Copyright © 2012 Ron Marston all rights reserved rev. D 2/12

2

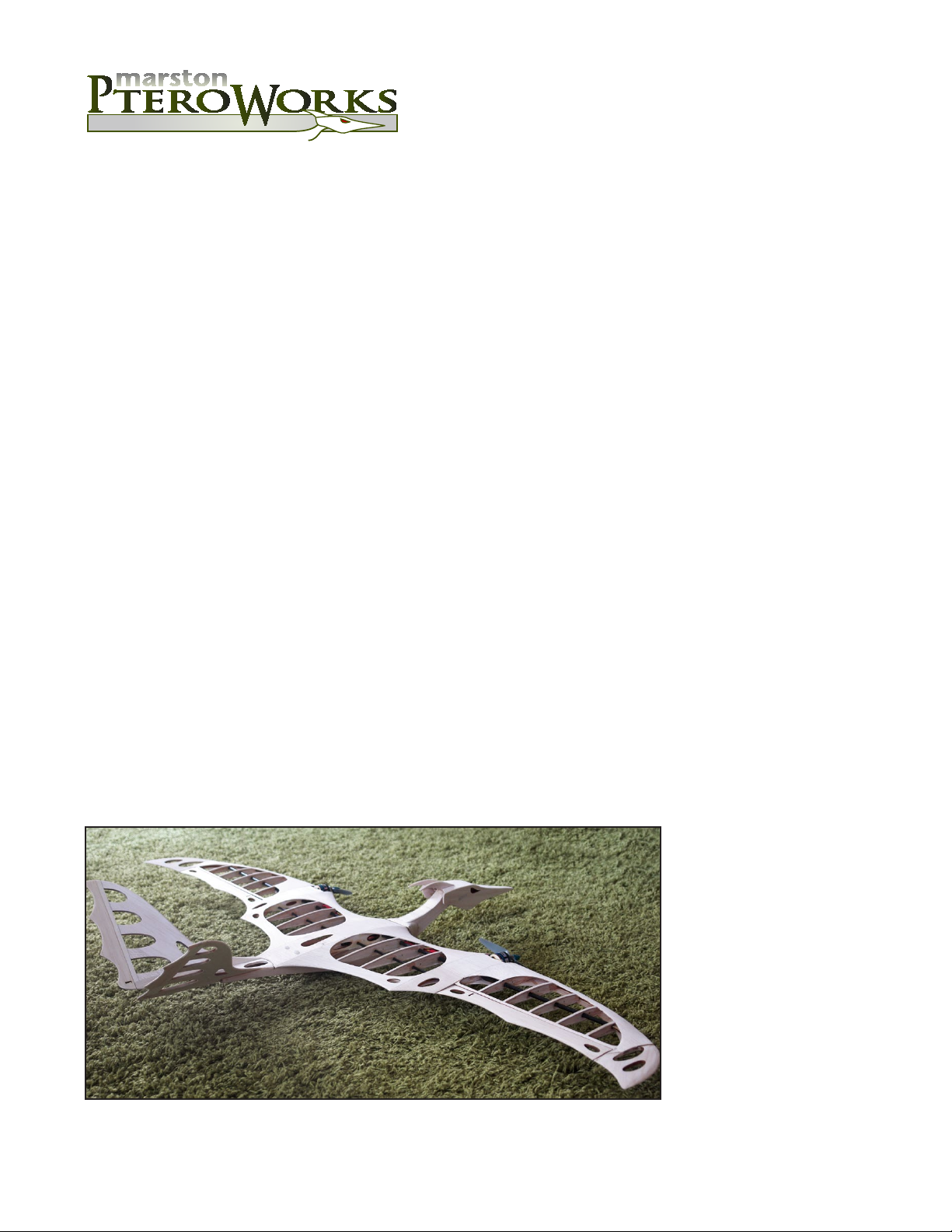

Wing

1. Cut carbon spars to proper length.

forward spar - .240” dia. 41.40”

rear spar - .156” dia. 45.40”

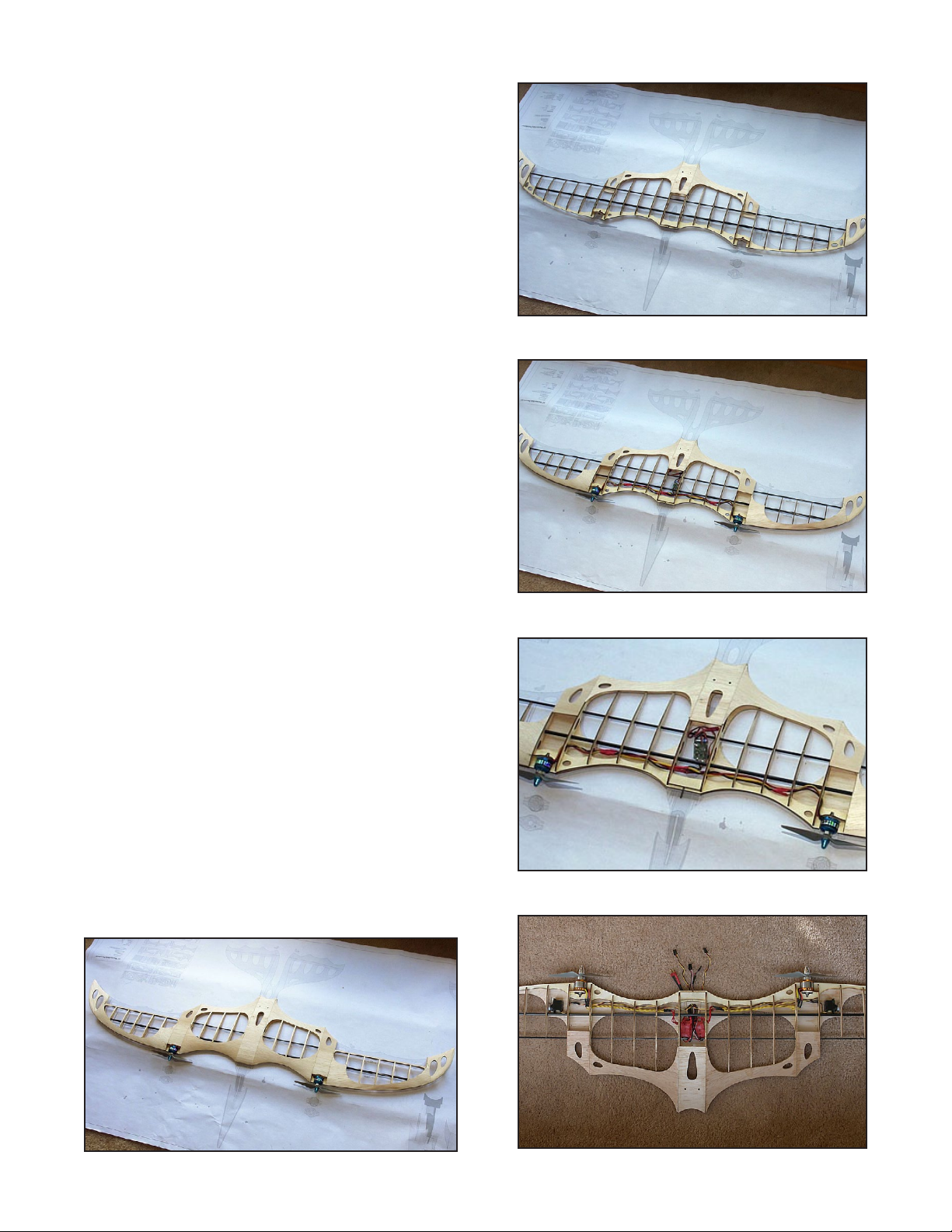

2. Layout all ribs on the plans then carefully feed them

onto the forward spar (.240”).

Do NOT glue yet. (B)

3. Carefully feed rear spar (.156”) onto ribs. Spin spar

as you push to facilitate feeding.

Do NOT glue yet. (C)

4. Attach 4 leading edge pieces. Lay parts on plan to

facilitate alignment. Do NOT glue yet. (C)

5. Glue doubler/connectors to leading edges at the

motor area and at the center of the wing. Then glue

motor mounts after ensuring the hole pattern will

work for your motors. If necessary, use supplied

blank motor mounts and drill appropriate holes for

your motors. Check motor mount incidence angle

for 0 to 1/2 degree of down thrust. (C)

Glue rib (12) in place on left and right sides of wing.

Note: Any twist in the wing should be turned to

create wash-out (trailing edge of wing at tip is

raised compared to trailing edge at root). (D)

6. Glue bottom trailing edge center ply strengthener

along with balsa center bottom trailing edge.

7. Glue remaining bottom trailing edge balsa pieces to

ribs. NOTE: many of the wing sheeting pieces

are different top and bottom. Top pieces are

marked with a “T” and bottom pieces are

marked with a “B”. Assemble with “B”s and “T”s

facing inward to avoid having them show. (D)

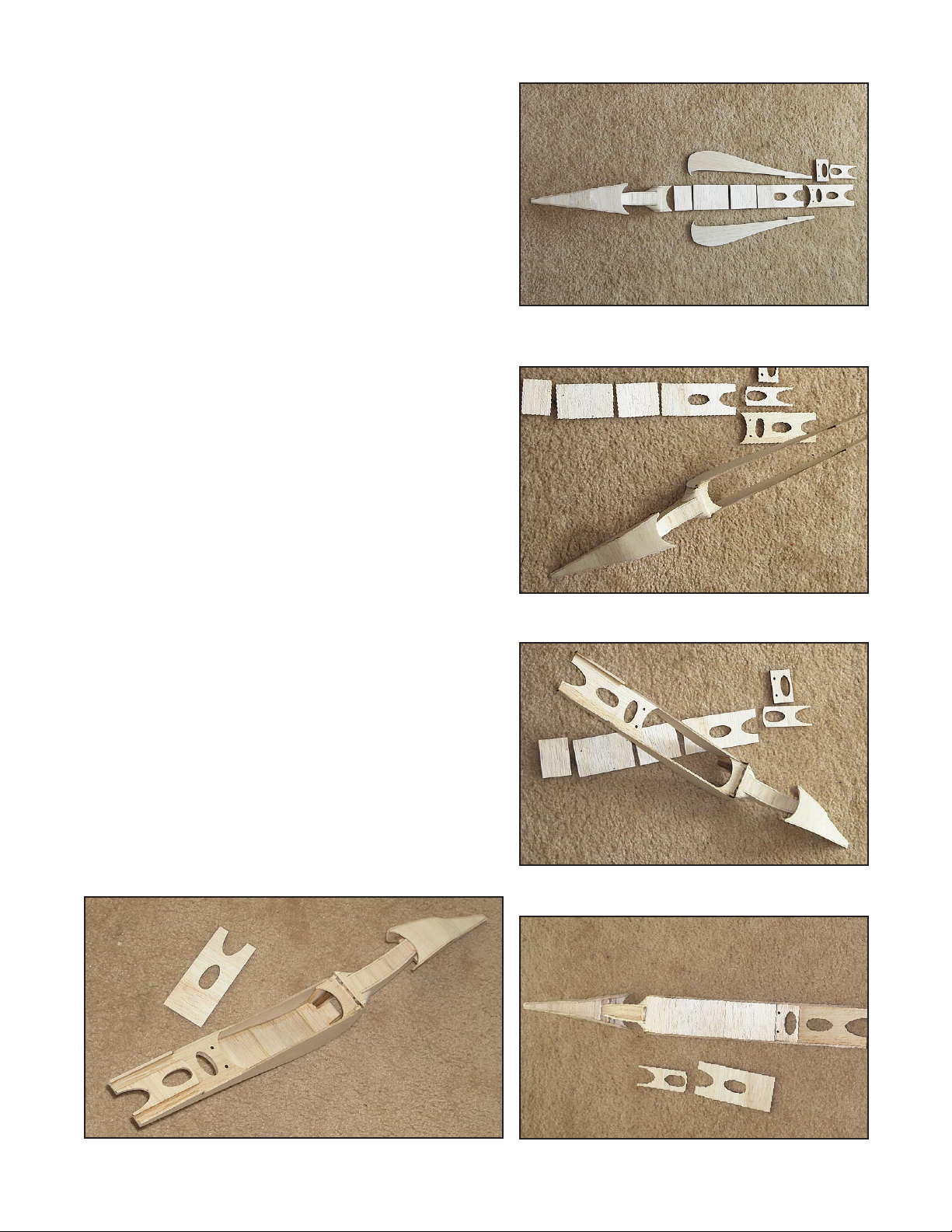

8. Sand rough airfoil into wing tip pieces and glue to

rib 12 on left and right sides. Sand about 5 degrees

into face where it mates with rib 12 so the wing tips

angle up slightly.

9. Lay wing on plans and ensure ribs are in proper

position and that there is no twist in the wing. Use

thin CA and glue all ribs to the carbon spars

and the leading edge pieces.

10. Stack both screw tower pieces together and glue in

place at center trailing edge where the screw holes

are. Sand top to match rib 1 prole. (E)

11. Sand then glue top center trailing edge piece to ribs.

A

B

C

D

E