1

TABLE OF CONTENTS

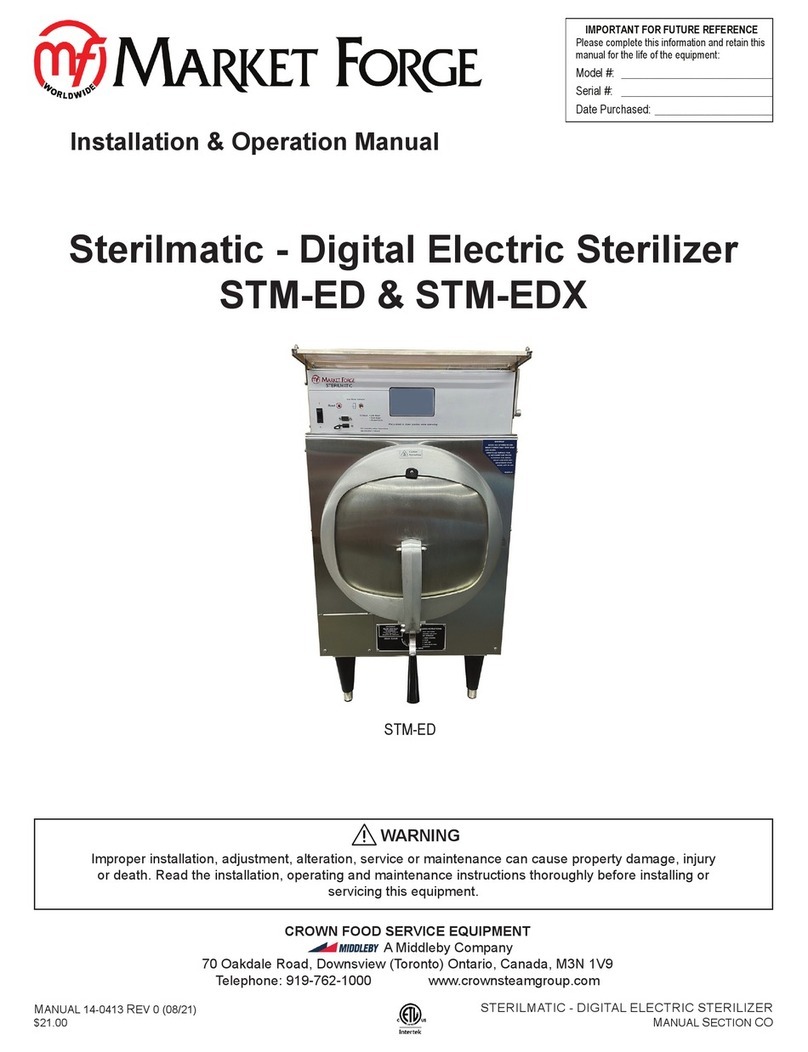

SECTION 1 INSTALLATION INSTRUCTIONS

INSTALLATION ........................................................................................................................................................................... 2

ELECTRICAL .............................................................................................................................................................................. 2

OUTSIDE VENTING .................................................................................................................................................................... 2

WATER-COOLED EXHAUST CONDENSER .............................................................................................................................. 2

RECORDING THERMOMETER .................................................................................................................................................. 2

TRAY SUPPORTS ...................................................................................................................................................................... 3

BAFFLE INSTALLATION ............................................................................................................................................................ 3

OPERATION CHECK .................................................................................................................................................................. 3

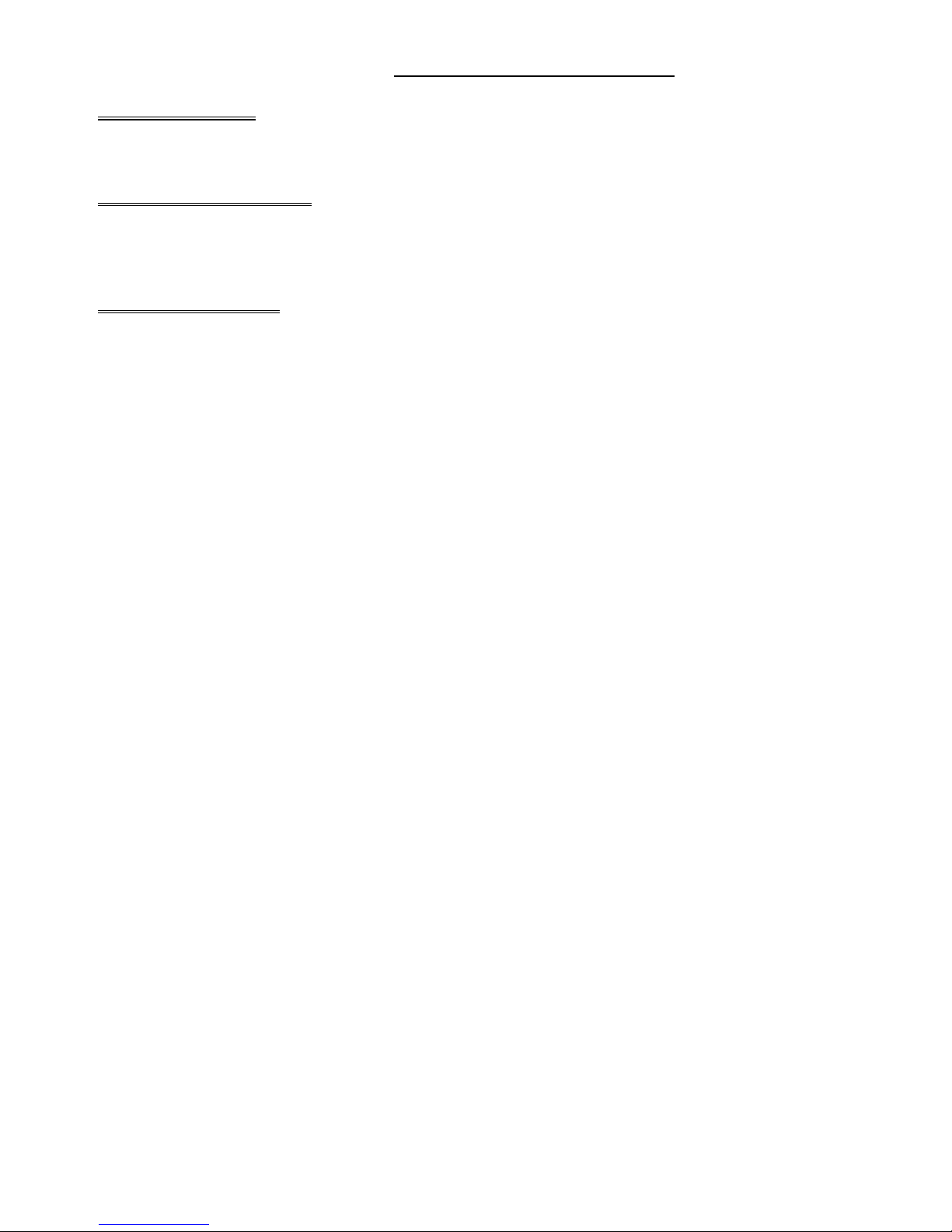

INSTALLATION INSTRUCTIONS FOR COLD WATER CONDENSER ....................................................................................... 4

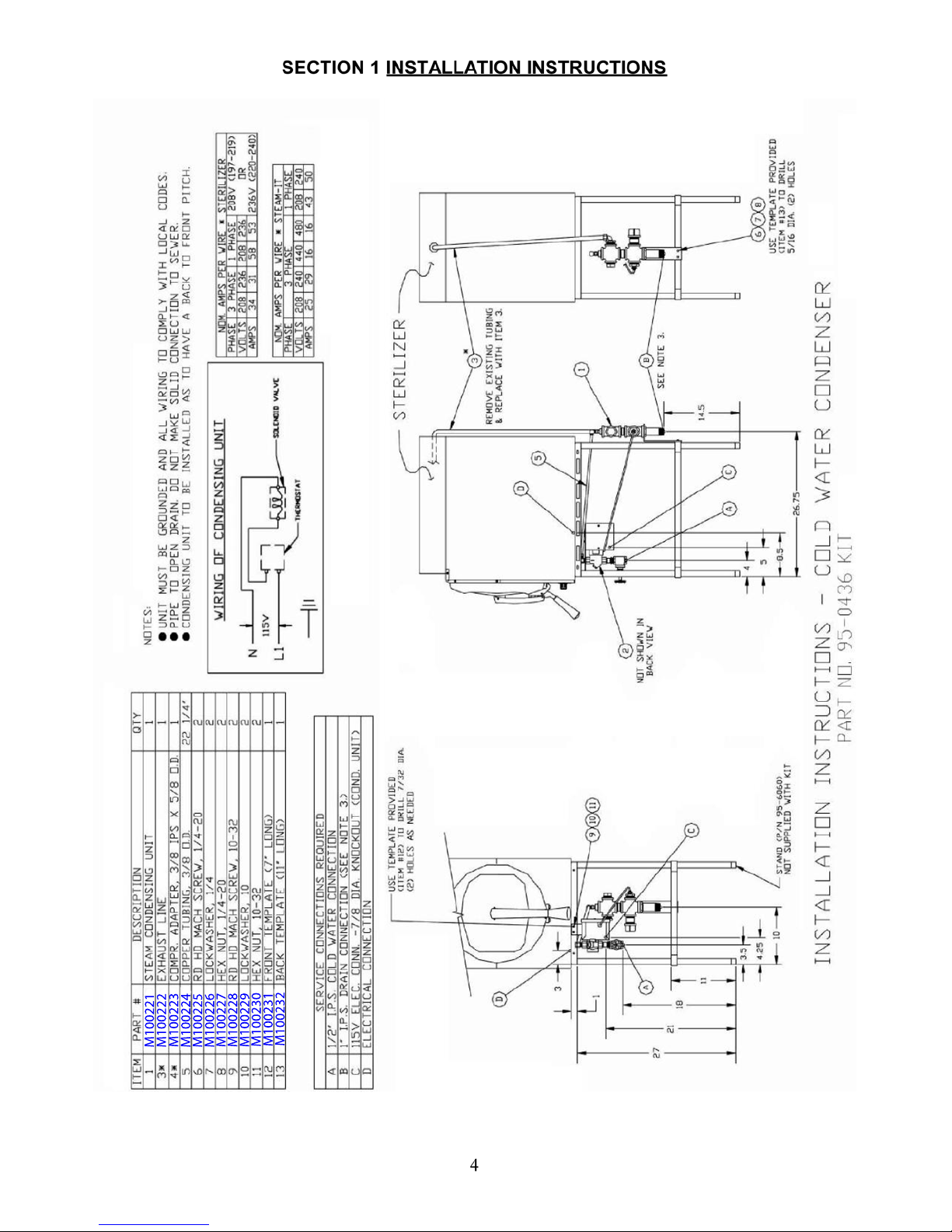

REQUIRED CONNECTIONS ...................................................................................................................................................... 5

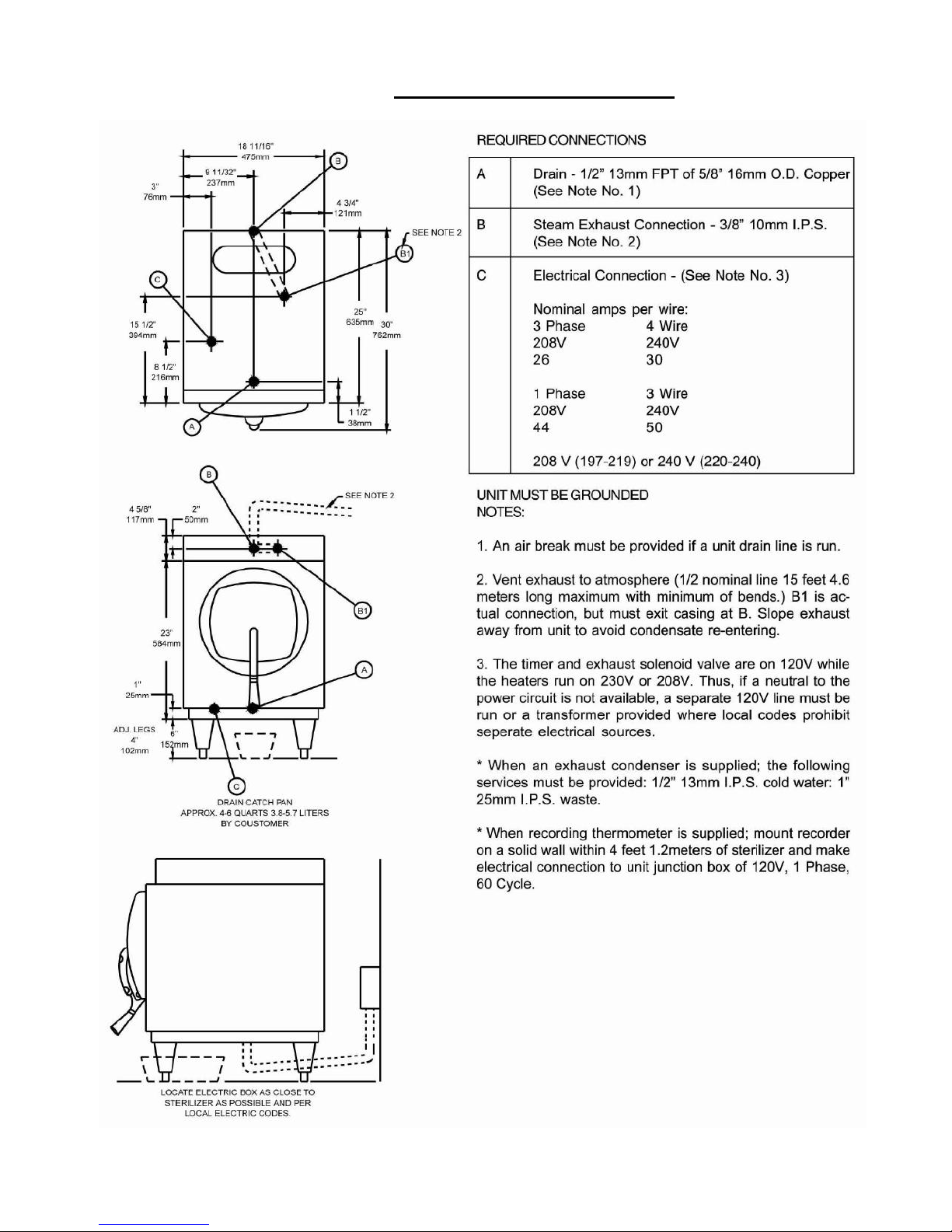

INSTALLING PAN SUPPORTS AND BAFFLES ......................................................................................................................... 6

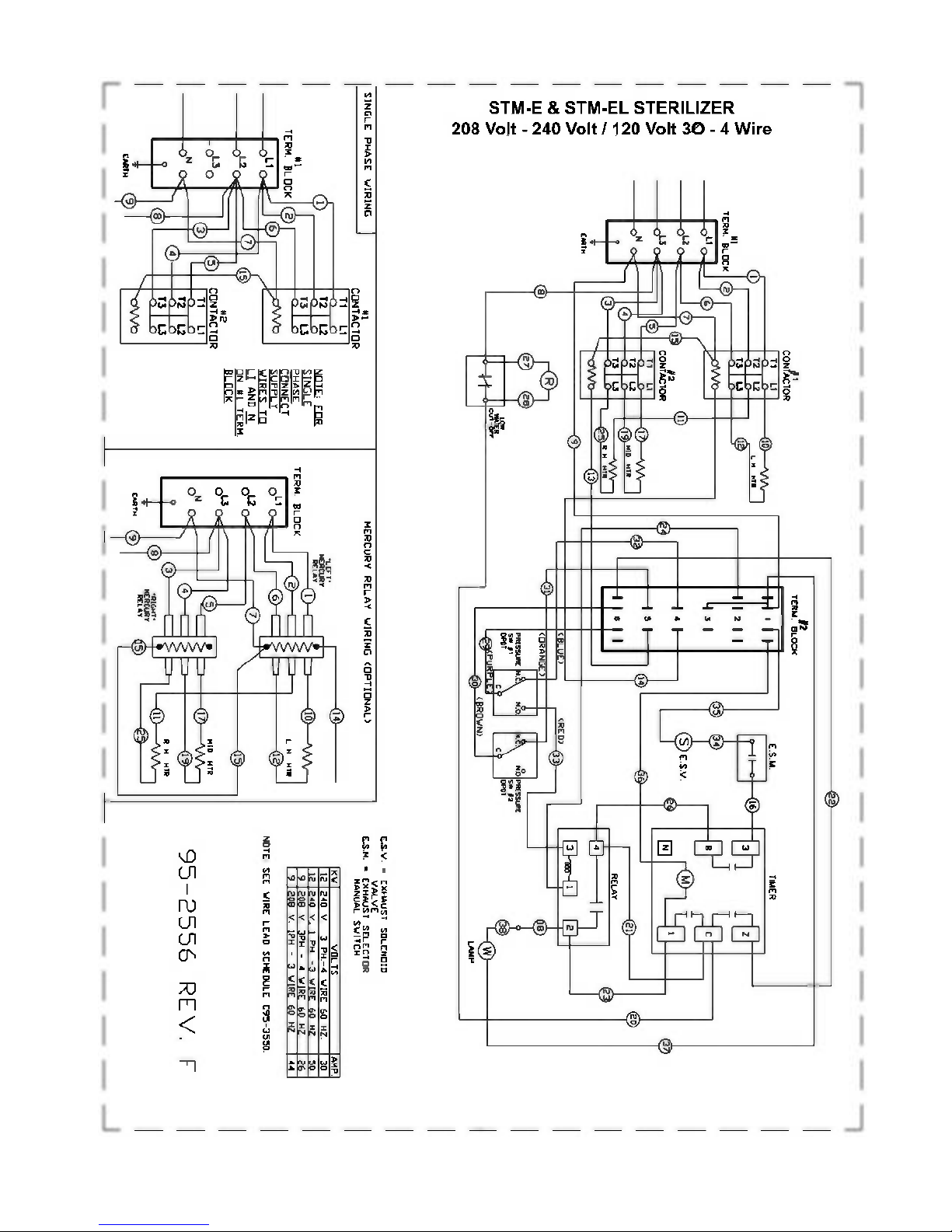

ELECTRICAL SUPPLY CONNECTIONS FOR STM-E AND STM-EL........................................................................................... 7

ELECTRICAL SUPPLY CONNECTIONS FOR STM-EX AND STM-ELX ..................................................................................... 7

DOMESTIC WIRE DIAGRAM FOR STM-E AND STM-EL ........................................................................................................... 8

DOMESTIC WIRE DIAGRAM FOR STM-EX AND STM-ELX ...................................................................................................... 9

TYPICAL CIRCUIT CONNECTION FOR STM-E AND STM-EL ...................................................................................................10

TYPICAL CIRCUIT CONNECTION FOR STM-EX AND STM-ELX EXPORT ...............................................................................11

INSTALLATION FOR OPTIONAL RECORDING THERMOMETER .............................................................................................12

TO REMOVE THE CHART ..........................................................................................................................................................12

TO INSTALL NEW CHART .........................................................................................................................................................12

PEN ADJUSTMENT ....................................................................................................................................................................12

REPLACEMENT PARTS FOR 24 HOUR THERMOMETER ........................................................................................................12

SECTION 2 WATER CONDITIONS ............................................................................................................................................13

SECTION 3 OPERATING INSTRUCTIONS

OPERATING INSTRUCTIONS ....................................................................................................................................................14

STERILIZATION GUIDE .............................................................................................................................................................15

MINIMUM STERILIZATION TIMES .............................................................................................................................................16

SECTION 4 DAILY CLEANING

DAILY CLEANING PROCEDURE ...............................................................................................................................................16

SECTION 5 ASSEMBLY

STERILMATIC OPEN STAND .....................................................................................................................................................17

STERILMATIC OPEN STAND WITH CONDENSER ...................................................................................................................17

PARTS LIST FOR CONDENSER WITH OPTIONAL STAND ......................................................................................................17

STERILMATIC DOOR ASSEMBLY .............................................................................................................................................17

DOOR ADJUSTMENT .................................................................................................................................................................18

THE DOOR GASKET ..................................................................................................................................................................18

DOOR LIFT SPRING ...................................................................................................................................................................18

TO REMOVE THE DOOR ASSEMBLY .......................................................................................................................................19

DOOR ASSEMBLY PARTS LIST ................................................................................................................................................19

THE FULCRUM AND DRAIN ASSEMBLY ..................................................................................................................................20

FULCRUM AND DRAIN PARTS LIST .........................................................................................................................................20

ROLLER ASSEMBLY ..................................................................................................................................................................21

DOMESTIC – THE PRESSURE ACTUATED TEMPERATURE CONTROL, STM-E AND STM-EL .............................................21

DOMESTIC – HOW IT WORKS .................................................................................................................................................. 21

DOMESTIC – ADJUSTING THE RANGE OR OPERATION, STM-E ...........................................................................................21

EXPORT - THE PRESSURE ACTUATED TEMPERATURE CONTROL, STM-EX AND STM-ELX .............................................22

EXPORT – HOW IT WORKS ...................................................................................................................................................... 22

EXPORT – CHECKING THE 100o

C SETTING, STM-ELX ...........................................................................................................22

EXPORT – ADJUSTING THE RANGE OF OPERATION, STM-ELX ...........................................................................................22

DOMESTIC – CHECKING THE 230oSETTING, STM-EL ........................................................................................................... 23

DOMESTIC – ADJUSTING THE RANGE OF OPERATION, STM-EL .........................................................................................23

CAST-IN THE HEATING ELEMENTS .........................................................................................................................................23

THE LOW WATER CUT-OFF (MANUAL RESET) .......................................................................................................................23

THE ELECTRIC CONTACTORS .................................................................................................................................................23

THE TIMER .................................................................................................................................................................................24

THE STEAM PRESSURE GAUGE ..............................................................................................................................................24

THE SAFETY VALVE ..................................................................................................................................................................24

THE FLUE ...................................................................................................................................................................................24

THE EXHAUST SOLENOID VALVE ............................................................................................................................................24

TO REPLACE A THERMOSTATIC ELEMENT ............................................................................................................................25

THE STEAM TRAP .....................................................................................................................................................................25

HOW IT WORKS .........................................................................................................................................................................25

SECTION 6 ILLUSTRATED PARTS

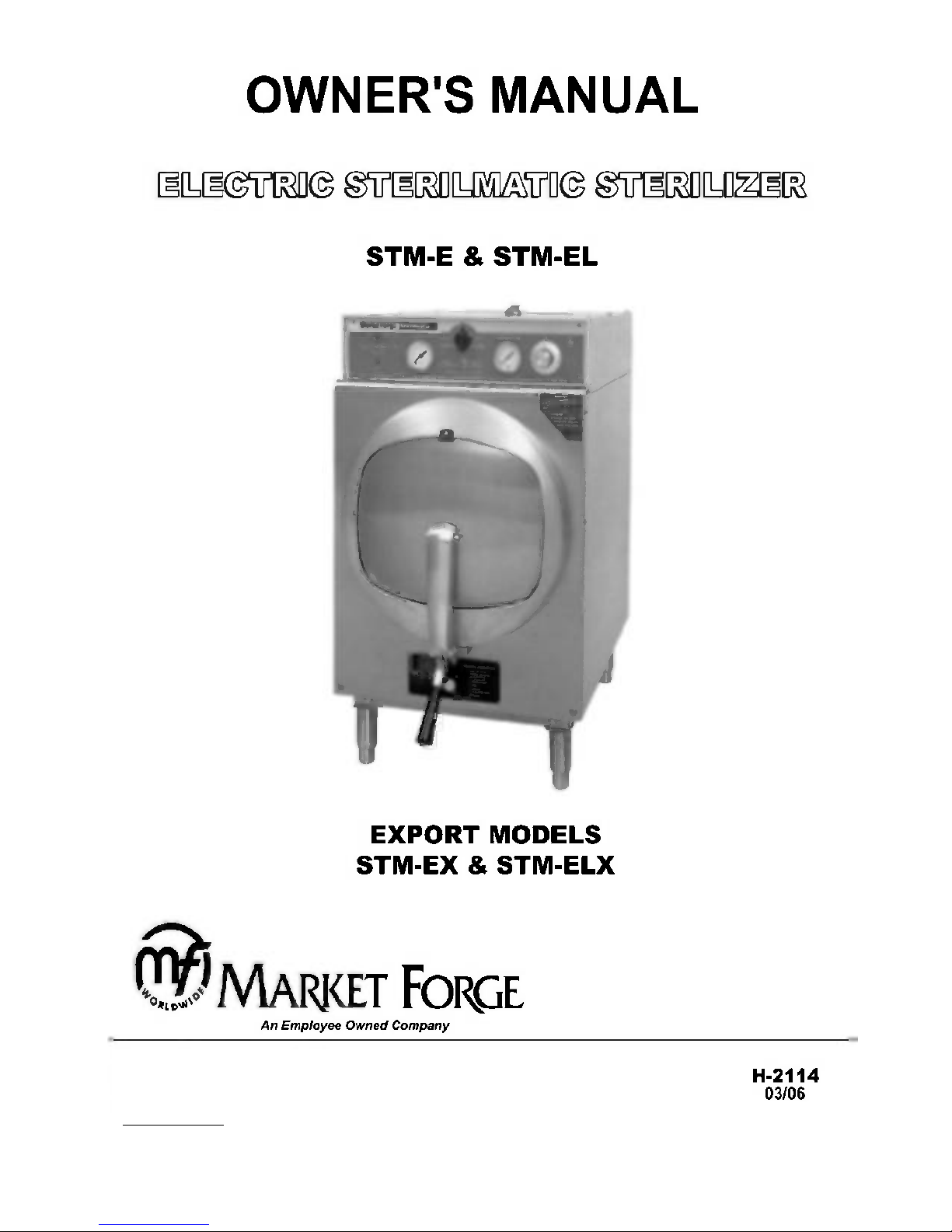

MASTER ILLUSTRATION AND PARTS, STM-E AND STM-EX .......................................................................................... 26 & 27

MASTER ILLUSTRATION AND PARTS, STM-El AND STM-ElX ......................................................................................... 28 & 29

CONTROL CONSOLE PARTS LIST FOR STM-E AND STM-EX .................................................................................................30

CONTROL CONSOLE PARTS LIST FOR STM-EL AND STM_ELX.............................................................................................31

DOOR HANDLE PARTS LIST .....................................................................................................................................................32

SECTION 7 TROUBLE SHOOTING

STEAM TRAP TROUBLE-SHOOTING ........................................................................................................................................33

TROUBLE-SHOOTING GUIDE ...................................................................................................................................................33

SECTION 8 WARRANTY INFORMATION ..................................................................................................................................34