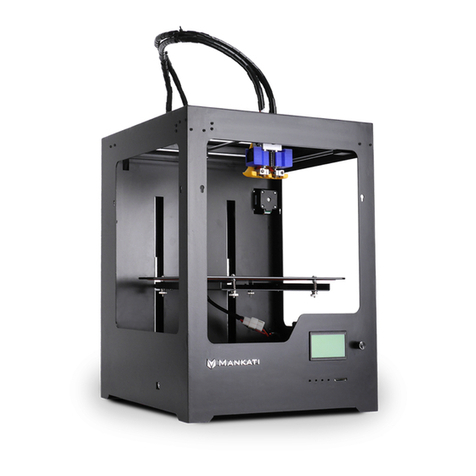

Mankati Fullscale XT User manual

Fullscale XT

a Fast, High Resolution, Huge Printing Volume 3D Printer

User Manual

WELCOME 1

Safty 2

Specications 3

How it Works 4

SETUP 5

Unpacking 6

Accessory 9

Tool Box 10

Setting Up Mankati Fullscale XT 11

Fullscale XT Outlook 15

LCD INSTRUCTION 16

LCD Menu Structure 17

LCD Menu 18

SOFTWARE 20

Download and Install 21

Interface 22

ParameterDenition 23

FIRST RUN 29

Stick the Kapton tape 30

Leveling Build Plate 33

Feed the Filament 35

Print from SD Card 36

Unload the Filament 37

MAINTENANCE 38

Maintenance 39

TROUBLESHOOTING 41

Setting and Calibration Problems 42

Hardware Problems 43

Printing Problems 45

Contents

TO THE

MANKATI FULLSCALE XT

WELCOME 1

To get perfect prints, your may need to experiment and tinker at the beginning.

This User Manual will guide you to start your journey with the Mankati Fullscale XT

easily and quickly.

Forget your existing knowledge of other 3D printers, take the time to learn about

your Mankati Fullscale XT, it will show you a completely new experience.

Print your idea right from now on!

2

Safty

GROUND CONNECTION

CAUTION: Make sure the power grounded, if not, may cause the accumulation of static-electricity so as to damage electronic system.

HEAT and HIT

WARNING: Mankati Fullscale XT 3D Printer generates high temperatures and includes moving parts that can cause injury. Please Never Touch the nozzle,

the heated aluminum block or the build plate after preheating or printing to avoid scalding.

CAUTION: Do not leave the printer attended for a long time during printing. If you have to do so, do follow these guidances:

• Ensure that the first layer of the print is properly land on the build plate.

• Ensure filament wound on the spool to keep feeding smoothly, in case of tangles.

• Monitor your print periodically.

CAUTION: The melt filament will emit the plastic odor during printing. Please keep ventilation in the work place.

CAUTION: In case of emergency disconnect power supply from wall socket.

CAUTION: Refit and modification privately may destroy the working and safty performance. So any refits and modifications not expressly approved by

Mankati can void the right of warranty and safty gurantee.

COMPLIANCE: Your Mankati Fullscale XT has been tested strictly by SGS with the permission of FCC, CE, IC, C-Tick and ROHS.

It complies with the rules and limits of EMC, MD and ROHS, to provide reasonable protection against harm to the human, from electromagnetic

compatibility, mechanical structure and chemical component.

The users have the right to ask for the testing report with Mankati.

www.mankati.com 3

Specifications

Fullscale XT

Forming Tech. Fused deposition modeling (FDM)

Extruder Number 1 or 2 (Dual extruders Perfect supported)

Build Size 250*250*300mm

Specication

Precision X,Y 0.01mm, Z 0.015mm

Layer Resolution 0.04mm-0.4mm

Nozzle Diameter 0.4mm

Max. Travel Speed 250mm/sec.

Max. Print Speed 180mm/sec.

Max. Extruder Temperature 270Deg.

Max. Hot Bed Temperature 110Deg.

Max. Extrude Speed 100mm/sec

Filament

Filament Type ABS, PLA(Spec.), PVA, PS, Nylon

Filament Diameter

3mm

Filament Temperature 150~270Deg.

Filament Colors Black, White, Red, Yellow, Green, Blue, etc.

Hardware

Controller Arduino ATmega2560 R3Micro Controller

Mother Board Mankati Stable Main Board V3.x

Stepper Motor X, Y axis 42*48, 1.3A; Z axis 42*63, 1.5A

Geared Motor E42*42, Ratio 1:10

Power Input 110~220V, 1.5A

Power Output 24V, 10.5A

Software

Operating System XP, Vista, Win7, Win8, Mac, Linux/Unbutu

File Format STL, OBJ, GCode

Printing Software and Slicer MankatiUM

Software Language

English, Deutsch, French, Nederlands, Spanish, Polish

Machinery

Dimensions 380*420*530mm

Weight Around 34KG

4

How it Works

Mankati Fullscale XT 3D Printer makes solid, three-dimensional objects out of melted filament.

Your 3D designed files are translated into instructions for the Mankati Fullscale XT and read by the machine via SD card.

The Mankati Fullscale XT then heats the filament and squeezes it out through a nozzle onto a heated surface to build a solid object,

layer by layer. This method is called Fused Deposition Modeling [FDM].

Preparing the model

Use a 3D modeling software

to output stl or obj format 3D

modelle.

MankatiUM

MankatiUM is a software to

preparethegcodeleforyour

Fullscale XT.

In MankatiUM, you can set

printing parameters for your

model, such as layer thickness,

printing speed and nozzle

temperature, then output a

gcodeleforprinting.

Transfer the GCode file

SavetheGCodeleintotheSD

card, and insert it into the SD

card reader of the printer.

Prepare the printer

Before 3D printing, you need to

loadthelamentfortheprinter.

Print it!

Operate the knob beside the LCD

and choose the model from the

SD card inserted into the printer.

SETUP 2

Your Mankati 3D Printer was built and packaged very carefully at the Mankati

factory. Please take your time and carefully unpacking it and getting set up.

6

Unpacking

1. PlacetheMankatiFullscaleXTontheoor.Leave

enough available space for unpacking

3. Removetherstcardboardlayer.Opentheplastic

bag.

2. Your Mankati Fullscale XT is packed multiply by

carton, cardboard, foam and sealed bag to ensure the

machine to your hands in perfect status.

NOTE: You can download a PDF copy of this User

manual under manual at the support page: http://www.

mankati.com/download.html

www.mankati.com 7

Unpacking

6. Removethestretchlmaroundthe3Dprinter.You

canseealltheaccessories,toolsandlaments.

5. Place it on a stable surface, and leave enough space

surrounding it to check accessories.

4. Now it’s time to take out your Mankati Fullscale

XT from the box. Lift it out by grasping the frame

rmlybutgentlyattheleft ①and right ②of the

Mankati Fullscale XT.

Caution: Be careful NOT to grip the belt or shaft of

the motion system.

8

Unpacking

8. T

akingoutthelaments:

Fortheeaseoftransport,thelamentsarexedtightly

by build plate supporter. Let’s take them out, following

thenext3steps:

1) Connect power wire to printer.

2) Turn on the printer.

3)GototheLCDmenu:"Prepare>Autohome",and

the two holders will go to the top of Z axis.

4)TakeoutthetwospoolsofPLAlamentandthetwo

feeding devices.

7. T

ake all the accessories out.

www.mankati.com 9

Accessory

Takingoutaccessories,toolboxandlamentandcheckifbelowthingsareincluded:

1)2spoolsofPLAlament,diameter3mm,1kg/spool;

2)1Buildplatform:ItispackedinthewhiteEPE.

3)1toolbox:includingthenecessarytoolsforinstallationandotheraccessories.

4)2feedingdevices:constitutedbygearmotorandfeederwiththeadvantagesof

high accuracy and easy to operate.

5)3enclosurecovers:installedon3sides(front,left,right)tokeepthetemperature

constant inside printing space.

10

Tool Box

Checking if you find that anything described in the manual is missing, email us at

1) 1*USB cable: Connect computer and printer when printing or renewing

hardware.

2) 1*Power wire: Supply power.

3) 1*8GB Kinston storage card to store Gcode file for printing.

4) 2*printer handles: Install on machine and help to move machine easily.

5) 2*filament holders: Hold filament spool.

6) 5*big nuts: 4 for installation of build platform, 1 for backup.

7) 1* black plastic nut: Backup nut for leveling the heat bed.

8) 5* small nuts: 4 to install on feeding device, 1 for backup.

9) 1* fuse: Backup for power interface.

10) 1* power switch: Backup for broken power switch.

11) 1* button: Backup for broken button.

12) 1* Heating tube: Backup for broken heating tube.

13) 1* temperature controller: Backup for broken temperature controller.

14) 1* Bottle lubricant oil: XY axis and guide rails need to lubricate terminally.

15) 1* Kapton tape: Stick on the build plate to ensure the model fixing on the

build plate.

16) 1* Scraper: To take out the model and clean the build plate.

17) 1* Screwdriver: Installation tool.

18) 1* Tweezer: Clean the platform after printing, or clean the nozzle and printer.

19) 2* Spanners: Installation tools

20) 1* Drill: Clean the nozzle.

21) 1* needle: Clean and unchoke the nozzle.

www.mankati.com 11

Setting Up Mankati Fullscale XT

1. Install the Holders

1). The four holes are

holders installation

position.

2). You need a screwdriver,

four screws and two

holders.

3). Use the screwdriver to

xthetwoholdersonleft

and right of the printer

top side.

Note: Please confirm

you have tightened the

screw to avoid accident

of getting loose when

moving the printer.

4). Holders installation

done.

12

4) Connect the power wire and data cable

of platform with the connectors.

Caution: Make sure the connection fully.

Otherwise, it can cause the platform

heating problems or connectors over-

heated.

5) Done.

Setting Up Mankati Fullscale XT

2. Install the Build Platform

1) Turn on your Fullscale XT, enter “Prepare

>Moveaxis>Move1mm>MoveZ”,

loweringZaxisalittle(forexample30mm)

to avoid collision between nozzle and

build platform while installation.

3) Take out the nuts ⑥and screwdriver

fromthetoolboxtoxtheplatformand

platformholderrmly.

Note: After installing the platform

installation, please tighten the four black

screws a little bit more under the build

plate to lower it to avoid knocking the

extruders in next operation.

2) Insert the platform’s holder into the

middle of platform.

Note: The end of platform with black

connection wire should toward the

printer.

www.mankati.com 13

4) Feeding device

installation done.

Setting Up Mankati Fullscale XT

3. Feeding Device Installation

1)Feedingmotor:

using small wrench

toxNo.1feeding

motor on position 1.

3) Connect the data cable

with feeding devices.

2) Insert the end

of feeding tube

into the socket of

feeding motor and

tightenrmly.

14

Setting Up Mankati Fullscale XT

4. Filament Spool Holder Installation

5. Lubricate the Guide Rails

1) Take the two spool

holders out of the tool

box.

We clean the guide

rails before sending

the printer out, so

please lubricate the

guide rails before the

rstprinting.

1). Lubricate the two

cross guide rails.

2). Lubricate the four

guide rails around the

printer framework.

Notice: Lubrication is very

important for good printing

performance, or else you

might encounter printhead

stuck problem.

2).Installlamentspool’s

holder.

www.mankati.com 15

Fullscale XT Outlook

1. SD-card slot

2. Push and rotate button

3. Display

4. Build plate screws

5. Build plate

10. Power Socket

11. Name plate

12. Spool holder

13. Material feeder

14. USB Socket

6. Print head

7. Filament guide tube

8. Printer holder

9. Power switch

LCD INSTRUCTION 3

In this chapter you will learn about detailed introductions of the LCD menus.

1 - Prepare

1.1 - Auto Home

1.2 - Disable Steppers

1.3 - Move Axis

1.3.1 - Move 10mm

1.3.1.1 - Move X

1.3.1.2 - Move Y

1.3.2 - Move 1mm

1.3.2.1 - Move X

1.3.2.2 - Move Y

1.3.2.3 - Move Z

1.3.2.4 - Extruder

1.3.2.5 - Extruder 2

1.3.3 - Move 0.1mm

1.3.3.1 - Move X

1.3.3.2 - Move Y

1.3.3.3 - Move Z

1.3.3.4 - Extruder

1.3.3.5 - Extruder 2

1.4 - Preheat PLA

1.4.1 - Preheat PLA 1

1.4.2 - Preheat PLA 2

1.4.3 - Preheat ALL

1.4.4 - Preheat PLA Bed

1.5 - PreheatABS

1.5.1 - Preheat ABS 1

1.5.2 - Preheat ABS 2

1.5.3 - Preheat ALL

1.5.4 - Preheat ABS Bed

1.6 - Leveling Bed

1.7 - Cool Down

2 - Control

2.1 - Temperature

2.1.1 - Nozzle

2.1.2 - Nozzle 2

2.1.3 - Bed

2.1.4 - Fan Speed

2.1.5 - Auto Temp

2.2 - Motion

2.3 - Restore Failsafe

2.4 - Save Memory

2.5 - Restore Factory

2.6 - Firmware Version

3 - Cool Down 4 - No SD Card

Info Screen

www.mankati.com 17

LCD Menu Structure

18

LCD Menu

Info Screen

1. Actual Temperature of Nozzle 1;

2. Preset Temperature of Nozzle 1;

3. Actual Temperature of Nozzle 2;

4. Preset Temperature of Nozzle 2;

5. Actual Temperature of Build Plate;

6. Preset Temperature of Build Plate;

7. Cooling Fan;

8. Fan Speed Rate;

9. Filament Feed Rate;

10. Printing Process Bar;

11. Printing Time;

12. Build Plate Coordinate;

1

9 10 11 12

2 3 4 5 6 7 8

Press the knob to enter the menu:

1 - Prepare: The printer enters ready state

1.1 - Auto home

Theprinterreturnstooriginalstate(InX.Ydirection,theextruderreturnstheleftbottomintop

view;InZdirection,thebuildplatereturnstotopposition)

1.3 - Move axis:

Move 10mm: Move 10mm each step

Move X: Move 10mm each step in X direction

Move Y: Move 10mm each step in Y direction

Move 1mm: Move 1mm each step

Move X: The extruder will move 10mm each step in X direction

Move Y: The extruder will move 10mm each step in Y direction

Move Z: The build plate will move 10mm each step in Y direction

Extruder: Thefeedingmotorofleftnozzlewillextrudethelamentineachstepof1mm

Extruder2: Thefeedingmotorofrightnozzlewillextrudethelamentineachstepof1mm

Move 0.1mm: Move 0.1mm each step

Move X: The extruder will move 0.1mm each step in X direction

Move Y: The extruder will move 0.1mm each step in Y direction

Move Z: The build plate will move 0.1mm each step in Y direction

Extruder: Thefeedingmotorofleftnozzlewillextrudethelamentineachstepof0.1mm

Extruder2: Thefeedingmotorofrightnozzlewillextrudethelamentineachstepof0.1mm

1.4 - Preheat PLA:

Preheat PLA1: PreheatextruderandbuildplatetotheworkingtemperatureofPLArequired(

Default:Extruder,215℃,

Build plate, 45℃)

Preheat PLA2: Preheat extruder 2 and Build plate to the working temperature of PLA

required(Default:Extruder,215℃; Build plate, 45℃)

Preheat PLA All: Preheat two extruders both and build plate to the working temperature of

PLArequired(Default:Extruder,215℃; Build plate, 45℃)

Preheat PLA Bed: PreheatbuildplatetotheworkingtemperatureofPLArequired(Default:

Build plate, 45℃)

1.5 - Preheat ABS:

Preheat ABS1: PreheatextruderandbuildplatetotheworkingtemperatureofABSrequired(

Default:Extruder,255℃; build plate, 45℃)

Preheat ABS2: Preheat extruder 2 and build plate to the working temperature of ABS

required(Default:Extruder,255℃; Build plate, 45℃)

Preheat ABS All: Preheat two extruders both and build plate to the working temperature of

Table of contents

Other Mankati 3D Printer manuals