2

Document No:SM-412 Issue C 28.01.21 Marlec Engineering Co Ltd

INTRODUCTION

This manualcontains important information concerningyour turbine towerand its

installation. It is strongly recommended that you read this manual and familiarise

yourself with its contents before installing and operatingthe Windcharger system.

Thecomplete kitis a base pivoted 6.5mhightwinguyed tower, for easy installation &

erection by2 people. The design complies with IEC1400-2.

The tower and rigging kits are available separately to allow the use of a single length of

tube (supplied bythe user) with the rigging kit. The customers own towershould be

40mmnominal medium (3.2mm wall) galvanisedtube. Inside diameter 41.7mm,

outside diameter 48.1mm. Single length 6.5m.

WARNING!

•Itis recommended thaterection of the tower isonly attempted in light winds.

•Standard Health and Safety working practices and appropriate personalprotective

equipmentshould be adopted duringthe followingprocedures.

•When using the Rutland 914i or Rutland 1200 Windchargers, mounting pole outside

diameter MUST NOT exceed 48.5mm. Larger section poles must not be used as this

will reduce the tower to blade clearance. In high wind conditions this could cause

damage to theWindcharger by allowing the blade to come into contact with the

mounting pole.

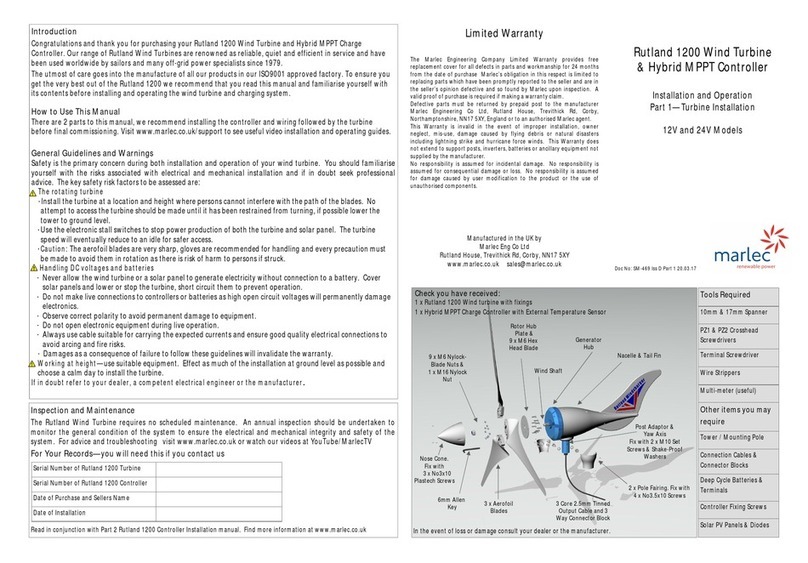

WHAT YOU WILL NEED

•Tape Measure, Spade, Concrete forfoundations, 13mm AF Spanner, 17mmAF

Spanner, 8mm AF Spanner, SpiritLevel

Other Items you will need if not using Sectioned Tower Kit

•6.5m length of 40mm Medium(3.2 wall) galvanised tube.

•Electric Drill

•10.5mm Drill

•8.5mm Drill