Malabar 150-30H User manual

MALABAR

INTERNATIONAL

Date: February 18, 2011

OWNER’S MANUAL FOR MALABAR MODEL

AIRCRAFT MAINTENANCE & SUPPORT EQUIPMENT

150-30H

1 LITER O-C FLUID GUN DISPENSER

* GENERAL DESCRIPTION

* OPERATION

* SERVICE

* PARTS BREAKDOWN

For Service & Spare

Parts, Please Contact: Malabar International

220 W. Los Angeles Avenue

Simi Valley, California 93065

Phone: (805) 581-0116

Fax: (805) 584-1624

Web site: http://www.malabar.com

OVER 65 YEARS OF SERVICE & EXPERIENCE

©2002 Malabar International. All rights reserved. Permission to reproduce all or part of this material must be obtained from Malabar International.

READ

AND

SAVE

THIS

INSTRUCTION

MANUAL

- 1 -

GENERAL DESCRIPTION, OPERATION, SERVICE AND PARTS BREAKDOWN

MALABAR MODEL 150-30H

1 LITER O-C FLUID GUN DISPENSER

CAUTION: AIRCRAFT MANUFACTURER’S SPECIFICATION AND INSTRUC-

TIONS MUST BE FOLLOWED IN THE EVENT OF CONTRADICTION

BETWEEN AIRCRAFT MANUFACTURER’S SPECIFICATIONS AND

MALABAR’S AIRCRAFT MANUFACTURER’S SPECIFICATIONS WILL

PREVAIL.

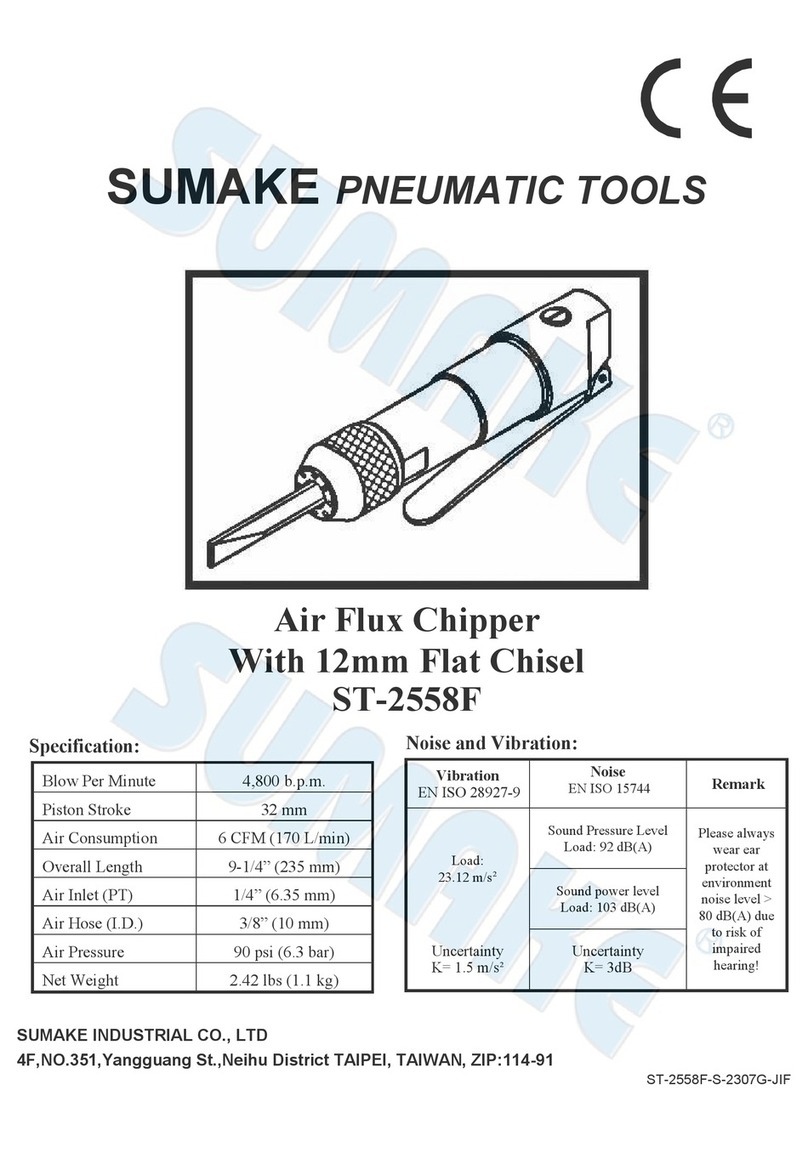

SPECIFICATIONS:

Fluid---------------------------------------------------------------------------------------------- Engine and IDG oil

Fluid Capacity --------------------------------------------------------------------------------- 1.06 quarts (1 liter)

Pump Outlet Pressure----------------------------------------------------------------------- 40 psig (276 kg/sq cm)

Volume Per Stroke --------------------------------------------------------------------------- 4 cubic inches (66 cc)

Hose Length ----------------------------------------------------------------------------------- 74 inches (1880 mm)

Net Weight (empty) -------------------------------------------------------------------------- 6.5 lbs (2.9 kg)

Filter Rating ------------------------------------------------------------------------------------ 3 micron nominal

GENERAL DESCRIPTION:

The Malabar Model 150-30H is a one liter original container fluid gun dispenser used to service various

commercial aircraft. The O-C Fluid Gun Dispenser consists of a hand pump assembly, filter assembly and

a fluid delivery hose with a coupling.

PREPARATION FOR USE:

1. Attach the hose assembly to the gun. Avoid over tightening the swivel nut.

2. The two latches attached to the clamp bars may require adjustment. Loosen the four screws, washers

and self-locking nuts and adjust latches to fit oil can before tightening screws.

OPERATION:

1. Slide piercer rod fully up and latch oil can to gun. Check the fluid specification and brand for

compatibility with the aircraft system.

2. Strike piercer handle firmly using palm of hand or rubber mallet to drive piercer through top of oil can.

Assure piercer is firmly placed in oil can.

CAUTION: TO PREVENT DAMAGE TO THE PIERCER ROD OR PIERCER HANDLE,

DO NOT USE ANY TOOL OTHER THAN A RUBBER MALLET.

3. Open the bleed screw on the sight gage (one turn only) and carefully pump the gun to prime and

eliminate any air bubbles. Close bleed screw.

CAUTION: AIR PUMPED IN WITH OIL MAY CAUSE FALSE LEVEL READINGS IN

AIRCRAFT SYSTEMS AS THE AIR EVENTUALLY BUBBLES OFF AND

THE LEVEL DROPS.

4. Remove dust plug from hose end coupling and connect hose end coupling to the aircraft service

- 2 -

point.

5. Use full steady pump strokes when operating pump assembly during replenishing. Stop pumping oil

when can is empty or air bubbles are detected in sight gage. Reprime gun when changing cans.

6. When finished, disconnect the hose end coupling from the aircraft service point. Replace the dust

plug and store the gun in a dry dust free location.

7. When gun is stored, it is advisable to keep oil can latched to the gun to prevent contamination and oil

mess.

SERVICING:

The frequency of filter change depends on operating conditions. Generally, changes should be made

every 3-4 months or sooner if more than normal resistance is felt on the pumping stroke at low pressure.

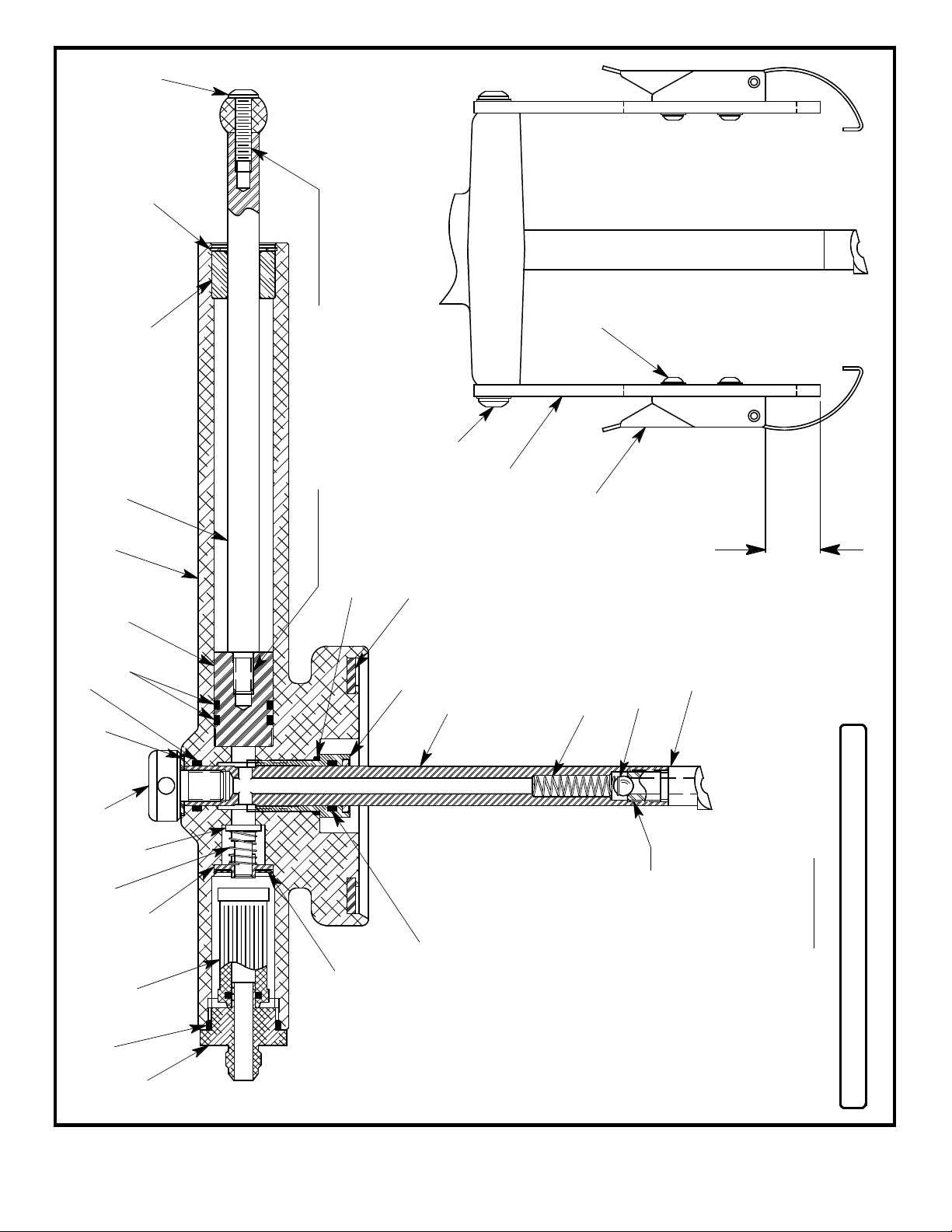

Refer to figure 1A, item 43 to change filter element.

REPAIR AND REPLACEMENT:

No definite time schedule can be established for the overhaul of the O-C fluid gun dispenser assembly for

the replacement of the various moving parts. The number of times the pump assembly is operated

materially affects the life of the working parts. The moving piston seals (figure 1A, item 20) and piercer

rod seals (figure 1A, item 22) are normally the first to wear. This is usually indicated by leakage of fluid

past the piston rod (figure 1A, item 2) or the piercer rod (figure 1A, item 12). It is advisable to change

piston seals (figure 1A, item 20) and piercer rod seals (figure 1A, item 22) immediately if leakage is

discovered. Regardless of apparent condition, replace all parts marked with (♦). A repair parts kit (P/N

150-6HPK) which contains all of the parts marked with (♦) is available and recommended to keep on

hand at your facility. Coat all o-rings with petroleum jelly prior to assembly. Clean all metal parts with

solvent and dry with compressed air. Lubricate all threads. Refer to sheet 6 for the complete list of parts

contained in the repair parts kit.

5/8 RECOMMENDED

FOR CAN

ADJUSTMENT

6

- 3 -

79

♦21

♦43

♦30

♦22

♦36

40

8

11

20 ♦

22 ♦

12

5

FIGURE 1A

APPLY LOCTITE

#609 ON THREADS

HOSE ASSEMBLY

NOT SHOWN FOR

CLARITY

MODEL 150-30H UNIT ASSEMBLY

31 ♦

33 ♦

13

APPLY LOCTITE #609

ON THREADS

1

29

2

24

27

19 ♦

10 ♦

23

37

♦PART OF REPAIR PARTS KIT

25

26

39

41

4

49

14

46 ♦

- 4 -

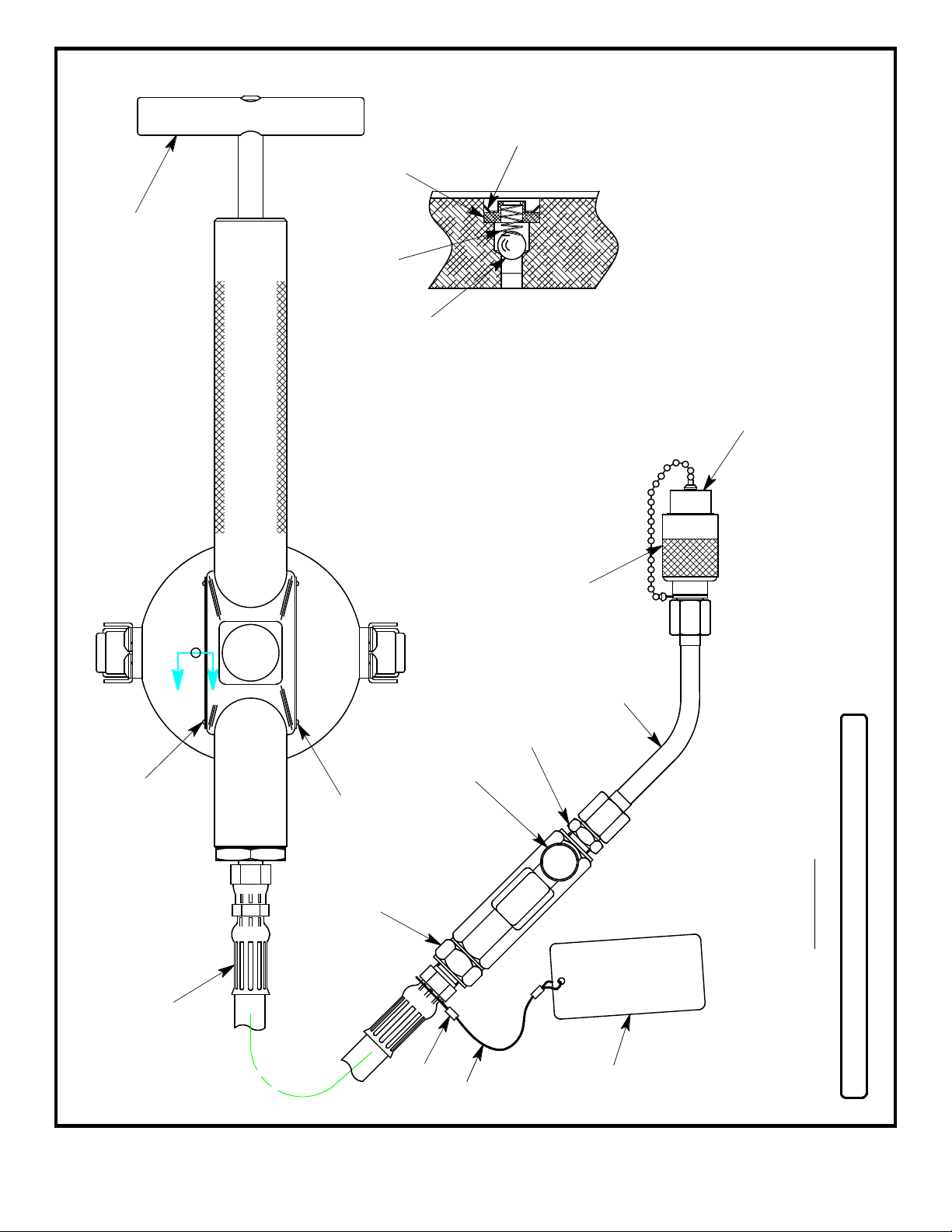

♦42

47

45

44

B

B

17

38

16

38

MODEL 150-30H UNIT ASSEMBLY

FIGURE 1B

ENGINE AND

IDG OIL

174468

18 48

28

♦34

♦PART OF REPAIR PARTS KIT

3

♦32 15

VIEW B-B ENLARGED

50

35 ♦

1 1 174493-2

2 1 174405

3 1 174406

4 2 174407

5 1 174459

6 1 174494

7 1 174412

8 1 174413

9 1 174414

10 1 174487

11 1 174416

12 1 174474

13 1 174461

14 1 174419

15 1 174420

16 1 174421

17 1 174467

18 1 174468

19 155934-019

20 255934-116

21 155934-120

22 255934-114

23 1 326-009

24 4 326-010

25 4 326-020

26 4 355-025

27 4 363-001

28 1 721-004

29 1 410-017

30 1 495-035

31 1 495-036

32 1 495-037

33 1 412-002

34 1 412-004

35 1 380-005

36 1 380-004

37 155926-100

38 8 393-004

39 4 362-045

40 1 369-002

41 2 491-056

42 1 174445

43 1PF55996

44 1 491-027

45 2 491-028

46 155934-904

47 1 174488

48 1PF55817

49 1 736-013

50 1PF55987

PUMP BODY MACHINE

PISTON ROD

HANDLE

CLAMP BAR

BEARING BOLT ASSEMBLY

PISTON

ADAPTER FITTING

VALVE POPPET

POPPET GUIDE

CAN SEAL

PIERCER HANDLE

PIERCER ROD

PIERCER

BLEED SCREW

SPRING SUPPORT

PLACARD

PLACARD, ENGINE AND IDG OIL

PLACARD, ENGINE AND IDG OIL

O-RING

O-RING

O-RING

O-RING

BHCS, 1/4-20 x 1" LG

BHCS, 1/4-20 x 5/8 LG

BHCS, 10-24 x 1/2 LG

HEX LOCKNUT, 10-24

SPLIT LOCKWASHER, 1/4

CONNECTOR, 3/8 37° x1/4 MPT

BRONZE BEARING

SPRING

SPRING

SPRING

BALL, CHROME, 5/16 DIA

BALL, CHROME, 1/4 DIA

RETAINING RING, PUSH ON

RETAINING RING, PUSH ON

RETAINING RING, PUSH ON

DRIVE SCREW, #2 x 3/16 LG

FLAT WASHER, #10

NYLON FLAT WASHER

LATCH

HOSE ASSEMBLY

FILTER ELEMENT

CABLE, .048 DIA x 6" LG

SLEEVE CRIMP

O-RING

SIGHT GAGE

FEMALE ELBOW ASSEMBLY

COUPLING

DUST PLUG

- 5 -

NO. QTY PART NO. DESCRIPTION

MODEL 150-30H UNIT ASSEMBLY PARTS LIST

HOSE ASSEMBLY

FILTER ELEMENT

CAN SEAL

O-RING

O-RING

O-RING

O-RING

O-RING

SPRING

SPRING

SPRING

BALL, CHROME, 5/16 DIA

BALL, CHROME, 1/4 DIA

RETAINING RING, PUSH ON

RETAINING RING, PUSH ON

REPAIR PARTS KIT LIST

1 174445

1PF55996

1 174487

155934-904

255934-114

155934-120

255934-116

155934-019

1 495-035

1 495-036

1 495-037

1 412-002

1 412-004

1 380-005

1 380-004

1 150-6HPKDOC

QTY PART NO. PART NAME

150-6HPK REPAIR PARTS KIT

- 6 -

Table of contents