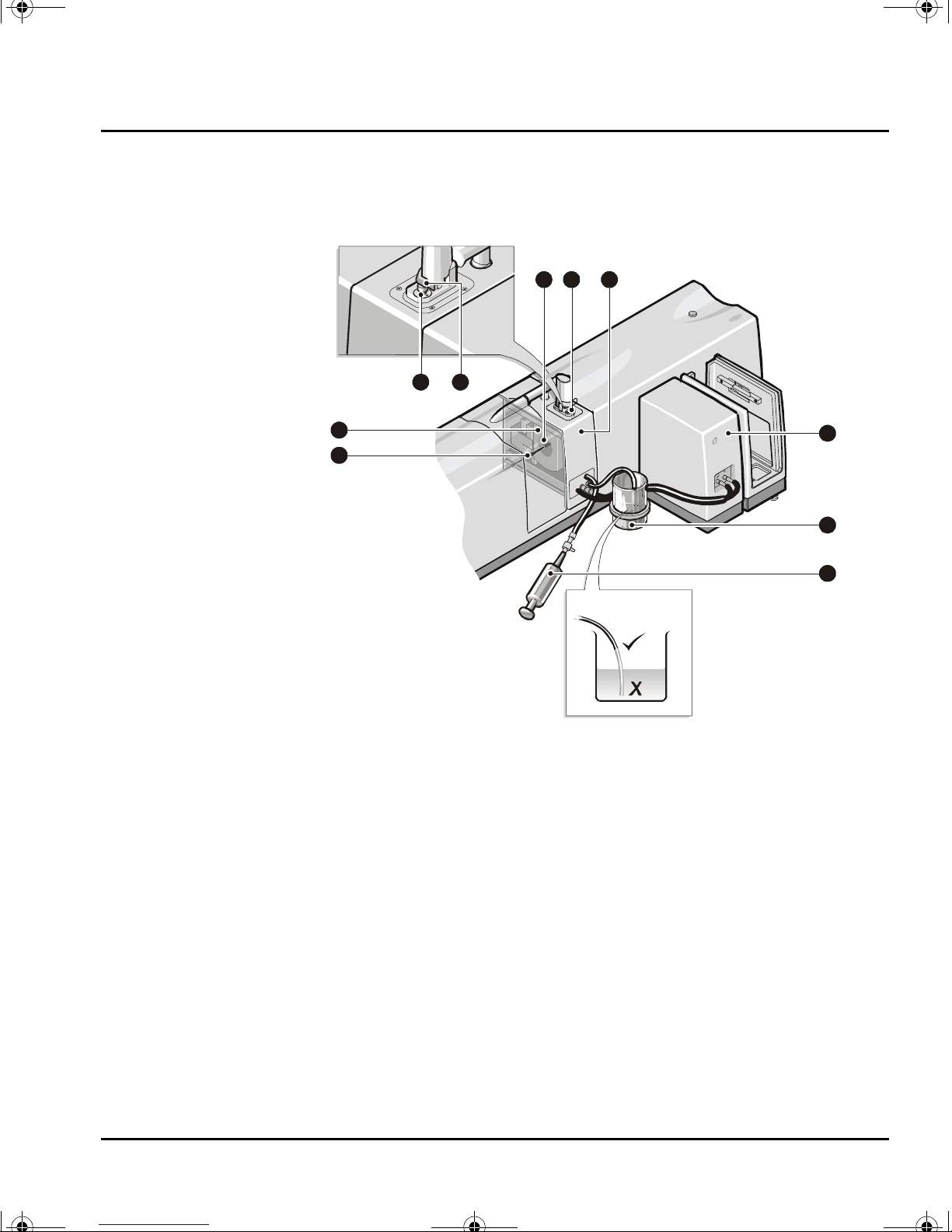

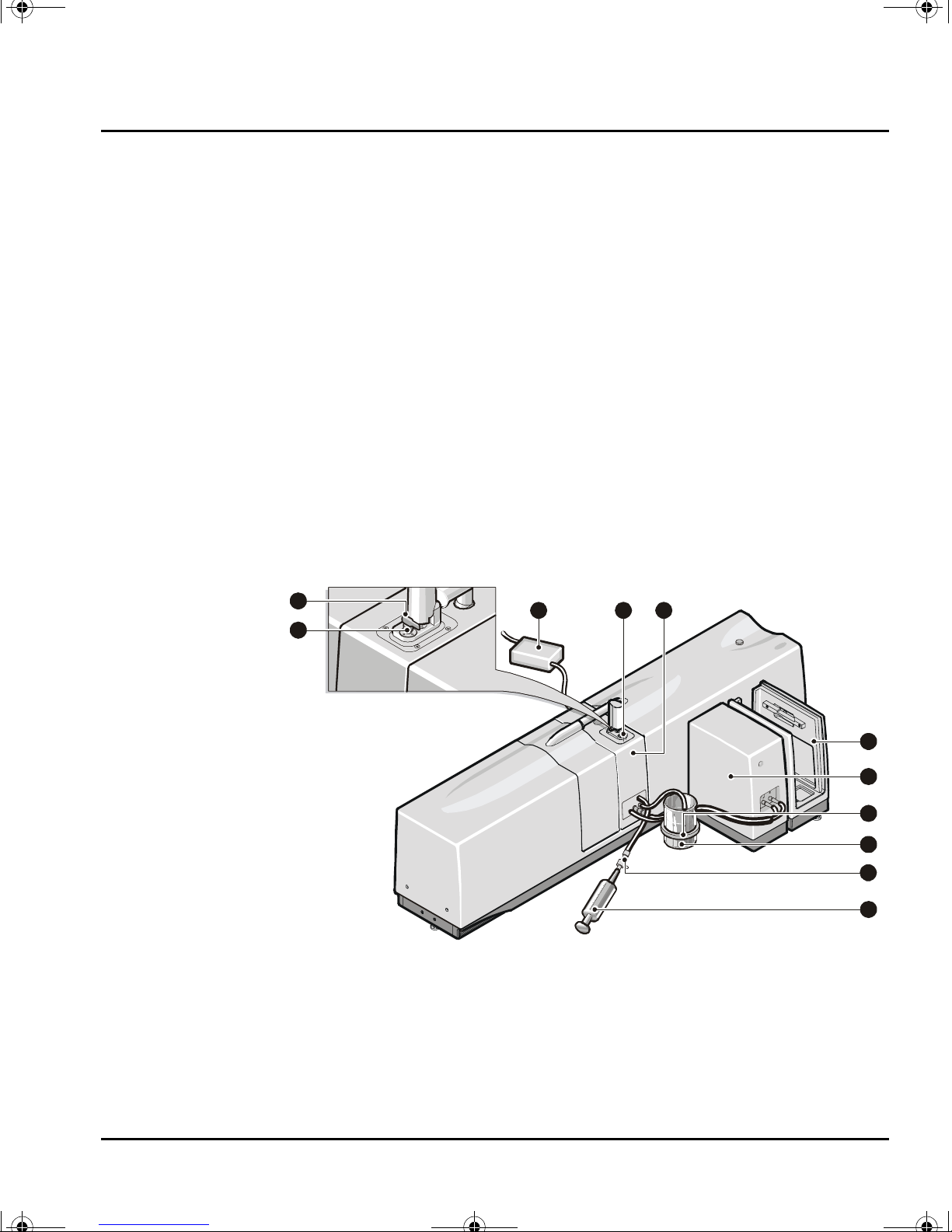

Malvern Hydro 2000uP User manual

Table of contents

Other Malvern Measuring Instrument manuals

Malvern

Malvern Zetasizer Nano Series User manual

Malvern

Malvern NANOSIGHT NS300 User manual

Malvern

Malvern Hydro 2000 G User manual

Malvern

Malvern Mastersizer Series User manual

Malvern

Malvern Zetasizer Nano Series User manual

Malvern

Malvern Scirocco 2000 User manual

Malvern

Malvern Mastersizer 3000 User manual

Malvern

Malvern NANOSIGHT NS300 User manual

Popular Measuring Instrument manuals by other brands

2B Technologies

2B Technologies UV-106W quick start guide

GROCO

GROCO SSA-3 Series Installation and operating instructions

SMART

SMART EX510 Installation and operation manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 66102APZ1 Installation and operating manual

Murata

Murata DATEL ACM20 Application note

imex

imex Moisture Pro MP100 user manual

turck

turck B1N360V-Q20L60-2Li2-H1151/3GD quick start guide

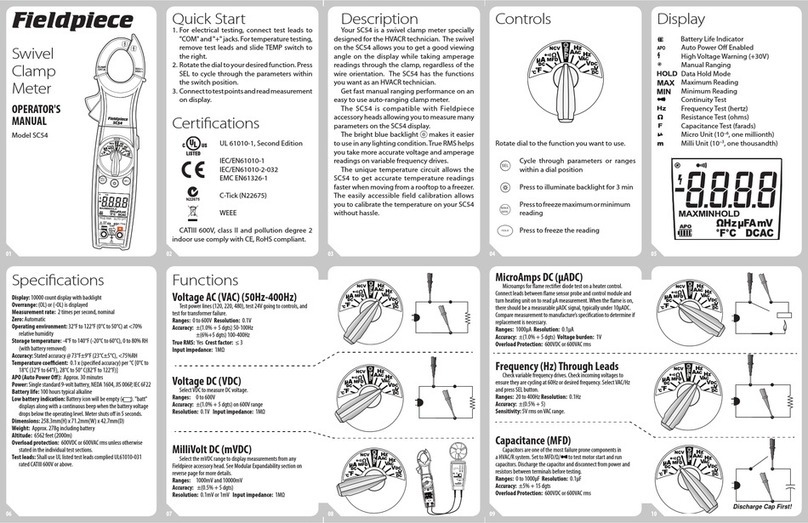

Fieldpiece

Fieldpiece SC54 Operator's manual

Sper scientific

Sper scientific 800019 instruction manual

Computer Weld

Computer Weld GTFM IV Operation & installation manual

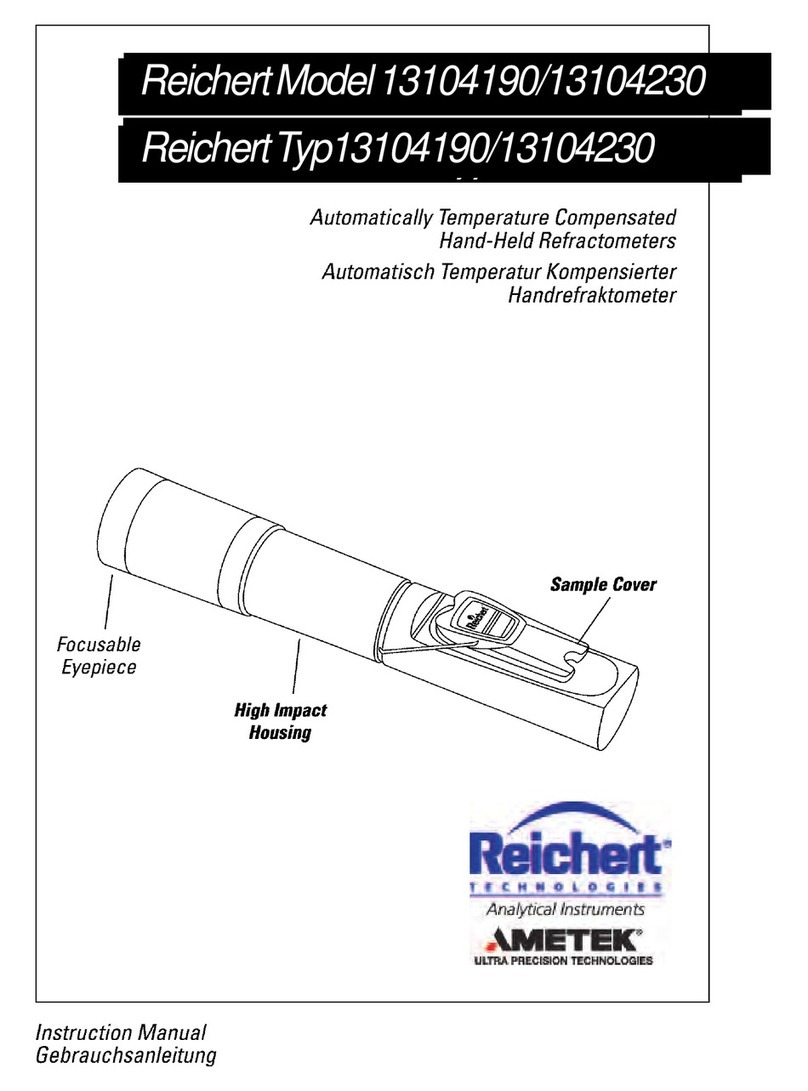

Ametek

Ametek Reichert 13104190 instruction manual

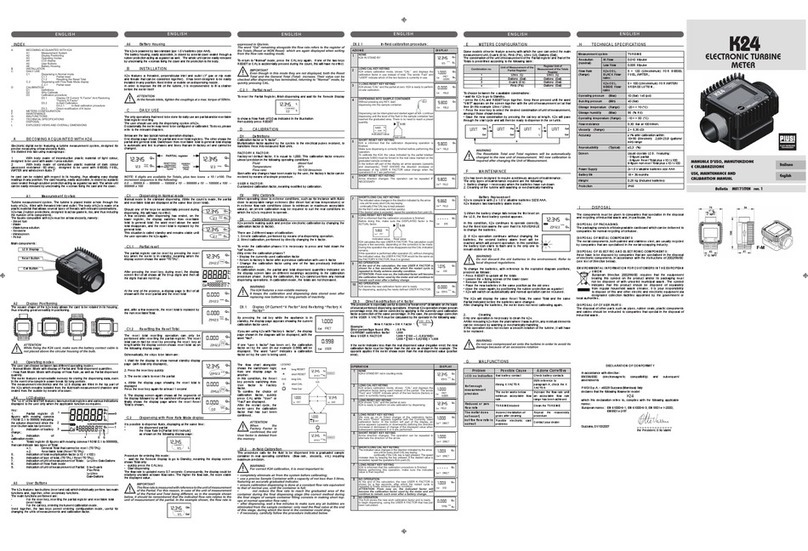

Piusi

Piusi K24 Calibration manual