9 Operation .................................................................................................................................................... 20

10 Maintenance................................................................................................................................................ 21

10.1 Maintenance schedule ......................................................................................................................... 21

10.1.1 Further information.................................................................................................................... 21

10.2 Replace of the maintenance kit............................................................................................................ 21

10.2.1 Required tools / material ........................................................................................................... 21

10.2.2 Starting point / preparatory activities......................................................................................... 21

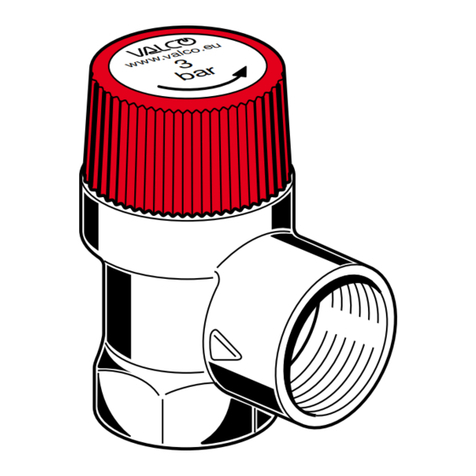

10.2.3 Disassembly of spring module and inlet connection................................................................. 22

10.2.4 Disassembly of control module ................................................................................................. 22

10.2.5 Maintenance of the stem........................................................................................................... 23

10.2.6 Assembly of the control module................................................................................................ 23

10.2.7 Assembly of spring module and connecting piece.................................................................... 24

10.2.8 Final activities ........................................................................................................................... 24

10.3 Torques ................................................................................................................................................ 25

10.4 Lubrication schedule ............................................................................................................................ 26

10.5 Spare parts and wearing parts ............................................................................................................. 27

10.5.1 Contact...................................................................................................................................... 27

10.5.2 Sending in the valve.................................................................................................................. 27

11 Error search, troubleshooting and repair ................................................................................................ 28

11.1 Malfunctions ......................................................................................................................................... 28

11.1.1 Help in case of malfunctions ..................................................................................................... 28

12 Decommissioning, dismantling and disposal ......................................................................................... 28

12.1 Decommissioning................................................................................................................................. 28

12.1.1 Preparation ............................................................................................................................... 29

12.1.2 Procedure ................................................................................................................................. 29

12.1.3 Subsequent activities ................................................................................................................ 29

12.2 Disassembly......................................................................................................................................... 29

12.2.1 Preparation ............................................................................................................................... 30

12.2.2 Procedure ................................................................................................................................. 30

12.3 Disposal ............................................................................................................................................... 30

13 Cleaning ...................................................................................................................................................... 30

13.1 External cleaning.................................................................................................................................. 30

13.2 CIP/SIP cleaning .................................................................................................................................. 31

13.2.1 Required tools........................................................................................................................... 31

13.2.2 Preparation ............................................................................................................................... 31

13.2.3 Procedure ................................................................................................................................. 32

13.2.4 Concluding activity .................................................................................................................... 32

14 Inspection and testing ............................................................................................................................... 32

14.1 Test plan .............................................................................................................................................. 32

14.1.1 Corrosion .................................................................................................................................. 32

14.1.2 Leakage .................................................................................................................................... 32

14.1.3 Damage and deformation ......................................................................................................... 33

14.1.4 Checking the set outlet pressure .............................................................................................. 33

15 Information on REACH and RoHS ............................................................................................................ 35

15.1 Declaration on the REACH Regulation 1907/2006 .............................................................................. 35

15.2 Declaration on the RoHS Directive 2011/65/EU .................................................................................. 35

3

DM 152V-4.X.231 Stand 14.04.2023 Made in Germany