SECTION 1 INTRODUCTION

.-~~-- ...-~~.~-.-=-:::-::~=-=-=~-=-=-:~-::::-:::-=-=-=-::-::-:'-~;-::-:-:--;-:---:---;--;-;----;-:------:-7-~--'----'

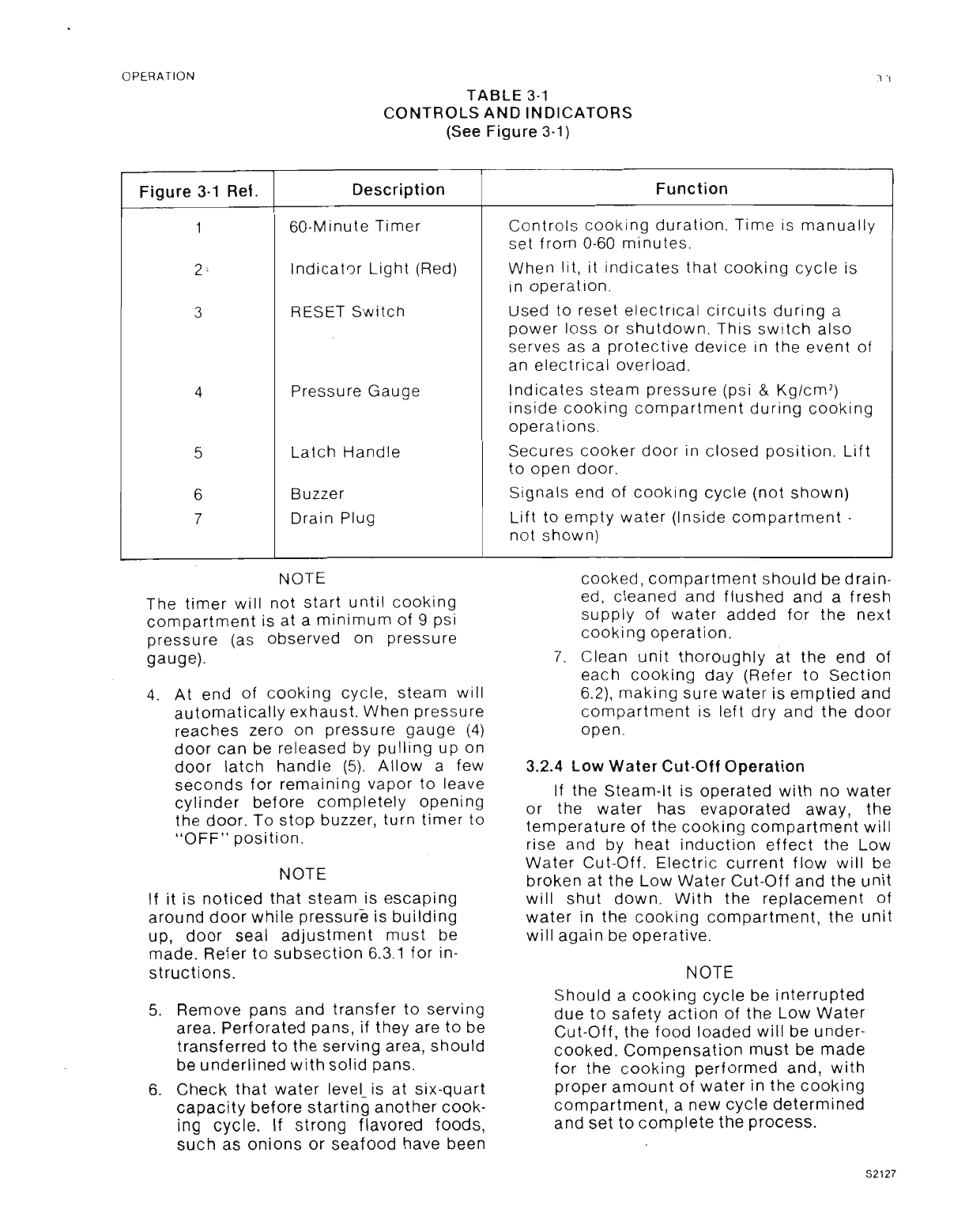

This service and parts manual contains general information, installation, operation, principles

of operation, trouble-shooting, and maintenance information for the Market Forge Steam-It,

Style F,Gas

Operated,

Model ST-AG. Also included is a parts list in which each replaceable part

IS Identified and shown in an accompanying exploded view.

1.1 DESCRIPTION

The Market Forge Model ST-AG Steam-It

Cooker is a gas fired pilotless, direct spark

ignition system cooker. The unit is designed

to operate from a natural, propane, butane or

manufactured gas supply. It consists of a

cooking compartment fitted with electrically

controlled steam circuits for application of

steam for the duration selected by the

operator. The cooking compartment and all

control components are enclosed within

stainless steel cover panels with operator

controls displayed on a front mounted panel.

(See Figure 1-1)

The major assemblies of the Model ST-AG

steam cooker are, the stainless steel cabinet

enclosure, a cooking compartment with pan

supports for cooking trays, the gas burner

and ignition control assembly for the direct

spark electrode, and a steam exhaust valve

assembly. Located on the lower front panel is

a 50-minute timer with a pilot light (red) "on"

indicator and a reset switch marked RESET.

The RESET switch is used to re-cycle the unit

in the event of shut off during a cooking

period.

The unit is designed to be mounted on a

stand which is offered and highly recom-

mended as an optional unit. However, the

Steam-It unit may be mounted on any heat-

resistant table, counter top etc. as long as

certain clearance from combustible

materials are maintained (refer to Section 2

for complete installation instructions) and

the unit is perfectly level.

1.2 BASIC FUNCTIONING

The Model ST-AG steam cooker becomes

operational when water is loaded into the

cooking compartment and the 60-minute

timer is set to the desired cooking time. With

the time set, the electric ignition comes on,

the exhaust valve closes automatically and

the burner ignitor is energized. The gas is ig-

nited by the electrodes to heat the water in

the cooking cylinder.

As the pressure builds up, cold air is

forced out of the cylinder through the ther-

mostatic steam trap. The air will continue to

escape as pressure builds up and the steam

trap will close after all the air has been forc-

ed out of the cooking compartment. When

the pressure reaches approximately 9-10

psi,the contact on the pressure switch will

close, thereby closing the circuit to the clock

motor and starting the actual cooking time

period. When the pressure in the cooking

compartment reaches 15 psi, the contacts on

the pressure switch will open. These con-

tacts will shut off gas to the main burner

when they are open, causing the pressure to

stop rising. When the cooking compartment

cools and the pressure drops to 13 psi, the

contacts on the pressure switch will close

gas will flow to the main burner and be re- ig:

nited by the electrodes. Any number of such

"OFF" and "ON" cycles might occur during

the selected cooking time.

1.3

SERVICE

Required service, both preventive and cor-

rective, is explained in Section 5. Should

repairs be required, a network of authorized

agencies is available to assist with prompt

service. A current Directory of Authorized

Service Agencies may be obtained by

contacting:

Product Service Department

Market Forge

35 Garvey Street

Everett, Massachusetts 02149

Telephone: (617) 387·4100

The Model and serial numbers must be

referenced when corresponding with Market

Forge. The data plate containing the serial

number pertaining to the equipment is

located on the front top of the cabinet.

1·1

S2127