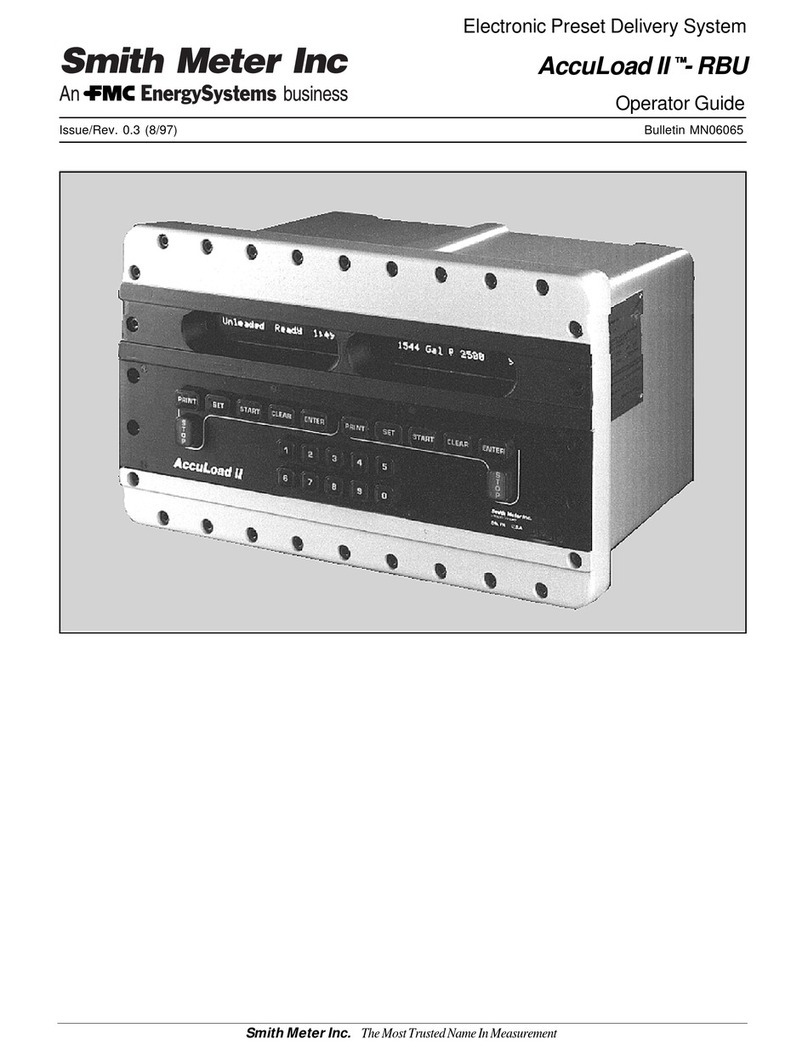

Section 1 - Introduction

2MN06053 Rev. 0.4 5/96

Significant communication capability is available from

the standard AccuLoad II. The instrument is

programmable for Polling, Polling and Authorization or

complete Remote Control via communications. The

EIA-232 communication port can be used to multi-drop

up to 32 meter positions to an ASCII printer for printing

load tickets or it can be used to network up to 32

meter positions to an automation system. Also

available is an additional communication port that is

EIA-485 interfacable. When used with a smart printer;

one that will signal when it is out of paper, cover is

open, etc., the AccuLoad II can alarm and display the

reason for the printer not working. The "speak when

spoken to" protocol of AccuLoad II is modeled after

the ISO Standard 1155. This allows quick access by

an automation computer for operational and

transaction information. The AccuLoad II also has a

built-in communication analyzer to aid in the

development and troubleshooting of communications.

For additional information on the AccuLoad II

communications, see the Communications Manual

(Bulletin MN06055L).

The AccuLoad II Sequential Blender provides several

loading system control functions: Additive Injection,

Pump Control, Alarm Control, Set Stop, Valve

Control, Back Valve Control, Back Pressure Control,

Automatic Adjustment of Final Trip Point.

•Up to seven different additive injectors can be

simultaneously paced or controlled through

communications per preset position.

•The AccuLoad II will monitor and totalize the

volume of additive injected by up to seven of the

additive injectors if the additive monitoring option

is purchased.

•AccuLoad II, if so programmed will automatically

calculate and adjust the additive pulse output to be

stopped at the first trip point of the product with

the same number of pulses as if the additive

output was stopped at the end of the batch.

•A contact is available to start and stop a pump or

other electrically operated equipment as well as a

program code that will set the time delay of that

start or stop.

•A programmable Alarm Contact is available. It can

be closed on a Valve Fault, on any alarm or not at

all depending on how it is programmed.

•The AccuLoad II contains the intelligence to

control a Smith Model 210 or 215 Digital Control

Valve which will provide low flow start and multi-

stage shut-down.

•Up to four product block valves can be controlled

(opened and closed) and sequenced by the

AccuLoad II Sequential Blender. The unit will

monitor these block valves to ensure that they

respond to signals sent to them. If for some

reason they do not respond, the AccuLoad II will

alarm and shut the system down.

•AccuLoad II contains the intelligence to

automatically reduce the flow of product and

ensure the flow is within the pumping capabilities

of the system.

•AccuLoad II, if so programmed, will automatically

adjust the final trip point of the batch (Preset).

Critical functions such as: minimum flow rate, excess

flow rate, temperature detection, preset volume

overrun and memory retention, are monitored by

internal circuits. Any failure will signal closure of the

valve. Should the valve fail to close within 10 seconds

after having been signaled, a contact is closed. This

can be wired through external relays to shut off the

pump and/or kill power circuits.

Environmental fluctuations within specified limits have

virtually no effect on the operation of this control

system. AccuLoad II is available in an explosion-proof

housing for hazardous locations. (See Bulletin

SS06014 for Specifications.)

How To Use This Manual

This manual is to be used as a guide for AccuLoad II-

SEQ firmware.

This manual is divided into five sections: Introduction,

Operations, Dynamic Displays, Program Mode and the

Program Codes.

"Operations" describes the daily operation of

AccuLoad II and what is required of an operator to

effectively load the product.

"Dynamic Displays" describes the information that can

be displayed by AccuLoad II while in the "READY"

state or in the Run Mode.

"Program Mode" describes how to get into the

Program Mode, Program Directory Selection, Program

Code Selection, how to change a program parameter

and how to view the Help Messages.