5

IOM - 7602-444 Communicating Service Tool

Option Selection Menu

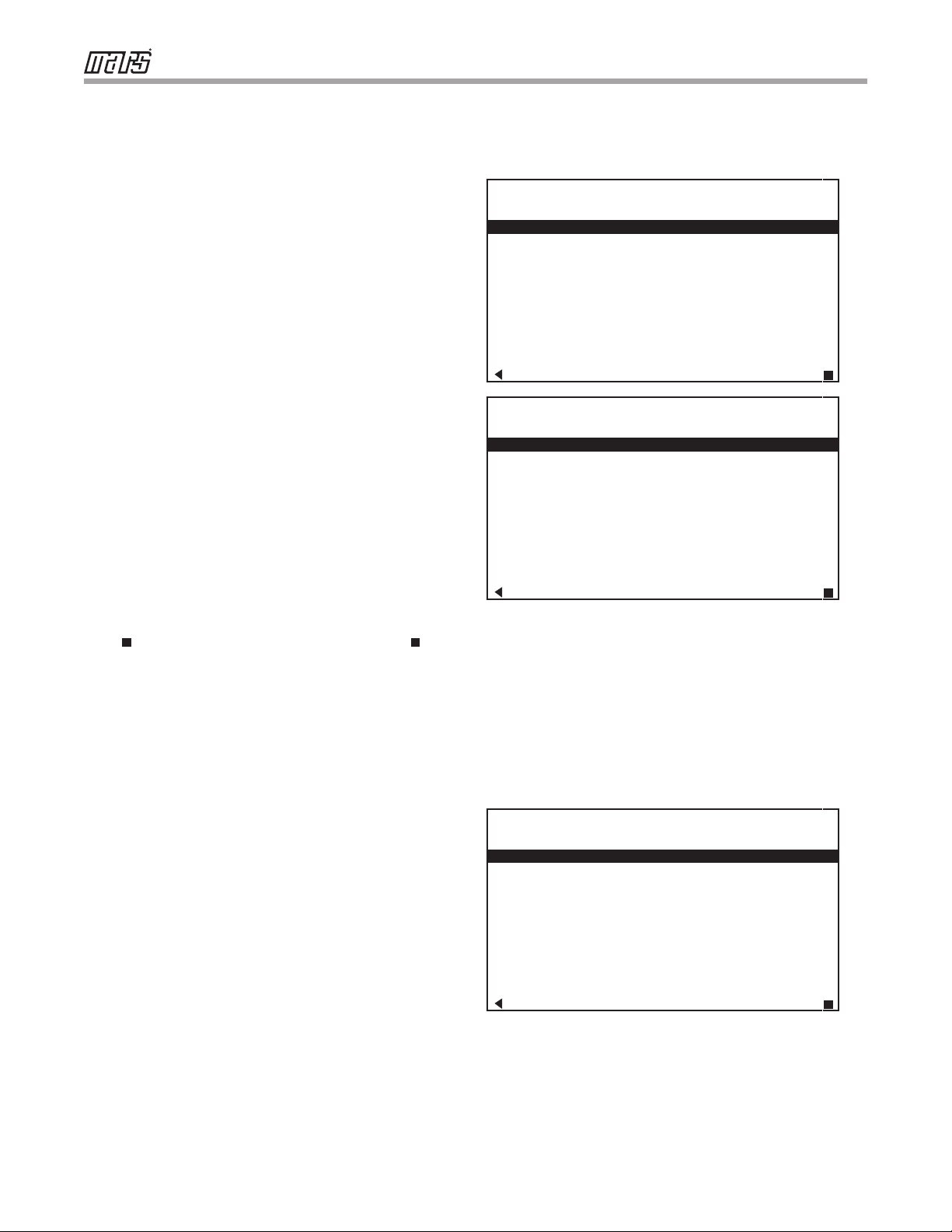

Unit Conguration Menu

OPTION SELECTION

MOTORIZED VALVE OFF

COMPRESSOR ASCD 0

SELECT OPTION

PREVIOUS SELECT

NOTE: “Motorized Valve” used here refers to a two-position

motorized water valve, not to be confused with the modulating

motorized water valve found in the LOOP CONFIG.

3.2 OPTION SELECTION

This option allows the conguration of heat pump options to

be modied.

Adjust the Option settings using the up/down arrow buttons.

Press the center button to select each item.

• Motorized Valve (defaults stored in control) – valid

range: O, On “On” delays compressor start until

the valve is fully open.

• Compressor ASCD (Anti-Short Cycle Delay (default

stored in control) – valid range: 5 to 8 (in 1 minute

increments)

NOTE 1: The Compressor Anti-Short Cycle Delay setting

provides equipment protection by forcing the compressor to

wait a few minutes before restarting.

NOTE 2: If multiple units are connected to one thermostat,

refer to section 3.6 for unit selection.

3.3 UNIT CONFIGURATION

Adjust the Unit Conguration settings including Heat

Pump Family, Heat Pump Size, Blower Type, and Loop

Conguration using the up/down arrow buttons. Press the

center button to select each item.

• Heat Pump Family (default stored in control) –

valid range: TE, TY, TES, TEP, TRT, TSM, TSL

• Heat Pump Size (default stored in control) – valid

range: depends on Heat Pump Family setting

• Blower Type (default stored in control) – valid

range: NO BLOWER, 2-SPD PSC, COM ECM-V,

1-SPD PSC, 2-SPD CTM, PWM ECM, VFD

• Loop Cong (default stored in control) – valid

range: Other, VS PUMP, MOD VALVE

Airow, pump and valves can be congured from ‘System

Conguration’ screen.

Select ‘VS PUMP PARALLEL’ when applying an internal

variable speed ow controller with other ow controllers on a

single loop in parallel.

NOTE: Refer to section 3.6.3 for multi-unit conguration

instructions.

UNIT CONFIGURATION

CURRENT CONFIG TE026

HEAT PUMP FAMILY TE

HEAT PUMP SIZE 026

BLOWER TYPE ECM

LOOP CONFIG VS PUMP

SELECT OPTION

PREVIOUS SAVE

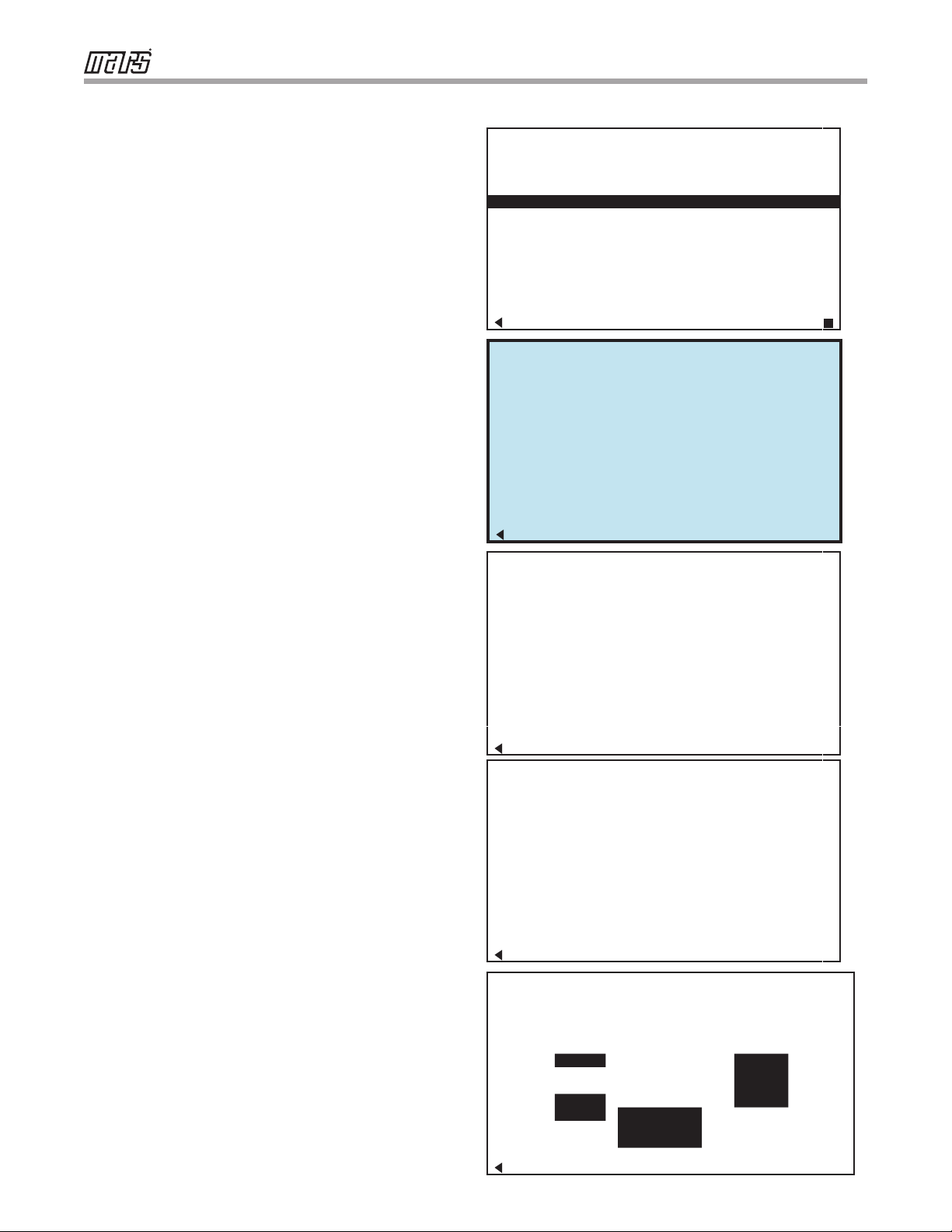

Equivalent Model Numbers

Heat Controller Climate Master

HE-Series TZ

HZ-Series TE

HZS-Series TES

HB-Series 0.5-5T TC

HB-Series 7-25T TL

HKV-Series TL

HRC-Series TRC