Mannesmann INDRAMAT ECODRIVE DKC01.1 User manual

ECODRIVE

DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P

Trouble Shooting Guide: ASE 02VRS

mannesmann

Rexroth

engineering

Indramat

271636

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

ECODRIVE Drive Controller s DKC01.1 / DKC 11.1

Trouble Shooting Guide

DOK-ECODRV-ASE-02VRS**-WAR1-DE-P

• Mappe 56-02V-EN / Register 10

• 209-0073-4304-00

This document is design to assists maintenance personnel in identifing

errors with the machinery

It should:

• help in understanding error messages

• help in finding the causes of errors

• describe the procedure for trouble shooting

• simplify the process of establishing contact with the INDRAMAT

Customer service department

This documentation is meant as a switch board panel supplement for the

machine manufacturer.

Docu-identification of released up to

this point

Enable date

Remarks

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P

07.96

First release

INDRAMAT GmbH, 1996

Transmission as well as reproduction of this documentation, exploitation

or communication of its contents is not permitted without expressed

written permission. Violation of these stipulations will require

compensation. All rights for the issuance of the patent or registered

design reserved. (DIN 34-1)

INDRAMAT GmbH •Bgm.-Dr.-Nebel-Str. 2 •D-97816 Lohr a. Main

Telephone 09352/40-0 •Tx 689421 •Fax 09352/40-4885

Abt. .END (HP)

Changes in the contents of the documentation and the delivery rights for

the products are reserved.

Title

Type of documentation

Docum. type

Internal filing index

What is the purpose of this

document?

help you use this

documentation

Procedure for change

Copyright notice

Publisher

Liability

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Contents I

Contents

1 Diagnostic Message Description 1-1

1.1 Overview of the Diagnostic Message Descriptions..............................................................................1-1

Diagnostic Message Types...........................................................................................................1-1

Construction of a diagnostic message..........................................................................................1-1

2 Description of Diagnostic Letters F... and E... 2-1

2.1 Error Diagnostic Messages..................................................................................................................2-1

UL Motor Type not Reported.........................................................................................................2-1

PL Default Value of the Parameter Load ......................................................................................2-1

F207 Switching to an Uninitilized Operating Mode........................................................................2-2

F218 Heatsink Overtemperature Shutdown..................................................................................2-2

F219 Motor Overtemperature Shutdown.......................................................................................2-2

F220 Bleeder Overtemperature Shut Down..................................................................................2-3

F226 Undervoltage Error...............................................................................................................2-3

F228 Excessive Deviation.............................................................................................................2-4

F229 Motor Encoder Error: Quadrant Error ..................................................................................2-4

F248 Low Battery Voltage.............................................................................................................2-5

F262 Status Outputs Short Circuited ............................................................................................2-5

F276 Absolute Encoder Error, Position Deviation > P-0-0097......................................................2-6

F630 Travel Limit Value Exceeded..............................................................................................2-6

F644 Travel Limit Switch Detected ...............................................................................................2-7

F822 Motor Encoder Failure: Signal too Small..............................................................................2-7

F860 Overcurrent: Short in Powerstage........................................................................................2-8

F870 +24 V Error...........................................................................................................................2-8

F873 Power Supply Driver Stage Fault.........................................................................................2-9

F878 Velocity Loop Error...............................................................................................................2-9

F879 Velocity Limit Value Exceeded (S-0-0092).........................................................................2-10

F895 4 kHz Signal Error..............................................................................................................2-10

2.2 Warning diagnostic messages...........................................................................................................2-11

E250 Heatsink Overtemperature Warning..................................................................................2-11

E251 Motor Overtemperature Warning.......................................................................................2-11

E252 Bleeder Overtemperature Warning....................................................................................2-12

E253 Target Position Out of Range............................................................................................2-12

E254 Drive not Referenced.........................................................................................................2-13

E255 Feedrate-Override(S-0-0108) = 0......................................................................................2-13

E256 Torque Limit Value = 0.......................................................................................................2-13

E257 Continuous Current Limiting Active....................................................................................2-14

E258 Selected Process Block is not Programmed .....................................................................2-14

E259 Command Velocity Limit Active .........................................................................................2-14

E264 Target Position not Representable ....................................................................................2-15

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

II Contents DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

E825 Overvoltage Warning.........................................................................................................2-15

E830 Position Limit Value Exceeded ..........................................................................................2-15

E831 Position Limit Value Reached During Jogging...................................................................2-16

E844 Travel Limit Switch Activated.............................................................................................2-16

3 Description of Diagnostic Letters C... and A... 3-1

3.1 Command Diagnostic Messages.........................................................................................................3-1

C100 Communication Phase 3 Transition Check.........................................................................3-2

C101 Invalid Communication Parameters (S-0-0021)..................................................................3-2

C102 Limit Error Communication Parameters (S-0-0021)............................................................3-2

C200 Communication Phase 4 Transition Check.........................................................................3-2

C201 Invalid Parameter Block (-> S-0-0022)................................................................................3-3

C202 Limit Error Parameter (-> S-0-0022)....................................................................................3-3

C203 Parameter Calculation Error (-> S-0-0022) .........................................................................3-3

C207 Loading Error LCA...............................................................................................................3-3

C208 Invalid SSI Parameter (-> S-0-0022)...................................................................................3-4

C211 Invalid Feedback Data (-> S-0-0022) ..................................................................................3-4

C212 Invalid Amplifier Data (-> S-0-0022)....................................................................................3-5

C213 Position Data Scaling Error..................................................................................................3-5

C214 Velocity Data Scaling Error..................................................................................................3-6

C215 Acceleration Data Scaling Error...........................................................................................3-6

C216 Torque Data Scaling Error...................................................................................................3-7

C217 Motor Feedback Data Reading Error...................................................................................3-7

C220 Motor Feedback Initilization Error........................................................................................3-7

C227 Modulo Range Error ............................................................................................................3-8

C300 Command: Set Emulation - Absolute Value........................................................................3-8

C300 Set Absolute Measuring.......................................................................................................3-8

C301 Setting Absolute Measurement not Allowed, Drive Enabled ...............................................3-8

C302 Absolute Measurement System not Installed......................................................................3-8

C400 Switch from Operational to Parameter Mode ......................................................................3-9

C401 Active Drive, Transition is not Permissable.........................................................................3-9

C500 Reset Class 1 Diagnostic ....................................................................................................3-9

C600 Drive Controlled Homing Procedure...................................................................................3-9

C601 Homing Procedure not Possible without Drive Enable........................................................3-9

C602 Zero Switch to Home Reference Error ..............................................................................3-10

C603 Homing Procedure not Possible in this Operating Mode...................................................3-10

C604 Homing Procedure not Possible with Absolute Measurement Control..............................3-10

C700 Basic Load.........................................................................................................................3-11

C800 Load Basic Parameters.....................................................................................................3-11

3.2 State diagnostic messages................................................................................................................3-12

A002 Communication Phase 2....................................................................................................3-12

A003 Communication Phase 3....................................................................................................3-12

A010 Drive Halt...........................................................................................................................3-12

A012 Control and Power Sections Ready for Operation.............................................................3-12

A013 Ready for Power................................................................................................................3-12

A100 Drive in Torque Mode ........................................................................................................3-12

A101 Drive in Velocity Mode .......................................................................................................3-12

A203 Position Control/Stepper Drive Interface............................................................................3-13

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Contents III

A204 Position Regulation without Lag/Stepper Drive Interface...................................................3-13

A206 Position Regulation/Positioning Drive................................................................................3-13

A207 Position Regulation without Lag/Positioning Interface.......................................................3-13

AF Drive Enable..........................................................................................................................3-13

JF Jogging in the Positive Direction............................................................................................3-13

JB Jogging in the Negative Direction ..........................................................................................3-13

4 Exchanging Drive Components 4-1

4.1 Procedure for Exchanging Devices......................................................................................................4-3

Exchange the DKC:.......................................................................................................................4-3

Motor exchange:............................................................................................................................4-4

Cable exchange: ...........................................................................................................................4-5

Directory of Customer Service Locations

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

IV Contents DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

Notes

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Diagnostic Message Description 1-1

1 Diagnostic Message Description

1.1 Overview of the Diagnostic Message Descriptions

Diagnostic Message Types

Each operational state of the drive controller will be characterized with a

diagnostic message.

Therein, it will be differentiated between:

•• Error diagnostic message

•• Warning diagnostic message

•• Command diagnostic message

•• State diagnostic message

•• Process states

Construction of a diagnostic message

A diagnostic message consists of:

• Diagnostic number and a

• Diagnostic text

F2/28 excessive output error

diagnostic number

diagnostic text

Figure 1-1: Construction of a diagnostic message from a diagnostic number and

a diagnostic text.

In the example shown, the “F2” and “28” alternate on the H1 display.

The parameter P-0-001, diagnostic number; appears in hexadecimal

form.

Also, the drive controller stores the diagnostic number and diagnostic text

as the string "F2/28, excessive output error" in the parameter

S-0-0095, diagnostic message.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

1-2 Diagnostic Message Description DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

H1-Display

The H1 condition display on the front side of the DKC gives information

about:

• Operating condition of the drive controller

• Drive controller or cable malfunctions

• Motor malfunctions

• Malfunctions caused by invalid parameter input

• Application errors

H1 DISPLAY

EK0003d1.ds4

Figure 1-2: H1-Display

The symoblized diagnostic number appears on this two positional-seven

segment display.The form of the display is seen on the diagram "Priority

dependent diagnostic message diagram."

In addition to the display, it is possible to use the communication interface

to quickly monitor the actual process state.

The operating mode is not evident from the H1-Display.If the drive is

enabled and no command was activated, the symbol "AF" appears on the

display.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Diagnostic Message Description 1-3

If more than one diagnostic message is generated at the same point

within the string, the diagnostic with the highest priority will be displayed

first.

The following graphic shows the order of priority.

Error

Warning

Command

error

P

R

I

O

R

I

T

Y

Command

active

Read

y

to o

p

erate ?

no

y

es

Communication phase

Drive lock

active

Ready to

operate

Drive

ready

Drive

Halt

Drive

enable

Figure 1-3: Priority dependent diagnostic message diagram

Clear Coded Text-Diagnostic Message

The clear coded text-diagnostic message contains the diagnositic number

followed by the diagnostic text; for example, "excessive output error" (Fig

1-1). It can be read from parameter “S-0-0095, diagnostic message”

and serves the direct display of the process state on a operator surface.

The clear coded text-diagnostic message will be changed over from the

language selection to the current language.

Priority of the diagnostic

message output

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

1-4 Diagnostic Message Description DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

Notes:

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Description of Diagnostic Letters F... and E... 2-1

2 Description of Diagnostic Letters F... and E...

2.1 Error Diagnostic Messages

UL Motor Type not Reported

Description:

The settings for current regulation, velocity command, and position loop

are stored in the feedback of the motor. After powering up, the drive

compares the motor type stored in the parameters with the connected

motor type. If the two do not match, the drive remains at this state.

By pressing the S1 button, the drive overwrites its stored parameters with

the control loop parameters from the motor feedback.

Cause:

Motor was exchanged.

The parameter "P-0-4036, contacted motor type" from which the motor

type is selected would be loaded..

Remedy:

Command "C700 Basic Load” or press the S1 button.

PL Default Value of the Parameter Load

Description:

After the exchange of the product (EPROMs), if the parameters have

been changed in regards to the old product, the drive displays "PL". By

pressing the S1 button on the drive or through starting of the „command

load basic parameter", all the parameters will be erased and restored with

the default values.

Cause:

Product was exchanged and the number of parameters of the new

product has changed in regards to the old.

Remedy:

Press the S1 button on the drive controller and all the parameters will be

erased and restored with default values

WARNING

⇒ With this procedure all parameters and process

blocks will be overwritten.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

2-2 Description of Diagnostic Letters F... and E... DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

F207 Switching to an Uninitilized Operating Mode

Description:

A valid operating mode has not been defined.

In the DKC 01, this error can not occur because the input of the operating

mode will be tested when entered.

Remedy:

Input correct operating mode

F218 Heatsink Overtemperature Shutdown

Description:

The temperature of the DKC heatsink will be monitored. If the

temperature of the heatsink is too high, the drive will power down in order

to protect against damage.

Cause:

1. Ambient temperature is too high. The specified

operational data is valid up to an ambient temperature

of 45°C.

2. The DKC's heatsink is dirty.

3. Air flow is prevented by other assembly parts or a

control cabinet panel assembly.

4. Heatsink blower may be defective.

Remedy:

For 1. Reduce the ambient temperature; for example, through cooling

of the control cabinet.

For 2. Remove any obstruction or dirt from the heatsink.

For 3. Install the device vertically and clear a large enough area for

proper heatsink ventilation.

For 4. Exchange drive.

F219 Motor Overtemperature Shutdown

Description:

The motor is too hot. The drive controller has issued the warning "E251

Motor Overtemperature Warning for approx. 30 seconds. The drive

immediately shuts down.

Cause:

1. The motor was overloaded. The effective torque demanded

from the motor was above its allowable continuous torque level

for too long.

2. The motor thermal connection is shorted or grounded.

3. Instability in the velocity loop.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Description of Diagnostic Letters F... and E... 2-3

Remedy:

For 1. Check the installation of the motor. If the system

has been in operation for a long time, check to see if the

the operating conditions have changed. (in regards to

pollution, friction, moved components, etc.)

For 2. Check wires and cables to the motor temperature monitor for

wire breaks and short circuits.

For 3. Check velocity loop parameters.

F220 Bleeder Overtemperature Shut Down

Description:

The regenerated energy from the mechanism of the machine via the

motor has exceeded the power capability of the bleeder resistor. By

exceeding the maximum resistance energy, the drive will shutdown

according to the set error reaction. Thereby protecting the bleeder from

temperature damage.

Cause:

The reflected energy from the machine’s mechanism over the motor is

too large.

Remedy:

With too much power ---> reduce the acceleration value

With too much energy ---> reduce the velocity

Check the drive installation.

May require installation of an additional bleeder module.

F226 Undervoltage Error

Description:

The level of the DC bus voltage will be monitored by the drive controller.

If the DC bus voltage falls below a minimal threshold, the drive

independently shuts down according to the set error reaction.

Cause:

1. The power source has been interrupted without first switching off

the drive enable signal (RF).

2. Disturbance in the power supply

Remedy:

For 1 Check the logic regarding the activation of the drive within

the connected control.

For 2 Check the power supply

The error can be cleared by removing the control enable signal.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

2-4 Description of Diagnostic Letters F... and E... DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

F228 Excessive Deviation

Description:

The drive could not process the given command value and reacted

according to the set error reaction.

Cause:

1. The acceleration ability of the drive was exceeded.

2. The motor shaft was blocked.

3. Parameterization error in the drive parameters.

4. "S-0-0159, Monitoring Window" was parameterized incorrectly

Remedy:

For 1. Check the Bipolar Torque Limit, S-0-0092 parameter

and set it equal to the maximum allowable value for

the application.

For 2. Check the mechanical system and eliminate any jamming

of the motor shaft.

For 3. Check the drive parameters

For 4. Parameterize "S-0-0159, Monitoring Window"

F229 Motor Encoder Error: Quadrant Error

Description:

An encoder signal error was found during the encoder evaluation.

Cause:

1. Defective encoder cable

2. Insulation disturbance on the encoder or the encoder cable

3. Defective drive controller

Remedy:

For 1. Check the encoder cable and change if necessary.

For 2. Use only insulated motor cable and power cables

Separate encoder cable from power cables

For 3. Exchange drive controller

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Description of Diagnostic Letters F... and E... 2-5

F248 Low Battery Voltage

Cause:

The connected motor has an absolute encoder. The absolute position

information is stored in the motor feedback. This memory has a battery

powered backup for the electronic circuit. The battery is designed for a

operating life of 10 years. If the battery voltage drops below 2.8 V, this

message appears. The absolute encoder function is preserved for about

2 weeks.

Instructions for Exchanging Batteries

Have the following tools and accessories ready:

• Torx screwdriver,size 10

• Needle nose pliers, torque wrench

• New packaged battery (Part no.: 257101)

If the control voltage of the installed battery is turned off, the absolute

position is lost.

The absolute position must be re-established through the process of the

command Set Absolute Measurement.

F262 Status Outputs Short Circuited

Description:

If the status outputs of the DKC are short circuited, the drive controller will

issue an error.

Cause:

Short circuited outputs (X2/6, X2/7, X2/8, X2/9, X2/10, X2/20, X2/21,

X2/22)

Remedy:

Eliminate short circuit

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

2-6 Description of Diagnostic Letters F... and E... DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

F276 Absolute Encoder Error, Position Deviation > P-0-0097

Description:

When turning off the drive controller with a absolute encoder (multiturn),

the actual feedback position will be stored. When powered up, the

absolute position given by the encoder is compared to the stored

position. If the deviation is larger than the paramaterized "Absolute

Encoder-Monitoring Window", the error "F276, Absolute Encoder

Error" will appear and be given to the control system.

Cause:

1. Turning on for the first time (invalid stored position).

2. The motor was moved further than allowed by the parameter in

the absolute encoder monitoring window, P-0-0097, while it was

turned off.

3. Incorrect position initialization

Remedy:

For 1. Press S1 to reset the error and set the absolute position.

For 2. The motor was moved while turned off and sits outside of its

permissible position. Check to see if the displayed position is

correct in relation to the machine zero point. Reset subsequent

errors.

For 3. An accident may occur by accidental shaft movement.

Check absolute position informartion. A feedback defect is

present if the absolute position information is false. The motor

should be exchanged and sent to the INDRAMAT Customer

Service .

see also the "Absolute Encoder Monitoring" function description

F630 Travel Limit Value Exceeded

Description:

The drive controller has been given a position command value which lies

outside of the allowable travel area. The drive controller has been

instructed to give an error when the travel range has been exceeded.

Exceeding the travel area as an error:

The drive controller brakes with maximum torque. After it has been

stopped the drive controller shifts to torque free operation. After the error

has been cleared, the drive can be once again activated and moved into

the allowable travel area.

Cause:

Position feedback value lies outside of the travel area

Remedy:

1. Input a command value in the direction of the travel area.

2. Shift the position limits

3. Turn off the position limit monitor

(when displaying the position data in modulo format).

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Description of Diagnostic Letters F... and E... 2-7

F644 Travel Limit Switch Detected

Description:

The motor was moved and tripped one of the two travel limit switches.

The control drive has been instructed to give an error when the travel

range has been exceeded.

Exceeding the travel area as an error:

The drive brakes with maximum torque. Subsequently, the drive goes into

moment free operation. After the error has been cleared, the drive can be

activated again and moved into the allowable travel area.

Cause:

One of the travel limit switches was tripped.

Remedy:

1. Input a command value in the direction of the travel area.

2. Move the travel limit switches, if necessary.

3. Turn off the position limit monitor (when displaying the position

data in modulo format).

F822 Motor Encoder Failure: Signal too Small

Description:

The motor encoder signals are monitored. If the signal amplitudes as

measured via AK1 and AK2 are outside of the allowable region between

Uss = 12.0V and Uss = 18.0 V, then the error message appears. The drive

becomes torque-free and an optional brake is immediately activated.

Cause:

1. Defective feedback cable.

2. Defective feedback.

Remedy:

For 1. Check the feedback cable

Lay the power cables separate from the feedback cable.

The cable shield must be connected to the drive controller.

(see project reference of the drive control).

For 2. Exchange motor.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

2-8 Description of Diagnostic Letters F... and E... DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

12 - 18 V

Figure 2-1: Methodically measured signal amplitude over AK: X31/1-2

F860 Overcurrent: Short in Powerstage

Description:

The current in the power transistor bridge has exceeded twice the peak

current of the drive. As a result, the drive will be immediately turned off.

The drive has switched to a torque-free condition. An optional brake is

immediately activated.

Cause:

1. Short circuit in the motor cable.

2. Defective power section of the drive controller.

3. The current regulator was incorrectly parameterized.

Remedy:

For 1. Check the motor cable for a short.

For 2. Exchange drive controller.

For 3. The current regulator parameters should not deviate from the

default values of the feedback.

F870 +24 V Error

Description:

The DKC requires a 24V control voltage. If the maximum allowable

tolerance of + or - 20% is exceeded, then the drive is immediately

switched to torque free operation. An optional brake is activated.

Cause:

Disturbance or overload of the 24 V supply voltage. Measure control

voltages.

Remedy:

Check wiring and/or replace power supply module.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96 Description of Diagnostic Letters F... and E... 2-9

F873 Power Supply Driver Stage Fault

Description:

The voltage supply of the driver stage is monitored and if the voltage is

too low then the drive is turned off.

Cause:

Voltage supply of the driver stage is too low

Remedy:

Exchange drive controller

F878 Velocity Loop Error

Description:

The velocity loop monitor will appear when the following conditions occur

simultaneously:

• The current command value is at the peak current limit

• The difference between the actual velocity and the command velocity

is larger than 10% of the maximum motor velocity.

• The velocity control deviation does not become smaller over a time

frame of 20ms.

Cause:

1. Motor cable is connected incorrectly.

2. Defective controller section of the drive.

3. Defective feedback.

4. Velocity loop paramaterized incorrectly.

Remedy:

For 1. Check motor cable connection.

For 2. Exchange drive controller.

For 3. Exchange motor

For 4. Check velocity controller to see if it is within operational

parameters.

ECODRIVE DKC01.1/DKC11.1 Drive Controllers

2-10 Description of Diagnostic Letters F... and E... DOK-ECODRV-ASE-02VRS**-WAR1-EN-P •07.96

F879 Velocity Limit Value Exceeded (S-0-0092)

Description:

The actual velocity is monitored in torque regulation mode. This error is

generated if the programmed velocity in the "S-0-0091, bipolar velocity

limit value" parameter is exceeded by 1.25 times or a maximum of 100

Rpm.

Cause:

The load torque was smaller or larger than the torque command value for

too long a time. This leads to an increase in the actual velocity up to the

maximum possible motor velocity.

Remedy:

Check the primary control loop.

see also the "Velocity Monitoring in Torque Control" function description

F895 4 kHz Signal Error

Description:

The 4kHz signal is synchronized with the software processing for creation

of the resolver signal. This error message is created when

synchronization occurs improperly.

Cause:

1. The synchronization of the resolver controller voltage is invalid

in regards to the software.

2. The error can be produced through an electrical discharge.

Remedy:

For 1. Exchange drive controller and return for testing.

For 2. Power down and then on. If this in not successful; exchange

drive controller.

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Emerson

Emerson Hytork XL Series Installation, operation and maintenance manual

Elvox

Elvox Vimar ESM3 Installation and operation manual

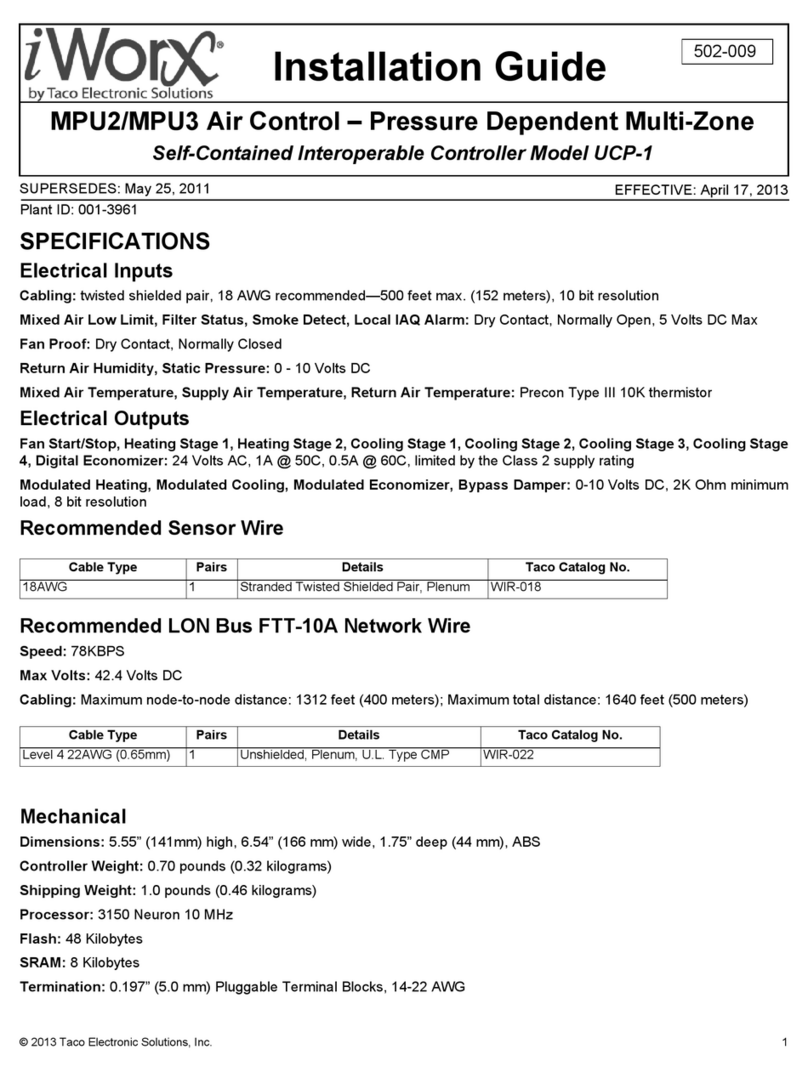

Taco Electronic Solutions

Taco Electronic Solutions iWorx MPU2 installation guide

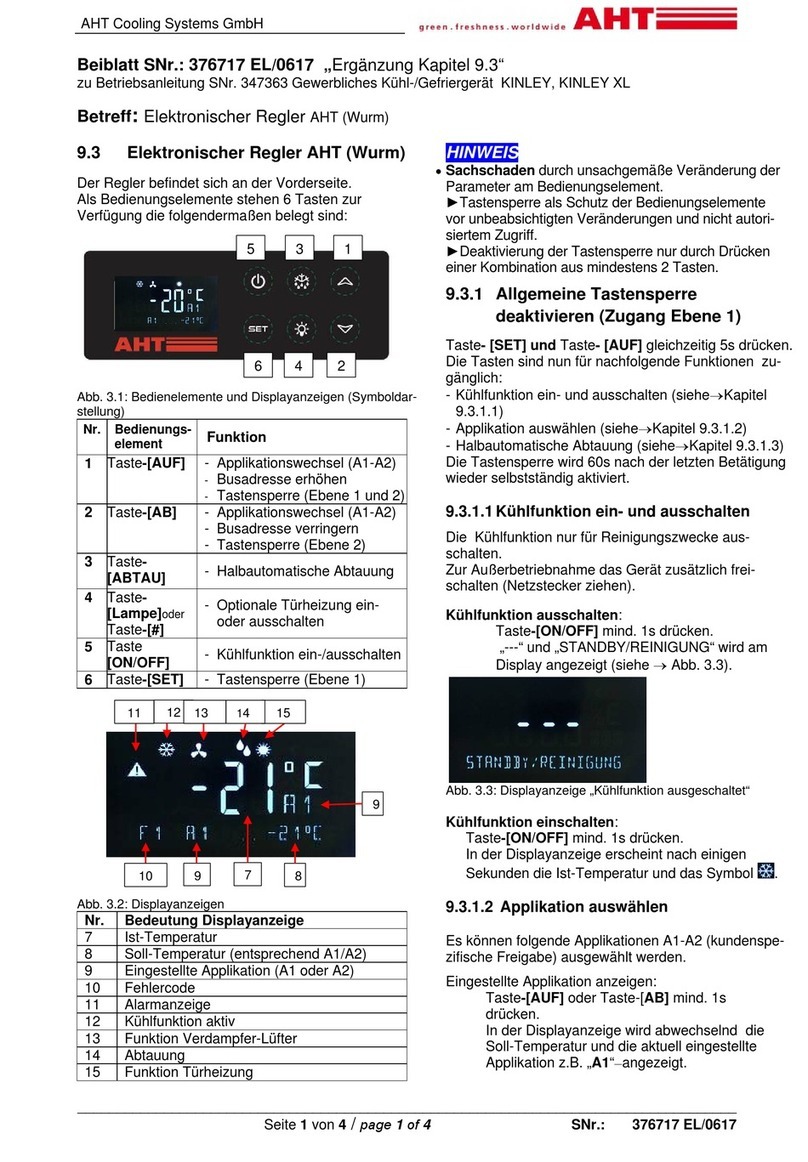

AHT

AHT 376717 EL/0617 quick start guide

Klafs

Klafs 18033 operating instructions

Linak

Linak Homeline TWINDRIVE TD5 Standard user manual