Installation Instructions Specifications are subject to change without notice Page 2

Roof Cowl Kits

REGULATIONS AND STANDARDS

Choosing the Right Fan to Comply

Fans cannot be selected on the basis of free-air performance only. Fans must now be selected on the basis of the complete installed system

performance for a designated room as per the table below.

1) Toilets only require ventilation if they have no openable windows

2) Simx recommends 40 l/s for laundries with unvented non-condensing tumble dryers as covered in AS 1668: Part 2 2012

Recent unregulated extract fan practices in New Zealand has trended to basic, low pressure axial fan products, as installed system performance has

not been defined for independent inspection testing and compliance signed off by local authorities.

New Zealand Building Code and Healthy Homes

The following two category requirements have been established for mandatory extraction ventilation in New Zealand.

The New Zealand Building Code for New Building Consents

The building regulatory system sets out a framework to promote good quality decisions being made during the Building Consent process. The

legislation and regulations work together, as the building regulatory system. The functional clauses of the NZ Building Code are grouped and

described by a letter and number. Clause G of the NZ Building Code covers services, with G4 setting out the performance requirements for

ventilation. The Building Code is enshrined in law. The New Zealand Building Code, G4, has been changed. This is supported by Acceptable Solution

G4/AS1 Fourth Edition that specifies mechanical ventilation in accommodation units that contain cooktops, showers and baths.

Residential Tenancy Regulations to the Healthy Homes Standards

Residential Tenancy Regulations for rental properties only is changing to the Healthy Homes Standards, sub part 4 - Ventilation Standards.

Complying with the Acceptable Solution G4/AS1

To comply, the mandatory mechanical extract system must deliver minimum airflow rates for the complete installed ventilation system. This means

that airflow rates must deliver the airflow after resistance of the ducting, internal and external grilles, as well as all other accessories, such as

backdraught shutters, are included.

Fan selection is important as some types are far better at overcoming ducting system pressure drops.

Additionally, the quality of the ducting system installation can be all important. Rigid duct systems are best as they are the most efficient. Good

installation practice is vital for flexible duct systems.

Room Airflow Rate (min.)

Intermittent Continuous

Toilet1) 25 l/s 10 l/s

Bathroom/shower 25 l/s 10 l/s

Laundry2) 40 l/s -

Kitchen 50 l/s 12 l/s

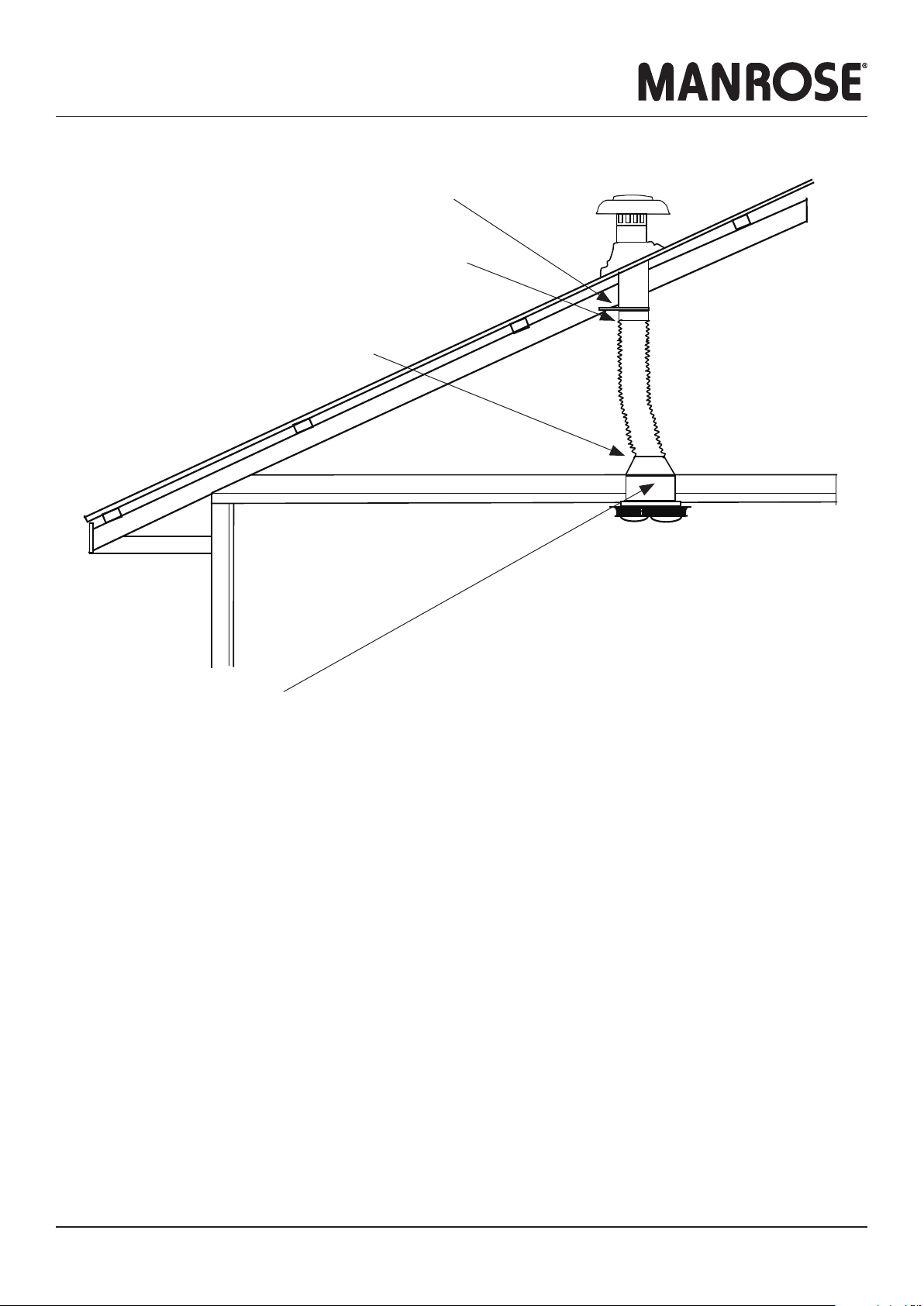

Duct Supports

Exterior Grille

Airflow

Airflow

Interior Grille

Sealant Cavity

Sleeve

Maximum length of

flexible ducting

Minimum radius =

diameter of ducting

Bathroom Kitchen

25 l/s Metres of Ducting 50 l/s Metres of Ducting

12345678910 12345678910

No. of

Bends

1

No. of

Bends

1

2 2

3 3

4 4

5 5

Fan Selection

Hyper150 EC Mixflo 150 Blue Jet

Preferred flexible

ducting route

Peaks and troughs

Restrictions