5

temperature before usage or shutdown. When the operating temperature is achieved, again

check for leaking fluids.

Periodic maintenance - see separate Marinediesel Service book.

Periodic maintenance important notes

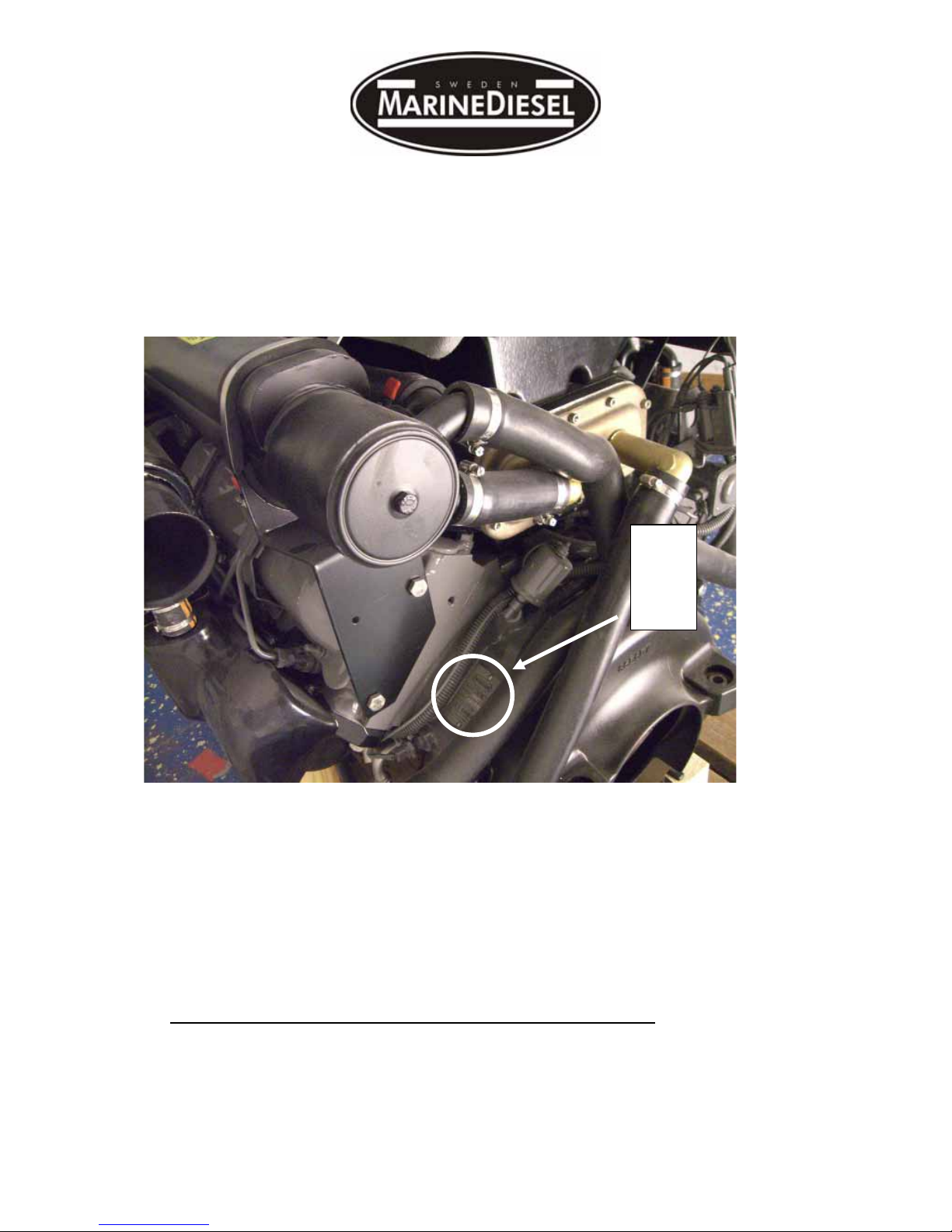

Periodic oil change on the supercharger (Only SC-models). USE ONLY Marinediesel

High Performance Supercharger oil. Do NOT overfill, correct level is critical. (Low level

can cause gear failure, high level can cause drive coupling failure)

Technical maintenance specifications

xRecommended engine oil: DO NOT USE SYNTHETIC OIL, use 15W/40 API: CH-

4, CG-4, CF-4, CF/SJ. Fill with 7,5 litres (including filter)

Warranty (

I. Marinediesel Sweden AB warrants each new production MarineDiesel Engine and Accessories attached thereto (here after referred to as “Product”),

manufactured by Marinediesel Sweden AB (hereafter referred to as the “Company”), to be free from defects in material and workmanship, but only

when the customer purchases or obtains pre-delivery service from a Dealer authorized by us to distribute MarineDiesel product in the country in

which the sale or pre-delivery service occurred. This warranty shall apply only to pleasure craft and light-duty craft applications.

II. This warranty shall become effective upon the date of sale to the first purchaser or user of the Product and receipt by MarineDiesel of a completed

Sea Trial Registration Form. The warranty period for standard engines (non RPM models) Pleasure Craft applications is one (1) year from the

date of sale to the first purchaser or user of the product or the

accumulation of 1500 hrs whichever occurs first. The warranty period for RPM series engines is one (1) year from date of sale to the first

purchaser or user of the product, or the accumulation of 750 hours of engine operation, whichever occurs first. The warranty period

for Light-Duty Craft applications is one (1) year from date of sale to the first purchaser or user of the product, or the accumulation of

750 hours of engine operation, whichever occurs first. The unused period of the applicable warranty, if any, is transferable to subsequent

purchasers only if the required maintenance records have been recorded by an authorized dealer. If the law applicable in the Country, State or

Province where the product is sold prohibits limitation of warranty coverage to one (1) years, then the warranty shall be the minimum

period required by law. For purposes of this warranty Pleasure Craft is defined as a recreational planing craft used only and

exclusively for pleasure and recreation. Light-Duty Craft is defined as a planing hull vessel used in any law enforcement,

commercial, or professional entertainment activity, or used in any enterprise or venture in which revenue in any amount is generated directly or

indirectly. The warranty will provide in the First Year: Parts and Labor. In no case will the warranty cover the cost of removing or

installing the engine in the boat, pulling the boat out of the

water, lifts or other associated incidental costs see item VII.

III. To validate the warranty, the “Warranty Registration Form”, and Pre-Delivery Inspection information included with each Product, must be properly

completed by the selling dealer and forwarded immediately after the Sea-Trial to Marinediesel Sweden AB, Metallgatan 6, 262 72 Engelholm

Sweden.

IV. Purchaser must provide proof of purchase and substantiate the original date of sale and delivery by presenting to the dealer, authorized to service the

Product, the original purchaser’s copy of the “Owner Warranty Registration Card”. If either of these items is not available, purchaser must provide a

copy of the original purchaser’s “Bill of Sale” (Sales Contract) for the Product to be serviced. Warranty claims will not be accepted by the dealer

until the original date of sale/delivery and Product serial number can be verified.

V. It is a condition for the continuation of this warranty that the Product be taken to an authorized Marinediesel Service Dealer, after 100 hours of

engine operation, but not later than 150 hours, for required checks and adjustments. A copy of the dealer service work order must be retained as

evidence of the completion of this requirement. This is an owner expense.

VI. Since this warranty applies to defects in material or workmanship, it does not apply to normal wear, adjustments, tune-ups or to damage caused by:

1) Neglect, lack of maintenance, accident, abnormal operation, improper installation or service;

2) Use of a propeller not properly suited to application/boat load or, failure to follow instructions in applicable service and warranty information

manuals or operation and maintenance manual;

3) As applied to twin installation vessels; continual operation of the vessel on only one engine in any condition other than an emergency

situation.

4) Use of an accessory or part not manufactured or sold by us;

5) Operation with fuels, oils, lubricants or coolants/ coolant additives which are not suitable for use with the Product or recommended by us;

6) Participating in or preparing for racing or other competitive activity;

7) Alteration or removal of parts;

8) Water entering engine cylinder/s through the exhaust system or air intake system;

9) Use or operation of the product in a manner inconsistent with the “Recommended Operation/Duty Cycle” section of the Operation and

Maintenance Manual.

10) Engine cooling system overheating.

11) Glow Plug Failure

VII. Reasonable access must be provided to the Product for warranty service. This warranty will not apply to: