3.4 Process chemicals

DEKO 190 GT ward washer disinfector is equipped with one

machine can be equipped with a descaling liquid pump.

Please note that the nature of the item to be processed can

require additional actions such as dismantling for separate

-

ble sites) by a manual process etc. prior to the item being

processed by the machine. Such pre-cleaning can be

necessary to reduce the initial bioburden and/or contamina-

tion. Please consult the manufacturer of the medical device

for processing instructions and note that the cleaning agents

and disinfectants used by manual processing must be

loaded into the washer-disinfector. Failure to do so, may

cause excessive foaming and/or pressure drop in the water

extending the cycle time.

Depending on the materials of the medical device being

processed a variety of different cleaning agents may be

used. Generally, detergents shall be liquid, non-foaming,

non-abrasive, free rinsing and biodegradable and have the

authorities’ approvals for their intended use, as required.

For chromium steel alkaline detergents in the pH range 8 --

14 are preferred. Acid based detergents should only be used

for stainless steel items. Medical devices made of aluminium

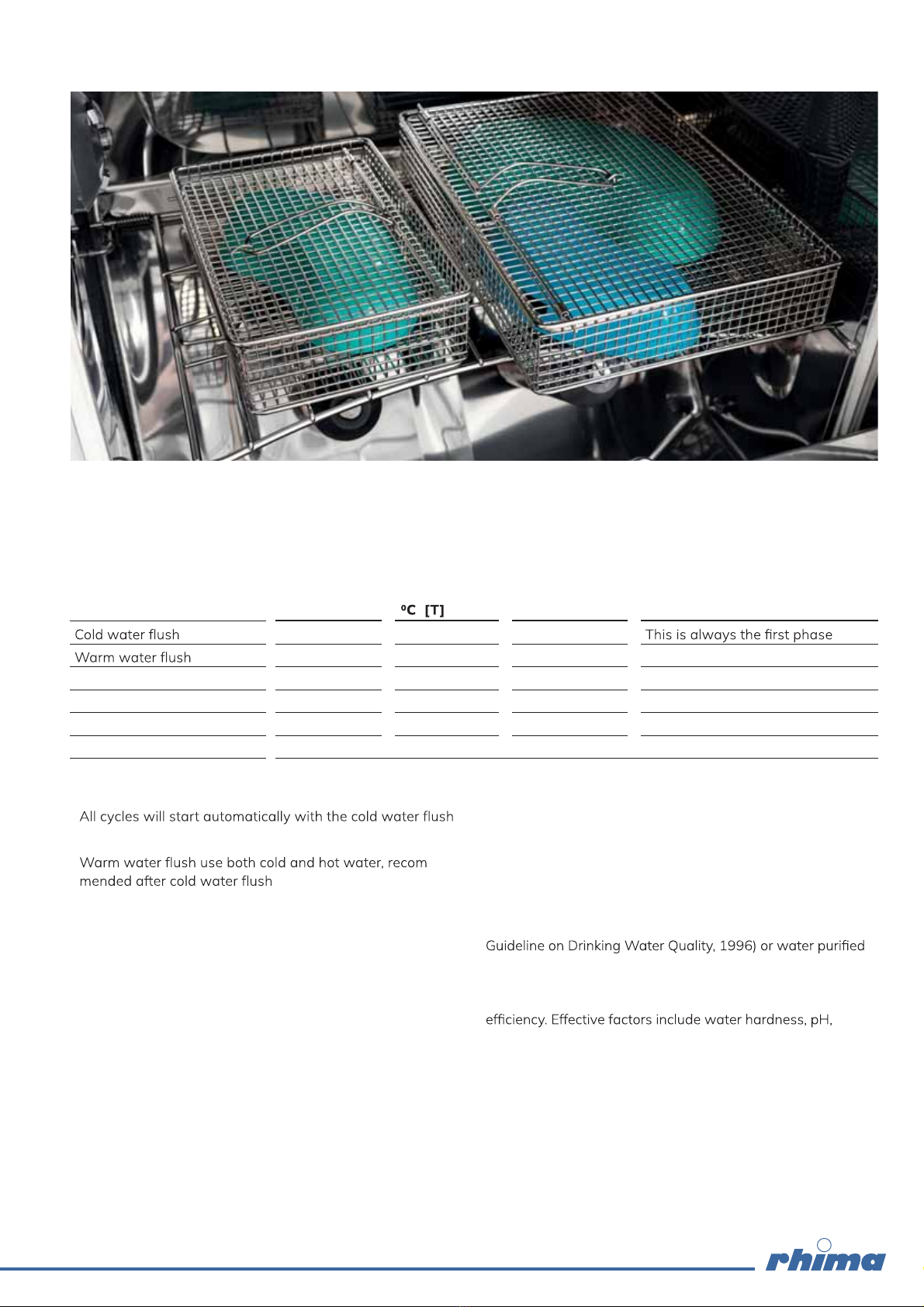

Please note that different chemicals may require different

process temperatures and times e.g. enzymatic cleaners a

temperature between 30 - max 45°C whereas an alkaline

one a temperature between 60 to 90 degrees. The instruc-

tions from the manufacturer of the chemical e.g. regarding

the concentration and temperature shall be followed. Volume

of water in the washing phase is 11 litres.

Please follow the instructions of the manufacturer of the

chemical additive for safe handling, data on the biocompati-

bility (e.g. the maximum permitted residual level on devices).

Note that the residual level, which can be tolerated, will

depend upon the nature of the chemical and the intended

may not be achieved if other process chemicals than those,

which have been tested during type testing, or separately

with certain process variables, are used.

Note.

chemical supplier the suitability for chamber material AISI

304 (EN 1.4301, BS 304 S31) and chemical dosing system

materials PVC and Silicone.

Chemical hoses are marked with the symbols:

Detergent:

3.5 Detergent requirements

•Use only liquid detergents.

•The detergent must not foam. Even a small amount of foam

will substantially decrease the cleaning effect.

•In case there is plenty of foam in the system the machine is

unable to clean the goods and the automatic foam removal

control will start. The machine will take clean water in and

•The liquid must be free of particles so that the nozzle or the

valves of the detergent pump will not get blocked.

•Normally detergents being used are highly alkaline with a

pH-value between 10 and 14.

•A strongly alkaline liquid will corrode aluminium and its

colouring.

•Please use special washing agents for aluminium items.

•The detergents are powerful and must be handled with

care.

•In case of accidental contact with the skin or clothing wash

immediately

•with clean water. For eyes, seek immediate medical

attention.

•Tighten the stopper properly in order to prevent accidental

spilling. If air tight it could implode container.

•Recommended dosage is normally 2–5 ml/l.

•The used concentration of detergent is related to

– the degree of water hardness

– the degree of uncleanness

– the water temperature

•Usually the temperature of washing water should be

approx. +60 0C, in case of blood somewhat lower.

Detergents are powerful and must

be handled with care. In case of

accidental contact with skin or

clothing rinse immediately with

plenty of clean water.In case

detergent gets in contact with eyes,

seek immediate medical attention.

10