Installation, Operation, Maintenance

4

Installation, Operation & Maintenance - HBH/HBV Compact Series

General Information

Safety

Warnings, cautions, and notices appear throughout this

manual. Read these items carefully before attempting any

installation, service, or troubleshooting of the equipment.

DANGER: Indicates an immediate hazardous situation,

which if not avoided will result in death or serious injury.

DANGER labels on unit access panels must be observed.

WARNING: Indicates a potentially hazardous situation,

which if not avoided could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation or

an unsafe practice, which if not avoided could result in

minor or moderate injury or product or property damage.

NOTICE: Notication of installation, operation, or

maintenance information, which is important, but which is

not hazard-related.

Inspection - Upon receipt of the equipment, carefully

check the shipment against the bill of lading. Make sure

all units have been received. Inspect the packaging of

each unit, and inspect each unit for damage. Ensure that

the carrier makes proper notation of any shortages or

damage on all copies of the freight bill and completes a

common carrier inspection report. Concealed damage

not discovered during unloading must be reported to the

carrier within 15 days of receipt of shipment. If not led

within 15 days, the freight company can deny the claim

without recourse.

Note: It is the responsibility of the purchaser to le

all necessary claims with the carrier. Notify your

equipment supplier of all damage within fteen (15)

days of shipment.

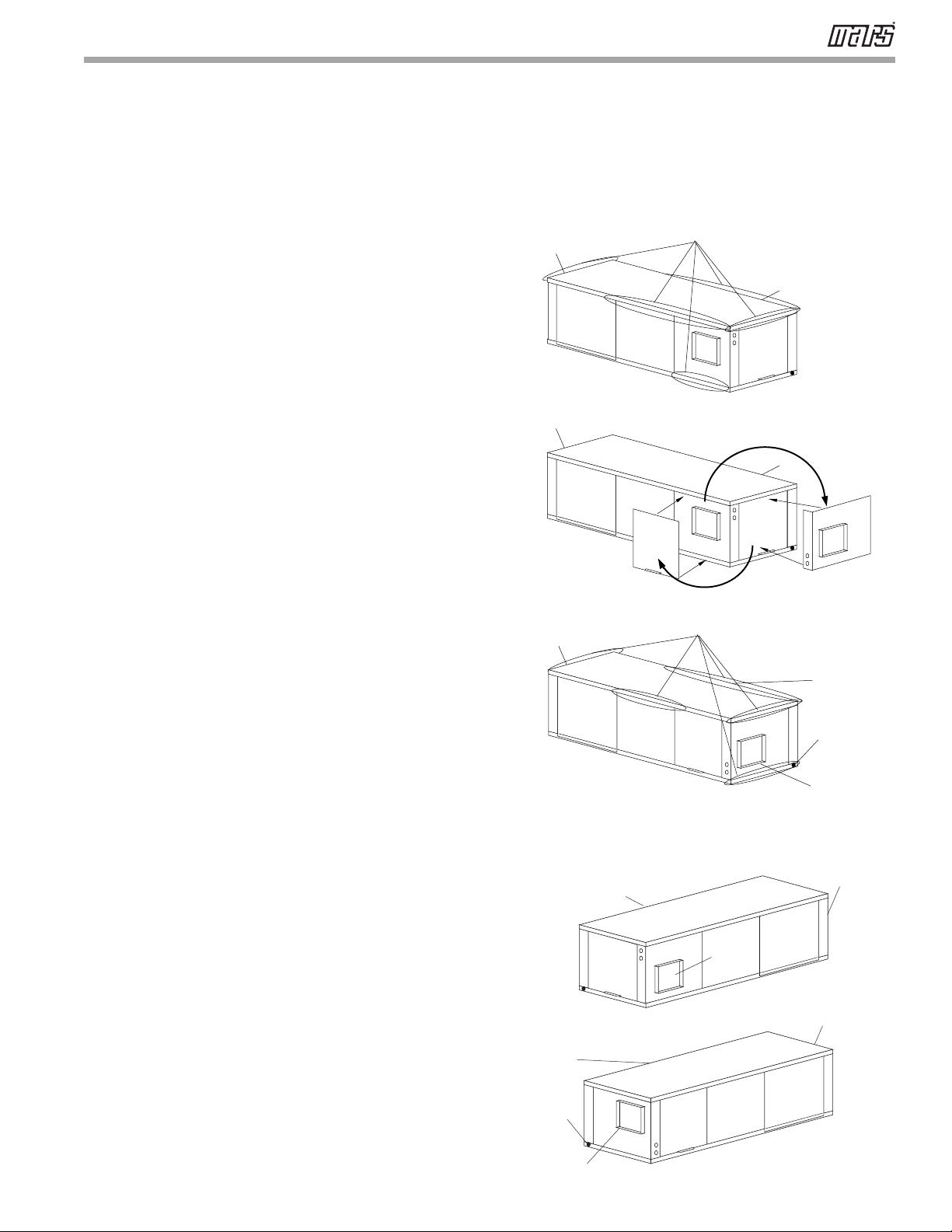

Storage - Equipment should be stored in its original

packaging in a clean, dry area. Store units in an upright

position at all times. Stack units a maximum of 3 units high.

Unit Protection - Cover units on the job site with

either the original packaging or an equivalent protective

covering. Cap the open ends of pipes stored on the

job site. In areas where painting, plastering, and/or

spraying has not been completed, all due precautions

must be taken to avoid physical damage to the units and

contamination by foreign material. Physical damage and

contamination may prevent proper start-up and may

result in costly equipment clean-up.

⚠

WARNING!

⚠

⚠

WARNING!

⚠

⚠

CAUTION!

⚠

⚠

WARNING!

⚠

WARNING! To avoid the release of refrigerant into the

atmosphere, the refrigerant circuit of this unit must be

serviced only by technicians who meet local, state, and

federal prociency requirements.

CAUTION! To avoid equipment damage, DO NOT use

these units as a source of heating or cooling during the

construction process. The mechanical components and lters

can quickly become clogged with construction dirt and debris,

which may cause system damage and void product warranty.

WARNING! The Application and Service Manual should be

read and understood before attempting to service refrigerant

circuits with HFC-410A.

WARNING! The installation of water-source heat pumps and

all associated components, parts, and accessories which

make up the installation shall be in accordance with the

regulations of ALL authorities having jurisdiction and MUST

conform to all applicable codes. It is the responsibility of

the installing contractor to determine and comply with ALL

applicable codes and regulations.

⚠

WARNING!

⚠

WARNING! All refrigerant discharged from this unit must

be recovered WITHOUT EXCEPTION. Technicians must

follow industry accepted guidelines and all local, state, and

federal statutes for the recovery and disposal of refrigerants.

If a compressor is removed from this unit, refrigerant circuit

oil will remain in the compressor. To avoid leakage of

compressor oil, refrigerant lines of the compressor must be

sealed after it is removed.