in people's accomodation places (like saloon, room).

•Use only the specified gas type. Do not use gas types hich are not suitable and didn't specified in this manual

• Do not run the radiant near combustible vapor, liquid and gases against explosion and fire danger.

• Leak check must be done ith appropriate tools ( for example ith soap bubble or pressure test) on every pipe and pipe connection points

of the gas line.

•Do not move the heater hile running or it is hot even it is off. Do not try to fix or touch it.

•Close the fuse key to stop running of radiator.

•Do not interfere in electricity connections of the radiant for any purpose

•Use heater only in directions of this manual.Producer company can not be held responsible for situations hich people benefit from or

radiant ill be damaged.

• Do not use the extension leads hich can make burning risk and has an overheat risk.

• Do not use the radiant if it falls or is damaged from any reason.

•Radiant mus be shut do n hile making cleaning and maintenace and unplug.

• In direction of this manual, some parts of the radiant can be cleaned ith using soft rubber and ashing agent (not solvent base).

• It is good for your safety and heating comfort to check the radiant visually.

Radiant heater installation and service must be in accordance ith valid standarts and instructions hich ill be announced in

future.Producer company can not be held responsible for the damages ill be caused from rong installation and miss-use.

ATTENTION; Only Autorised Services and Producer is responsible for the Radiant. Besides these do not allo anyone to fiddle ith

adjustment of radiant.

WARNING: Natural gas is an actually odourless but it is aromatised ith rotten garlic smell for noticing the gas leakage easily. When you notice a

similar smell or feel a gas leakage, firstly close the gas entrance valve and clear the air, then apply to autorised services and gas company hich is

responsible for your region.

12

When a gas leak detected

•Close the gas valve.

•Avoid the moves that caused sparkles, do not s itch on the electricity if it is on it must me s itched off, do not strike a match or

lighter, do not plug, refrigirator door shouldn't open.

•Open doors and indo s for ventilation.

• Do not use the phones in gas leakage place.

• Empty the place here has smell

•.Do not try to repair breakdo n by yourself.

IMPORTANT; Radiant is designed for orking only ith natural gas and it is forbidden to transform other gas types for any reason.

In case of disobeying the ban, radiant ill be out of arranty and producer company can not be held responsible for financial and emotional

damage caused from this.

NOTE: Unconfirmed part mounting to the system or making changes ithout permission can cause damages on radiant and cause the

damage to be out of guarantee. For this reason, only confirmed spare parts ( by Maktek) must be used hile changing parts.

TRANSPORT OF THE RADIANT

•Take precautions like rapping ith bubble pack and supporting ith protective stuff like stafor for preventing damages of radiant hile

carrying the radiant.

•Prevent the parts of the radiant getting et during carriage.

• Take the proper steps for preventing the harms of fall, crash and smash.

•Do not store the radiant in open places.

HUMAN HEALTH AND ENVIRONMENT

MAKTEK Radiant Heater is not dangerios for human and environment health if it is used proper ith directions.

13

899.*

First Operation must be done only by MAKTEK Autorised Services for safe and efficient running and validation of the arranty.

before firs use;

•Gas type and pressure must be checked.

•Be sure that gas line is open and reaches the radiant.

•Be sure that electric line is open and and current reaches to the radiant.

•Be sure gas and electric lines are isolated from each other.

9.:

IMPORTANT: This guide definetly must be read before first operation and kept.

Open the fuse key hich heater is connected after being sure of installation done in the correct ay in accordance ith arnings and informations

stated in this guide and after reading this guide.

If there is energy entrance for the system yello led on bottom of burner flashes constant. Please observe this.If yello led doesn't flash use

error detection guide and search for probable reasons of the problem and call maktek autorised service if necessary.

NOTE: A little bit bending is normal can ve acceptable because of the hot orking temperature of radiant.

ERRORS AND SOLUTION METHODS:

is important for not If there is a problem at radiant heater's running or radiant doesn't ork please try to find the source of the problem by using the

error detection guide on page 11. It is important that you do not have to ait for the service for a problem that you may be able to solve by yourself ,

or that you are not trying to correct a malfunction that requires service intervention.

IMPORTANT: Flashing red led means reset is needed. Ho to make reset: Shut do n the fuse key. And ait 15

seconds an open again.

RUNNING AND ERROR CONDITIONS:

Yello led on the burner flashes hile radiant is po ered. After running ith safety control, 10 seconds pre- s eeping operation is performed. After

pre-s eeping, ignition starts. Ignition operation stats ith the arc that po ereing ignition electrode. At that time gas valve po ered also. If inginition

occured successfully, ionisation electrode detects the flame ans stops the ignition.

If flame doesn't occure for any reason, radiant sho s error and red led flashes. Close the fuse key radiant connected, ait 15 seconds and lift

the key again after being sure that gas source is open. If error condition occures after resetting, reasons must be searched. In electrical

problems, electric connections inside the radiant, problems can be caused from the building electricity line ( eak grounding, ground ressistance,

phase neutral polarisation etc.) must be considered.

14

ERROR LEDS AND ERROR DETECTION GUIDE

Yello Led;

Unflashing yello led means system doesn't have energy input. Check the electricity line and connection points. Yello led ill nonstop flash as

long as there is energy for running the system.

Red Led;

Red error led flashes in case of unstarting ignition and in case of an ignition problem in burner. Eventual problems and solution offers are lined

up belo :

If red error led flashes ithout ignition starts:

1. Flammable gas can not reach the system; Check the gas line and gas connections and make reset after being sure that gas reaches

the system. Push the reset button that is on hand remote control. It is given ith the heater.

If ignition occurs in burner but ends after a short hile and red error led flashes after this;

Phase- neutral polarisation can be occurred. Change phase and neutral cable ends and connect , try to run the radiant in this ay. Sorun

çözülürse kablo uçlar bu pozisyonda bal kalsn. If the problem continues, the reason is not phase- neutral polarisation and reconnect the

phase- neutral cable ends in first position not to form a polarisation hich doesn't exist.

•There can be a problem in grounding line, call an electrician and check.

•Burner gas input can not be at right pressure. Optimal ptressure in 20mbar in natural gas. Radiant is damaged the above this pressure level.

If the ignition problems continues even you follo ed all rules and red error led flashes, call Maktek autorised service and make necessary

investigation and repair done.

Green Led;

If Green Error Led Flashes:

•There can be loose contact in fan sockets.. Make necessary controls and be sure that sockets are assembled in correct ay.

•There can be obstruction in silicone hoses, check and clean if there is an obstruction.

If the problem continues even you follo ed all rules and green error led flashes, call Maktek autorised service and make necessary investigation

and repair done.

15

CLEANING AND MAINTENANCE OF THE RADIANT

ROUTINE MAINTENANCE

ATTENTION! Surface of the heater can be hot. Do not get close to heaters ithout using necessary protective equipment and clothes and taking

security precautions.

Reflectors can be cleaned ith soft fabric by using unflammable and nonabrasive (not solvent based ) detergent after being sure heater cold and

electricity line is s itched off. In adition, cleaning of radiant pipes and burner can be done similarly (or ith compressed air).

Follo ing control and maintanance are recommended to be done yearly by an autorised service.

1-Checking the strenght of the hang chains and hang profiles of the place radiant hanged on.

2-Inspecting radiant's general situation and checking if it is balanced in hanged place.

3-Checking the leakages in gas circuit, if necessary providing sealing by changing joints and o-rings.

4-Checking the general conditions of components that continues burning and keeping in touch ith flames (injector, turbulator and electrods) inside

the burner, cleaning the components in un elcomed conditions like getting dirty, clogging.

5-Checking gas and ignition pressure if necessary adjusting (maximum gas pressure is 20mbar)

6-Checking the electricty net ork connection of the radiant.

7- Making the aste gas anaylse.

8- Making the chimney cleaning.

*Parts Needs to Be Changed in T o Years Period:

•O- Rings and Joints

•Sealing paste

*Parts Needs to Be Changed in Three Years Period:

•Prosestat

•Injector

* Parts Needs to Be Changed in Five Years Period:

•Gas Valve

ATTENTION! : Be sure gas and electricity disconnected and the radiant is cold before starting trouble shooting, cleaning and maintenance

operations.

16

WARRANTY CONDITIONS

This guarantee is valid 3 years from the first operation date of the radiant First operation and and intermediate maintenances must be done by

only autorised services for arranty to be valid.

ATTENTION: It is necessary to obey all the rules and regulations that MAKTEK and subscribed gas company determined hile choosing

radiant mounting place. Producer company can not be held responsible for negative conditions caused from violating legal rules and

regulations.

GUARANTEE WILL BE UNVALID IF ONE OR A FEW ITEMS BELOW OCCURED

1-Damages and errors hich can be caused from rong installation mounting and rong electricity net ork connection.

2-Damages and errors can be caused in case of nounting unoriginal and unrecognised parts from the producer company.

3-Damages and errors caused from extreme heat and freezing here boiler is placed.

4- Damages and errors can be caused from inappropriate storage conditions in inappropriate places,

5- Damages and errors can be caused hile carrying the the radiant from one place to another.

6- Damages and errors can be caused from using bad and dirty fuel.

7- Damages and errors can be caused from first opeartion and interventions by people except Maktek autorised services.

8-Damages and errors can be caused from mounting and maintenance that is not comply ith the regulations.

9- Damages and errors can be caused from rong chimney connection and inadequate chimney draught.

10-Damages and errors can be caused from design and production misuse of the radiant.

11- Damages and errors caused from aiting for a long time in improper place and conditions for displaying.

12- If the user does not have the documents hich user has to have and prepared from autorised service

13- If the serial number of the radiant has changed and cause destruction on serial number.

NOTE: Lifetime of the radiant is 10 years.

PRODUCER COMPANY IS NOT RESPONSIBLE FOR FAILURES AND DAMAGES CAUSED FROM MISUSE.

17

ATTENTION! : FIRE OR EXPLOSION RISK. Disconnect the gas and electricty connection before starting any repairing or service operation!

PART REPLACEMENT AND VE REPAIR METHOD

•DISMANTLING THE BURNER

For changing any part in burner box;

•Remove the gas and electric connections,

•Remove the setscre s hich are in point of burner and radiant pipes junction, as sho n in picture 1a.

•Finally dismantle the burner from radiant pipes, place in a orkable safe place like ground or table.

18

This manual suits for next models

3

Table of contents

Other Maktek Heater manuals

Popular Heater manuals by other brands

Calix

Calix M5T 258 Assembly instructions

Strend Pro

Strend Pro VT-020 instruction manual

Webasto

Webasto Dual Top Evo 6 operating instructions

Noirot

Noirot 7358-3T Operating & installation instructions

Propex

Propex Heatsource HS2000 Installation & operation instructions

ARDES

ARDES AR4P19 Instructions for use

Sharper Image

Sharper Image EVSI-HTR70 Instruction manual and warranty

Teddington

Teddington Rondo operating manual

Jandy Pro Series

Jandy Pro Series JXi 200 installation instructions

Comfort Furnace

Comfort Furnace CF0035 user manual

Stelrad

Stelrad LECCO quick start guide

Pro-Elec

Pro-Elec PEL00923 quick start guide