NanoSight NS300 Operating Manual

(MAN0516-08-EN-00) 3

NANOSIGHT NS300

OPERATING MANUAL

Contents

1.1 INTRODUCTION ......................................................................................................................................... 5

1.2 EXPLANATION OF WARNING SYMBOLS ................................................................................................. 5

1.3 IMPORTANT NOTES .................................................................................................................................. 5

1.3.1 SAFETY ................................................................................................................................................... 5

1.3.1.1 Laser Safety ................................................................................................................................... 5

1.3.1.2 Electrical Safety.............................................................................................................................. 6

1.3.1.3 General Safety ............................................................................................................................... 6

1.3.2 SERVICING ............................................................................................................................................... 7

1.3.3 MAINTENANCE ......................................................................................................................................... 7

1.3.4 HANDLING............................................................................................................................................... 7

1.3.5 UNPACKING AND INITIAL INSPECTION............................................................................................................. 8

1.3.6 INSTALLATION AND RELOCATION .................................................................................................................. 8

1.3.7 RETURNING EQUIPMENT.............................................................................................................................. 8

1.3.8 WARRANTY ............................................................................................................................................. 9

2. NANOSIGHT NS300 HARDWARE.............................................................................................................. 10

2.1 NS300 TECHNICAL SPECIFICATIONS ...................................................................................................... 10

2.1.1 NS300 INSTRUMENT HOUSING.................................................................................................................. 10

2.1.2 NS300 LASER MODULE ........................................................................................................................... 10

2.1.3 LASER CLASSIFICATION ............................................................................................................................. 10

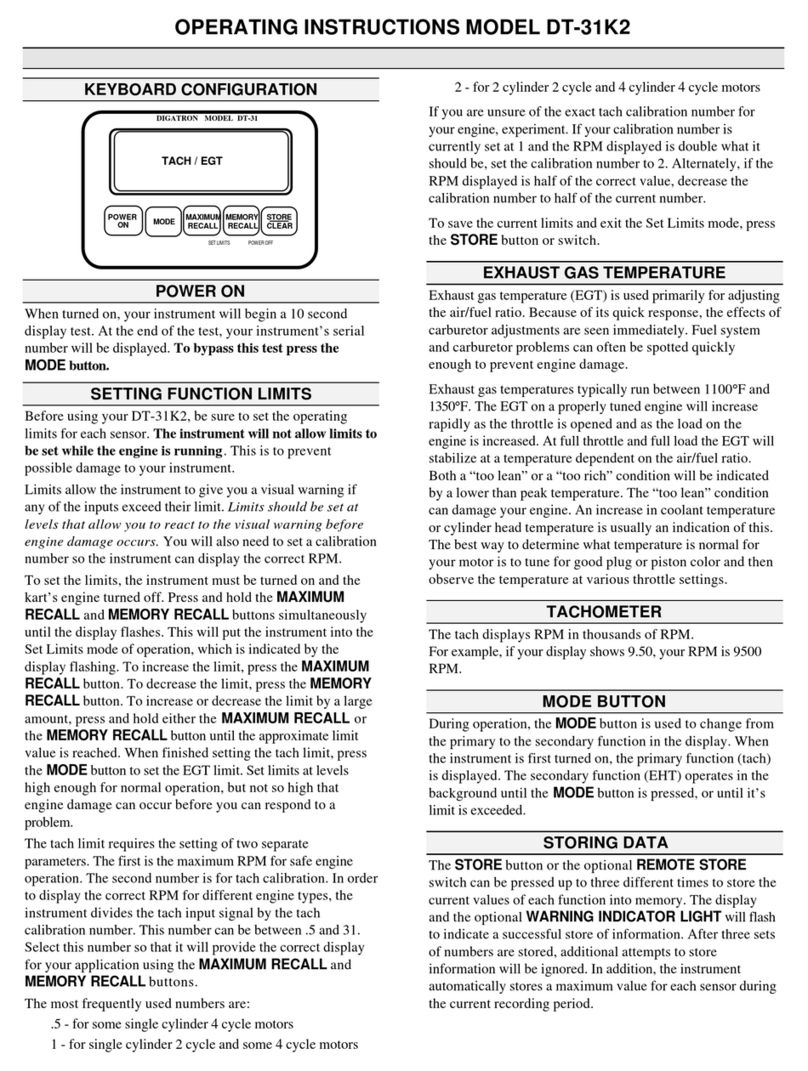

2.2 NS300 SETUP ........................................................................................................................................... 11

2.2.1 INSTRUMENT COMMUNICATIONS ................................................................................................................ 11

2.2.2 LASER MODULE CONFIGURATION ............................................................................................................... 11

2.2.3 TOP-PLATE SELECTION.............................................................................................................................. 11

2.2.4 EXTERNAL FLUIDIC SETUP .......................................................................................................................... 12

3. LOW VOLUME FLOW CELL ....................................................................................................................... 13

3.1 SYSTEM SETUP ........................................................................................................................................ 13

3.1.1 FLOW CELL ASSEMBLY ............................................................................................................................. 13

3.1.2 FLOW CELL TUBING CONNECTION .............................................................................................................. 14

3.2 FLOW CELL USAGE.................................................................................................................................. 15

3.2.1 PRIMING TUBING..................................................................................................................................... 15

3.2.2 CHANGING INLET TUBING SYRINGE ............................................................................................................. 15

3.2.3 LOADING AN INITIAL SAMPLE ..................................................................................................................... 15

3.2.4 CHANGING SAMPLES ............................................................................................................................... 16

3.2.5 MANUAL CLEANING PROCEDURES .............................................................................................................. 17

3.2.5 DRYING THE LOW-VOLUME FLOW CELL ....................................................................................................... 18