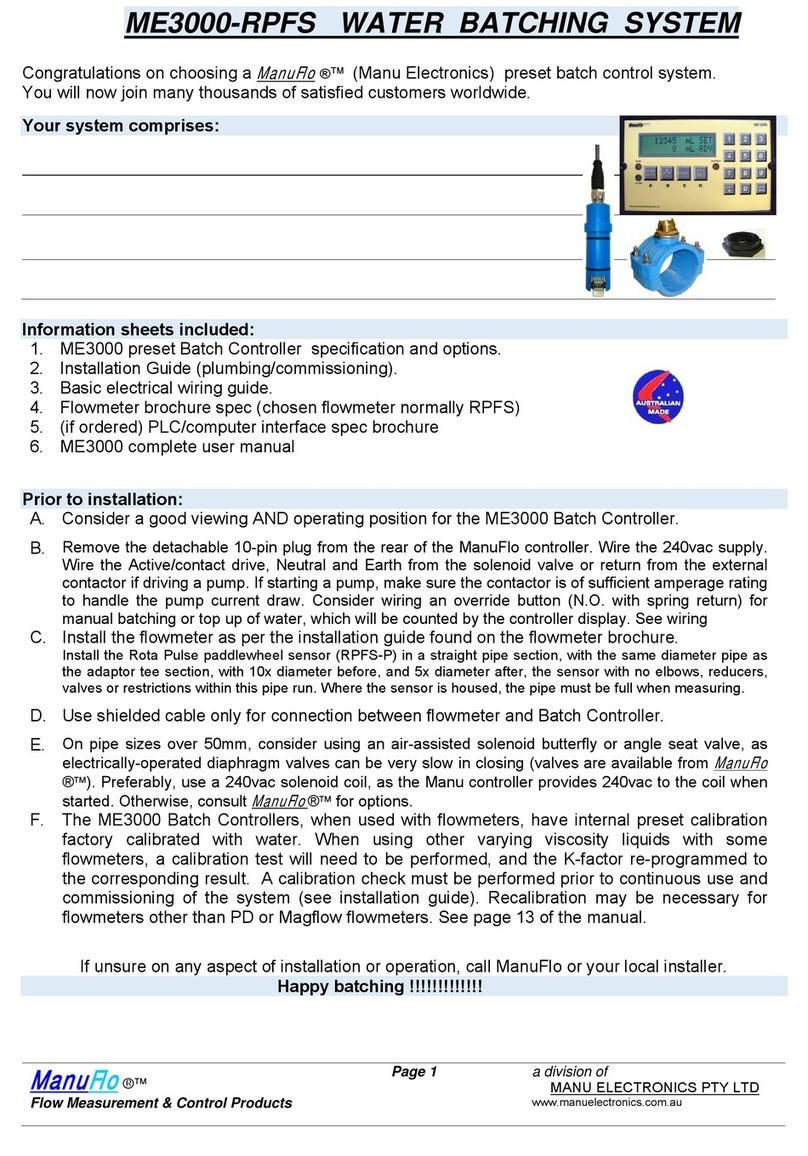

MANU ELECTRONICS ManuFlo ME697 User manual

ME697 INTERFACE CARD (Eagle version)

FLOWMETER (MES20) TO EAGLE COMPUTER

PULSE COUNTER INTERFACE CARD

with manual batch facility and pulse fail safety.

FEATURES:

•6x 8 digit LCD counters, displayed in millilitres.

•Supports up to six MES20 flowmeters.

•Optional variable pulse dividers.

•110 - 240vac pulse outputs (Triac switching)

with LED indication.

•Provides important cross-reference batch figure.

•Pulse Fail and Batch Limit safety override

with LED warning indicators and alarm.

•6 channel override batching facility.

•Easy plug-in connectors.

•Compact housing.

INTRODUCTION

The ME697 counter divider interface card was designed to act as a support product in interfacing upto six ManuFlo

admixture 20mm pulse output flow meters ( MES20, KGG20, MEK20 ) with Eagle and other USA industrial computer

systems, requiring low frequency pulse rates and 110-240vac pulse inputs. This new design incorporates new high

resolution missing pulse and maximum batch limit overrides, as well as a six-channel manual batching facility.

FUNCTION

The computer system provides an AC output start and hold drive signal (black Opto22) to ME697 start input. The

ME697 output drive supplies power to external contactor coils driving pumps and/or solenoids. ME697 supplies

+12VDC to flowmeters which in turn send back pulses which are counted by individual channel LCD displays in

millilitres. The pulses are then sent to the computer inputs (yellow Opto22). When the computer system has OPTO22,

110 - 240 vac input optos, incoming pulses are limited to 14 Hz maximum. Due to high resolution pulsing of

flowmeters, the pulse rates must be divided. The onboard selectable dip switches are then set to the desired pulse

division rate (see Fig.1).

The divided output pulses are indicated by the pulse LEDs. The pulses are stepped up (via Motorola MOC3041 Triacs)

to 110 - 240 vac switching pulses. These pulses arereceived by the computer input card (through Yellow OPTO22).

When computer has completed batch cycle, a 110 or 240 vac reset signal is supplied to the ME697 master reset relay,

thus reseting all counters.

SAFETY OPERATION

If, at any time during batch cycle, any flowmeter stops pulsing (e.g. due to flow obstruction, failure, blockage, pump

failure etc), or the preset upper safety limit is reached, the inbuilt Pulse Fail feature will activate, shutting down flow

regardless of computer's status operation. If Pulse Fail (P.F.) is activated, warning LED(s) will illuminate, indicating the

channel at fault. Also, an audible alarm will sound. If upper batch limits are set, and if they are reached, the same

safety features will activate. If channel(s) pulse failed, remember the quantity displayed. Reset unit to resume batching.

Order Code for ME697 for Jonel Computer: ME697-1A-2A-3A-4A-5A (see Page 7)

ManuFlo

®™

Flow Measurement Products

Page 1 MANU ELECTRONICS PTY LTD

ME697 (Eagle version)

OPERATION To batch in manual mode (without computer) :

•Switch on power. Reset or zero counters by pushing the reset button.

•Push and hold one (or more) of the six run buttons. When the desired amount is reached, release button.

You can also batch from the computer’s manual mode at console panel.

•When batching automatically (computer mode), do not touch reset or run buttons.

•If alarm activates, always cross-reference ME697 and computer screen displays to see if they are corresponding in

the quantity dispensed.

*********************************************************************************************************************************

If Pulse Fail (P.F.) occurs repeatedly and alarm sounds, do not persist - qualified service or advice is required.

*********************************************************************************************************************************

INSTALLATION

1. Find a suitable position to wall-mount box - consider good view of LCDs and room for wiring.

The ME697 is fixed to the cover lid, therefore cable gland entries can be fitted to box at any location.

2. Use at least a 10-core shielded cable for flowmeters. Wire flowmeter cable to 8-pin (J4) flowmeter input plug,

taking care to observe correct channel (1-6) identification, and that wiring to + and - terminals is correct.

3. Connect 240vac supply to 3-pin plug (J5).

4. Connect from 7-pin plug (J1), AC pulse output drives to computer's yellow OPTO22 pulse inputs.

5. Connect from 8-pin (J2) input start and master reset plug, to 6 x computer black Opto22 output start drives and

1 x master reset opto located in computer I/O panel.

6. Wire from 7-pin plug (J3) output drive plug, to external contactor coil and/or solenoid flow control drives.

Make sure only one common active line and neutral is used to interconnect wiring on ME697 card, from the computer

supply. Do not mix active pump drive with computer's Uninteruptable Power Supply (UPS).

NOTE: Neutral J2 and J5 is already bridged internally.

J5 active line after switch and fuse is bridged to J1 Active and J3 Active. Only wire A.N.E. J5 power input plug.

* Six wires from J1 to computer yellow Opto22 (pulses).

Seven wires from J2 to computer black Opto22 (six start drives, one master reset).

From J3, six wires will drive each contactor coil, return neutral to J2 neutral.

From J4, wire six pulse wires, one +12V, one O.V. or shield to flowmeters.

SPECIFICATIONS

Display: 6 x 8 digit LCD counters in millilitres

Power supply: 220-260 vac (optional 110 vac)

Supply to flowmeters: 12 VDC (10mA per flowmeter)

ManuFlo

®™

Flow Measurement Products

Page 2 MANU ELECTRONICS PTY LTD

Pulse inputs: Up to 6 x MES20 flowmeters (1 millilitre per pulse) max. 1kHz

Computer pulse outputs: 240vac Triac, 15 Hz max. (optional 110vac)

Computer start/reset: 240 vac via relays (11KΩcoil) - 110 vac optional

Output starts: 240 vac via relays - 110 vac optional

(requires contactors to drive pumps)

Pulse fail: Triggers below (adjustable) 25Hz (25 mls per sec flowrate)

with LEDs illuminated.

Preset batch limits: 640 to 51200 ml. max. or infinite. Selectable via 4-way DIP.

Optional pulse division: ÷10, 20, 50 or 100 (mls per pulse). Selectable via 4-way DIP.

LED output pulsers: Blinks at divided pulse rate (e.g. 100mls)

Manual batch start: Via 6 x momentary push buttons.

Connectors: Plug-in J1, J2, J3, J4, J5

Enclosure: IP55 wall mount 225L x 180W x 90D

Weight: 1.5 kg

BLUE DIP

Limit x Divided Pulse

4 ON only = 64 x PulseDiv

3 ON only = 128 x PulseDiv

2 ON only = 256 x PulseDiv

1 ON only = 512 x PulseDiv

Due to continuous product improvement, specifications are subject to change without notice.

ME697 (Eagle version)

ManuFlo

®™

Flow Measurement Products

Page 3 MANU ELECTRONICS PTY LTD

ME697 Troubleshooting

• keep input rate to AC Computer/PLC below 15 Hz (otherwise overdose could occur due to computer missing pulses).

• if the ME697 appears disabled (e.g. displays read zero, does not count, no functions even in manual mode) then the

Master Reset black Opto on the PLC is leaking, or is stuck on causing a continual reset drive to the ME697.

Measure the leakage voltage between the Master Reset (Connector J2, pin 7) and Neutral (Connector J2, pin 8). If

there is more than 60vac voltage, then:

oreplace the Black Optos; and/or

ofit a 12-15 KΩ10W resistor between the Master Reset and Neutral (i.e. between pins 7 and 8 of Connector J2).

If there is still a problem, then it is a Computer issue that the master reset is stuck on. Disconnect the plug connecting

the Computer to J2 and batch manually.

•if the batching computer’s black Optos are leaky (i.e. there is more than 60vac residual voltage after Opto latches off,

which could cause batching to continue because the ME697 relay is being held on), then:

oreplace the Black Optos; and/or

ofit a 12-15 KΩ10W resistor between each black Opto’s Active 240vac Computer Start (i.e. relevant pin on

connector J2) and Neutral (pin 8 on Connector J2).

• if experiencing slow counts on one channel after batch completes: ensure that Check Valve is not faulty.

• if experiencing phantom counts on one channel: check wiring and shield.

•if experiencing constant phanton counts on many channels: the internal 1000 μF electrolytic capacitor may have

failed, so return the ME697 to ManuFlo for service.

ME697 (Eagle version)

Page 4

INSTALLATION GUIDE for ME697 Interface Card

with MES20 and other flowmeters

(1) Locate the most appropriate position to mount the MES20 flowmeter. Preferably:

•your site’s flowmeters should be grouped together off the ground on a stand.

•protect the flowmeters from the elements by using a cover, which should be lightweight with handles for easy access

by service personel.

•a vibration free area is recommended, as the MES20 is sensitive to high vibrations which can cause some stray

pulses (see the “Installation” section in the MES product brochure).

(2) Establish the outlet point position in relation to the storage tank:

2a) If the outlet point is above the top of the storage tank (the most commonly used setup), then

the equipment you will need is at least: a pump, non-return valves or spring loaded check valves (12psi), flow

restriction gate or ball valve, a flowmeter with pulse output and, optionally:

•a solenoid valve (air-assisted ball valve type) for instant shut off of flow, recommended to prevent the Venturi effect

when injecting into water lines, but may not be required if the installation has reasonable head height.

•a 3-Way Valve to provide an easily accessible calibration point.

ADMIX

STORAGE

TANK PUMP

Gate Valve

restricts flow

Filter

Non-Return

Valve

tank

Valve Flowmeter Non-Return Valve

optional 3-Way Valve

(calibration point)

optional Solenoid – to

prevent Venturi effect

if injecting into

water lines.

outlet line

above level of

Storage Tank

(most common)

ME697

Contactor

2b) If the outlet point is at the same level as the storage tank, then the equipment you will need is at least: a pump,

a flow restriction gate or ball valve, a flowmeter with pulse output, and a solenod valve to stop free flow.

ADMIX

STORAGE

TANK

PUMP

Gate Valve

restricts flow

Filter

Non-Return

Valve

tank

Valve Flowmeter Non-Return

Valve

optional 3-Way Valve

(calibration point)

Solenoid

outlet line

at same level as

Storage Tank

ME697

Contactor

2c) If the outlet point is below the level of the storage tank, then the equipment you will need is at least: a flow

control solenoid valve, a flow restriction gate or ball valve, and a flowmeter with pulse output.

ADMIX

STORAGE

TANK

Gate Valve

restricts flow Filter

tank

Valve

Flowmeter

outlet line

below level of

Storage Tank ME697

Solenoid

an optional pump

may be used to

speed up flowrate

PUMP

ME697 (Eagle version)

Page 5

( A

ME697 (Eagle version)

Page 6

ME697 (Eagle version)

ManuFlo

®™

Flow Measurement & Control Products

Rev: 0709/1

a division of

Page 7

MANU ELECTRONICS PTY LTD

41 Carter Road, Brookvale

Sydney NSW 2100 Australia

Ph: + 61 2 9905-4324, 9938-1425

Fax: + 61 2 9938-5852

Web: www.manuelectronics.com.au

ME697 Order Code Options

When ordering ME697 card, add the codes to indicate which specification options are required

to suit your PLC/Computer/IO control card and external contactors/coils.

e.g. Order Code for ME697 for Eagle Computer: ME697-1A-2A-3A-4A-5A

ME697 6-channel flowmeter-to-PLC/Computer interface card,

with safety and manual batch facility.

POWER SUPPLY (to card)

-1A 240 vac power supply

-1B 110 vac power supply

-1C 24 vac power supply

-1D 24 VDC power supply

START INPUT DRIVES and MASTER RESET (from Computer starts)

-2A 240 vac power supply

-2B 110 vac power supply

-2C 24 vac power supply

-2D 24 VDC power supply

START OUTPUT DRIVES (from ME697 to contactor coils and solenoids)

-3A 240 vac power supply

-3B 110 vac power supply

-3C 24 vac power supply

-3D 24 VDC power supply

-3E OPEN CONTACT

PULSE OUTPUT (to computer input)

-4A 24-240 vac triac pulse output switching

-4B 5-24 VDC 4N33 opto isolated pulse output switching (sink = pulse to O.V.)

-4C 5-24 VDC 4N33 opto isolated pulse output switching (source = pulse to +)

PULSE DIVISION (to computer input)

-5A standard dividers 10, 20, 50, 100

-5B 1 ml in, 1 ml out

-5C SCC signal conditioner card fitted to nominated input channels

(for flowmeters other than MES20).

Table of contents

Other MANU ELECTRONICS Control System manuals

Popular Control System manuals by other brands

Honeywell

Honeywell RP908A Series Service data

Lippert Components

Lippert Components OneControl ConnectAnywhere owner's manual

HEIDENHAIN

HEIDENHAIN TNC 150 B Mounting instructions

Roger

Roger RUD-3-DES operating manual

Rain Bird

Rain Bird Freedom System for Maxicom2 user manual

Mi-Light

Mi-Light fullwat TRIAC CONTROL owner's manual