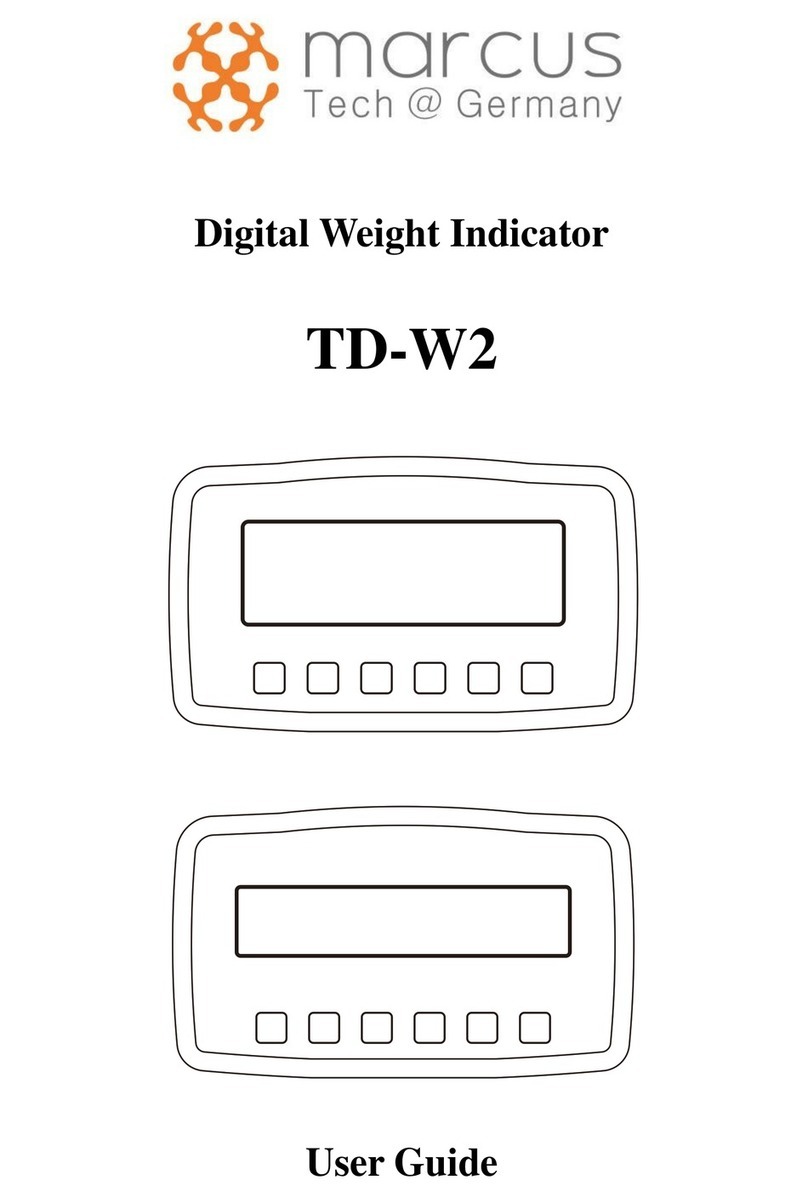

MARcus TD-WI 1 User manual

TD-WI 1

WEIGHING INDICATOR

Operation Manual

Table of Contents

SECTION 1 INTRODUCTIONS………………………………………………………………1

1.1 Introduction……………………………………………………………………………………1

1.2 Specification…………………………………………………………………………………..1

1.3 Installation…………………………………………………………………………..………...1

SECTION 2 KEYS DESCRIPTIONS………………………………………………………2

SECTION 3 OPERATIONS…………………….……………………………………….…..3

3.1 Power on/off...................................................................................3

3.2 Functions and parameters setting...........................................................................3

3.3 Zero the scale...................................................................................3

3.4 Tare the scale………………………………………………………………..…….4

3.5 Parts counting (KEY=1)…………………………………………………………4

3.6 Accumulation (KEY=2)…………………………………………………………….5

3.7 Holding the weight (KEY=3)………………………………………………….5

3.8 Presetting tare value (KEY=4)……………………………………………….5

3.9 Animal weighing (KEY=5)…………………………………………………………5

3.10 Check-weighing........................................................................6

3.11 Print (KEY=2)...................................................................................6

SECTION 4 FUNCTIONS AND PARAMETERS……………………………………..…7

SECTION 5 RS-232 OUTPUT……………………………………………………………..8

SECTION 6 ERROR CODES……………………………………………………………9

--

1

SECTION 1 INTRODUCTIONS

1.1 Introduction

The indicator provides an accurate, fast and versatile series of general purpose weighing indicator with counting,

check-weighing, animal weighing functions and preset tare.

1.2 Specification

Housing

Stainless steel plastic housing

Power supply

220~240V AC (110V optional) 50/60Hz

built-in rechargeable battery 6V1.3AH.6V4AH.

Display

6 digits 1’LED. 1’LCD

Max input

15mV

Offset Range

≥0.2mv (10000 Count)

ADC

Σ-Δ

External Resolution

1/40000

Interface

RS-232 Output

Stabilisation time

1 second typical

Operating temperature

0°C - 50°C / 32°F - 104°F

Load cell drive voltage

5V/ Max 150mA

Other function

Real-time clock and units conversion

Load cells

Up to eight 350 ohms cells

1.3 Installation

The weighing indicator should be sited in a location accuracy would not be degraded.

Avoid extremes of temperature.

Avoid unstable power sources. Do not use near large users of electricity such as welding equipment or large

motors.

Verify the voltage showing on the label matches the voltage in your area.

connection of loadcell:

Plastic housing connect to Din9 Stainless steel housing on PCB :

S- S+ SH E- SN-SN+ E+

+EXC

+SEN

1

+SIG -SIG 2

8

4

5

7

-SEN

-EXC

LOAD CELL

3

--

2

connection of RS232

Plastic housing connect to Din9 Pin 2 RXD Pin3 TXD Pin5 GND

Stainless steel housing on PCB TXD GXD RXD

SECTION 2 KEY DESCRIPTIONS

SOFT POWER ON/OFF Key

Power on/off the indicator.

ZERO Key

1) When self-checking, Press ZERO Key to enter parameter setting;

2) Set the zero point for all-subsequent weighing;

3) Move the cursor to change the digit when setting parameters or other functions.

TARE Key

1) When self-checking, Press TARE Key to enter fast calibration;

2) Tare the scale. Store the current weight in memory as a tare value, subtract the tare value from the weight and

shows the net weight. Entering a value using the keypad will store that value as the tare value;

3) Cycle through the functions or increase the active digit when setting value for parameters or other functions.

MOD/ ESC Key

1) Enter / Cancel the counting mode from weighing mode when “F3 KEY”=1;

2) Accumulate and print when “F3 KEY”=2;

3) “Hold”Function keep and cancel when “F3 KEY”=3;

4) Enter pre-tare value when “F3 KEY”=4;

5) Parameter setting for animal weighing when “F3 KEY”=5;

6) Cancel or quit from the operations.

FUN Key

1) Select or enter the function and save the setting values of parameters;

2) View unit weight, counts and total weight when counting mode (“F3 KEY”=1);

3) View nos. of accumulated weight and total weight when “F3 KEY”=2;

--

3

4) Enter/Cancel animal weighing function when “F3 KEY”=5;

UNIT Key

1) When self-checking, press UNIT Key to set unit conversion coefficient.

2) Unit conversion when weighing.

SECTION 3 OPERATIONS

3.1 Power on/off

Press ON/OFF Key to power on the Indicator and the indicator self-checks, then goes into the weighing state.

3.2 Functions and parameters setting

When self-checking, press ZERO Key to enter parameter setting. Then display shows “F1 CLK”. Press TARE

Key to move functions cycle. Press FUN Key to enter the desire function or MOD Key to cancel or quite. See

details on Section 4 Functions and Parameter Sections.

When self-checking, press TARE Key to enter “P8 CAL”calibration function.

When self-checking, press MOD Key to enter “P13 UT”unit setting.

When self-checking, press FUN Key to stop self-checking and it goes into the work state.

When self-checking, press UNIT Key to enter unit conversion coefficient setting.

3.3 Zero the scale

Press ZERO Key to set the zero point from which all other weighing and counting is measured. Usually this will

only be necessary when the platform is empty. When the zero point is obtained the ZERO indicator is ON.

The scale has an automatic re-zeroing function to account for minor drifting or accumulation of material on the

platform. However you may need to press ZERO Key to re-zero the scale if small amounts of weight are shown

when the platform is empty.

3.4 Tare the scale

When a container is applied it needs to tare off and obtains a net weight. Remove all weights from the platform

and make the platform empty. Make sure that the ZERO indicator is on. Place a container on the platform and the

container’s weight will be displayed. Press TARE Key to tare the scale. The container’s weight will be stored as a

tare value and the value will be subtracted from the display, leaving a zero value on the display. The TARE

--

4

indicator will be on to show the indicator is now under tare operation. A product is placed in the container and it

will show only the weight of the added product. The scale should be tare a second time if another is added to the

first one.Again only the weight added after tare will be displayed.

When the container is removed a negative value will be shown. If the scale was tare just before removing the

container this value is the gross weight of the container plus all products that were removed. The ZERO indicator

will also be on because the platform is back to the same condition it was when the ZERO Key was last pressed.

To clear the tare value, empty the platform and press TARE Key again, TARE indicator will be goes off.

3.5 Parts counting (KEY=1)

Tare the weight of any container that is used, leaving the empty container on the scale. Place samples on the

scale. The number of samples should match the options for parts counting, 10, 20, 50, 100 or 200 pieces.

Weighing sample: Press MOD Key to begin the parts counting. The scale shows "P 10" asking for a sample

size of 10 parts. Change the sample size by pressing the TARE Key, the display will cycle through the options:

10/20/50/100/200.

Counting: Press FUN Key when the number matches the sample size. Remove samples from the container

and place the desire parts for counting purpose. Display will show the number of parts (pcs).

Viewing the Unit Weight, Nos. of Counts & Total Weight:

Press FUN Key to cycle through Unit Weight, Nos. of Counts and Total Weight. (Note that the Unit Weight will

show in gram.)

Press MOD Key to return to normal weighing.

3.6 Accumulation (KEY=2)

Accumulate the weight:

When weighing, press FUN Key for accumulation.

Place the products that to be weighed, when the STABLE indicator is on, press MOD Key and the weight value

will be stored in the memory. The display will show nos. of accumulation. After that it goes to normal weight

display. Do other subsequent weighing by the similar procedure as described above. Note: This Indicator can

store 200 Nos. of accumulation.

View the accumulated total weight:

Empty the scale by removing the weights. Press FUN Key it will display the Nos. of weights, and then total

weight.

Clear the accumulated weight from memory:

Press ZERO Key during display of the nos. of weights and total weight, accumulated weights are cleared from

memory.

--

5

3.7 Holding the weight (KEY=3)

Press MOD Key to enter the hold function. After every weighing, the weight value will be kept on the display.

MOD Key can be pressed to cancel hold function.

3.8 Presetting tare value (KEY=4)

Press MOD Key to preset tare value. While every weighing, the value displayed is the one actual weight

substrate the preset tare value.

3.9 Animal weighing (Key=5)

Press MOD Key to set parameters of animal weighing.

1) Stable time “Fil n”. Options: 1/2/3/4/5. 1 is the fastest and 5 is lowest. The longer of stable time, the harder to

lock.

2) Display range “Rang n”. Options: 1/2/3. Option 2 is recommended.

3) Leaving lock range. If the change of weight exceeds the value, the indicator will get a new display.

Press FUN Key to enter or cancel the animal weighing function.

3.10 Check-Weighing

Check-weighing is a procedure to cause alarm to sound when the weight on the scale meets or exceeds values

stored in memory. The memory holds values for a high limit and a low limit.

Check range:

Set hi-limit and low-limit as different values, and hi-limit value is larger than low-limit value.

Check key point:

Set hi-limit and low-limit as same value.

Check mode:

Setting the parameter: Select ”F4 CHK”to enter check mode. Press FUN Key to enter and sub select “BEEP 1,

BEEP 2 or BEEP 3”; Press FUN Key, it will show “XXXXXX”. Then begin to set high-limit value; Press Enter to

set low-limit value;

Mode 1: BEEP=1, never beep whether it is eligible or not, but the indicator HI or LO will be on or off to show the

result. When the weight is higher than the high-limit, indicator HI will be on, while lower than the

low-limit indicator LO will be on. Otherwise indicator HI & LO will be both on.

Mode 2: BEEP=2, beep when it is eligible;

Mode 3: BEEP=3, beep when it is not eligible.

Note: The weight must be greater than 9 scale divisions for the check weighing to operate. To disable the

check-weighing function press UNIT Key to set both high and low limit to zero.

--

6

3.11 Print (KEY=2)

Set “P10 PS”: “RS Prt” is selected for the Serial Printer.

When weighing, press MOD Key to print.

SECTION 4 FUNCTIONS AND PARAMETERS

“F1 CLK”:Date and time setting

When “F1 CLK”is showed, press FUN Key. It will display the time.

Time setting: ZERO Key: shift digit; MOD Key: cancel and esc;

TARE Key: value up; FUN Key: enter and esc;

Select date setting mode by pressing TARE Key. “YY-MM-DD”, “MM-DD-YY” or “DD-MM-YY”

Date setting: Same as time setting.

“F2 SLP”:Sleep function For LED Version

SLP no: Set to “SLP no” means the indicator will never sleep.

SLP 3: Set the time span 3 minutes for the sleep. This sleep mode has two options: “off & dot”, which can be

selected by pressing FUN Key when displaying “SLP 3”. ”off” means cutting off the power and “dot” means only

a dot at the last digit will be displayed. When “dot”, weight changing can wake up the indicator.

SLP 5/10/15: Same as SLP 3.

“F2 BK”: Backlight mode setting For LCD version

Auto mode: The backlight will distinguish when no action is taken during a certain time.

Off mode: The backlight is off all the time.

On mode: The backlight is always on.

“F3 KEY”: MOD Key setting

KEY 1

To set the MOD Key for counting, gross / net weight display switch.

KEY 2

To set the MOD Key for accumulation & print.

KEY 3

To set the MOD Key for holding the weight value.

KEY 4

To set the MOD Key for setting tare value in advance.

KEY 5

To set the MOD Key for animal weighing parameters setting.

“F4 CHK”: Check-weighing setting

Options: BEEP 1/2/3.

“F5 Brt”: Adjust the brightness of LED display. For LED version

Select 1-8 : 8 is most bright

“F5 INP”: Display the internal counts For LCD version .

Used to check the connection of loadcell and working status of ADC circuit.

Press “TARE” to exit.

--

7

“F6 INP”: Display the internal counts For LED version

“F6 CAL”: Calibration for LCD Version. See below:

“F7 CAL”: Calibration

“PN”:Press FUN Key to enter “PN”. Initiate password is 0000

“P1 SP”: Set AD converting speed. Options: 1/2/3/4/5. 1 is the fastest and 5 is the slowest.

“P2 AUT”:Select the “Power on “zero maintenance, Options: 0/2/5/10/20/50/100% of the capacity.

“P3 RAN”: Select the manually zero maintenance, Options: 2/ 4/10/20/50/100% of the capacity.

“P4 AZ”: Select the auto zero maintenance, Options: 0.5d/1d/2d/4d. “d”means division.

“P5 DEC”: Set the decimal point. Options: 0/0.0/0.00/0.000/0.0000.

“P6 CAP”: Set the capacity.

“P7 INC”: Set division increment. Options: 1/2/5/10/20/50.

Make sure enter all P5,P6 ,P7 and set parameters in order

“P8 CAL”: Calibration

After finishing all necessary settings above, the indicator is ready for calibration. (Note: If the scale has settings

already done you can directly calibrate it.) Press FUN Key when displaying “P8 CAL”. Display will show

“noLoAd”. Empty the platform by removing the weight if any. When platform is empty and STABLE indicator is on

then press FUN Key to confirm. Display shows “XXXXXX”. Set it to be the weight of the weigher you want to put

on. Press FUN Key toconfirm, and it will show “LoAd”. Put the calibration weigher on the platform and press FUN

Key after the STABLE indicator is on. Indicator will go to weighing state. The calibration is finished.

“P9 INT”: Initialize the memory to ex-work state.

“P10 RS”: Communication mode.

This option is used for the RS232C serial port mode setup. Options: “RS Cot” is continuous Data Transmission

for using Remote Display or External Display, “RS Prt” is used for the Serial Printer. “RS Aut”is used for

“transmission after every weighing”.

“P11 FL”: Weight adjustment for acceleration of gravity.

“P12 KB”: When “on”, keyboard is pressed with sound.

“P13 UT”: Unit setting. Lb, U1 or U2 is optional, which could be “ON”or “OFF”through pressing the FUN Key

and TARE Key. When U1/U2 is “ON”, the conversion coefficient can be set through pressing UNIT Key while

self-checking. When U1/U2 is “OFF”, it could not be set unless entering the P13 UT menu and set it “ON”.

“P14 Pn”: Press “FUN”to display “P1 ----”set the passwords and press “FUN”. It display “P2 ----”and set

passwords again to confirm. When successful ,it will show “Done”

SECTION 5 RS-232 OUTPUT

Specifications: RS-232 output of weighing data, 1200/2400/4800/9600/19200 bps,1 stop bit, 8 data bits, No

Parity.

Mode 1: Continue output

--

8

ST,GS 0.119,kg

ST for stable; US for unstable ; GS for gross weight; NT for net weight ; 0.119 for weighing value; kg for unit (kg,

lb); HEX 0d and HEX oa : HEX for hex; 0d for enter; 0a for next line.

Mode 2: Automatic output

Automatic output mode is same as continue output. The only difference is:

After weighing, when take away the goods display returns to zero, then transfers.

Data Format for normal weighing operations. Examples as follow:

2000/02/11 21:21:58

No. TARE NET GROSS TOTAL

-----------------------------------------------

001 0.000U1 0.034U1 0.034U1 0.034U1

DATE 2000/02/11

TIME 21:26:56

NO. 001

TARE 0.000kg

NET 0.076kg

GROSS 0.076kg

DATE 2000/02/11

TIME 21:27:41

NO. 002

TARE 0.125kg

NET 0.035kg

GROSS 0.160kg

----------------

NO. 002

TOTAL 0.111kg

--

9

SECTION 6 ERROR CODES

ERROR

CODES

DESCRIPTION

RESOLUTION

- - OL - -

Over range

Remove weight from the scale.

Err 1/Err 2

Date and Time not right

Reset again.

Err 4

Zero Setting Error

The scale was outside the normal zero setting

range either when it was turned on or when

the ZERO Key was pressed. Remove weight

from the scale and try again. Use the TARE

Key to set the display to zero value.

Table of contents

Other MARcus Measuring Instrument manuals