(Start Delay) for user to leave the room

• After clicking the option to be set, a numeric input keyboard

will pop up:

• According to actual needs, after setting the desired parameters,

the total working time (Sterilization Time) and the total amount

of disinfectant liquid (Total Dose) will be automatically calculated.

According to the total amount of disinfectant liquid, the user needs

to pour the corresponding amount into the disinfectant bottle. After adding the disinfectant, and after

setting the Start Delay to leave the room, click the Start button, and ensure that all personnel leaves

the room quickly, and the disinfection operation will start immediately after the countdown is over.

• When equipment is in delay countdown or already in disinfection operation, the use can press “Stop”

(“Start” button becomes “Stop” when equipment has started countdown) to immediately stop the

equipment operation and return to pre start status.

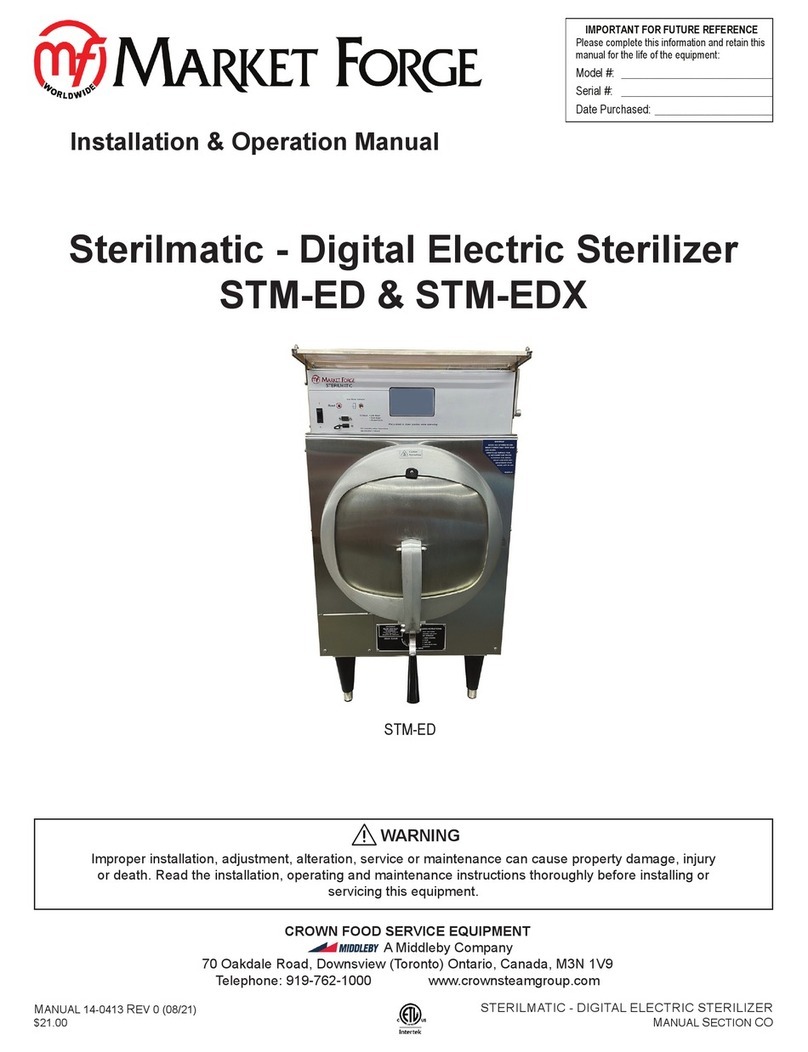

7. Disinfect operation process

There are a total of 3 stages in the operating cycle of the equipment.

A: First, spray sterilization (automatically calculated according to room area)

Move the equipment to the sterilizing area, place on selected location, and plug in the power

supply. Turn on the equipment power switch, and enter the settings interface, set the room size and

delay time settings according to the actual sterilization area size and equipment location. Enter

actual volume of the sterilization area into the Room Volume; Delay time can be set according to

the user’s needs. After each setting is set, the interface will automatically display the estimated

dosage, total added amount, sterilization time and running time.

Move the equipment in place, then open any inner doors of each room within the area to be

sterilized to ensure clear air flow, and then close the outermost door. Confirm the initial

temperature and humidity in the room to ensure that it is within the normal range, the temperature

is 18-26 degrees Celsius, and the humidity is 30-60%. Turn off the air conditioning system, and

after all personnel have left the sterilization area, click the [start] button to turn on the equipment

and enter the sterilization process. Note that one full bottle is 1000ml, so if the user sets the room

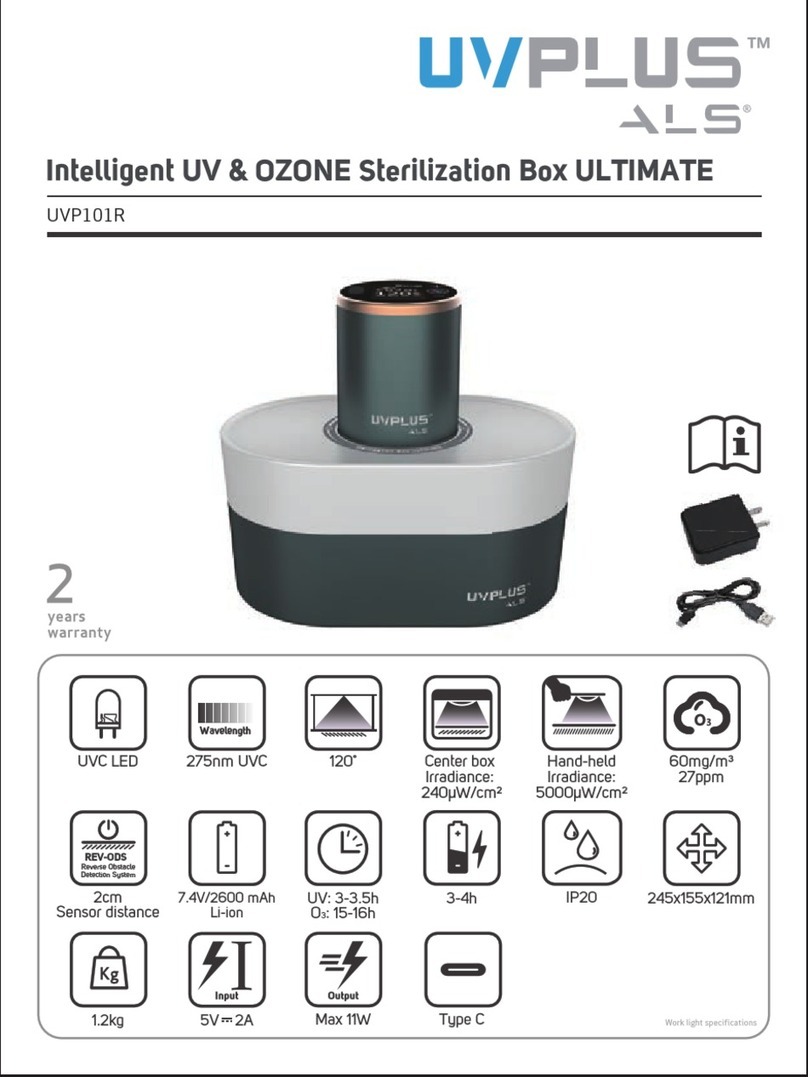

volume above 200m³ as per below picture A, the sprayer will stop after the bottle is depleted. The

UI display will then display per below picture B (total dose reduced since 1 full bottle is already

used up and run time shows one spray session has concluded):

The user has to then refill the bottle with disinfectant, press continue and then vacate the room, the

equipment will resume after the countdown is finished. This cycle (conclude spraying, refill bottle,

resume spraying) continues until the total dose is 0. Then the equipment will move on to the next

phase (dwell period)

A

B