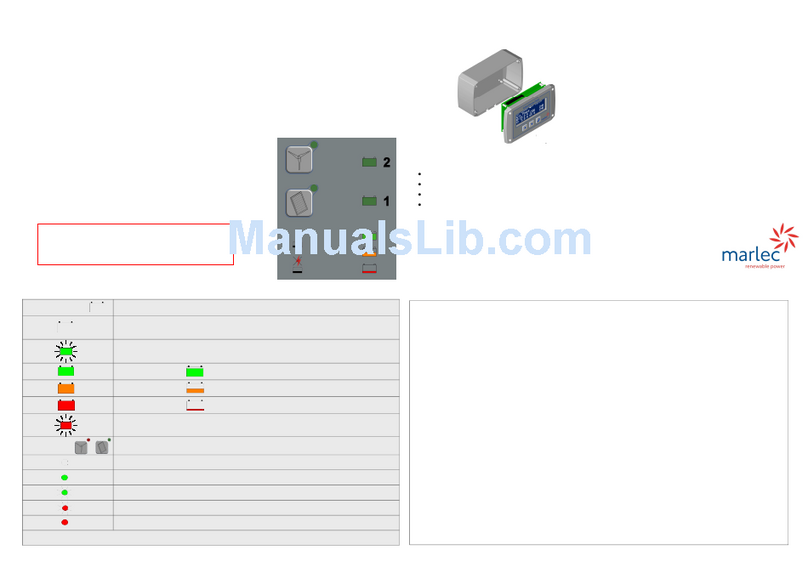

On Board Systems

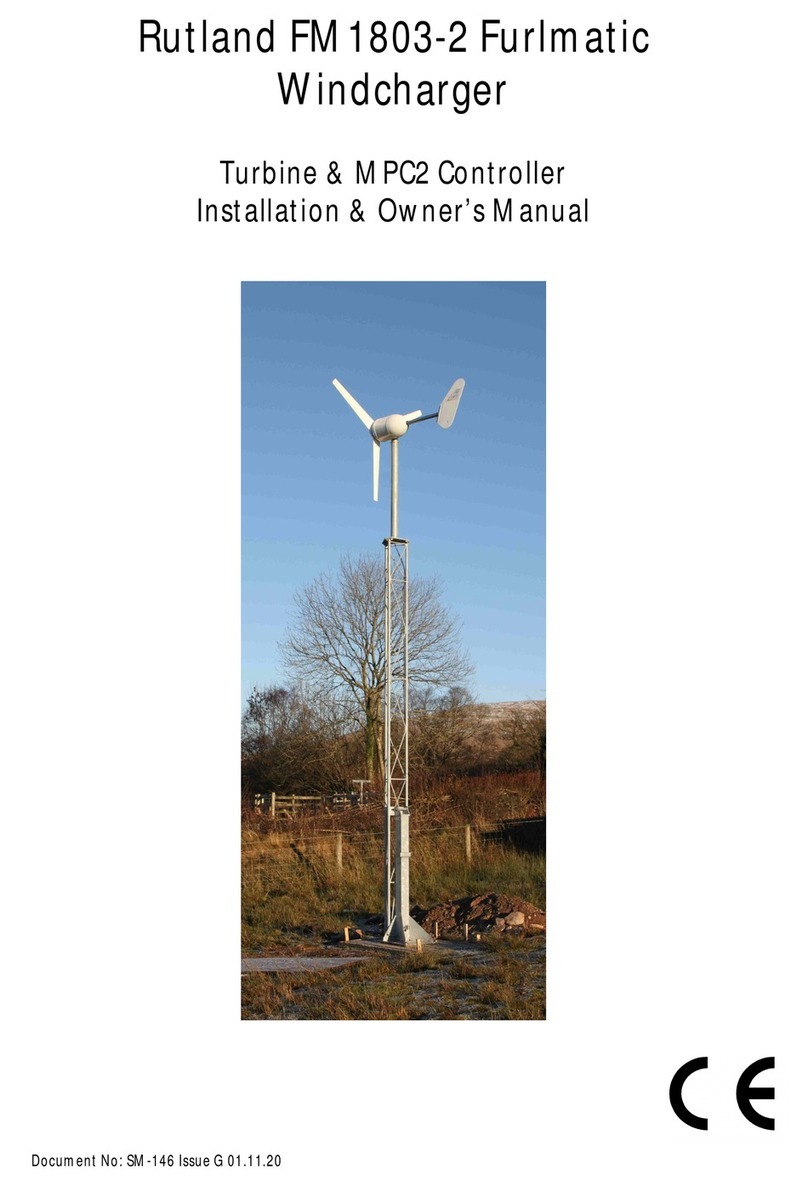

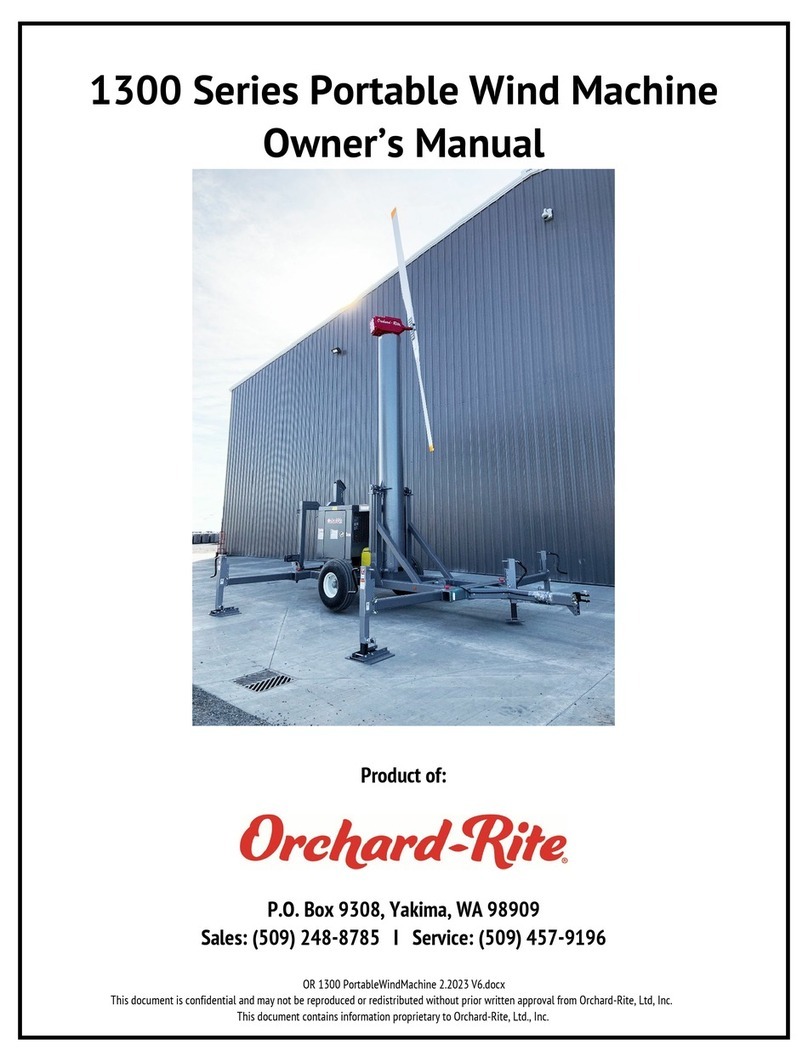

Land Based Systems

The smooth flow of wind over land and water is often interrupted by a multitude of obstructions causing wind sheer and turbulence. The location and height

of the mounting pole or tower for the wind turbine will be the major factor in the overallperformance and lifetime of the system.Wind speeds decrease and

turbulence increases where obstructions exist so the siting of the turbine is very important to ensure good yields and turbine lifetime. On yachts, the open

water will deliver better yields than in typically sheltered marinas.

The Wind Turbine should be mounted in a safe

position, a minimumof 2.7 metres above the deck

and away from other obstacles which could

interfere with the blades or tail assembly.

The pole should be supported to maintain it in the

upright position against lateral movement in high

winds.

The Rutland Marine Mounting Kit & Stays Kits are

available for deck mounting. We suggest the

following mountings according to preference:

Tower Selection

River Boats

A pivot pole is ideal for riverboats as this enables

the turbine to be easily raised and lowered. Rigid

stays are required to support the upright pole.

Push Pit

A suitable pole mounted to the deck with deck

plates and stays is the most popular method of

mounting the wind turbine on yachts, eg. Rutland

Marine Mounting & Stays Kit

For good performance mount the Rutland 1200 at

a minimum of 6m above ground level following the

siting guidelines.

Pivot type towers are suggested for ease of raise

and lowering. Performance is impaired if the

tower is not maintained vertical in operation.

Lattice or other types of freestanding columns can

be selected. Ensure that all loadings are calculated.

Freestanding Tower

A tower can be erectedusing a 6.5metre (21 feet)

galvanised (medium) tube and must be supported

by a minimum of two sets of four guy lines. The

Marlec Land Tower & Tower Rigging Kit are

available at www.marlec.co.uk

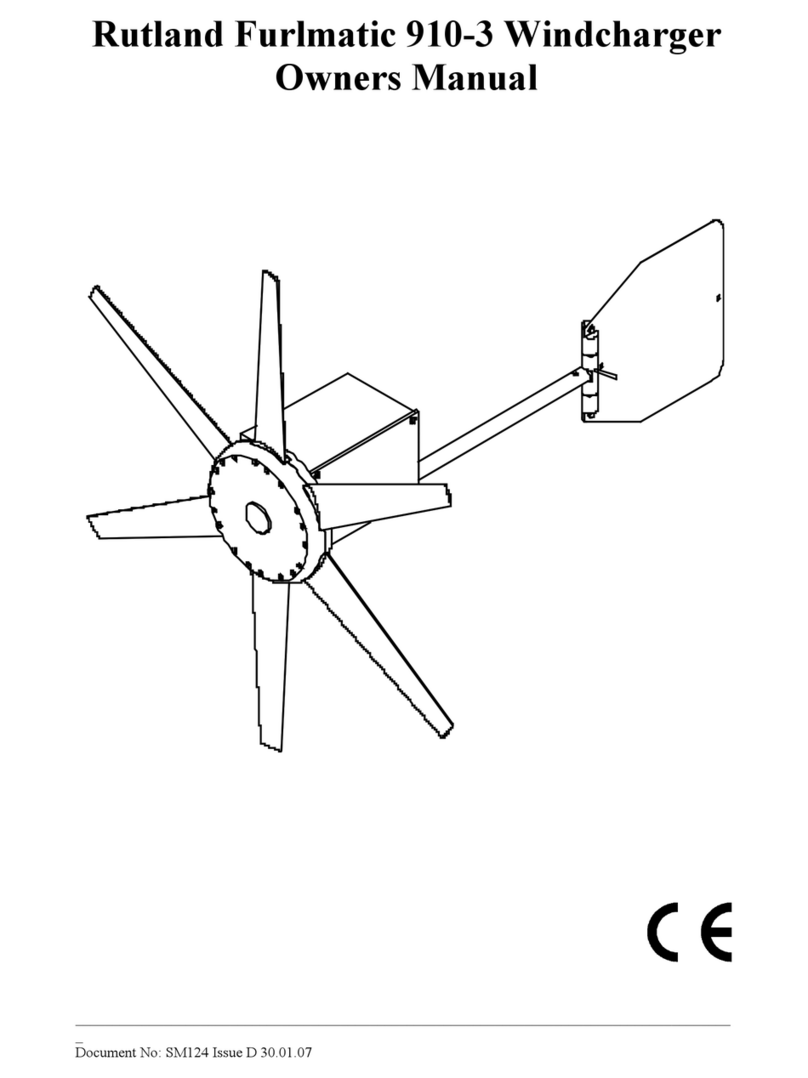

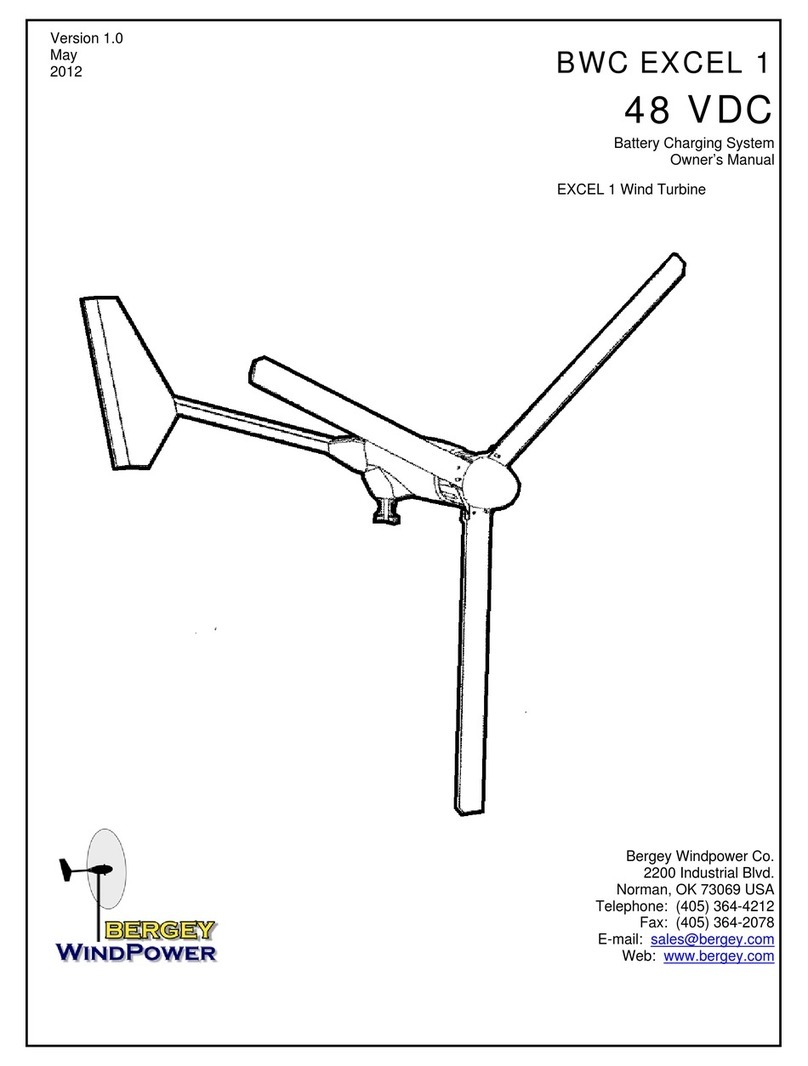

Rotor Blade Assembly

1.Place a M6Nylock nutinto the nut recess in the

aerofoil blade.

2.Align with a hole inthe Rotor HubPlate and

partly tighten a M6screw infrom the back of the

plate. Repeat with 3fasteners on all 3blades.

Caution - All 9 screws must be fitted!

Fit the Main Shaft Nut

1.Fit the M16 Nylock nut (supplied pre-greased)

into the recess created by the 3 blades.

2.Finish tightening the M6 blade screws using a

10mm spanner from the back of the Rotor Hub

Plate. Hold the blades near theroot to avoid

damaging the aerofoils. Check tightness of all

screws but do not over-tighten.

Assemble and Install the Turbine

Fitting the Rutland 1200to the Tower

Select an aluminium or stainless steel tube.

Internal diameter 41mm (1⅝”). For blade

clearance the pole must not exceed 48.5mm(2’’)

outside diameter for the top 0.6m.

Drill 2 holes diametrically opposite as shown.

Connect the Cables - See table in Manual Part 2

1.Thread the 3 core turbine cable through the pole

allowing at least 1m of extra cable for lifting the

turbine on and off.

2.Strip back 10mm of the wind turbine and tower

cables. Join them using the 3-way connector block.

Wrap the connection with insulation tape to

secure and protect from the environment.

Alternativelyjoin the cables using a latching plug

andsocket. Loop back the cable and secure witha

cable tie to provide strainrelief to the joint.

3.Coat the post adaptor with petroleum jelly to

protect it.

4.Carefully push the cables down the pole as you

slide the post adaptor into position, lining up the

screw holes.

5. Secure in place with the M10screws and shake-

proof washers using a 17mm spanner. Tighten up

to the shake-proof washer finishing with the head

in either of the positions shown ready for fitting

the pole fairing.

20mm

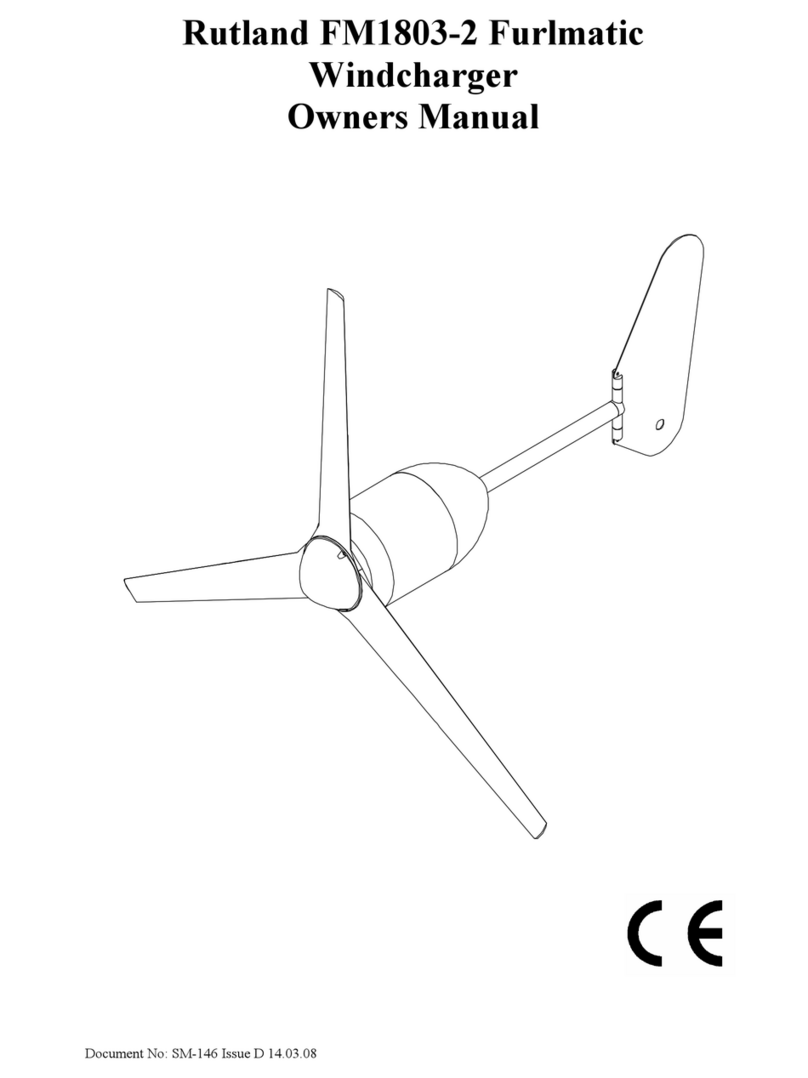

Fit the Turbine to the Generator

1. Offer up the rotor blade assembly to the

generator and place thegreased M16 Nylock nut at

the centre over the windshaft.`

Hold the blades near the root to avoid damaging

the aerofoils. CAUTION: The blades are sharp.

2. Carefully start to screw the rotor blade assembly

onto the windshaft by turning it clockwise. When

engaged place the 6mm Allen key provided at the

centre of the shaft and hold this firmly as you

continue to screw the rotor to full tightness.

IMPORTANT: Ensure the turbine hub plate is

squarely located on the shaft’s shoulder.

At this time you should restrain the turbine from

turning or keep the mounting pole lowered. If the

cable is already connected to the controller the

turbine will be prevented from turning.

Fit the Nose Cone

1.Locate the nose cone over the rib on the rotor

blade assembly and align the 3 screw holes.

2 . Secure nose cone using the 3 No3x10 Plastech

screws and a PZ1 screwdriver.

Fit the Pole Fairing

Note: For thick wall poles the tab on the inside of

the fairings should be trimmed back to the step as

indicated.

1. Push the Pole Fairing over the M10 Hexhead.

This also acts as a locking device.

2. Screw together the pole fairing using the 4

No3.5x10 Plastech screws and a PZ2 screwdriver.

Before raising the tower or allowing the turbine to

rotate follow the Commissioning section inthe

Manual Part 2

Commissioning

Turbine Dimensions

Turbine Orientation

The Rutland 1200 is designed

for use in the orientation

shown in this manual it

should not be installed and

operated upside down.

48.5mm

41mm

11mm

Siting the Turbine

Base Pivot Tower