MANDREL welder EErgo User manual

Instruction Manual

Bedienungsanleitung

Suitable for: Nylon (PA) / PP / TPEE / TPX

EErgo

Hot paddle welder for mandrels

Version 115V

Version 230V

2

Table of content

1.0 Explanation of symbols............................................................................. 3

1.1 Scope of delivery ................................................................................ 4

1.2 Introduction ........................................................................................ 5

1.3 Product description............................................................................. 5

1.4 Safety instructions .............................................................................. 6

1.5 Intended use ..................................................................................... 11

1.6 Risk of electric shock........................................................................ 11

1.7 Transport and storage ....................................................................... 11

1.8 Product information.......................................................................... 12

2.0 Welding................................................................................................... 12

2.1 Set up of the mandrels that need to be welded ................................. 12

2.2 Set up of the EErgo paddle welding tool ........................................... 13

2.3 Welding process .............................................................................. 13

2.4 Recovery from error modes.............................................................. 14

3.0 Service / Maintenance

3.1 Preventive Maintenance .................................................................... 14

3.2 Replacement of the paddle welding tool............................................ 15

3.3 Shipping to the BEHA customer service............................................ 15

3.4 Repair ............................................................................................... 16

4.0 Technical specifications .......................................................................... 16

5.0 Warranty ................................................................................................ 17

3

This operating manual describes the paddle welding tool in all its product varia-

tions. The exact product identification can be found on the product. Please make

sure, the product fits your application. If applicable just sections of the instruc-

tion manual might be significant for several products. Indication can be found at

the corresponding sections.

1.0 EXPLANATION OF SYMBOLS

Symbols used on the device and in the operation manual and their respective

meanings:

Caution! Warning of a potential danger. Please follow operation manual.

Caution! Hazardous voltage, danger of electric shock.

Caution! Hot surface.

Attention. Please observe under any circumstances.

Protection class I according to DIN EN 61140 (VDE 0140-1). All electrical-

ly conductive housing parts are connected with the protective conductor.

Mark of conformity, confirms compliance with the currently valid EMC

directive (2014/30/EU), the standard EN 61326-1 and the low voltage

directive (2014/35/EU) DIN EN 60335-1.

Unit complies with directive (2012/19/EU) WEEE. Do not dispose of unit

in household garbage, but dispose of at recycling center for electric and

electronic end-of-life equipment.

4

Please observe under any circumstances:

The operating manual contains information and instructions neces-

sary for the safe use and operation of the device.

Read operating manual carefully before use of the device and follow it in any

respect.

If this operating manual is not followed or the cautions and instructions

are not observed, this may lead to serious injuries of the user or damage

the device.

1.1 Scope of delivery

After receiving the products, check if the delivery is complete and without dam-

age. The delivery contains the following:

1 pc. EErgo,

115V or 230V 1 pc. Torx - wrench 1 pc. FZ01 Vario (guide

clamp, up to Ø 10 mm)

1 pc. FZ02/3 (guide clamp,

Ø 10 - 26 mm) 1 pc. Carrying case 1 pc. Instruction manual

5

Optional Accessories:

EErgo tool plate protection,

protection holder and

bench vise

Ratchet Cutters and/or

spare blades

for straight mandrel cut

Edge cutter SE02

for welding bead cleaning

FZ02/2S (guide

clamp, Ø >26 mm) Storage Stand with

magnetic base for

EErgo

Spare paddle EErgo Heat conducting

paste

1.2 Introduction

The paddle welding tools are especially designed for welding mandrels made

of PP, Nylon (PA), TPEE and TPX. They are characterized by a short heating-up

period, an easy and ergonomic handling as well as a faultless performance.

The devices are excellently suitable for maintenance and repair as well as for

production.

6

1.3 Product description

Paddle welding plate

Torx Screws for

change of hot paddle Handhold

Connector

LED Operating status

red / green

Button PP Button Nylon,

TPEE, TPX

The BEHA EErgo paddle welding tool has the following properties:

• Short heating-up time of approx. 5 minutes

• Easy selection of welding temperature through push buttons (PP / 200°C,

Nylon, TPEE, TPX / 260°C)

• Simple indication: green LED: welding temperature achieved, red LED:

heating-up respectively cooling down

• Accurate electronic regulation of the welding temperature

• Ergonomic operation through a 90° angle between paddle welding plate and

handle

• Compact design

• Meets the standards EN 60335-1 and EN 61326-1

7

1.4 Safety instructions

The BEHA EErgo paddle welding tool was manufactured and

tested in accordance with standard DIN EN 60335-1 and has

left the factory in perfect condition. To maintain it in perfect

condition, the user has to observe the safety instructions in

this manual.

In all cases, the currently valid accident prevention

regulations of the Accident Prevention & Insurance

Association for electrical plants and equipment have to

be followed.

Operation is only permitted with the voltage(s) specified

on the product or in this operating manual! Non-obser-

vance of the admissible voltage(s) may cause risks for

the user (high voltage) or damage the unit!

Only connect the product to correctly installed sockets.

Take special care that the grounding (PE) is correct.

To avoid electric shock, observe the relevant safety and

VDE standards concerning too high touch voltages when

working with voltages exceeding 120V (60V) DC or 50V

(25V) eff. AC. The voltages given in brackets apply to

specific fields such as medical or agricultural.

Before powering on the product, ensure that the mains

plug as well as the product itself are in perfect working

conditions. Check in particular if the cable or housing

is cracked, attrited, inadmissibly bent, cut or somehow

damaged.

8

Safety of the user is no longer guaranteed in the follow-

ing cases:

• Visible damage such as cracks, ruptures, holes in

insulation or housing etc.

• The product does not function any longer

• The product was stored in unfavorable conditions

• The product was modified/changed

Do not use damaged or modified products, there is

danger of an electric shock!

At the end of the lifetime dispose of products according

to regulations.

Always pay attention to ensure the welding plate can

never touch the ground surface or anything else when

putting down the paddle welding tool.

The product is featured with an internal electrical fuse as

well as a thermal protection circuit. The exchange of the

internal fuse has to be done through the BEHA Service.

Only qualified personnel are allowed to carry out repair

work. For this purpose, please return the product to an

authorized BEHA service partner or directly to BEHA

headquarters.

Please avoid that direct sunlight heats up the product.

This is the only way to ensure that the product works

properly and has a long life. Direct sun light may cause

9

overheating and damage to the product and jeopardize

the safety of the user.

The product is intended for use in dry and enclosed

spaces. Do not use the product in a wet or humid envi-

ronment. Avoid contact of the product with water.

EX Never use the product in potentially explosive

environments.

The paddle welding plate heats up very hot (about

200°C or rather 260°C) during operation. Never

directly touch the welding plate. Only hold the product

on the specified handle. Never get the paddle welding

plate in contact with inflammable material. Never touch

the power supply connection cable with the welding

plate.

Only qualified personnel is allowed to exchange the pad-

dle welding plate. The mains plug has to be unplugged

and the paddle welding plate has to be cooled down.

Only original BEHA paddle welding plates have to be

used for replacement.

The quality of the welded connection is depend-

ing on the melting performance, cooling down times

and the environmental conditions as well as the

correct implementation of the welding process. Just

correct welding ensures a reliable connection of the

mandrels. Detect the correct times plus the right proce-

dure through testing. Get familiar to the welding process.

10

A scratched or contaminated paddle welding plate

might lead to defective welding results. Only use

clean and undamaged paddle welding plates.

After each welding procedure the paddle welding

plate has to be cleaned with a soft cotton cloth. In no

case use peaked or sharp-edged objects for clean-

ing. Only use clean paddle welding plates as other-

wise burnt welding remains might cause a heavy

impact on the quality of the welding seam.

Never operate the paddle welding tool unattended! Put

down the running tool only for a short period of time. In

longer lasting breaks it is absolutely necessary to unplug

the product.

Never use the paddle welding tool without the attached

paddle welding plate!

This appliance can be used by children aged from 12

years and above and persons with reduced physical,

sensory or mental capabilities or lack of experience and

knowledge if they have been given supervision or in-

struction concerning use of the appliance in a safe way

and understand the hazards involved.

Children shall not play with the appliance.

Cleaning and user maintenance shall only be made by

trained persons.

11

1.5 Intended use

The unit may be used only under the conditions and for the purposes for

which it was designed. Therefore, especially observe the safety instruc-

tions and technological specifications such as environmental conditions

and use in a dry environment.

Only qualified personnel instructed in the use may operate the product.

Please ensure that the product is only used in a safe environment.

The product meets the current regulations and standards with respect to

the electromagnetic compatibility. Very rarely it may occur that the product

has a negative impact on other electrical or electronic devices or the func-

tioning gets disrupted through other electrical or electronic devices.

Clean product with dry cloth only. Do not use water or cleaning agents.

1.6 Risk of electric shock

When product is opened, modified or damaged the operational safety is no

longer guaranteed. Only authorized service technicians may open the unit.

Repair of the product must be done by BEHA repair service.

1.7 Transport and storage

Please keep original packaging for reshipment, e.g. in case of repair. Damage in

transit is not covered by warranty.

The product has to be stored in an enclosed and dry space. Handle the unit

with care during transport to avoid damage.

Store the product outside of the reach of unauthorized persons, e.g. chil-

dren.

If the product is moved at extreme temperature differences (≥20°C), an

acclimatization time of at least 2 hours is necessary before connecting it to

the mains.

12

1.8 Product information

The nameplate including product name, part number and serial number is

attached to the back of the product. Please note these data in the operating

manual.

Product name

Part number

Purchase date

2.0 WELDING

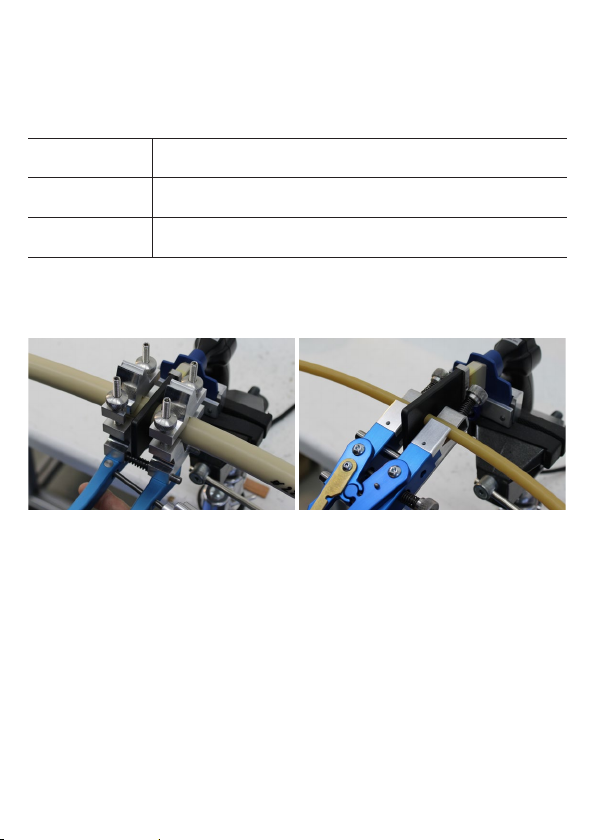

2.1 Set up of the mandrels that need to be welded

• Recommendation: Heating up the mandrels to room temperature to achieve the

best welding result.

• Cut the ends of the mandrel to be connected flat.

• Fix the mandrel in the guide clamp FZ01 or FZ02/3 and align the ends.

13

2.2 Set up of the EErgo paddle welding tool

• Plug in the welding tool into the socket.

• Set up the temperature by pressing the button PP or Nylon.

• Red LED indicates that the tool is heating up.

• Wait with welding until the LED lights up green.

• To change the temperature press the corresponding button.

• The red LED indicates either that the product is heating up or cooling down.

• Wait with welding until the LED lights up green.

• Check the temperature of the paddle welding plate using a temperature meas-

uring device with surface sensor every now and then.

PP-Button 200°C / 392°F PP

Nylon-Button 260°C / 500°F Nylon (PA), TPEE, TPX

2.3 Welding process

• Insert the paddle welding plate into the slot between the mandrels.

• Slightly press the mandrel ends against the paddle welding plate.

• Melt and weld the material for about 5-10 seconds, depending on the mandrel

thickness. The welding bead has to be bubble free and formed as a 3-4mm

wide bulge along the mandrel ends. The whole mandrel end must show the

bulge.

• Slightly open the guiding clamp to remove the paddle welding plate.

• Press the mandrel ends against each other quickly and tighten the lock screw.

• Cool down the mandrel inside of the guide clamp for 5-10 minutes.

• Use the SE02 edge cutter to cut off or remove the bulge.

• After every welding process use a cotton cloth to remove adhering plastics

from the paddle welding plate. Never use peaked or sharp-edged objects for

cleaning as the Teflon coating might be damaged.

14

• The exact melting- and cooling times are depending on the type of mandrel as

well as the environmental conditions. We suggest to practice the welding pro-

cess and to do testing in advance.

2.4 Recovery from error modes

• If both of the LEDs are blinking (green or red), alternating or simultaneously,

the EErgo has entered one of the error modes.

• It is possible to try to recover an error mode by pressing one of the keys, ac-

cording to desired working temperatur, PP or Nylon.

• In case of repeatedly entering an error mode, the number of the recovery at-

tempts is limited to four.

• However, in case of an error mode, a user is advised to immediately contact the

service, since operating in an error mode can lead to overheating of the unit.

3.0 SERVICE / MAINTENANCE

3.1 Preventive maintenance

Please clean hot paddle after every welding process and replace hot pad-

dle, if permanent polluted surface and/or antisticking layer is released/

weared out.

15

3.2 Replacement of the paddle welding plate

The paddle welding plate can be replaced

through instructed personnel. Not correct-

ly assembled paddle welding plates can

cause incorrect welding or endangering

persons. We suggest to do the replace-

ment through the BEHA service.

• The mains plug hast to be unplugged and the paddle welding plate has to be

cooled down.

• Only original spare parts may be used.

• Loosen the screws at the adapter with the supplied Torx - wrench.

Attention: Only pull or push the hot paddle. Turning or twisting can dam-

age the tool.

• Take off the paddle welding plate. Ensure to not damage the heating elements.

• Apply heat conducting paste to the heating elements.

• Attach the new paddle welding plate. Ensure not to damage the heating ele-

ments.

Attention: Only pull or push the hot paddle. Turning or twisting can dam-

age the tool.

• Screw the paddle welding plate with the adapter.

Spare Parts information

Spare paddle for EErgo, Order-No. FBWEE002

16

3.3 Shipping to the BEHA customer service

Please always register the BEHA EErgo hot paddle welder by phone or

e-mail before sending it to BEHA customer service. The goods must al-

ways be declared with the IncoTerm "DDP" (delivered duty paid). In this

way you avoid a possible rejection at customs and additional extra costs.

Please refer to the return note for the declaration of the repair (see www.

mandrel-welder.com).

3.4 Repair

Should the machine fail despite careful manufacturing and testing proce-

dures, the repair must only be carried out by an authorised BEHA custom-

er service centre.

If it is necessary to replace the connecting cable, this must be done by the

manufacturer or his representative in order to avoid safety hazards.

4.0 TECHNICAL SPECIFICATIONS

Admissible ambient

temperature: 0…40°C (32…104°F)

Operating voltage: EErgo 230 V: 230 V / 220 V AC, 50/60Hz

EErgo 115 V: 115 V AC, 50/60Hz

Heating-up period: approx. 5 minutes

Power: 120 W

Welding temperature: PP:

200°C, ± 10°C; 392°F, ± 10°F

Nylon / TPEE / TPX:

260°C, ± 10°C; 500°F, ± 10°F

Indicator: 2 red / green LEDs

Welding mirror: Teflon coated

Altitude for operation: max. 2000 m

Maximal humidity: 80%, 40°C (104°F)

17

5.0 WARRANTY

BEHA EErgo hot paddle tools are subject to strict quality controls. Should, how-

ever, defects in functioning occur in daily practice, we grant a warranty of 12

months (only valid in conjunction with the invoice). Productions or material

defects will be removed by us free of additional charge if failure occurs without

third party interference and the product returns to us unopened.

Damage resulting from dropping or resulting from incorrect use are explicitly

excluded from the guarantee. This applies in particular for the welding mirror

with Teflon coating.

Modifications and errors excepted.

18

19

Bedienungsanleitung

geeignet für: Nylon (PA) / PP / TPEE / TPX

EErgo

Schweißspiegel für Schlauchdorne

Version 115V

Version 230V

20

Table of content

1.0 Erklärung der Symbole............................................................................ 21

1.1 Lieferumfang..................................................................................... 22

1.2 Einleitung.......................................................................................... 23

1.3 Produktbeschreibung........................................................................ 24

1.4 Sicherheitshinweise .......................................................................... 25

1.5 Bestimmungsgemäße Verwendung................................................... 29

1.6 Gefahr durch elektrischen Schlag...................................................... 29

1.7 Transport und Lagerung.................................................................... 30

1.8 Informationen zum Gerät .................................................................. 30

2.0 Schweißen............................................................................................... 31

2.1 Vorbereiten des zu verschweißenden Schlauchdorns........................ 31

2.2 Vorbereiten des EErgo Spiegelschweißgerätes ................................. 31

2.3 Schweißvorgang ............................................................................... 32

2.4 Wiederherstellen bei Fehlermodus .................................................... 32

3.0 Service / Maintenance

3.1 Vorbeugende Instandhaltung ............................................................ 33

3.2 Tauschen des Schweißspiegels ......................................................... 33

3.3 Versand zum BEHA-Service .............................................................. 34

3.4 Reparatur.......................................................................................... 34

4.0 Technische Daten ................................................................................... 35

5.0 Garantie................................................................................................... 35

Table of contents

Languages:

Other MANDREL welder Welding System manuals

Popular Welding System manuals by other brands

Hypertherm

Hypertherm powermax1000 Service manual

ASKAYNAK

ASKAYNAK MasterSTICK 505 user manual

Lincoln Electric

Lincoln Electric VANTAGE 400 (AU) Operator's manual

Miller Electric

Miller Electric SWINGER 180 Installation, operation & maintenance manual

Lampert

Lampert PUK 3s professional operating instructions

Lincoln Electric

Lincoln Electric SEVERE DUTY SVM187-A Service manual