Rutland FM1803-2 Installation & Operation

Document No: SM-146 Issue D 14.03.08 Marlec Engineering Co Ltd

8

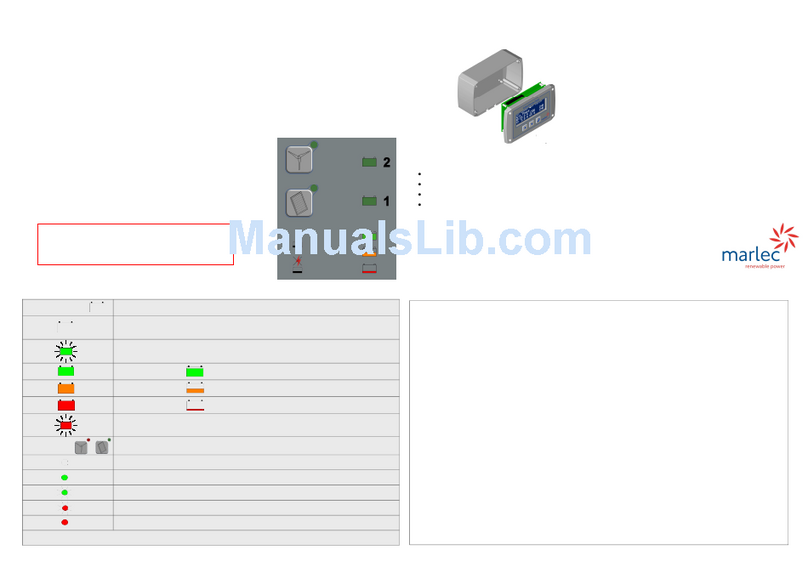

Transitional modes indicated by LEDs:

Charge/Stall LED Flashing Green/Amber – Currently in charge mode, the

battery voltage has reached the fully charged level & a time delay period has

started prior to entering stall mode, the voltage must remain at this level for the

whole of the time period before a mode change will take place. If the voltage falls

again while in this phase, the LED will stop flashing & the controller will stay in

charge mode. This is to prevent unnecessary change of mode during transient

voltage changes.

Charge/Stall LED Red/ pulsing off once per second – The Controller has

switched to stall mode & a time delay period has started to allow the turbine to

stabilize in the new operating mode before re-checking the battery voltage.

Charge/Stall LED Flashing Red/Amber – Currently in stalled mode, the battery

voltage has reached the lower voltage limit & a time delay period has started prior

to entering charge mode, the voltage must remain at this level for the whole of the

time period before a mode change will take place. If the voltage rises again while

in this phase, the LED will stop flashing & the controller will stay in stall mode.

This is to prevent unnecessary change of mode during transient voltage changes.

Charge/Stall LED Green/ pulsing off once per second – The Controller has

switched to charge mode & a time delay period has started to allow the turbine to

stabilize in the new operating mode before re-checking the battery voltage.

Low/High Wind LED Flashing Green/Amber – Currently in Low wind mode,

the charge current has reached the upper limit for low wind mode & a time delay

period has started prior to entering High wind mode, the current must remain at

this level for the whole of the time period before a mode change will take place. If

the current falls again while in this phase, the LED will stop flashing & the

controller will stay in Low wind mode. This is to prevent unnecessary change of

mode during transient current changes.

Low/High Wind LED Red/ pulsing off once per second – The Controller has

switched to High wind mode & has started a time delay period to allow the turbine

to stabilize in the new operating mode before re-checking the charge current.

Low/High Wind LED Flashing Red/Amber – Currently in High wind mode, the

charge current has reached the lower limit for high wind mode & a time delay

period has started prior to entering Low wind mode, the current must remain at this

level for the whole of the time period before a mode change will take place. If the

current increases again while in this phase, the LED will stop flashing & the

controller will stay in High wind mode. This is to prevent unnecessary change of

mode during transient current changes.