MANU ELECTRONICS ManuFlo ME3000-RPFS Manual

ManuFlo

Flow Measurement & Control Products

Page 1 a division of

MANU ELECTRONICS PTY LTD

www.manuelectronics.com.au

ME3000-RPFS WATER BATCHING SYSTEM

Congratulations on choosing a

ManuFlo

® (Manu Electronics) preset batch control system.

You will now join many thousands of satisfied customers worldwide.

Your system comprises:

Information sheets included:

1. ME3000 preset Batch Controller specification and options.

2. Installation Guide (plumbing/commissioning).

3. Basic electrical wiring guide.

4. Flowmeter brochure spec (chosen flowmeter normally RPFS)

5. (if ordered) PLC/computer interface spec brochure

6. ME3000 complete user manual

Prior to installation:

A. Consider a good viewing AND operating position for the ME3000 Batch Controller.

B. Remove the detachable 10-pin plug from the rear of the ManuFlo controller. Wire the 240vac supply.

Wire the Active/contact drive, Neutral and Earth from the solenoid valve or return from the external

contactor if driving a pump. If starting a pump, make sure the contactor is of sufficient amperage rating

to handle the pump current draw. Consider wiring an override button (N.O. with spring return) for

manual batching or top up of water, which will be counted by the controller display. See wiring

C. Install the flowmeter as per the installation guide found on the flowmeter brochure.

Install the Rota Pulse paddlewheel sensor (RPFS-P) in a straight pipe section, with the same diameter pipe as

the adaptor tee section, with 10x diameter before, and 5x diameter after, the sensor with no elbows, reducers,

valves or restrictions within this pipe run. Where the sensor is housed, the pipe must be full when measuring.

D. Use shielded cable only for connection between flowmeter and Batch Controller.

E. On pipe sizes over 50mm, consider using an air-assisted solenoid butterfly or angle seat valve, as

electrically-operated diaphragm valves can be very slow in closing (valves are available from

ManuFlo

®). Preferably, use a 240vac solenoid coil, as the Manu controller provides 240vac to the coil when

started. Otherwise, consult

ManuFlo

® for options.

F. The ME3000 Batch Controllers, when used with flowmeters, have internal preset calibration

factory calibrated with water. When using other varying viscosity liquids with some

flowmeters, a calibration test will need to be performed, and the K-factor re-programmed to

the corresponding result. A calibration check must be performed prior to continuous use and

commissioning of the system (see installation guide). Recalibration may be necessary for

flowmeters other than PD or Magflow flowmeters. See page 13 of the manual.

If unsure on any aspect of installation or operation, call ManuFlo or your local installer.

Happy batching !!!!!!!!!!!!!

ManuFlo

Flow Measurement & Control Products

Page 1 a division of

MANU ELECTRONICS PTY LTD

www.manuelectronics.com.au

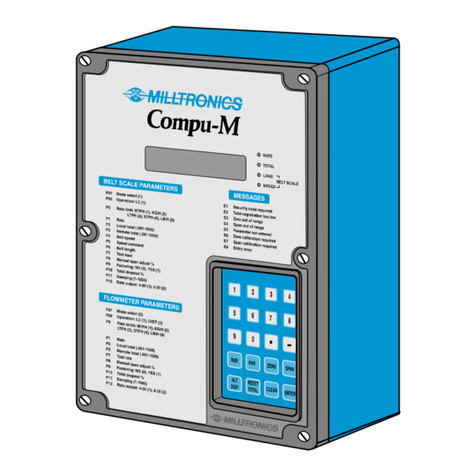

ME3000 MICROPROCESSOR PRESET BATCH CONTROLLER

FEATURES

Programmable - counts in ml, Litres, KL, ML.

keypad input for batch setting, and configuration.

2 line x 16 character display for quantity set and

dispensed. 3 indicator LEDs. IP64 front face.

Alarm messages shown on LCD display.

Safety features include missing pulse detection.

Functions include Preact and preset maximum limit.

Internal downloadable Event Log.

Single channel, can be used with any size flowmeter.

Optional PLC/Computer control interface.

Optional RS232 printer interface for batch tickets.

The ME3000 microprocessor-based preset Batch Controller can be used with pulse output flowmeters of any size, for

preset liquid batch control applications. Batch counting can be in units of millilitres, Litres, KiloLitres or MegaLitres. The

Controller is fully programmable, and has a range of safety features e.g. if no pulses arrive within a configurable batch

start period, or if pulses are interrupted during the batch cycle or if the flow rate falls below the allowed minimum, then

the pump voltage contact drive is automatically shut off and an alarm is raised.

RUN LED indicates voltage contact output drive when pump or solenoid is activated.

FLOW LED monitors and indicates incoming pulses from field flowmeter.

OUTPUT LED indicates scaled pulses output from Batch Controller e.g. to a PLC/Computer.

Internal audible ALARM sounds momentarily upon completion of batch cycle, and continuously if an error occurs.

With the ME3000 Batch Controller using the same instrument housing, and the same 10-pin Weidmuller receptacle plug,

as other ManuFlo Batch Controller models, changeover or upgrade is instant with no rewiring necessary. It can be easily

interfaced with PLCs (through the optional computer control interface), thus incorporating the controller's safety features

and providing a backup batch facility. An optional RS232 interface allows the printing of batch tickets through an

associated printer, and the downloading of the internal event log to a laptop/PC for analysis.

The controller operates from standard 220 - 250 vac (or optional 110 vac or 12 - 24 VDC) voltage supplies. Contact

output drive is via a relay (optional open contact). Standard controllers are in panel mount form, or optionally can be

housed in a metal box or IP65 ABS wall mount enclosure.

Displays Configuration Features

Quantity set/dispensed

Flowrate

Backflow amount

Grand Total (resetable)

Batch Id (resetable)

Alarms

No pulses from flowmeter

Batch Limit exceeded

Max Flow Limit exceeded

Pulse Output Rate exceeded

Backflow

Overbatch

Calibration i/p pulse scaling

Output pulse scaling

Pulse output rate limit

Batch limit

Backflow threshold

Min/Max flow limits

Batch Units

Start/stop delay

4-20mA current output

Preact

Time and date

Date last calibrated

Event log (upto 300 batches)

Indicator LEDs - Run/Flow/Output

Optional Outputs

scaled Open Collector pulse output

e.g. to PLC/Computer

4-20mA output representing flowrate

Optional Interfaces

PLC/Computer control (stop/start/reset)

RS232 printer interface for batch tickets and

event log download.

The ME3000 controller is designed for compatibility with ManuFlo flowmeters and many other types.

N 15022

ManuFlo

Flow Measurement & Control Products

Page 2 a division of

MANU ELECTRONICS PTY LTD

www.manuelectronics.com.au

OPERATING INSTRUCTIONS ME3000

Switch the power ON to unit. In a few seconds, the display shows SET and RDY(ready), with a zero quantity for RDY, all LED

indicators and alarms are off. The unit is ready for batching or configuration.

BATCHING: When SET/RDY is displayed, entering a batch quantity via the numeric keypad buttons will cause the displayed SET

value to change and flash. Then, pressing the SET button locks in the new value, or pressing CANCEL reverts the value to its

original setting, and the display digits stop flashing.

Press the START BATCH button to start batch batching the set quantity. The RDY line title changes to REC (received).

The voltage contact drive activates, the RUN LED illuminates indicating pump or solenoid are energized, followed by FLOW LED

illuminating, indicating pulsing and operation of flowmeter. The digits on the REC (received) display line begin counting upward

towards the selected batch quantity.

Upon REC digits reaching the selected batch quantity the alarm sounds (short beep) indicating completion of batch; RUN, FLOW

and OUTPUT LEDs turn off. The displayed SET and REC values should correspond. If REC digits overshoot target, then scale back

the difference by changing the Preact value via the Configuration Mode (see below).

To interrupt batch, push STOP button; REC counting will stop, and drive contact goes off. Push START BATCH to resume batch.

On batch completion or termination, press RESET. Display REC line title changes to RDY (ready).

To dispense the same set quantity again, press START BATCH. Otherwise, use the keypad to enter a new batch quantity.

Warning: if RUN or FLOW LED indicators are on, but controller is not counting, discontinue use and call for service.

EVENT LOG: using a straight-through female- to-female DB9 cable, connect from the Batch Controller’s (optional) RS232 port to a

Laptop/PC serial port. On the Laptop, start the HyperTerminal software (supplied as part of Windows), set up a connection at 9600

baud, 8 Data Bits, no parity, 1 stop bit, and capture text to a file. On the Controller, press the CANCEL and RESET buttons (those

marked with ‘#’) simultaneously for 5 secs, and the Event Log will download. To stop download, press CANCEL for 2 secs.

CONFIGURATION: The Controller is factory configured to your requirements, but can be re-programmed by the user if required.

Configuration Mode is entered from the SET/RDY display by pressing the CANCEL and STOP buttons (those marked with a ‘*’)

simultaneously for 5 seconds.

Use the buttons with the up/down arrows to step through configuration settings.

When a configuration value is diplayed, entering a new value via the keypad causes the display value to change and flash. Then,

pressing SET locks in the new value, or pressing CANCEL reverts value to its original setting, and the display digits stop flashing.

Use the up/down arrows buttons to step through more configuration settings, or press CANCEL for 2 seconds to exit to the

SET/RDY display.

CALIBRATION

1) The Batch Controller is set up for the connected flowmeter using the Calibration Input pulse scaling item under Configuration Mode,

to match the flowmeter’s output pulse value.

On-site calibration adjustment and test:

2) Must adjust what is shown as received (REC) on the Batch Controller LCD display to match a known amount dispensed. So, set

batch quantity to say 190L, and batch into a 200 litre (44 gallon) drum.

3) If the amount collected is more than the REC amount shown on the LCD display, then decrease the Calibration Input value

by the same % difference e.g. if collected 200L when 190L on LCD, this is 10L more or 5% over (10/190x100%).

So, decrease the calibration value by 5% i.e. if Calibration Input value is 300, new value is 300-5% = 300-15 = 285.

4) If the amount collected is less than the REC amount shown on the LCD display, then increase the Calibration Input value by the

same % difference. e.g. if collected 180L when 190L on LCD, this is 10L less or 5% under (10/190x100%).

So, increase the calibration value by 5% i.e. if Calibration Input value is 300, new value is 300+5% = 300+15 = 315.

5) PREACT: To calibrate inflight overflow, enter Configuration Mode (as described above), and set the Preact value to the same

overflow reading as indicated by the LCD display, where overflow = (the REC quantity) - (the SET quantity).

Example: You set 190 Litres, batch the quantity, 200 Litres is shown on display, and 200 Litres is collected in drum. A valve may take

extra time to close, so the received quantity usually overshoots. So, set 10 Litres on Preact to deduct the 10 Litres overshoot. Next

batch, the set batch quantity, LCD REC reading and amount collected in drum are all 190 Litres.

SPECIFICATIONS

shown with optional

-SC and -5P interfaces

Power supply 220-250 vac (optional 110 vac or 12-24 VDC)

Fuse 1 Amp (5 x 20mm case)

Frequency input 5 KHz

Event Log internally records up to 300 batches

Output to flowmeter 12 VDC upto 100mA

Relay Max. 240 vac, 1 A. Open Contact on request.

Display 2 line x 16 character, for quantity set and dispensed.

Connection 10 pin Weidmuller mating plug and socket

Batch entry quantity selection and commands via IP64 keypad

Optional Outputs scaled pulse output; 4-20mA output

Optional interfaces RS232; PLC/Computer stop/start/reset

Instrument housing ABS hi-impact case mould

Mounting Panel mount. Panel cutout :190 L, 122 H mm

External dimensions 206 L, 130 H, 90 D mm.

Weight 1 kg

Due to continuous product improvement, specifications are subject to change without notice.

ManuFlo

Page 4 MANU ELECTRONICS PTY LTD

Flow Measurement Products 41 Carter Road, Brookvale NSW 2100

Website: http://www.manuelectronics.com.au

RPFS_Datasheet 23/02/2018

ME3000

Batch Ticket Event Log example

ORDER CODES

ME3000 Batch Controller, 240vac.

Options:

Code Description Code Description

-110 110 vac powered -DC 12-24 VDC powered

-OC Open Contact output -OP Alarm output, Batch complete output,

and 4 - 20 mA output.

-L For connection to a coil-type

flowmeter.

-SSR External command: Start/Stop/Reset, for

connection to HB2500-SSR housing box.

-SC RS232 Serial interface -5P 5-pin computer interface plug (start, stop, reset,

pulse, +12V) for Jonel, Eagle etc PLCs.

-MC 4-pin PLC/Computer Command

(Start/Stop/Reset) interface plug

-MC2 2-pin plug for scaled open collector pulse output.

Includes 4-pin external command

(Start/Stop/Reset) interface plug.

e.g. “ME3000” is the standard Batch Controller, 240vac powered, without any of the options,

whereas “ME3000-MC2” is an ME3000 Batch Controller with a scaled open collector pulse o/p,

and external Start/Stop/Reset.

ACCESSORIES

Code Description

TTP-A5 Thermal Ticket Printer.

with power supply.

suitable for custody transfer dockets

for ME3000-SC.

TMP ME3000-SC and TTP-A5 printer, wired and mounted in

a key lockable rugged IP64 hinged enclosure.

automatic ticketing.

prints Batch ID, quantity, time and date.

ribbon and paper easily changed.

Ideal for delivery trucks or loading and discharge

locations where a custody transfer docket is required.

ManuFlo

Page 5 MANU ELECTRONICS PTY LTD

Flow Measurement Products 41 Carter Road, Brookvale NSW 2100

Website: http://www.manuelectronics.com.au

RPFS_Datasheet 23/02/2018

RPFS

ROTA PULSE FLOW SENSOR

(Slip Insertion Paddlewheel) DATASHEET

FEATURES

± 2.5% accuracy @ velocity range 0.5 to 8.5 m/sec.

± 1 % accuracy over linear range 0.7 to 7.0 m/sec.

Repeatability of ±0.6%.

NPN inductive pulse with internal amplification.

Square wave output with short circuit protection.

Inductive coil pulse option for low current applications.

High Pressure options to 2000kpa

50C or 120C temperature models.

Simple installation and maintenance.

Large range of pipe adapter fittings in sizes 20 to 110mm.

(Larger pipe sizes to 500mm using “Long Stem” –LS version)

Stainless Steel 17-4PH paddlewheel rotor without magnets.

Australian made since 1984. (Now with new high speed bush option).

DESCRIPTION

The Rota Pulse Flow Sensor (RPFS) paddlewheel insertion type flowmeter uses a proven

principle of flow measurement, which is used worldwide. The RPFS comes in four model

variants:

RPFS-P for liquids up to 50C (plug-in cable)

RPFS-H for liquids up to 120C

RPFS-P

All model variants insert directly into a large range of pipe adapter fittings available in PVC, Galvanized Iron, Brass, Stainless

Steel or Polypipe materials, covering pipe sizes 20 to 110mm (standard sizes). This makes the RPFS suitable for a wide range of

liquid flow measurement, monitoring and batching applications. Using the BSPB & BSPSS fittings adaption to larger size pipes is

possible depending on pipe wall thickness, alternatively the Long Stem (-LS) versions with adaptors are then used.

With only one moving part and limited intrusion into the pipe, and combined with its flow-through design, the RPFS allows

accurate measurement of liquid flows with virtually no head losses.

Each of the 4 blades of the rotor (paddlewheel) extends approximately one centimetre into the flowing liquid. The RPFS-P sensor

generates a square wave pulse with the frequency output proportional to flow velocity and proportional to pipe diameter. The

RPFS-P incorporates internal amplification, allowing pulse transmission up to 1000 metres to the receiver device. The RPFS-P

model is specially constructed with a metal shielding jacket making it immune to electrical interference.

Magnets are not used in the RPFS models, thereby eliminating iron particles jamming the rotor. The alloy rotor used also makes

the RPFS less susceptible to interference from turbulence and particles hitting the rotor, thereby giving superior flow results.

SPECIFICATIONS

Model

RPFS-P RPFS-H

Supply voltage 5-30VDC 5-30VDC

Output signal NPN open collector NPN open collector

50% duty cycle pulse 50% duty cycle pulse

Current draw @ 5VDC / 24VDC 2.5mA / 10mA 2.5mA / 10mA

Max. switching current 200 Ma (at 24VDC) 200 mA (at 24VDC)

Cable length 5 metres, plug-in cable 2 metres cable

3-core (3 wire) 2-core shielded (3 wire)

Fluid temperature 50 °C max. 120 °C max.

Weather rating IP67 IP65

Pressure rating 200psi 400psi

Accuracy ± 2.5% for 0.5 to 8.5 m/s, ±1% for 0.7 to 7.0 m/s, Repeatability ± 0.6%

For Pipe Sizes 15 to 110mm standard,

Larger pipes via BSPB-LS special adaptor or saddle clamps.

1

SENSOR CONSTRUCTION RPFS

Model RPFS-P RPFS-H

Body Delron (Acetal) Brass

O-rings x 2 Neoprene Viton

Rotor Stainless Steel 17-4PH

Bushes Delron

Axle Tungsten Carbide

Lockcap PVDF Brass

Dimensions

Overall (approx.)

130L x 30W mm 150L x 30W mm

ORDERING CODES:-

NOTE: All RPFS sensors are supplied with a screw-down LC locking cap

Item Description

RPFS-P NPN transistor 5-25VDC sinking pulse,

liquid temperature to 50C

RPFS-H NPN transistor 5-25VDC sinking pulse,

liquid temperature to 120C

SPARE PARTS

PW-N Spare wheel

PWAH Axle

PC5 5 mtr m12 lead

LC Locking Cap

BS020 Orings

MAINTENANCE RPFS

Recommended Periodic Checks:

With clean liquids, sensor check of the paddle wheel is recommended once every year. In applications with reclaimed or

contaminated fluids, regular quarterly maintenance checks are recommended.

Removal of RPFS from Pipe adaptor Fitting ‘Square’ Keyway Type Nipple Adaptor:(see FIG 5)

1 - Unscrew the black PVC locking cap (anti-clockwise).

2 - Place a small to medium sized flat thin bladed screwdriver in the join where the insertion sensor body meets the nipple

adaptor (See FIG 4), twist the screw driver to prize the two apart till the slots clear the keyways, then pull or twist upwards

until the sensor is released (never pull via the cable).

Removal of RPFS from Pipe adaptor Fitting ‘Triangular’ Keyway Type Nipple Adaptor:(see FIG 6)

1 - Unscrew the black PVC locking cap (anti-clockwise).

2 - Hold the neck of the Tee piece in your left hand, grasp the RPFS body with your right hand and turn slowly anti-clockwise

until the sensor hydraulically raises out of slot then pull upwards out of the socket (never by the cable).

**When returning the sensor to nipple adaptor insert so the keyway and slots line up then then push down until they locate.

Screw the black locking cap clockwise to hold the sensor in place (hand tightened only).

Cleaning:

1 - If the paddlewheel (rotor) and or sensor body is coated with scale, immerse the sensor section in diluted hydrochloric acid,

scour gently if required.

2 - For ease of removal or refitting of sensor we strongly recommend to lubricate the body O-rings using petroleum jelly.

3 - If the paddlewheel requires servicing, push out the axle using a small hole punch or similar implement, remove the

paddle wheel and service or replace rotor and/or axle as required (spare parts available from ManuFlo).

Fault Diagnosis & Rectification:

If the RPFS sensor ceases to count, the paddlewheel may be blocked, remove inspect and clean as described above.

If the RPFS pulses when there is no flow, a nearby 50Hz AC field is probably causing these false counts. Move the flow sensor

away from the 50Hz field, or move the source of the field if practical.

If the standard cable length supplied is not sufficient and needs extending contact ManuFlo for suitable ‘screened’ cable and

never run extended cable across or near to other cables that are potential EMF sources.

2

INSTALLATION GUIDE RPFS

Adapter Tee keyway fittings are available in:

1. PVC Class 18 Cat. 19 Slip tees (F-glue-ends) pressure pipe

Sizes: 20, 25, 32, 40, 50, 65, 80 & 100 mm.

PVC high pressure saddle clamps: 40, 50, 80 and 100mm.

2. Galvanized Iron threaded connections:

BSP (F): pipe sizes 25, 32, 40 & 50 mm;

BSP (M) pipe sizes 80 & 100mm.

3. Gunmetal BSP(m) threaded connection end pipe tube tees 20 mm.

4. Polypipe saddle clamps in pipe sizes 40, 50, 63, 75, 90, 110 mm

5. PVC saddles 40, 50, 80 and 100mm.

6. Stainless steel 25, 32, 40 & 50mm, larger sizes fabricated on request.

7. FOR PIPE SIZES 110mm and larger refer to the RPFS-LS model

**Further custom made fittings are available on request.

Use ManuFlo BSPB, BSPB-LS (Long Stem) Brass or BSPSS Stainless Steel

pipe adapter keyway nipple - with locknut, which has a 1” OD BSP thread for

screwed insertion into 1”(female BSP) half-sockets which can be welded

directly to pipe, the BSPB fittings can be coupled to any 1” BSP female entries

including saddle clamps.

Installation Conditions

IMPORTANT: A minimum of 10x pipe diameter before (upstream of) the

sensor and at least 5x pipe diameter after sensor of straight pipe section

must be fitted, with no bends, reductions, enlargements, restrictions, valves

etc within this section. This will help eliminate flow turbulence to ensure

optimum accuracy performance.

The RPFS sensor must measure in a full pipe flow section.

Can be installed in a horizontal, inclined or vertical pipe position.

(Note: If mounted in horizontal or inclined pipe, make sure

insertion position of sensor is at top or 45 from top, not on the underside).

Selection of pipe diameter:

(For best results, use the table below):

Pipe size Flowrange (Litres/min) Pulses/Litre

(mm) Min Max (approx.)

(1)(2)

20 13 160 116

25 20 250 75

32 30 410 46

40 50 640 30

50 90 1000 20

63 132 1580 11.7

65 120 1690 12

75 180 2250 8.3

80 190 2560 7.3

90 244 3240 5.7

100 300 4005 4.6

110 (-LS) 343 4845 3.8

125 (-LS) 426 6255 3.0

140 (-LS) 516 7850 2.4

150 (-LS) 600 9010 2

160 (-LS) 650 10200 1.8

200 (-LS) 950 16000 1.16

250 (-LS) 1480 25000 0.7

ELECTRICAL INSTALLATION/DATA Cable connection:

RPFS-P# Black = Pulse

Brown = + 5-30 VDC

Blue = O.V. ground/shield

looking at

plug on

RPFS-P sensor

Brown

(5-30 VDC)

Black

(Pulse)

Blue

(Ground)

looking at

socket on

RPFS-P cable

Brown

(5-30 VDC)

Black

(Pulse)

RPFS-H# White = Pulse

Red = + 5-30 VDC

Shield = O.V. ground/shield

# If connecting to non-ManuFlo equipment, a 2K2 pull-up resistor

may be required between (+) and Pulse.

For extra cable length, use shielded cable only!

WARNING: To avoid electrical interference the RPFS-H and RPFS-L

should not be installed within 30cm of any AC fields, otherwise 50Hz

could be detected and create oscillations.

(1) For >315mm diameter pipes:

Pulses per Litre = 50273 / [ (Pipe diameter in mm) 2.016 ]

(2) NOTE: Due to gravitational forces, the pulse output value can differ

up to 6% between a vertical flow that is upwards or downwards. Where

possible, perform a calibration check to determine pulse rate given the

pipe diameter and flow conditions. Once calibrated, meter will give linear

and repeatable results within the flow range

Installin

g

Into Existin

g

Pi

p

e Lines

FI

G

.1

IMPORTANT:

3

ORDER CODES FOR PIPE ADAPTOR FITTINGS RPFS

Material GAL PVC PVC Polypropylene Polypropylene STAINLESS BRASS BRASS

Type T-Piece slip T-piece Saddle Clamp Saddle Clamp Saddle

Clamp

T-Piece T-piece Socket

For Gal pipe Pressure pipe Pressure pipe Pressure pipe Poly Pipe

Black

S/Steel pipe Brass

pipe

20 mm PVC20 BRA20

25 mm GAL25 ( -T2) PVC25 SS25 BRA25

32 mm GAL32 PVC32 SS32 BSOC:

1” BSP

Brass

pipe socket

adaptor

for

25-100mm

pipes

also

BSPB &

BSPSS

nipple adaptor

40 mm GAL40 PVC40 PVC40SC SCP40 SC40 SS40

50 mm GAL50 PVC50 PVC50SC SCP50 SC50 SS50

63 mm SCPE63 SC63

65 mm PVC65 SCP65 SC75

75 mm SC75

80 mm GAL80 PVC80 PVC80SC SCP80 SC90

80 mm GAL80-F

(Table D flanged)

90 mm SCPE90 SC90

100 mm GAL100 PVC100 PVC100SC SCP100 SC114

100 mm GAL100-F

(Table D flanged)

110 mm SCPE110 SC110

BSOC:

1” BSP

Brass

pipe socket

adaptor

for

100-500

mm pipes

also

BSPB-LS

Long Stem

nipple adaptor

125 mm SCPE125-LS SC125-LS

140 mm SC140-LS

150 mm PVC150SC-LS SCP150-LS SC160-LS

160 mm SCPE160-LS SC160-LS

200 mm PVC200SC-LS SCP200-LS SC200-LS

225 mm SCPE225-LS SC225-LS

250 mm SCP250-LS SC250-LS

280 mm SC280-LS

300 mm PVC300SC-LS SCPE300-LS SC315-LS

Galvanised iron

threaded ends

BSP (female)

2000 kPa

Note: 25mm

can be supplied

with straight

pipe sections

already fitted

(Part GAL25-T2)

PVC

T-piece

Class 18 Cat

19

Glue-in

(female)

1100 kPa

PVC

1400 kPa

PVC

≤ 150mm:

1600 kPa

> 150mm:

1000 kPa

Poly-pipe

agricultural

Saddle Clamps

≤ 150mm:

1600 kPa

> 150mm:

1000 kPa

Stainless

Steel 316

T-piece.

BSP

(female)

threaded entry

2000 kPa

Brass

T-piece

BSP

(female)

threaded

entry

2000 kPa

1” BSP

Brass

pipe

socket

adaptor

& BSPB

BSPB-LS

BSPSS

nipple

adaptors

(see Fig 1

Page 3)

GAL80 - 80mm Galvanized Iron pipe adapter

(80mm ɸ x 600mm long)

BSPSS Stainless Steel

adapter nipple

for 25-100mm pipes

BSPB brass

adapter nipple

for 25-100mm

pipes

Due to continuous product improvement, specifications are subject to change without notice.

** Pipe fitting options for the RPFS are as per the table however other fitting types may also be available on request**

4

ME3000 / ME995 wiring with RPFS or other powered flowmeters

5

ME3000 / ME995 wiring with RPFS or other powered flowmeters

6

PLUMBING / INSTALL options guide for RPFS or other ManuFlo flowmeters

7

ManuFlo

Flow Measurement & Control Products

a division of

MANU ELECTRONICS PTY LTD

www.manuelectronics.com.au

TROUBLE SHOOTING GUIDE

ManuFlo

®

TM

FOR BATCH CONTROLLER / ROTA PULSE FLOW METER SYSTEMS

PROBLEM POSSIBLE CAUSE SUGGESTED SOLUTION

No power to batch controller Blown fuse or holder not tightened Check fuse, tighten fuse holder (at rear of controller)

or displays not on +12vdc and O.V. shorted Check pulse cable from DCD to RPFS meter

No main power supply Check power supply, check wiring

Pulse fails at start of batch •Check calibration (K-factor) setting •000 calibration –pulse-fails. Make sure a calibration value is set.

(1.5 seconds after typical)

Seized paddlewheel Remove RPFS, inspect; clean with acid, check axle/bushes

make sure paddlewheel spins freely

Solenoid valve not opening Check and service solenoid valve, check output control voltage is

240vac(N & C, pins 7&9) when pushing start button

Restriction or service gate valve closed Open gate valve

Empty water tank Check water level

Pump not turning Check and service pump

•Pump foot valve failed •Empty pipe, Install non-return valve

Signal cable cut, bad joint at JB, Check signal cable for 12VDC at junction box near RPFS meter

oxidized cable- leakage If no power, cable cut or oxidized- repair/replace.

Unwire RPFS, take up to batch-room, remove extension cable and

hardwire RPFS direct into the Batch controller (P,+,-), spin wheel

should count on display, if so, then extension cable or connections

at JB faulty, if no counts & 12vdc present then RPFS faulty

•RPFS not positioned in pipe •Check RPFS slots are in keyway position, lock cap secured

Paddlewheel not inserted into flow stream

RPFS Flowmeter faulty Replace with new RPFS

Pulse fails during batch cycle Flowrate too slow Open restriction gate valve, or increase minimum flowrate in

program. Pipe diameter too big for flowrate (reduce pipe dia. or increase flow)

Pipe buildup restricting flow Cleanout pipelines, calcium buildup on pipe walls -recycle systems

Paddlewheel problem Calcium buildup on wheel, soak in diluted acid. Warn bushes.

Backflow alarm Non return valve faulty (jammed open) Clean, service or replace

after batch complete •Solenoid valve not properly closed •damaged seal, faulty solenoid

Batch target display counter Flowrate too fast excessive overflow Turn down gate valve to restrict flowrate

counts past batch selection or set preact (overflow deduct) function to compensate

Reduce delivery pipe diameter

•Intermittent overflow past batch select •Faulty solenoid valve not closing •service solenoid valve, check air pressure

or water does not stop properly, insufficient air pressure

Over batch alarm sounds

Wet loads, more water Paddlewheel bushes worn Check paddlewheel

collected than indicated Wheel dirty, flowing over range Replace with new paddlewheel, recalibrate

Dry loads, less water Requires recalibration test Set new calibration figure.

collected than indicated

Controller starts counting Active and contact power Contactor fused due to excessive current draw from pump

when power switched on drive short circuited Relay fused due to excessive current draw on solenoid coil

- install higher current rated contactor or install contactor

Interference on pulse cable input –use shielded cable only.

ANY OTHER PROBLEMS REFER TO ME3000 USER MANUAL –Trouble shooting guide.

Sequential fault finding and rectification

1. If a another ManuFlo controller (any model) is available, simply unplug doubtful unit and plug in exchange unit. If the new unit is also not

operating correctly, then the problem is isolated to the pulse flowmeter or wiring.

2. When checking flowmeter, reset the ManuFlo controller. Remove the flow sensor and spin the paddlewheel. Check that the ManuFlo

controller has registered a number of counts on its display. If so, the lectrical connections are probably OK. If no counts are registered, check

that 12VDC is supplied to the flow sensor. If supplied, then switch off the ManuFlo controller and replace the RPFS flow sensor.

3. The flow sensor paddlewheel is jammed, damaged etc. (For servicing, refer to the flow sensor brochure).

If in further doubt, contact your local representative, or ManuFlo on ph +61 2 9938 1425 or 9905 432

Table of contents

Other MANU ELECTRONICS Control System manuals

Popular Control System manuals by other brands

Ascon tecnologic

Ascon tecnologic A01 instruction manual

Topline

Topline TEC750A manual

Mitsubishi Electric

Mitsubishi Electric CITY MULTI PAR-40MAAU Instruction book

HWH Corporation

HWH Corporation 625S Series Operator's manual

Castel

Castel XELLIP XEMED-P quick start guide

Mitsubishi Electric

Mitsubishi Electric M80 Series Maintenance manual

Norac

Norac UC4.5 installation manual

Roger Technology

Roger Technology AGILIK 1 Series Instruction and warnings for the installer

Hayward

Hayward HLXPROUPG Operation manual

Tranberg

Tranberg TEF 4900 Installation and user manual

heat-timer

heat-timer Digi-Span TSC Pressure Installation & operating instructions

CAME

CAME CAT Serie manual